Fabricated building construction process

A kind of building construction and assembly technology, which is applied in the direction of construction, building structure, and building material processing, etc. It can solve the problems of poor integrity and air tightness of structural connections, inability to integrally connect concrete structures, and inability to integrally connect the bottom of wall panels, etc. , to achieve the effect of making up for the defects in the fiber, reducing the thickening effect, and quickly developing the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A prefabricated building construction process, comprising the following steps:

[0033] (1) Design and manufacture prefabricated components according to design requirements, the prefabricated components include wall panels, floor slabs and stairs, and the outer wall panels in the prefabricated components are provided with reserved holes for connecting walls;

[0034] (2) Numbering the prefabricated components, drawing the construction control line, measuring and laying out the line at the installation site;

[0035] (3) Installation of prefabricated components, install the wall panels of the first layer of buildings on the prepared floor layer, and then correct, fix, and pour concrete slurry; after the concrete slurry poured into the wall panels reaches the strength, the first layer A layer of outer wall protection frame is installed on the outer wall plate of the building through the preset connecting wall reserved holes;

[0036] (4) Install the floor slab of the nex...

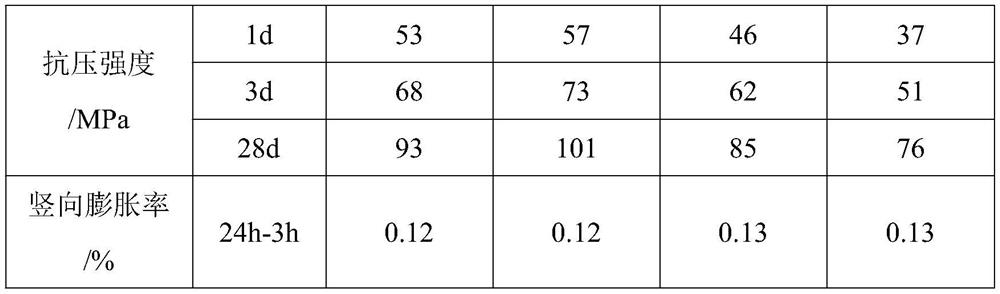

Embodiment 2

[0039] A perfusion concrete slurry for prefabricated building construction, in parts by weight, the concrete slurry has the following components: 140 parts of Portland cement, 10 parts of beta-hemihydrate gypsum, and a fineness modulus of 2.6 -2.9 zone II medium sand 125 parts, ii grade separation fly ash 30 parts, limestone micropowder 18 parts, sulfamate water reducing agent 3 parts, naphthalene water reducing agent 2 parts, sodium gluconate 3 parts, 8 parts of interface enhancer, the water-to-binder ratio is 0.35;

[0040] The interface reinforcing agent is a graphene-based modified carbon fiber, and its preparation method comprises the following steps:

[0041]S1, carry out 10000rpm × 10min high-speed centrifugation to the aqueous dispersion of graphene oxide to remove impurities and large aggregates, take the supernatant and concentrate to a concentration of 5-8mg / mL, to obtain a concentrated solution, under stirring conditions, in all Slowly add an anhydrous ethanol sol...

Embodiment 3

[0045] A perfusion concrete slurry for prefabricated building construction, in parts by weight, the concrete slurry has the following components: 140 parts of Portland cement, 10 parts of beta-hemihydrate gypsum, and a fineness modulus of 2.6 -2.9 zone II medium sand 125 parts, ii grade separation fly ash 30 parts, limestone micropowder 18 parts, sulfamate water reducing agent 3 parts, naphthalene water reducing agent 2 parts, sodium gluconate 3 parts, 8 parts of interface enhancer, the water-to-binder ratio is 0.35;

[0046] The interface reinforcing agent is a graphene-based modified carbon fiber, and its preparation method comprises the following steps:

[0047] S1, carry out 10000rpm × 10min high-speed centrifugation to the aqueous dispersion of graphene oxide to remove impurities and large aggregates, take the supernatant and concentrate to a concentration of 5-8mg / mL, to obtain a concentrated solution, under stirring conditions, in all Slowly add an anhydrous ethanol so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com