Fireproof gelatinizing agent and preparation method thereof

A technology of fireproof glue and gelling agent, which is applied in the field of fireproof materials, can solve the problems of no fireproof function, and the gelling agent is not environmentally friendly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

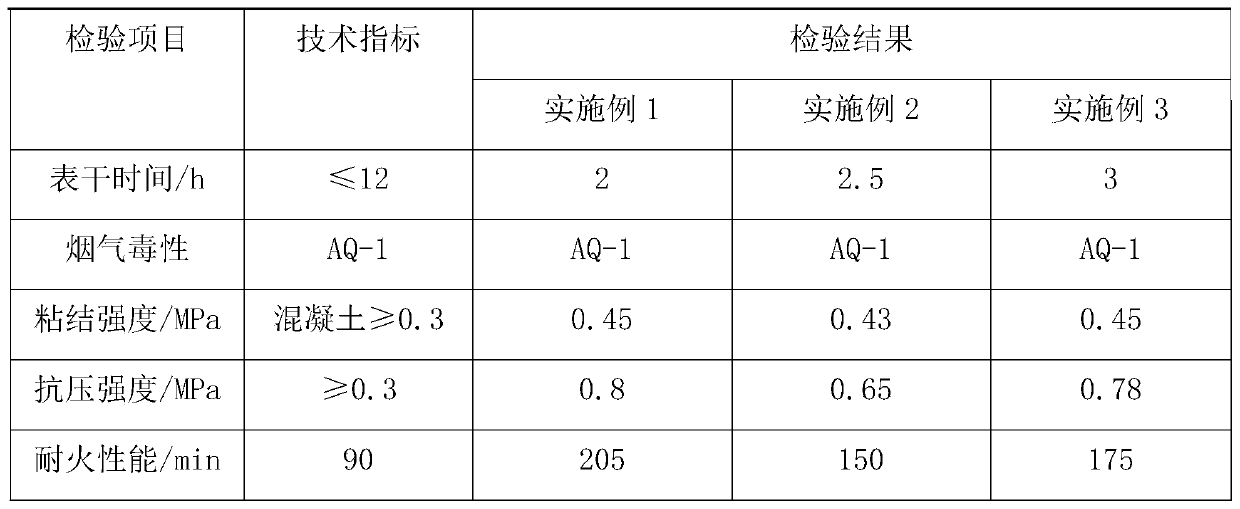

Examples

Embodiment 1

[0023] A fireproof gelling agent is characterized in that: it comprises the following raw materials in parts by weight:

[0024] 50 parts of magnesium oxide, 8 parts of magnesium chloride, 8 parts of gypsum, 6 parts of water glass, 6 parts of expanded vermiculite, 80 parts of water, 6 parts of silicone modified resin, 3 parts of calcium carbide and 5 parts of glass fiber.

[0025] A kind of preparation method of described fireproof gelling agent, comprises the steps:

[0026] (1) Take the required parts by weight of magnesium oxide, magnesium chloride, gypsum, water glass, water, organic silicon modified resin, calcium carbide and glass fiber and add it to a spherical mixer and stir for 8 minutes;

[0027] (2) Take the required parts by weight of expanded vermiculite, and cross 30 mesh sieves;

[0028] (3) Add the sieved expanded vermiculite into a spherical mixer and continue to stir for 10 minutes, then discharge to obtain the required fireproof gelling agent.

[0029] The...

Embodiment 2

[0031] A fireproof gelling agent is characterized in that: it comprises the following raw materials in parts by weight:

[0032] 40 parts of magnesium oxide, 5 parts of magnesium chloride, 5 parts of gypsum, 5 parts of water glass, 15 parts of expanded perlite, 50 parts of water, 5 parts of silicone modified resin and 1 part of calcium carbide.

[0033] A kind of preparation method of described fireproof gelling agent, comprises the steps:

[0034] (1) Take required parts by weight of magnesium oxide, magnesium chloride, gypsum, water glass, water, organic silicon modified resin and calcium carbide and add in spherical mixer and stir for 5 minutes;

[0035] (2) take required weight part expanded perlite, cross 30 mesh sieves;

[0036] (3) Add the sieved expanded perlite into a spherical mixer and continue to stir for 8 minutes, then discharge to obtain the required fireproof gelling agent.

Embodiment 3

[0038] A fireproof gelling agent is characterized in that: it comprises the following raw materials in parts by weight:

[0039] 60 parts of magnesium oxide, 10 parts of magnesium chloride, 10 parts of gypsum, 8 parts of water glass, 18 parts of a mixture of expanded vermiculite and expanded perlite, 100 parts of water, 8 parts of silicone modified resin, 5 parts of calcium carbide and 10 parts of glass fiber .

[0040] A kind of preparation method of described fireproof gelling agent, comprises the steps:

[0041] (1) Take the required parts by weight of magnesium oxide, magnesium chloride, gypsum, water glass, water, organic silicon modified resin, calcium carbide and glass fiber and add it to a spherical mixer and stir for 10 minutes;

[0042] (2) Take the mixture of expanded vermiculite and expanded perlite in required parts by weight, and cross 40 mesh sieves;

[0043] (3) Add the sieved mixture of expanded vermiculite and expanded perlite into a spherical mixer and con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com