Environment-friendly superfine powder railway coal transportation and storage dust suppressant and preparation method

A technology of ultra-fine powder and dust suppressant, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of complex use, environmental pollution, etc., and achieve fast curing speed, high coagulation strength, and good storage stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

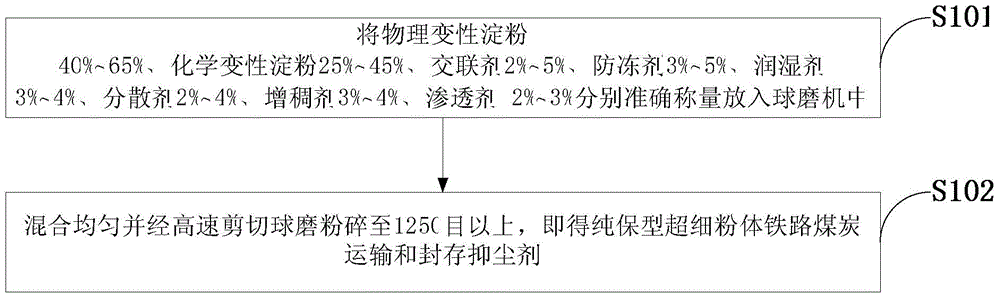

[0029] Such as figure 1 As shown, the environment-friendly ultrafine powder railway coal transportation and sealing dust suppressant preparation method of the embodiment of the present invention comprises the following steps:

[0030] S101: Add 40% to 65% of physically modified starch, 25% to 45% of chemically modified starch, 2% to 5% of crosslinking agent, 3% to 5% of antifreeze, 3% to 4% of wetting agent, and 2% of dispersing agent % ~ 4%, thickener 3% ~ 4%, penetrant 2% ~ 3%, respectively accurately weighed into the ball mill;

[0031] S102: Mix evenly and pulverize through high-speed shearing ball milling to more than 1250 mesh to obtain pure shape-preserving ultra-fine powder railway coal transportation and sealing dust suppressant.

[0032] Working principle of the present invention:

[0033] The purpose of the present invention is to provide a kind of non-polluting and reproducible different plant-type modified starch as binder, and add related additives to form an e...

Embodiment 1

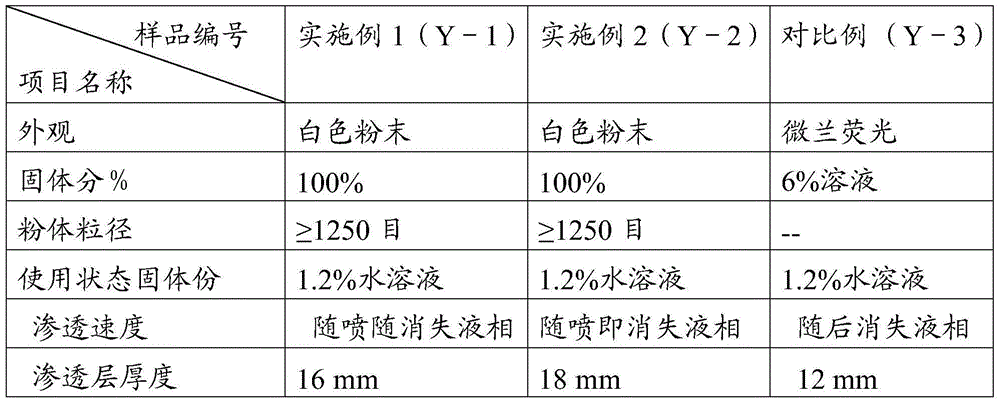

[0035] Example 1 (Y-1):

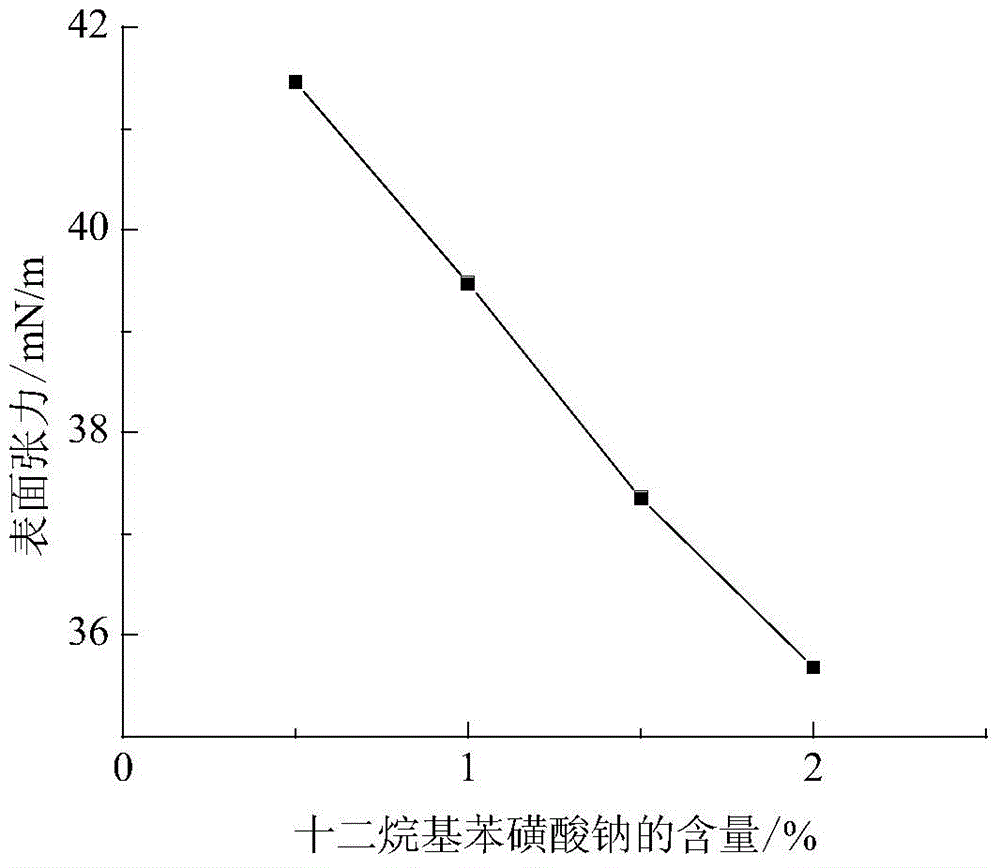

[0036]Weigh 20 grams of potato starch, 80 grams of white dextrin, 5 grams of calcium chloride, 0.75 grams of sodium silicate, 1 gram of sodium dodecylbenzenesulfonate, 2 grams of hydroxyethyl cellulose, and 1 carat of powder and 0.5 gram of borax were added one by one in the pulverizer, and after pulverizing for 15 minutes until the fineness was qualified, the relevant properties were measured.

Embodiment 2

[0037] Embodiment 2 (Y-2):

[0038] Weigh 30 grams of tapioca starch, 50 grams of corn oxidized starch, 5 grams of calcium chloride, 0.75 grams of potassium silicate, 1 gram of sodium dodecyl sulfonate, 2 grams of hydroxyethyl cellulose, 1 carat of open powder and Add 0.5 g of boric acid into the pulverizer one by one, pulverize for 15 minutes until the fineness is qualified, and measure the relevant properties.

[0039] The application effect of the present invention is further illustrated by comparative example:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com