Patents

Literature

37results about How to "High coagulation strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

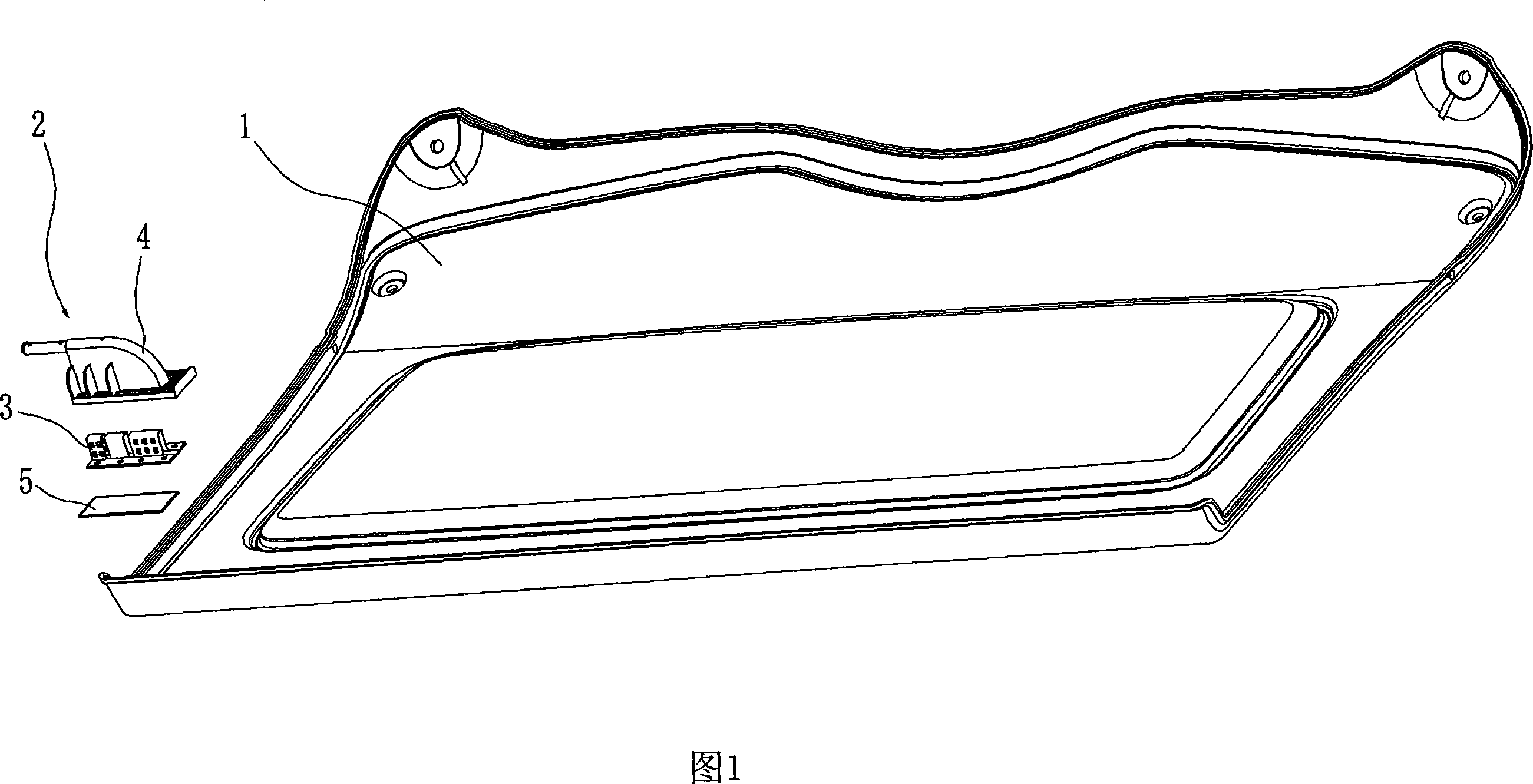

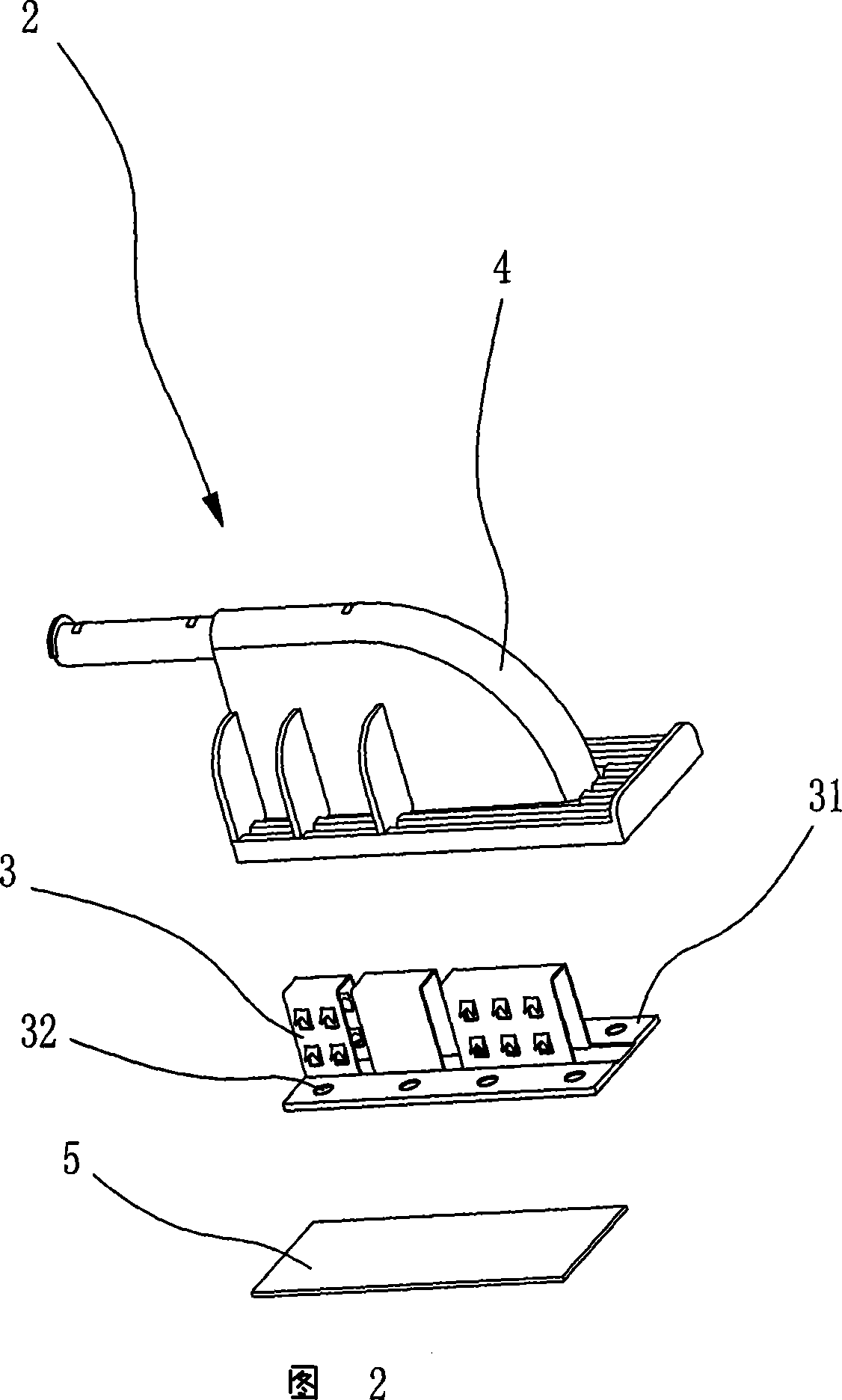

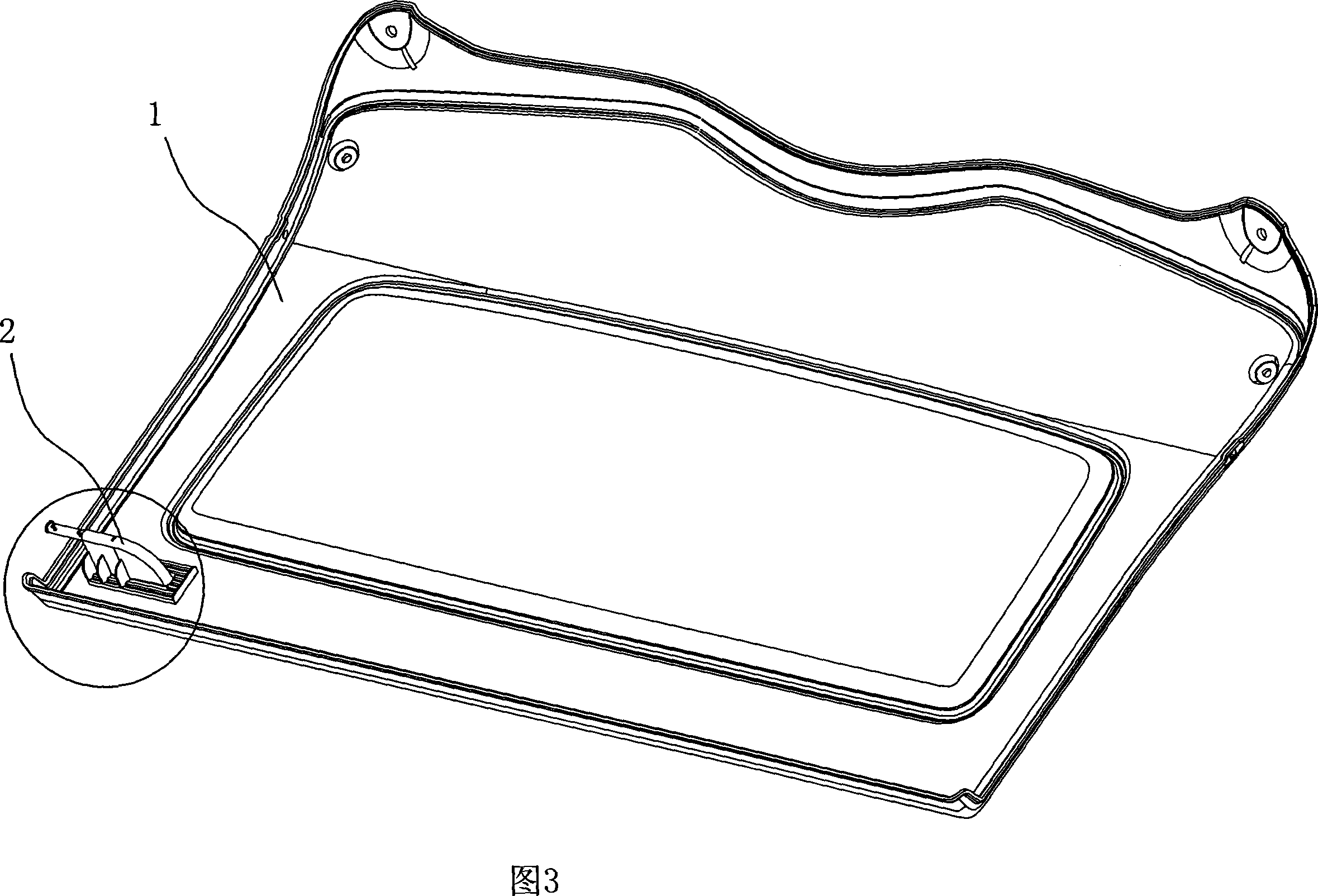

Automobile internal decorative piece and making method

InactiveCN101024387ASolve the problem of not being able to bond effectivelyEffective bondingSheet joiningSuperstructure subunitsFrame basedPolypropylene

The invention discloses a vehicle inner ornament and the manufacturing method. It is made up of frame base material and fixed a buckle that includes bottom board. The feature is that the frame base material compounding or polypropylene included woodflour board including polypropylene board, and the bottom board of fixed buckle is connected on the polypropylene board or the woodflour board. The method includes the following steps: softening frame base material and polypropylene board or woodflour board, putting fixed buckle into mold and locating the polypropylene board or woodflour board and base material into mold, and ensuring the polypropylene board and woodflour board is located between bottom board and frame base material; taking pressure forming. The bond strength between buckle and frame base material could reach 420N, and it is low cost. It is convenient to produce and has high efficiency.

Owner:宁波拓普隔音系统有限公司

Phase-transition self-temperature-regulating heat-preserving facing brick of external wall and manufacturing method thereof

InactiveCN101705741AHigh quality light weight, compressive strengthLight in massCovering/liningsSolid waste managementBrickSilicon oxide

The invention relates to a phase-transition self-temperature-regulating heat-preserving facing brick of an external wall, which is an integrated structure compacted by a phase-transition heat-preserving layer and an inorganic facing layer, wherein the phase-transition heat-preserving layer is mixed by proportion and compacted by hull-type expanded perlite heat-preserving aggregates, phase-transition temperature-regulating aggregates and cements; the inorganic facing layer is mixed by quartz sand, calcium carbonate, calcium oxide, cement and silicon oxide powders; and the phase-transition temperature-regulating aggregate is made of phase-transition cores and encapsulated hulls. The manufacturing method not only effectively solves the encapsulation problem of the phase-transition material, leads the prepared phase-transition self-temperature-regulating heat-preserving facing brick of the external wall to have excellent heat-preserving performance, waterproof performance and permanent anti-ageing performance, but also radically solves the obsolescence of thermo-physical property and the leakage problem of phase-transition material in the circulation process. The facing brick has the advantages of light weight, strong adhesion strength, large compressive strength, heat insulation, heat preservation, waterproof and moisture-proof performances, obvious energy-saving effect, and the like.

Owner:信阳天意节能技术股份有限公司

Red mud-fly ash polymerization type inorganic cementing material, preparation method and application thereof

The present invention discloses a red mud-fly ash polymerization type inorganic cementing material, which comprises the following raw materials, by weight: 75-95 parts of industrial waste, 5-20 parts of an activator, and water, wherein the water is added according to a solid-to-liquid ratio of 1.5-2.5 g: 1 ml. According to the present invention, characteristics of simple raw material formula, wide source, low cost, strong operability and substantial industrial waste consumption are provided, wherein the amount of the waste material in the solid raw material can be 80-90%; the raw materials are not added with cement and other ingredients, cementing property of the obtained product is from the excitation reaction of the technology, and the formula is not added with sodium hydroxide and other alkaline activators, such that the cost is low, and the side effect is less; and the use is wide, and the obtained product can be used for adhesion between stones and stones, between stones and ceramics, and between ceramics and ceramics, and can further be used for adhesion of stones or ceramics on the cement-base surface.

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI

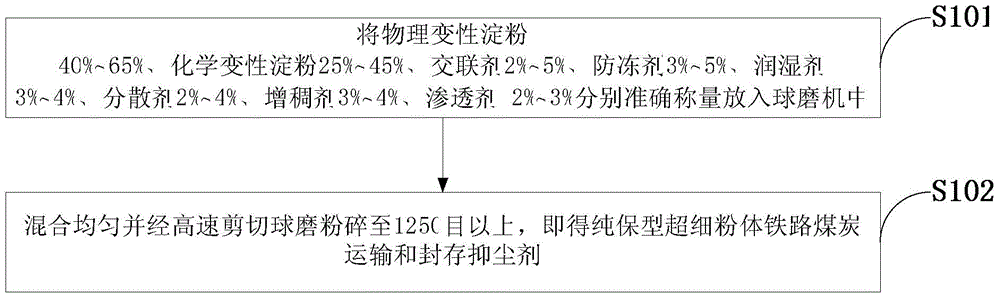

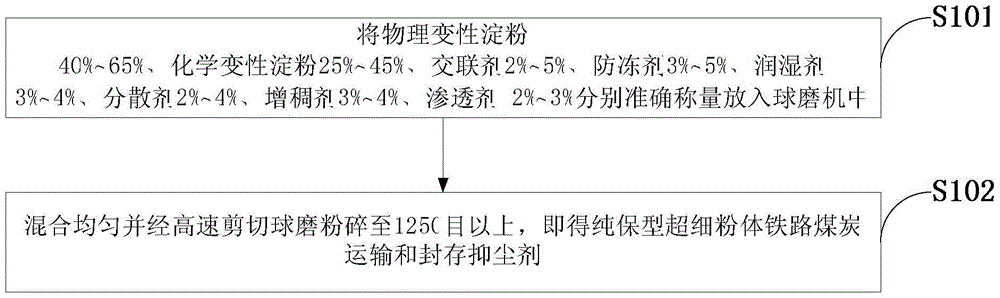

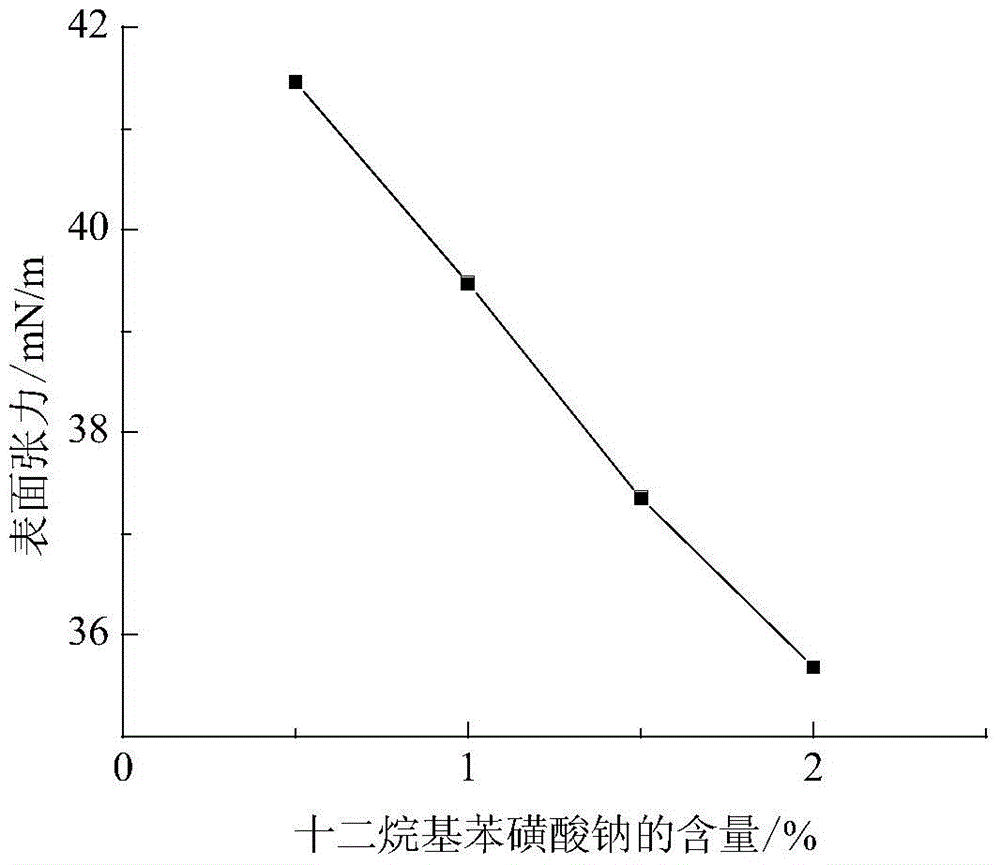

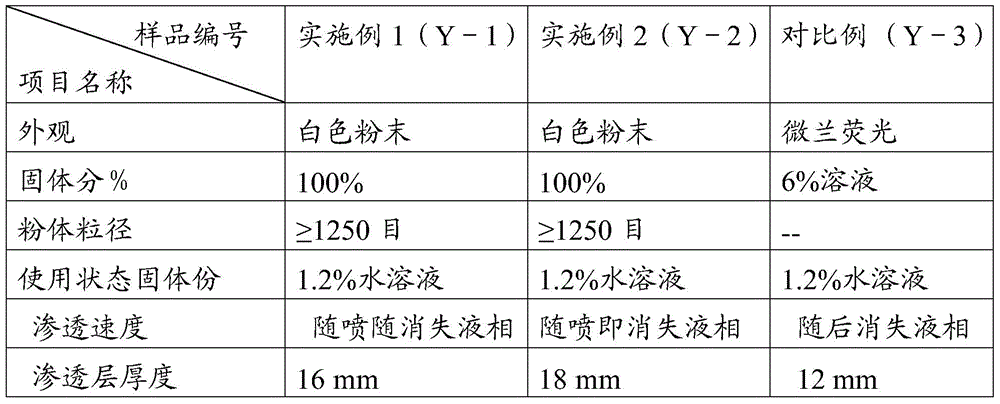

Environment-friendly superfine powder railway coal transportation and storage dust suppressant and preparation method

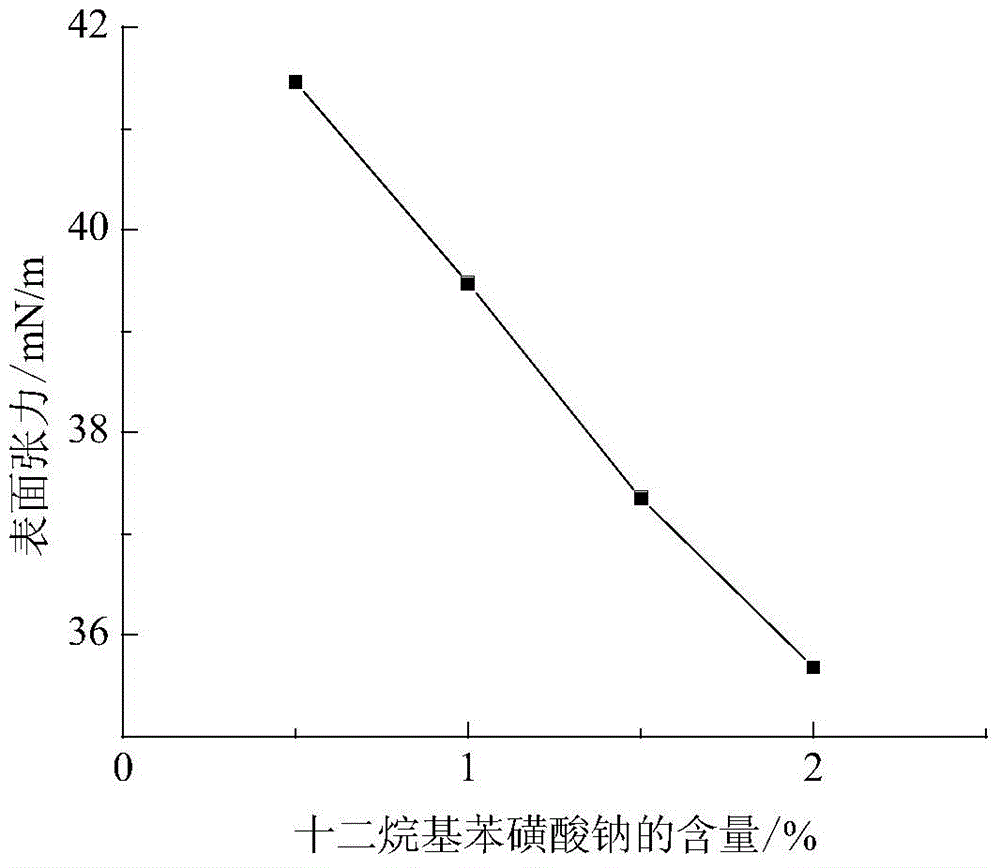

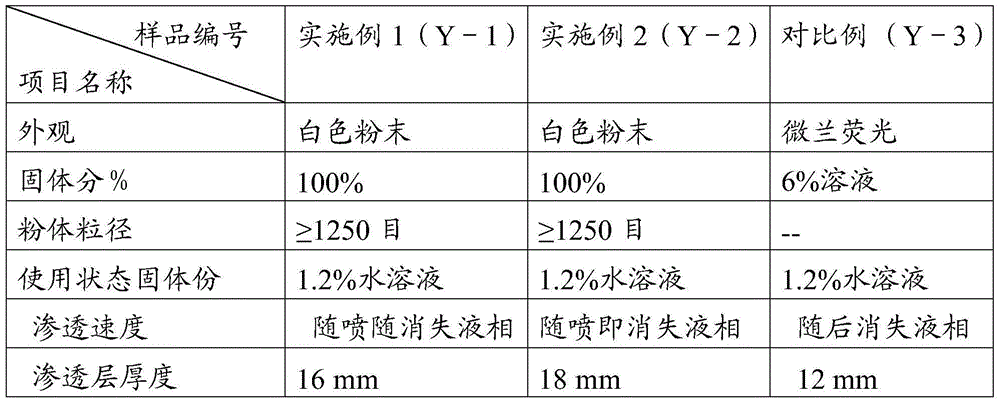

InactiveCN103980860ASuppress flyingImprove wettabilityOther chemical processesAnti freezingCross linker

The invention discloses an environment-friendly superfine powder dust suppressant for railway coal transportation and storage and a preparation method. The environment-friendly superfine powder dust suppressant for railway coal transportation and storage comprises the following components in percentage by weight: 40-65% of physical modified starch, 25-45% of chemical modified starch, 2-5% of cross linker, 3-5% of anti-freezing agent, 3-4% of wetting agent, 2-4% of dispersant, 3-4% of thickener and 2-3% of penetrating agent. The preparation method for the environment-friendly superfine powder dust suppressant for railway coal transportation and storage comprises: weighing the components of the dust suppressant in percentage by weight respectively and putting the components into a ball mill; and mixing uniformly and performing high-speed shear ball milling to above 1,250 meshes, thus obtaining the environment-friendly superfine powder dust suppressant for railway coal transportation and storage. The superfine powder material is prepared by compounding the physical modified starch and the chemical modified starch, adding an inorganic gel material and adding multiple aids, and has the construction effects of good coal bed wetting effect, thick pervious bed, high curing speed, large setting strength of the pervious bed and good dust suppression effect.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

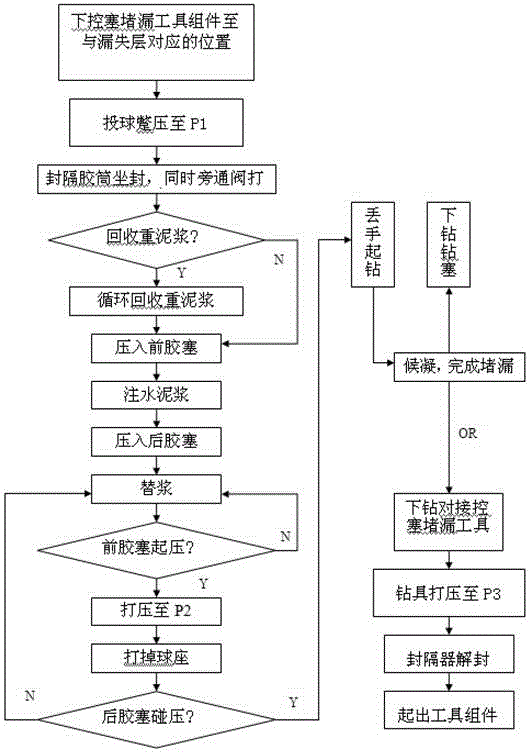

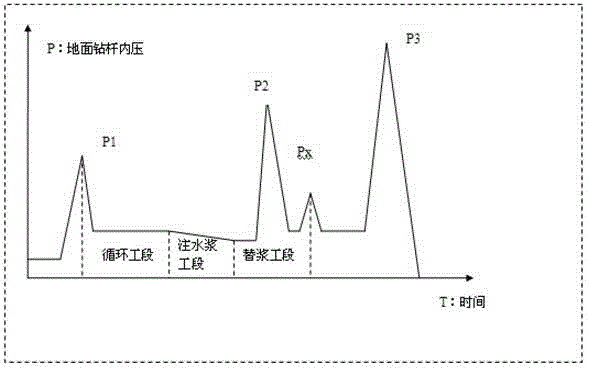

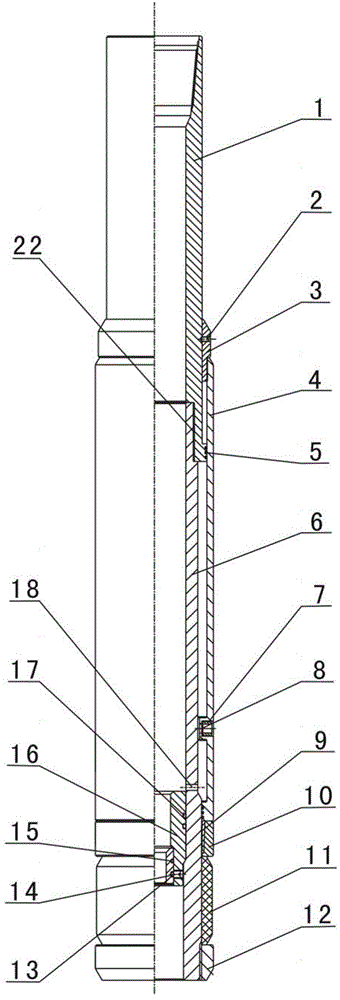

Blocking controlling and leaking stopping tool assembly and leaking stopping method applied to drilling engineering

The invention discloses a blocking controlling and leaking stopping tool assembly applied to drilling engineering. The blocking controlling and leaking stopping tool assembly comprises an inner barrel, a cylinder sleeve, a locking ring, a locking sleeve, a sealing and separating glue barrel, an end base, a rubber plug base, a ball seat, a ball, a front rubber plug and a back rubber plug, wherein the ball seat is matched with the ball, and the rubber plug base is matched with the front rubber plug and the back rubber plug. The inner barrel is sleeved with the cylinder sleeve which can move. The end base is arranged at the lower end of the inner barrel in a sleeved mode. The sealing and separating glue barrel is arranged between the locking sleeve and the end base. The cylinder sleeve is arranged above the locking sleeve. Circulating holes are formed in the inner barrel. The invention further discloses a method for stopping well drilling leaking through the blocking controlling and leaking stopping tool assembly. The method comprises the following steps that the blocking controlling and leaking stopping tool assembly is placed downwards to a well; the ball is thrown to the needed position to increase the pressure, and the sealing and separating glue barrel is used for sealing in a sitting mode; heavy mud is recycled; the front rubber plug is pressed to the needed position, and water and mud injection is carried out; the back rubber plug is pressed to the needed position; the mud is replaced; the pressure is increased to knock down the ball seat; the mud is continuously replaced until the back rubber plug makes contact with the front rubber plug; mud replacing is stopped, and the tool assembly is pulled out of the hole; cement setting is carried out, and leaking stopping is finished. When the tool assembly is used for stopping leaking of the well, annulus mud and formation fluid cannot be mixed into cement paste, pollution is not produced during waiting on cement stopping, and the setting strength of a cement sheath plug is high.

Owner:SICHUAN HAYWARD PETROLEUM ENG TECH

Liquid film type microcapsule deep water blocking agent and its preparing method

InactiveCN1944571AProlong clotting timeHigh coagulation strengthDrilling compositionActivator 1Dodecylsulfonic acid

The liquid film type microcapsule deep water blocking agent consists of water glass 5-30 wt%, formaldehyde as activator 1-10 wt%, coating agent 0.1-2.0 wt%, aluminum citrate as chelating agent 0.3-5.0 wt%, coagulant aid 0.01-0.14 wt% and water for the rest. It is superior to common water blocking agent, and has long setting time, high setting strength, controllable gel temperature and simple construction process.

Owner:SHANDONG UNIV

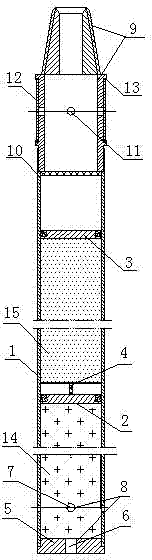

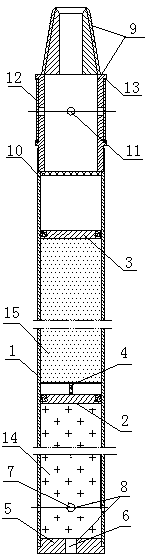

Coal field drill hole leak blocking system

The invention relates to a coal field drill hole leak blocking system, belonging to the technical field of coal field drill holes. The coal field drill hole leak blocking system comprises an infusion system, a drill pipe connection system and a slurry system, wherein the infusion system comprises a infusion pipe, a check valve, a pipe boot, an infusion bottom hole, an infusion round hole, and a first level piston and a second level piston arranged in the infusion pipe from the bottom up; the drill pipe connection system comprises a drill pipe joint, a jump ring, an expansion sleeve sleeved and wound on the groove of the drill pipe joint, and a punching hole arranged at the groove on the middle part of the drill pipe joint; and the slurry system comprises insulating liquid and leak blocking liquid. The coal field drill hole leak blocking system has the advantages that the insulating liquid and the leak blocking liquid are injected at different periods for blocking holes, fractures and cracks on the rock body of the drill hole wall when an organic polymer film is formed on the wall of the drill hole, so that the leak blocking effect is improved; the expansion sleeve expands to tightly attach with the wall of the drill hole under the effect of slurry pressure to form an effective blocking space so as to be beneficial to the directional flowing of the insulating liquid and the leak blocking liquid. The system has the advantages of simple structure, convenience for operation ad low engineering cost.

Owner:SHANXI LUAN ENVIRONMENTAL ENERGY DEV

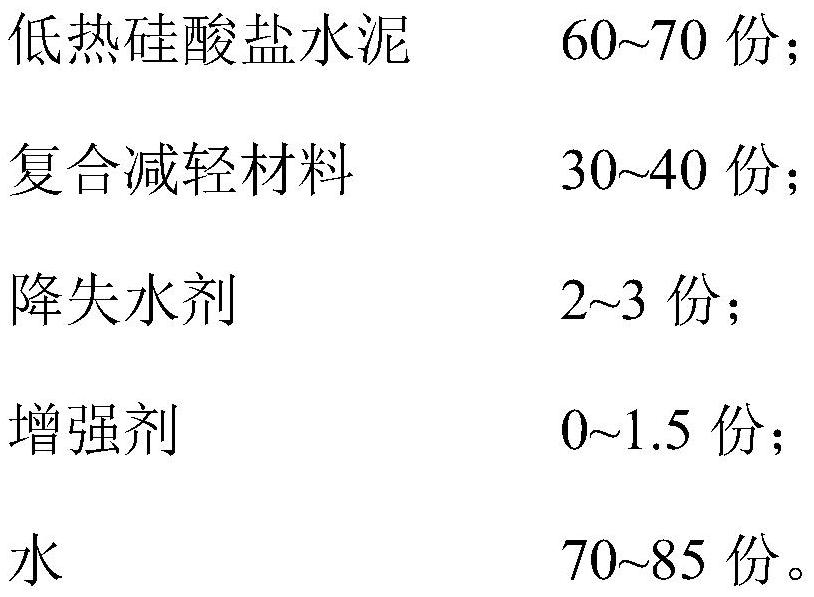

Low hydration heat and low density cement paste system for well cementation and preparation method and application thereof

ActiveCN112723822AHigh coagulation strengthImprove technical levelSolid waste managementDrilling compositionComposite materialMineralogy

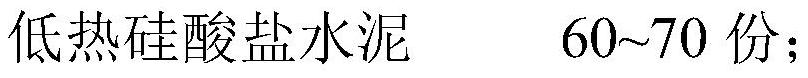

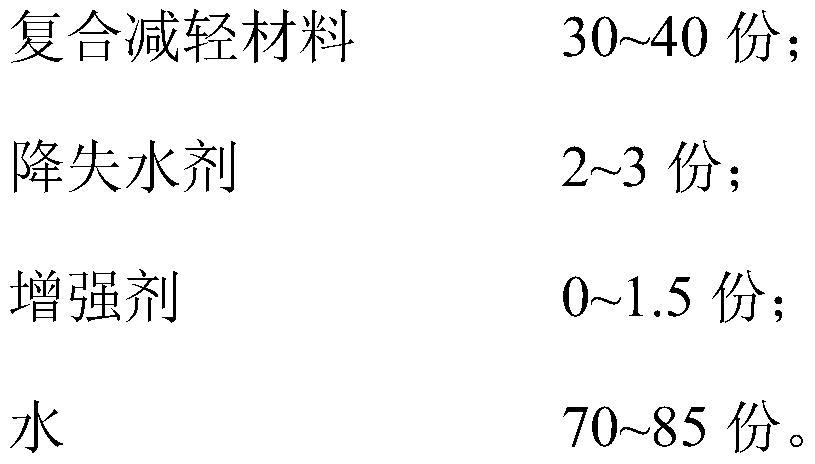

The invention provides a low hydration heat and low density cement paste system for well cementation, and a preparation method and application thereof, the low hydration heat and low density cement paste system comprises the following components by weight: 60-70 parts of low heat portland cement; 30-40 parts of a composite lightening material; 2-3 parts of a fluid loss agent; 0 to 0.15 part of retarder; 0-1.5 parts of a reinforcing agent; and 70-85 parts of water. The low-hydration-heat and low-density cement paste system prepared by the invention has a wide temperature application range of 40-85 DEG C and a moderate density application range of 1.25-1.45 g / cm < 3 >; and compared with a G-grade cement low-density system under the same condition, the thickening time is longer (40-80 min is prolonged), and the solidification strength is higher (15-30% is improved) for 24 / 48 h. Meanwhile, the performance of a formula system is adjusted, a reasonable one-way adjustment space is reserved, the contradiction and problem that a retarder and a reinforcing agent are used at the same time in an existing system are solved, and meanwhile, the use amount of additives is greatly reduced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Shallow-layer plugging agent

InactiveCN105694833ARapid strength development in the early stage of settingHigh coagulation strengthDrilling compositionActive agentSlurry

The invention relates to a shallow-layer plugging agent. Oil-well cement is used as a substrate, a fluid loss agent, a dispersant, an active agent and a modifier are added, the plugging agent is mainly characterized in that additives are used for changing conventional cement paste performance, so that the construction requirement of plugging, perforation plugging and non-plug perforation plugging is met, in the plugging construction process, a specific construction technology is adopted, the one-time plugging success rate is increased effectively, shallow-layer plugging agent slurry in casings can be circulated out of the ground, and plugging agent plugs are not reserved.

Owner:东营利丰化工新材料有限公司

Aluminate cement and preparation method thereof

The invention belongs to the technical field of building materials, and particularly relates to aluminate cement and a preparation method thereof. According to the preparation method provided by the invention, after aluminate cement clinker is prepared, sulfate, iron-ore slag and titanium dioxide are added, so that not only can the hydration solidification of the aluminate cement be shortened, butalso the solidification strength is improved, more importantly the problem that the traditional aluminate cement is poor in long-term strength can be improved, and the compressive strength of the cement after being hydrated for 28 days can still reach 65 to 75 MPa.

Owner:河源市极致知管信息科技有限公司

Rapidly-fixed desert mortar

The invention discloses a rapidly-fixed desert mortar, and relates to the field of building materials. The rapidly-fixed desert mortar provided by the invention comprises the following components in parts by mass: 15 to 25 parts of portland cement, 6 to 14 parts of high-aluminum cement, 2 to 8 parts of anhydrite, 6 to 13 parts of fly ash, 32 to 45 parts of desert sand, 9 to 16 parts of mineral slag powder and 3 to 6 parts of a composite auxiliary agent. The rapidly-fixed desert mortar provided by the invention has good compressive strength, fluidity and tensile adhesive strength.

Owner:史建华

Fabricated building construction process

PendingCN114592592AImprove liquiditySmall expansionSolid waste managementFibre chemical featuresPortland cementArchitectural engineering

The invention provides an assembly type building construction technology, and belongs to the technical field of buildings, the assembly type building construction technology comprises the steps of prefabricated part designing and manufacturing, measuring, paying off, prefabricated part installing, correcting, fixing, concrete slurry pouring and the like, and the concrete slurry is prepared from, by weight, 130-150 parts of Portland cement, 8-10 parts of gypsum and 115-160 parts of fine aggregate; the concrete comprises the following components in parts by weight: 25-45 parts of an active admixture, 15-30 parts of an inactive admixture and 8-20 parts of an additive, the water-binder ratio is 0.29-0.45, and the additive comprises a high-efficiency water reducing agent and an interface reinforcing agent; the concrete slurry disclosed by the invention has the characteristics of good fluidity, low expansion degree and fast strength development, also has high coagulation strength and excellent workability and construction performance, can meet the requirements of an assembly construction grouting technology, and has positive promotion significance for assembly type building construction.

Owner:瑞洲建设集团有限公司

Modified inorganic thermal-insulation mortar

The invention relates to a modified inorganic thermal-insulation mortar which comprises the following components in parts by mass: 5-10 parts of Portland cement, 1-2 parts of coal ash, 0.1-0.3 part of latex powder, 0.05-0.1 part of hydroxypropyl methylcellulose, 0.01-0.03 part of polypropylene fiber and 0.05-0.2 part of wood fiber. The ratio of the weight value (Kg) of the sum of raw materials to the volume value (L) of the modified light-weight aggregate is 1:4-1:8. A waterproofing agent is utilized to coat a Portland cement layer on the surface of the thermal-insulation light-weight aggregate to obtain the thermal-insulation aggregate, and a plurality of cementing materials are added to obtain the thermal-insulation material. The thermal-insulation mortar is convenient and simple to prepare, improves the properties of the thermal-insulation aggregate, and enhances the strength and hydrophobicity.

Owner:戚小平

Fly ash polymerization type cementing material, preparation method and application thereof

InactiveCN103664010ASingle formulaWide variety of sourcesCement productionToxic industrial wasteWaste material

The present invention discloses a fly ash polymerization type cementing material, which comprises the following raw materials, by weight: 70-90 parts of industrial waste, 1-10 parts of a synergist, 10-25 parts of an activator, and water, wherein the water is added according to a solid-to-liquid ratio of 1.5-2.8 g: 1 ml. According to the present invention, characteristics of simple raw material formula, wide source, low cost and substantial industrial waste consumption are provided, wherein the use amount of the waste material in the product can be 75-85%; the raw materials are not added with cement and other ingredients, cementing property of the obtained product is from the excitation reaction of the technology, and the formula is not added with sodium hydroxide and other alkaline activators, such that the cost is low, and the obtained cementing material has characteristics of short solidification time and high solidification strength; and the use is wide, and the obtained product can be used for adhesion between stones and stones, between stones and ceramics, and between ceramics and ceramics, and can further be used for adhesion of stones or ceramics on the cement-base surface.

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI

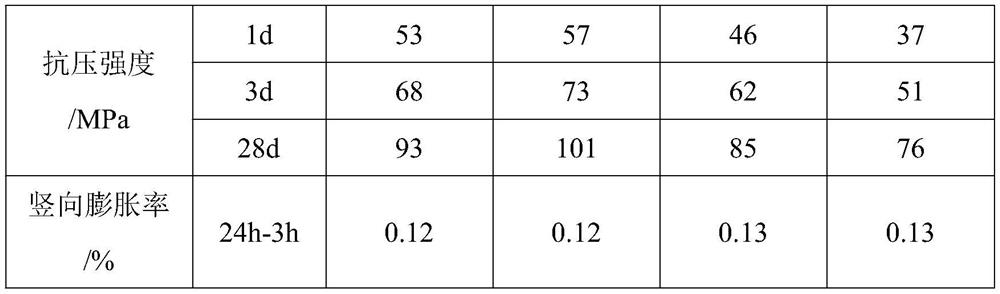

Fireproof gelatinizing agent and preparation method thereof

The invention discloses a fireproof gelatinizing agent and a preparation method thereof, and relates to the technical field of fireproof materials. The fireproof gelatinizing agent is characterized bycomprising the following raw materials in parts by weight: 40-60 parts of magnesium oxide, 5-10 parts of magnesium chloride, 5-10 parts of gypsum, 5-8 parts of sodium silicate, 15-18 parts of a filler, 50-100 parts of a solvent, 5-8 parts of organic silicon modified resin and 1-5 parts of calcium carbide. The fireproof gelatinizing agent does not contain any heat-seal toxic substance, is non-combustible, does not generate any toxic gas when being burnt, and is safe and environment-friendly.

Owner:黄圣焱

Novel ultralow-density cementing fluid

InactiveCN113045250AImprove thixotropyHigh coagulation strengthDrilling compositionChemical reactionWell cementing

The invention discloses an ultralow-density high-strength well cementing fluid which comprises the following components in percentage by mass: 10-30% of a modified perlite vitrified microbead lightening material, 60-75% of a reinforcing material, 5-9% of a coagulation accelerating early strength agent, 5-9% of a coagulation accelerating early strength additive and 10-15% of G-grade cement. The perlite vitrified microbeads in the lightweight material are subjected to surface treatment, and the components interact under a calcium-containing alkaline condition to realize physical and chemical reactions, so that the obtained mixture can realize good thixotropy and high coagulation strength; and in the using process, the ultra-low-density high-strength well cementing fluid and an ultra-low-density well cementing fluid leading slurry system (prepad fluid) can be obtained through the material proportion. The well cementing fluid leading slurry system has good compatibility with the drilling fluid, that is, the well cementing fluid leading slurry system is not afraid of pollution of the drilling fluid. Therefore, the replacement efficiency can be improved, the mixed slurry can be reduced and the well cementing quality can be improved by using the well cementing fluid leading slurry system for well cementation construction.

Owner:内蒙古中府一鼎石油工程技术有限公司 +2

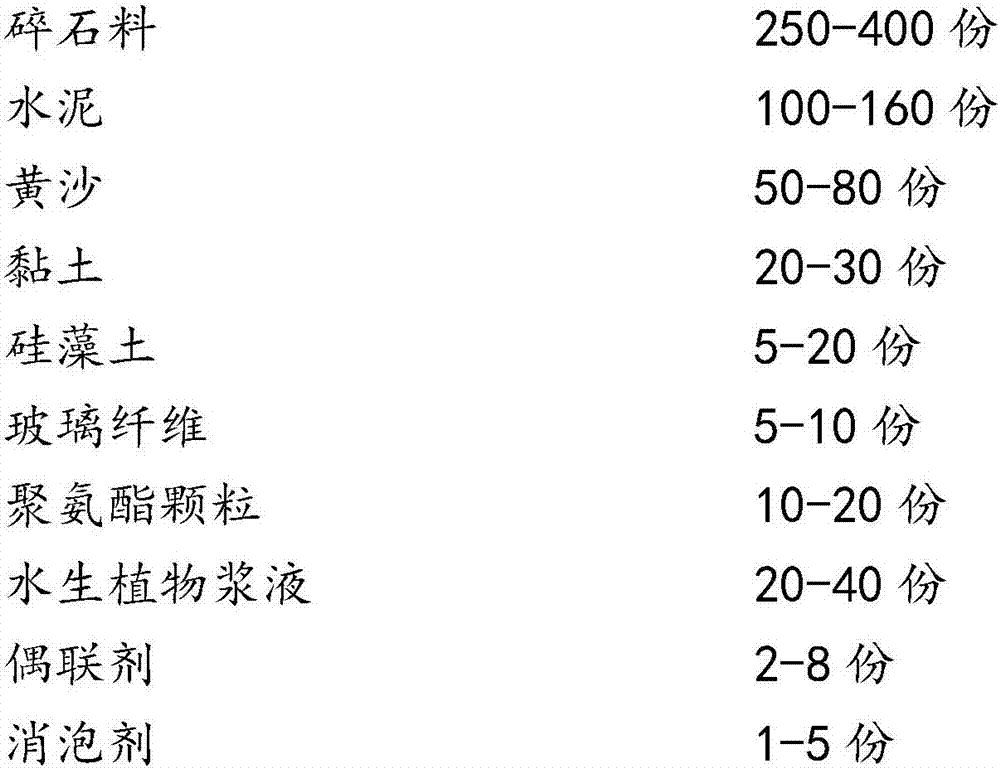

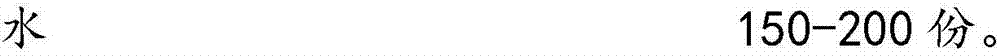

Aquatic plant improved concrete

The invention discloses aquatic plant improved concrete. The concrete is prepared from raw materials in parts by mass as follows: 50-400 parts of metaling, 100-160 parts of cement, 50-80 parts of yellow sand, 20-30 parts of clay, 5-20 parts of diatomite, 5-10 parts of glass fibers, 10-20 parts of polyurethane particles and the like. The aquatic plant improved concrete has good structural strength, toughness and weather resistance, an excellent anti-seismic property and stable performance and is not prone to crack.

Owner:SUZHOU TANGSHI JIANHUA CONCRETE PILE

High-strength pervious concrete and preparation method thereof

The invention discloses high-strength pervious concrete and a preparation method thereof, and the high-strength pervious concrete comprises the following raw materials: cement, gravel, polypropylene fiber, a water reducing agent, a retarder and water. The modified zeolite powder, the acrylate emulsion and the sulfamate water reducing agent are added, after the concrete mixture is added, the cement particles are dispersed, the workability of the cement particles can be improved, the unit water consumption is reduced, and the flowability of the concrete mixture is improved; the concrete is high in coagulation strength, and has excellent adhesion, crack resistance, freezing resistance, seepage resistance, corrosion resistance, chloride ion permeation resistance, aging resistance and corrosion resistance.

Owner:WUHAN TEXTILE UNIV

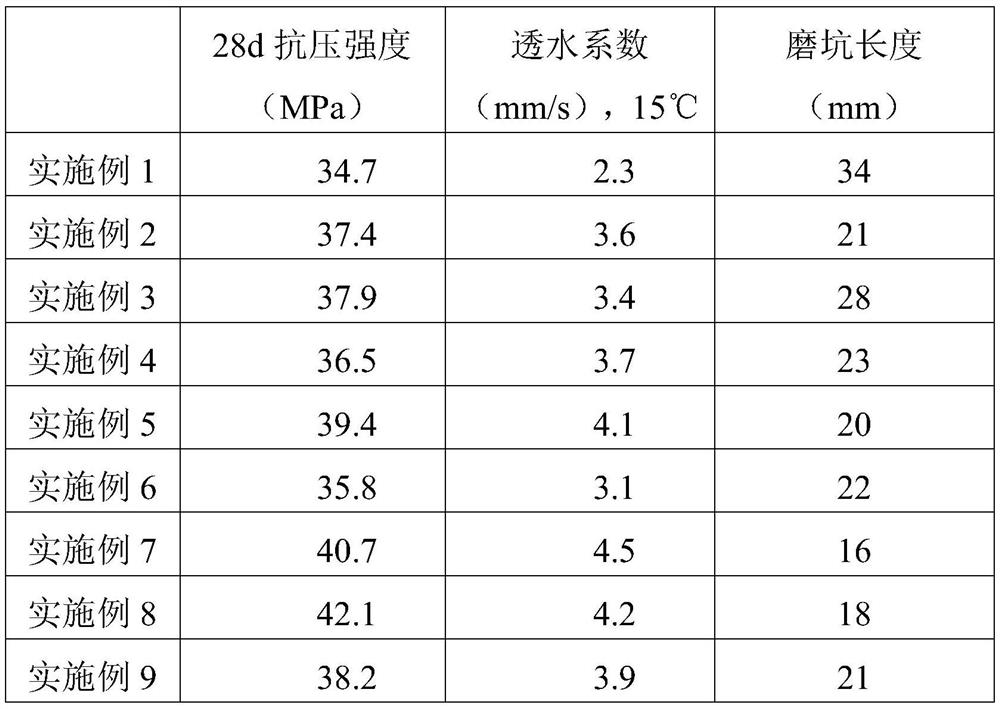

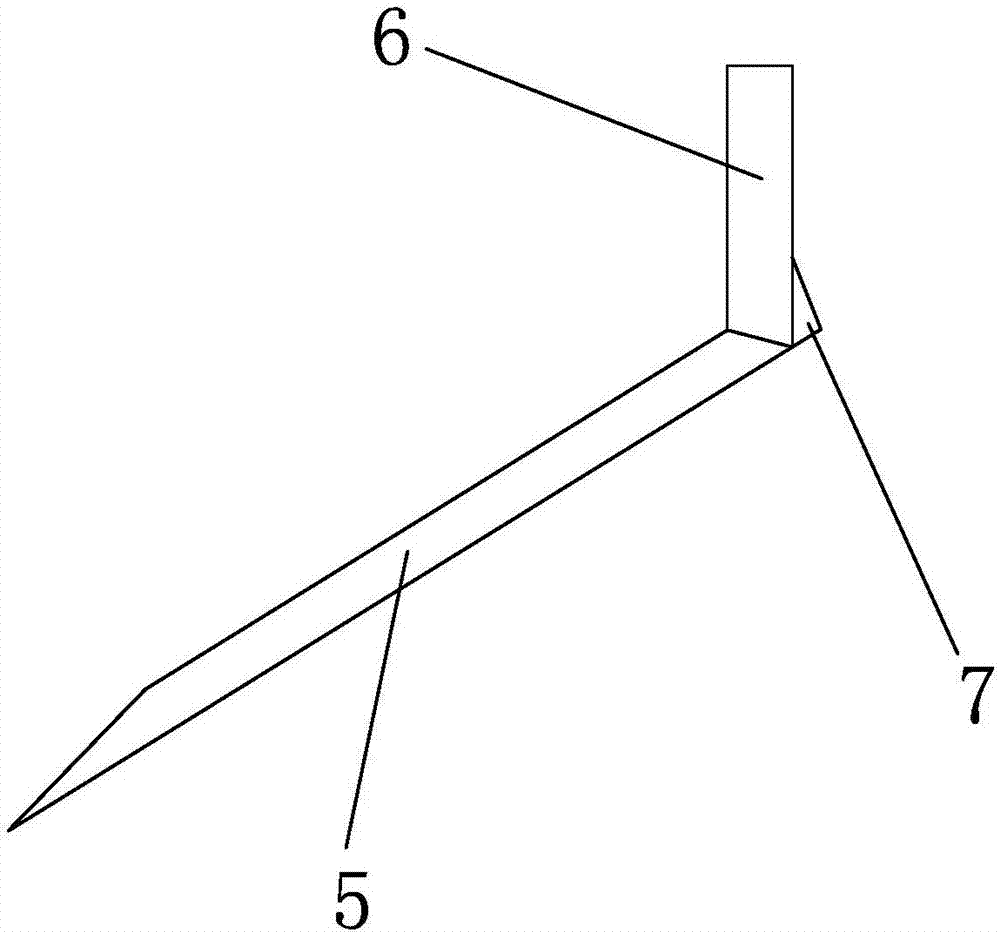

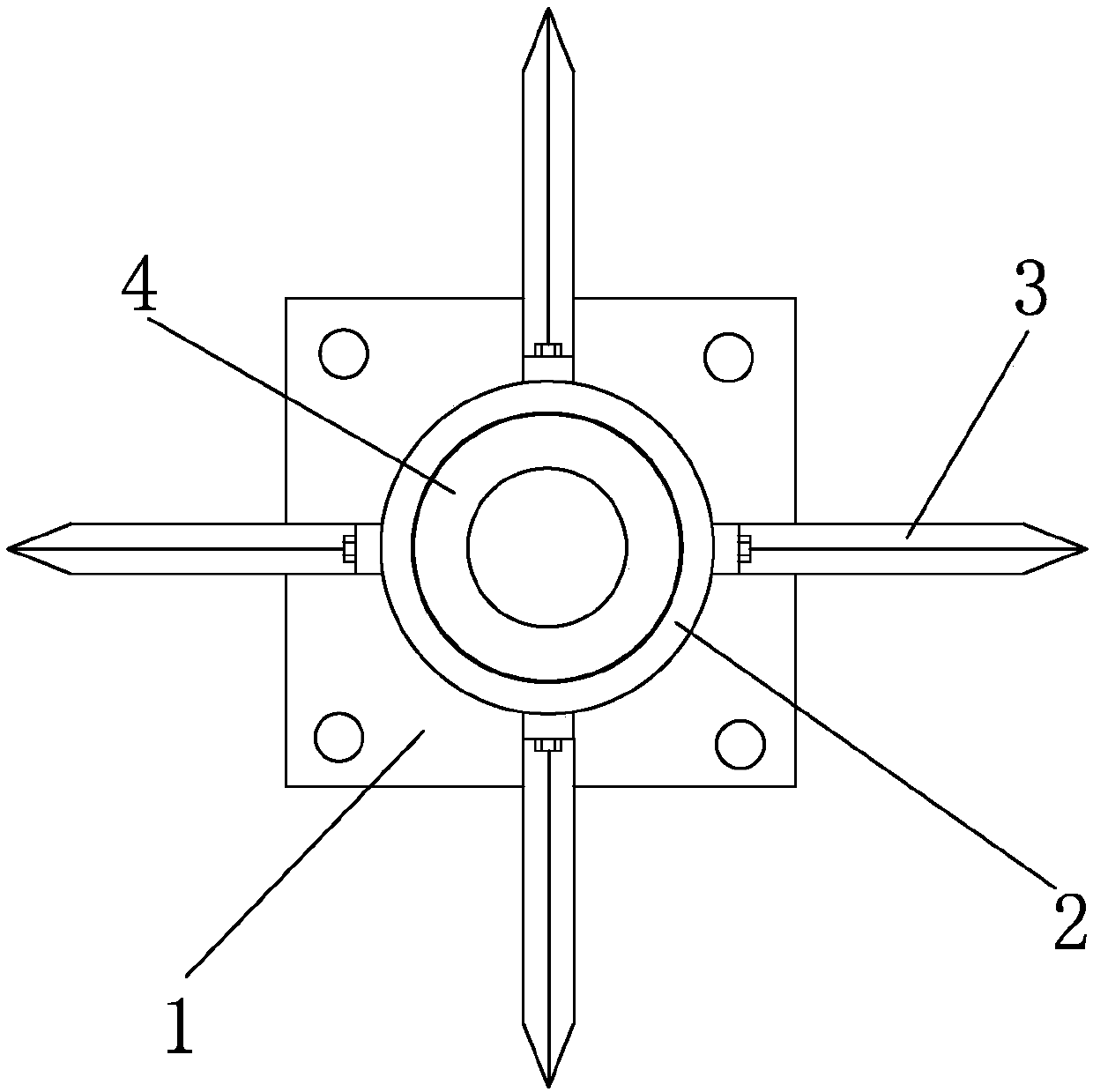

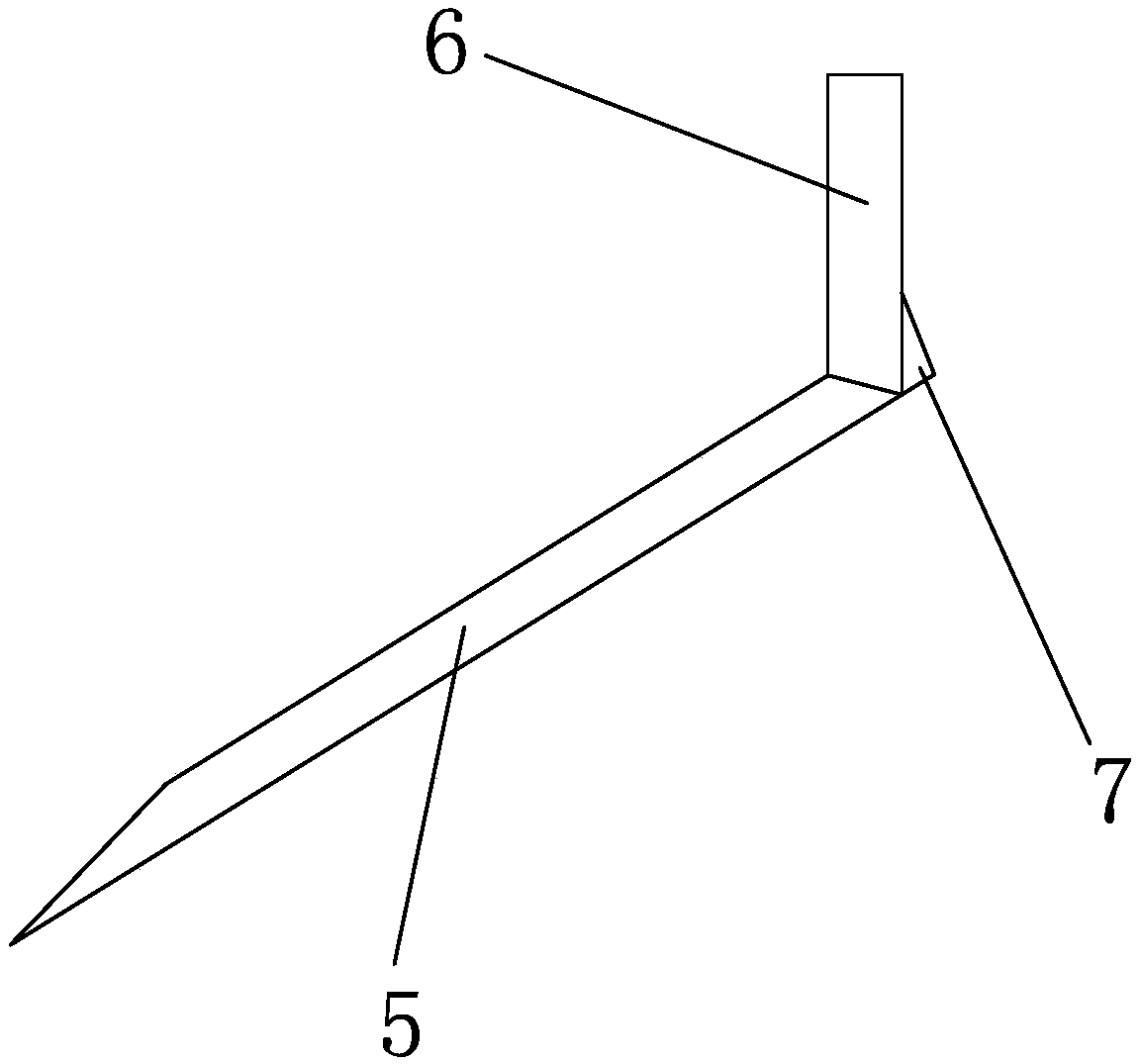

Construction method for anti-seismic and pulling-resisting pipe pile

ActiveCN106978808AHigh strengthHigh coagulation strengthBulkheads/pilesUltimate tensile strengthBearing capacity

The invention discloses a construction method for an anti-seismic and pulling-resisting pipe pile. The construction method includes the following steps that firstly, an installation pit is formed in a set pile position; secondly, a folded pulling-resisting part is installed; thirdly, an anchoring seat and the pipe pile are installed in the installation pit; and fourthly, concrete is poured in the installation pit, and filing and curing are conducted. The construction method is short in construction period, the anti-seismic and pulling-resisting strength of the pipe pile is good, and the bearing force is high.

Owner:SUZHOU TANGSHI JIANHUA CONCRETE PILE

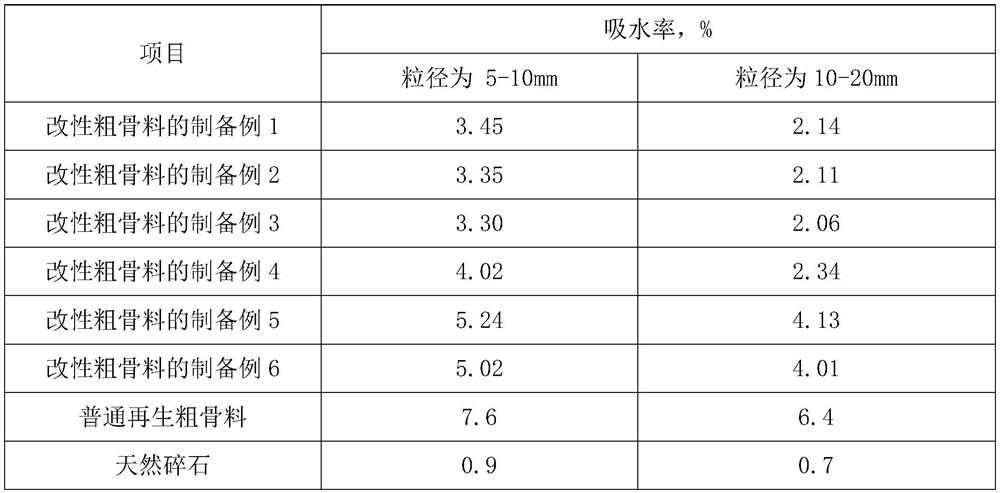

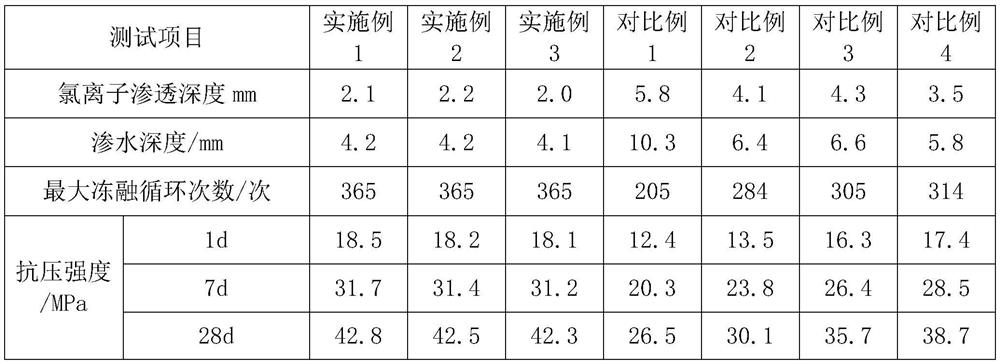

Recycled concrete and its preparation method

ActiveCN109721296BHigh mechanical strengthReduce porositySolid waste managementSlagUltimate tensile strength

Owner:西安天盛混凝土有限公司

A kind of construction method of anti-seismic and anti-extraction pipe pile

ActiveCN106978808BHigh strengthHigh coagulation strengthBulkheads/pilesUltimate tensile strengthBearing capacity

The invention discloses a construction method for an anti-seismic and pulling-resisting pipe pile. The construction method includes the following steps that firstly, an installation pit is formed in a set pile position; secondly, a folded pulling-resisting part is installed; thirdly, an anchoring seat and the pipe pile are installed in the installation pit; and fourthly, concrete is poured in the installation pit, and filing and curing are conducted. The construction method is short in construction period, the anti-seismic and pulling-resisting strength of the pipe pile is good, and the bearing force is high.

Owner:SUZHOU TANGSHI JIANHUA CONCRETE PILE

Environment-friendly ultrafine powder railway coal transportation and storage dust suppressant and preparation method

InactiveCN103980860BSuppress flyingHigh coagulation strengthOther chemical processesAnti freezingUltra fine

The invention discloses an environment-friendly superfine powder dust suppressant for railway coal transportation and storage and a preparation method. The environment-friendly superfine powder dust suppressant for railway coal transportation and storage comprises the following components in percentage by weight: 40-65% of physical modified starch, 25-45% of chemical modified starch, 2-5% of cross linker, 3-5% of anti-freezing agent, 3-4% of wetting agent, 2-4% of dispersant, 3-4% of thickener and 2-3% of penetrating agent. The preparation method for the environment-friendly superfine powder dust suppressant for railway coal transportation and storage comprises: weighing the components of the dust suppressant in percentage by weight respectively and putting the components into a ball mill; and mixing uniformly and performing high-speed shear ball milling to above 1,250 meshes, thus obtaining the environment-friendly superfine powder dust suppressant for railway coal transportation and storage. The superfine powder material is prepared by compounding the physical modified starch and the chemical modified starch, adding an inorganic gel material and adding multiple aids, and has the construction effects of good coal bed wetting effect, thick pervious bed, high curing speed, large setting strength of the pervious bed and good dust suppression effect.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Spillway tunnel bottom plate construction method

InactiveCN112281766AReduce disturbancePrevent water seepageBarrages/weirsFoundation engineeringWater seepageStructural engineering

The invention provides a spillway tunnel bottom plate construction method. The spillway tunnel bottom plate construction method comprises the following steps that underground earthwork is gradually excavated in a target area section by section to form a plurality of linear tunnel sections and a plurality of bent tunnel sections, all the linear tunnel sections and all the bent tunnel sections are finally communicated in sequence according to the excavation sequence to form a spillway tunnel, meanwhile, bottom plate units are built in a segmented mode in sequence in the extending direction of the spillway tunnel, all the bottom plate units are finally and sequentially connected according to the building sequence to form the spillway tunnel bottom plate, and when the bottom plate units are located in the linear tunnel sections, the corresponding bottom plate units are shorter than 8m, and when the bottom plate units are located in the bent tunnel sections, the corresponding bottom plate units are shorter than 4m. By the adoption of the technical scheme, disturbance to surrounding rock of the spillway tunnel is reduced, the surrounding rock is reinforced in time, water seepage is effectively prevented by excavating the spillway in a segmented mode, building the bottom plate units in a segmented mode and pouring concrete in a layered mode, and the safety protection performance is enhanced by building side wall units on the left sides and the right sides of the bottom plate units; and the concrete engineering construction quality is improved.

Owner:SINOHYDRO BUREAU 9

Anti-cracking and anti-hollowing dry-mixed mortar additive, and dry-mixed mortar containing additive

The invention discloses an anti-cracking and anti-hollowing dry-mixed mortar additive. The anti-cracking and anti-hollowing dry-mixed mortar additive comprises, by weight, 5-10 parts of zwitterionic liquid modified dehydroabietylamine, 2-5 parts of polyethylene glycol diacrylate / triethoxysilyl propylmaleic acid / N,N'-methylene bisacrylamide copolymer, 1-3 parts of humic acid, 10-20 parts of pumicepowder, 8-12 parts of zircon sands, 3-8 parts of seashell powder, 10-20 parts of palygorskite powder, 5-10 parts of pearl stone powder, 2-5 parts of plant polysaccharides and 0.5-1.5 parts of cholineglycerophosphate. The invention also discloses a preparation method of the dry-mixed mortar additive. The dry-mixed mortar additive has the advantages of good performance stability, small mixing amount, effectiveness in improvement of the water retention rate and cohesiveness of mortars, improvement of the strength of the mortar and the cohesiveness and synergistic deformation performances of themortar and a base layer, effectiveness in prevention of cracking and hollowing of wall surfaces, and high economic, social, promoting and applying values.

Owner:HUNAN CHENLI NEW MATERIAL CO LTD

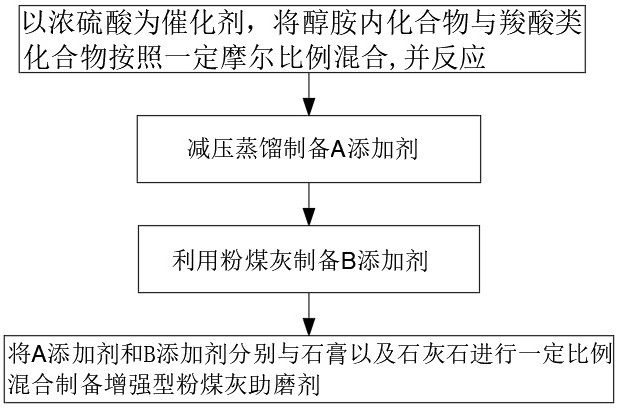

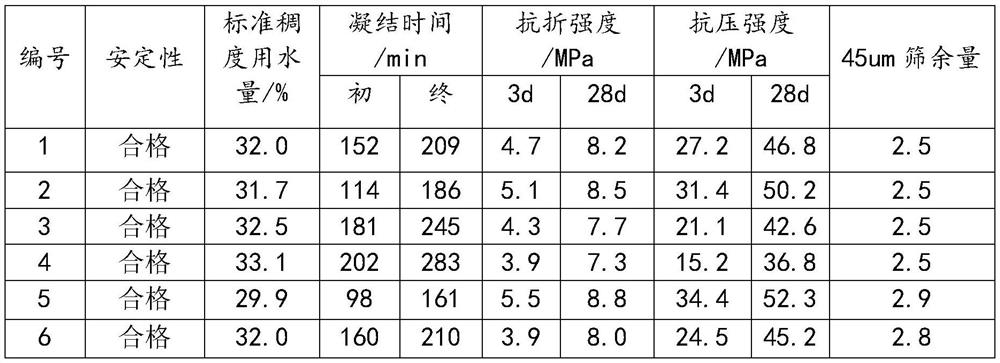

Preparation method of enhanced fly ash grinding aid

The invention discloses a preparation method of an enhanced fly ash grinding aid, and the specific method is as follows: firstly preparing an additive A, then preparing an additive B, then mixing the additive A, the additive B, gypsum and limestone according to a certain proportion, and stirring to obtain the enhanced fly ash grinding aid. According to the cement grinding aid, the stability of cement is guaranteed, the setting strength of the cement is enhanced, meanwhile, the compressive strength and the breaking strength of cement mortar are guaranteed, the prepared grinding aid is high in activity, the grinding efficiency is greatly improved, in the grinding process of the cement, the over-grinding reality and the ball and forging wrapping phenomena are avoided, the use amount of the cement is greatly reduced, and the cost is reduced. According to the invention, the carboxylic acid compound is used as the raw material, and the preparation process is free of chlorine element, so that the reinforcing steel bar cannot be rusted when the cement is used.

Owner:湖南格林朗科技有限公司

Nickel-iron slag building material and preparation method thereof

ActiveCN113896494AHigh strengthIncreased pozzolanic activitySolid waste managementClinker (waste)Slag

The invention provides a nickel-iron slag building material and a preparation method thereof, and belongs to the technical field of metal smelting solid waste utilization. The nickel-iron slag building material comprises the following components by weight: 40-60 parts of cement clinker, 1-25 parts of nickel-iron slag micro powder, 2-8 parts of gypsum, 2-8 parts of phosphate, and 0.1-10 parts of an additive, wherein the nickel-iron slag micro powder is prepared by using industrial nickel-iron slag as a raw material and conducting a grinding process to obtain a micro powder with the specific surface area of 350-550 m<2> / kg. By optimizing and adjusting the grinding particle size, the blending ratio and the composition structural characteristics of the nickel-iron slag micro powder, the setting strength of the cement clinker is improved.

Owner:吴联权

Phase-transition self-temperature-regulating heat-preserving facing brick of external wall and manufacturing method thereof

InactiveCN101705741BLight in massQuality improvementCovering/liningsSolid waste managementBrickSilicon oxide

The invention relates to a phase-transition self-temperature-regulating heat-preserving facing brick of an external wall, which is an integrated structure compacted by a phase-transition heat-preserving layer and an inorganic facing layer, wherein the phase-transition heat-preserving layer is mixed by proportion and compacted by hull-type expanded perlite heat-preserving aggregates, phase-transition temperature-regulating aggregates and cements; the inorganic facing layer is mixed by quartz sand, calcium carbonate, calcium oxide, cement and silicon oxide powders; and the phase-transition temperature-regulating aggregate is made of phase-transition cores and encapsulated hulls. The manufacturing method not only effectively solves the encapsulation problem of the phase-transition material, leads the prepared phase-transition self-temperature-regulating heat-preserving facing brick of the external wall to have excellent heat-preserving performance, waterproof performance and permanent anti-ageing performance, but also radically solves the obsolescence of thermo-physical property and the leakage problem of phase-transition material in the circulation process. The facing brick has the advantages of light weight, strong adhesion strength, large compressive strength, heat insulation, heat preservation, waterproof and moisture-proof performances, obvious energy-saving effect, and the like.

Owner:信阳天意节能技术股份有限公司

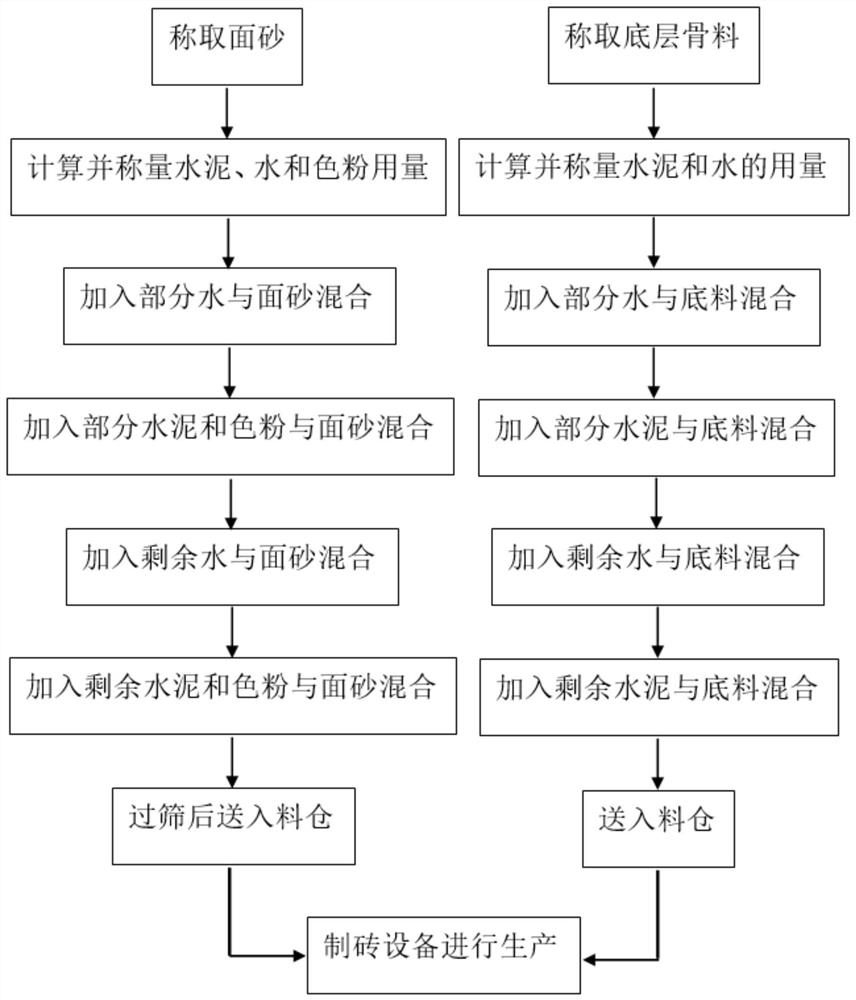

Preparation method of inorganic binder sand-based water permeable brick and water permeable brick

The invention discloses a preparation method of an inorganic binder sand-based water permeable brick and a product. The invention belongs to the field of building materials. Facing sand which is moderate in particle size, narrow in distribution range and good in particle shape is adopted as aggregate, flowability of the facing sand is more balance, and the contact area between the facing sand andcement is increased, so that the pore uniformity of a surface layer and the bonding strength between adjacent sand grains are improved; besides, the number of times of addition and addition time points of water, cement, facing sand and a backing material in the surface material and a backing material are changed, the binding force and the pore structure between the cement and the facing sand and between the cement and the backing material are changed, the contact area between the cement and the water is increased through a two-time water-cement adding method, the cement is more sufficiently hydrated, and the setting strength of the cement is improved. The method solves the problem that the strength, wear resistance and water permeability of the existing inorganic binder sand-based water permeable brick cannot be considered at the same time, and also solves the problem that the weather resistance and service lifetime of the existing sand-based water permeable brick are reduced as the strength, wear resistance and water permeability of the existing sand-based water permeable brick are improved by adopting an organic binder.

Owner:赣州市建恒建筑材料有限公司

Coal field drill hole leak blocking system

The invention relates to a coal field drill hole leak blocking system, belonging to the technical field of coal field drill holes. The coal field drill hole leak blocking system comprises an infusion system, a drill pipe connection system and a slurry system, wherein the infusion system comprises a infusion pipe, a check valve, a pipe boot, an infusion bottom hole, an infusion round hole, and a first level piston and a second level piston arranged in the infusion pipe from the bottom up; the drill pipe connection system comprises a drill pipe joint, a jump ring, an expansion sleeve sleeved and wound on the groove of the drill pipe joint, and a punching hole arranged at the groove on the middle part of the drill pipe joint; and the slurry system comprises insulating liquid and leak blocking liquid. The coal field drill hole leak blocking system has the advantages that the insulating liquid and the leak blocking liquid are injected at different periods for blocking holes, fractures and cracks on the rock body of the drill hole wall when an organic polymer film is formed on the wall of the drill hole, so that the leak blocking effect is improved; the expansion sleeve expands to tightly attach with the wall of the drill hole under the effect of slurry pressure to form an effective blocking space so as to be beneficial to the directional flowing of the insulating liquid and the leak blocking liquid. The system has the advantages of simple structure, convenience for operation ad low engineering cost.

Owner:SHANXI LUAN ENVIRONMENTAL ENERGY DEV

Red mud-fly ash polymeric inorganic cementitious material and its preparation method and application

The present invention discloses a red mud-fly ash polymerization type inorganic cementing material, which comprises the following raw materials, by weight: 75-95 parts of industrial waste, 5-20 parts of an activator, and water, wherein the water is added according to a solid-to-liquid ratio of 1.5-2.5 g: 1 ml. According to the present invention, characteristics of simple raw material formula, wide source, low cost, strong operability and substantial industrial waste consumption are provided, wherein the amount of the waste material in the solid raw material can be 80-90%; the raw materials are not added with cement and other ingredients, cementing property of the obtained product is from the excitation reaction of the technology, and the formula is not added with sodium hydroxide and other alkaline activators, such that the cost is low, and the side effect is less; and the use is wide, and the obtained product can be used for adhesion between stones and stones, between stones and ceramics, and between ceramics and ceramics, and can further be used for adhesion of stones or ceramics on the cement-base surface.

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com