Construction method for anti-seismic and pulling-resisting pipe pile

A construction method and technology of pipe piles, applied in the direction of sheet pile walls, foundation structure engineering, buildings, etc., can solve the problems of long construction period, weak earthquake resistance and pullout resistance, etc., achieve short construction period, improve bearing capacity, total porosity The effect of rate reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

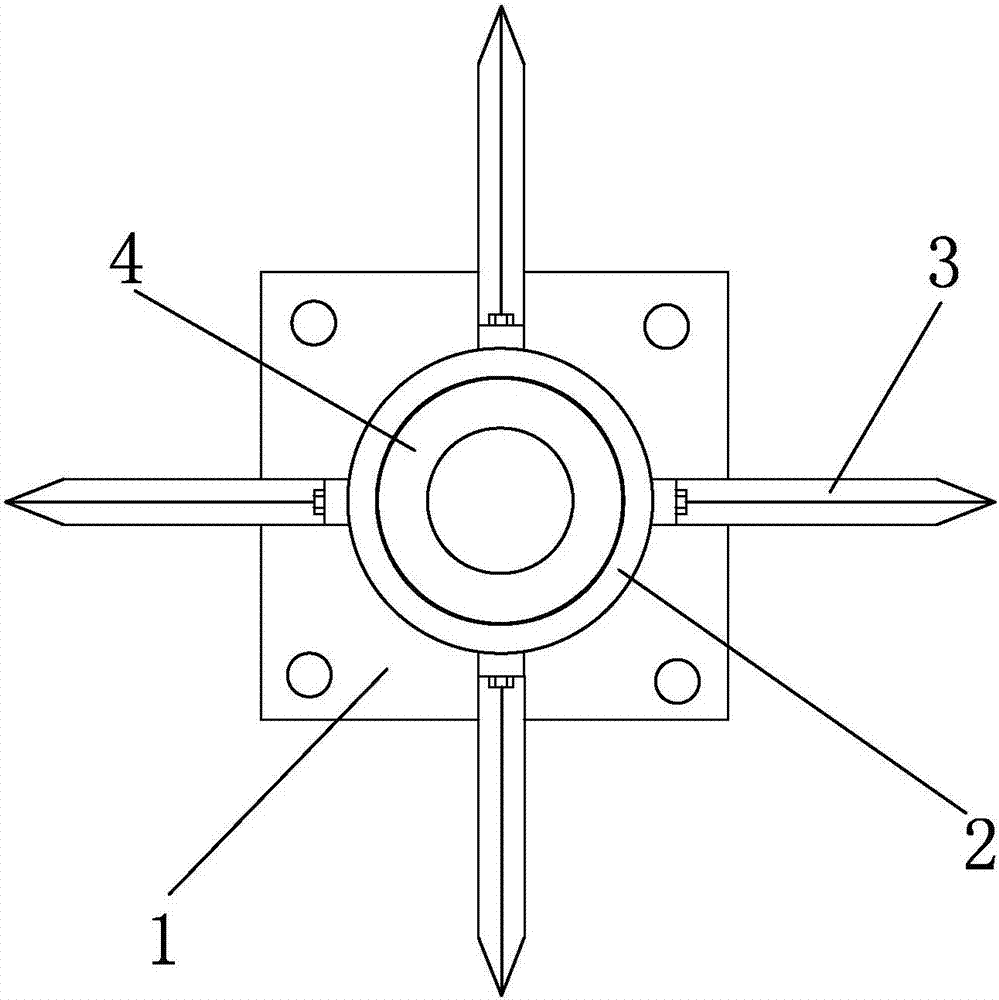

[0026] to combine figure 1 , figure 2 , the present invention provides a construction method for earthquake-resistant and pull-out pipe piles, which is used for the construction of prefabricated pipe strings 4 . This method mainly comprises the following steps:

[0027] Step 1: At the set pile position, dig a square installation hole according to the diameter of the pipe pile. In order to ensure the strength of the construction, the side length of the installation pit is preferably 2.8-4.5 times the outer diameter of the pipe string 4 .

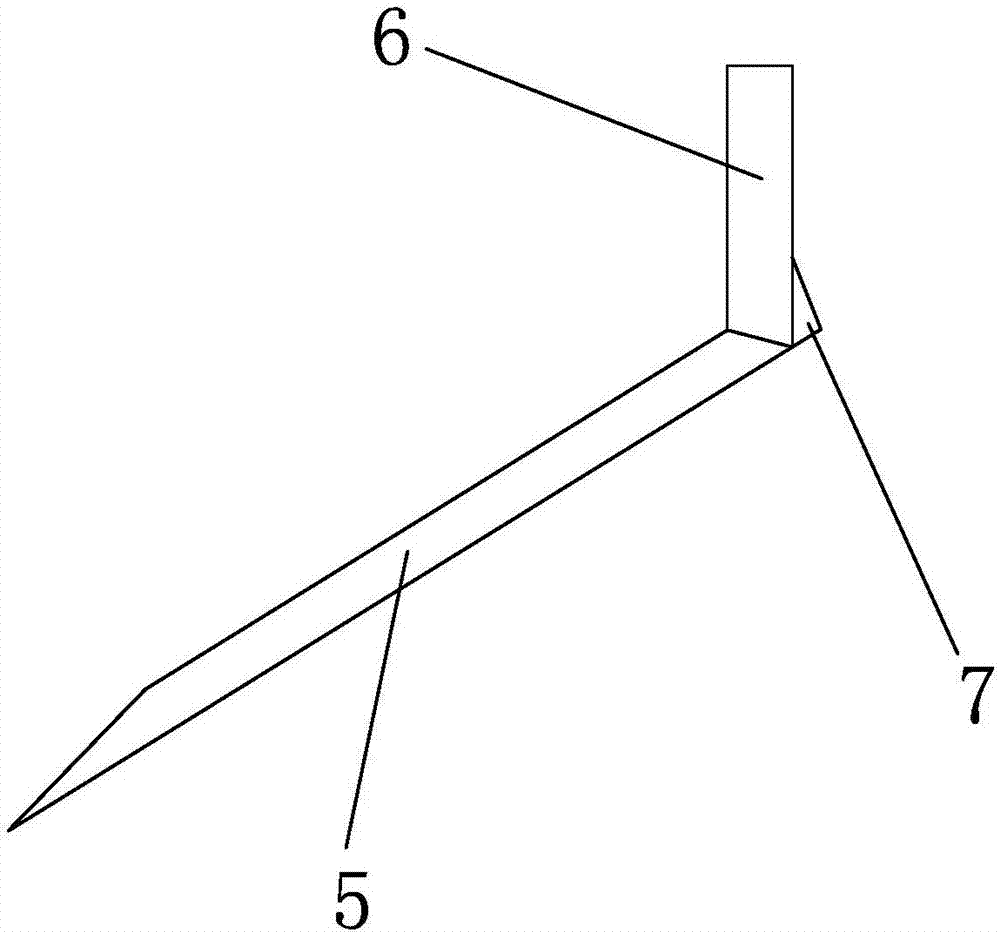

[0028] Step 2, installing the folded anti-lift piece 3, which is in a folded shape with an inner fold angle of 120-150°. One end of the folded anti-lift piece 3 is a picket 6, and the other end is a mounting column 5. Keep the installation column 5 vertically, and insert the picket 6 into the pit wall of the installation pit. The number of folded anti-pull pieces 3 can be 3-12. In order to facilitate construction, the tail of the picke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com