High-strength pervious concrete and preparation method thereof

A permeable concrete and high-strength technology, applied in the field of concrete, can solve problems such as increasing the burden of drainage facilities, hidden dangers of urban management safety, waterlogging, etc., and achieve the effects of reducing unit water consumption, improving workability, and high coagulation strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

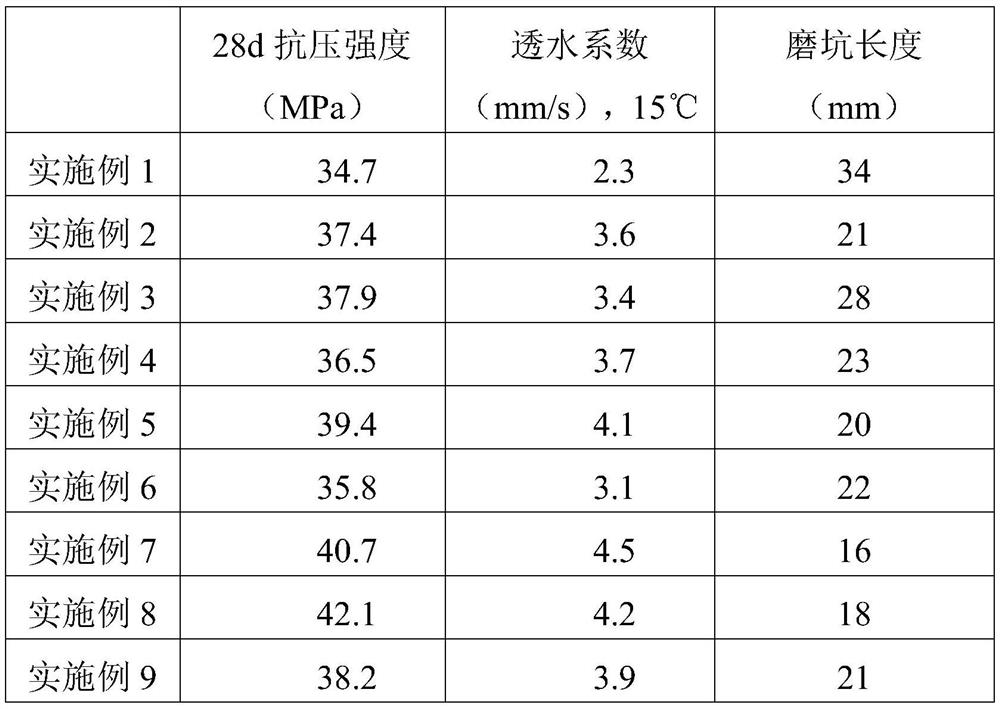

Examples

Embodiment 1

[0035] High-strength permeable concrete is prepared from the following raw materials: 300kg of cement, 1400kg of limestone crushed stone, 150kg of zeolite powder, 10kg of polypropylene fiber, 10kg of Point-TBS polycarboxylate high-performance water reducer, 6kg of sodium citrate, Acrylate emulsion 9kg, water 92kg.

[0036] The preparation method of above-mentioned high-strength permeable concrete comprises the following steps:

[0037] Add Point-TBS type polycarboxylate high-performance water reducer and acrylate emulsion into water and stir and mix evenly to obtain a mixed solution; add cement, limestone gravel, zeolite powder, polypropylene fiber, and sodium citrate into a concrete mixer and stir Mix well, then add the mixture and continue to stir until it is evenly mixed.

Embodiment 2

[0039] High-strength permeable concrete, prepared from the following raw materials: 300kg of cement, 1400kg of limestone crushed stone, 150kg of modified zeolite powder, 10kg of polypropylene fiber, 10kg of Point-TBS polycarboxylate high-performance water reducer, sodium citrate 6kg, 9kg of acrylate emulsion, 92kg of water.

[0040] The modified zeolite powder is prepared by the following method: 1 kg of isopropyl tris (dioctyl pyrophosphate acyloxy) titanate (also known as titanate coupling agent NDZ-201, CAS number: 67691-13 -8) Mix evenly with 20kg of ethanol to obtain a mixed solution; add 10kg of zeolite powder to the mixed solution and stir for 30 minutes at a speed of 400 rpm at 60°C, then filter with a 3000-mesh sieve, and vacuum-dry at 80°C for 4 hours, the modified zeolite powder was obtained.

[0041] The preparation method of above-mentioned high-strength permeable concrete comprises the following steps:

[0042] Add Point-TBS type polycarboxylate high-performanc...

Embodiment 3

[0044] High-strength permeable concrete, prepared from the following raw materials: 300kg of cement, 1400kg of limestone crushed stone, 150kg of modified zeolite powder, 10kg of polypropylene fiber, 10kg of sodium dibutylnaphthalenesulfonate, 6kg of sodium citrate, and 9kg of acrylate emulsion , Water 92kg.

[0045] The modified zeolite powder is prepared by the following method: 1 kg of isopropyl tris (dioctyl pyrophosphate acyloxy) titanate (also known as titanate coupling agent NDZ-201, CAS number: 67691-13 -8) Mix evenly with 20kg of ethanol to obtain a mixed solution; add 10kg of zeolite powder to the mixed solution and stir for 30 minutes at a speed of 400 rpm at 60°C, then filter with a 3000-mesh sieve, and vacuum-dry at 80°C for 4 hours, the modified zeolite powder was obtained.

[0046] The preparation method of above-mentioned high-strength permeable concrete comprises the following steps:

[0047] Add sodium dibutylnaphthalene sulfonate and acrylate emulsion into wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com