Magnetic separating device for rice processing

A magnetic separation device, rice processing technology, applied in the application, magnetic separation, solid separation and other directions, can solve the problems of inconvenience, low work efficiency, poor magnetic separation effect, etc., to achieve convenient use, quality assurance, magnetic separation effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

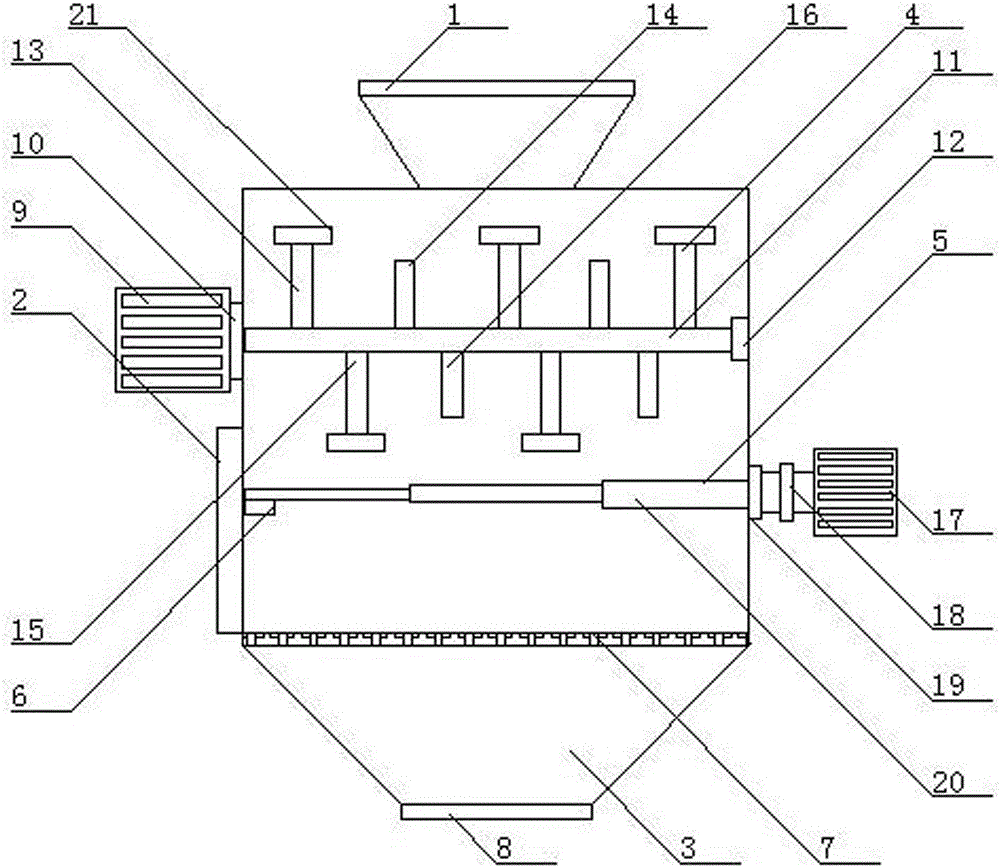

[0016] As shown in the figure, a magnetic separation device for rice processing includes a fuselage, a feed funnel 1 is installed in the middle of the top of the fuselage, a cleaning door 2 is installed at the lower end of the left side of the fuselage, and a conical discharge hopper 3 is installed at the bottom of the fuselage. , the inner upper end device of the fuselage stirs the magnetic separator 4, the telescopic baffle mechanism 5 of the lower end device inside the fuselage, the fixed clip 6 of the lower end device inside the left side of the fuselage, and the metal adsorption net 7 of the lower end device inside the fuselage.

[0017] The discharge port 8 is installed at the bottom end of the conical discharge hopper 3 .

[0018] The stirring magnetic separator 4 is composed of a stirring motor 9, a head bearing 10, a stirring shaft 11, and a tail bearing 12. The stirring motor 9 is fixed on the left upper end of the fuselage through the head bearing 10, and the stirrin...

Embodiment 2

[0023] Further, the length of the first stirring rod 13 is greater than the length of the second stirring rod 14 .

Embodiment 3

[0025] Further, the length of the third stirring rod 15 is greater than the length of the fourth stirring rod 16 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com