Patents

Literature

67results about How to "Reduce unit water consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

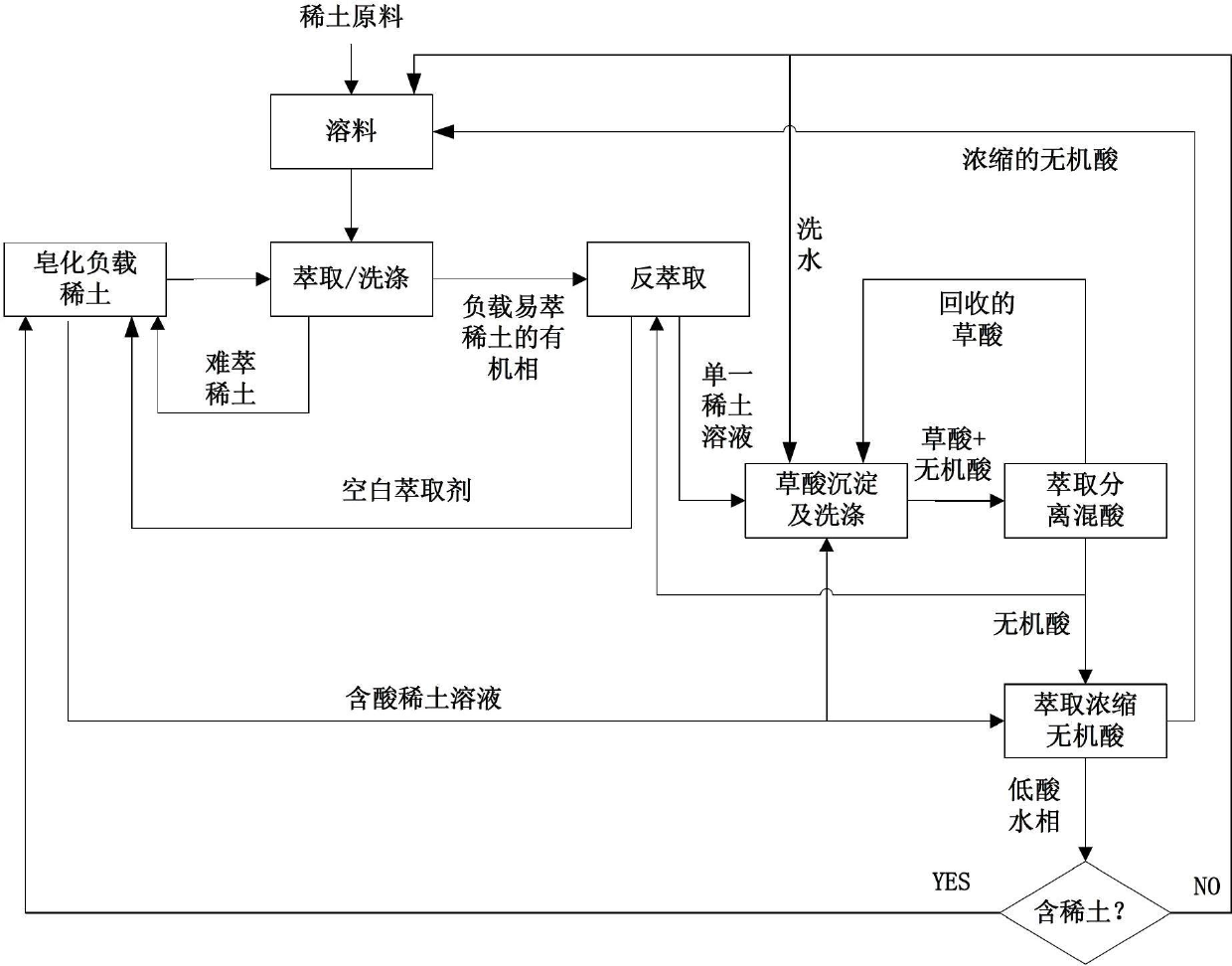

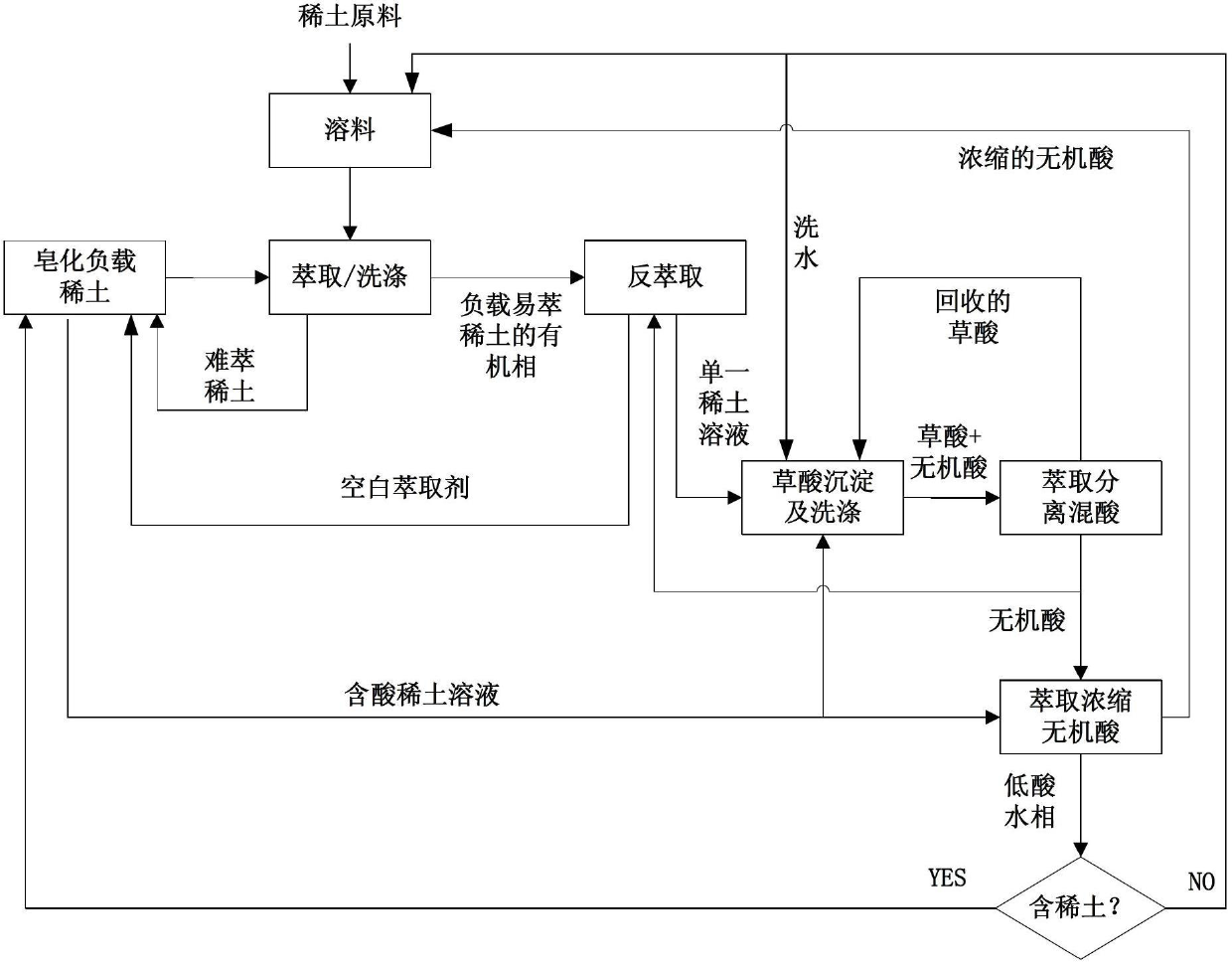

Rare earth separation method with material linkage cyclic utilization function

ActiveCN102676853ALow costSolve the problem of low extraction capacityProcess efficiency improvementOxalateCacodylic acid

The invention relates to a rare earth separation method with the material linkage cyclic utilization function. The rare earth separation method comprises the following steps: the organic phase of loaded rare earth prepared by extractant A and rare earth soap stock through mixing is used for the follow-up linkage extraction separation, and inorganic acid in the residual water phase is extracted and concentrated by extractant C and is then reused for material dissolving or recovering rare earth with oxalic acid precipitated therein; purified rare earth solution is subjected to extraction separation, the rare earth is precipitated through oxalic acid, sediment mother solution containing oxalic acid and inorganic acid is mixed with extractant B, the oxalic acid is extracted to be reused for precipitating rare earth, and the residual inorganic acid is directly used for washing and back extraction processes or is used for material dissolving after being concentrated by the extractant C. With the rare earth separation method provided by the invention, intermediate materials generated in the rare earth separation process can be recycled in process sections in a linkage manner, the alkali saponification process is avoided, and the material dissolving, washing and back extraction processes can be finished only by the recycled inorganic acid, so that the rare earth separation and purification process disclosed by the invention does not consume alkaline and inorganic acid, the cost is low, and the rare earth separation method is green and environmental-friendly.

Owner:CHINA MINMETALS BEIJING RES INST OF RE

Coal mine underground coal bed waterproof paint

The invention provides a coal mine underground waterproof paint, which is characterized by comprising the following components in part by weight: 13 to 27 parts of re-dispersible latex powder, 30 to 40 parts of cement, 35 to 40 parts of quartz sand, 5 to 10 parts of graphite powder, 5 to 10 parts of fly ash, 4 to 6 parts of vermiculite powder, 4 to 6 parts of expanded perlite powder, 4 to 6 parts of aluminum hydroxide, 2 to 4 parts of magnesium hydroxide, 0.003 to 0.024 part of air entraining agent, and 0.02 to 0.09 part of water reducing agent. Compared with other waterproof paint, the coal mine underground waterproof paint has the advantages of good waterproofing quality, flame resistance, antistatic property, elasticity, good cohesive property with coal, light weight, environmental protection, nontoxicity, easy construction and the like, and is suitable for coal mine underground waterproofing.

Owner:SHANXI LUAN ENVIRONMENTAL ENERGY DEV +1

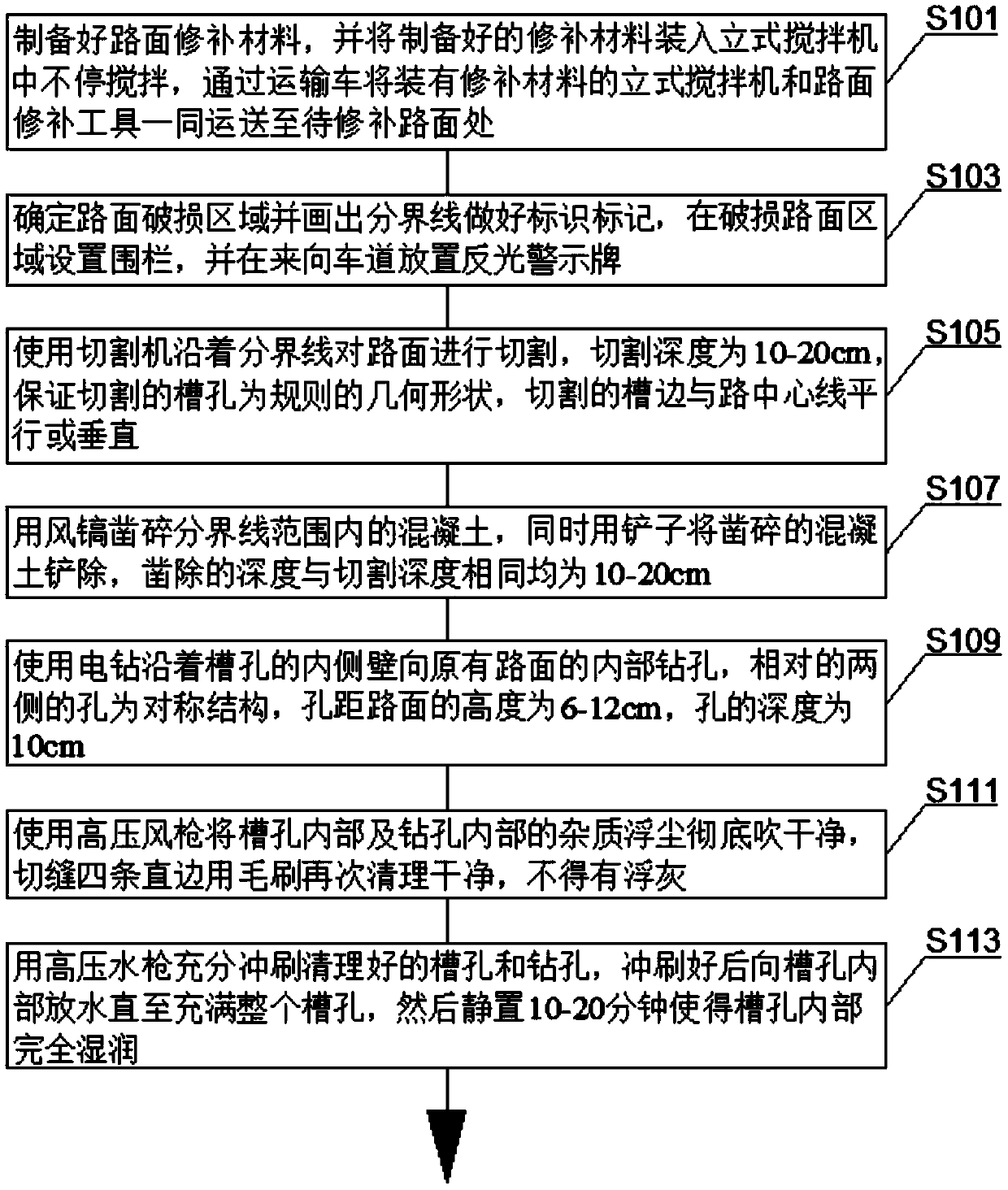

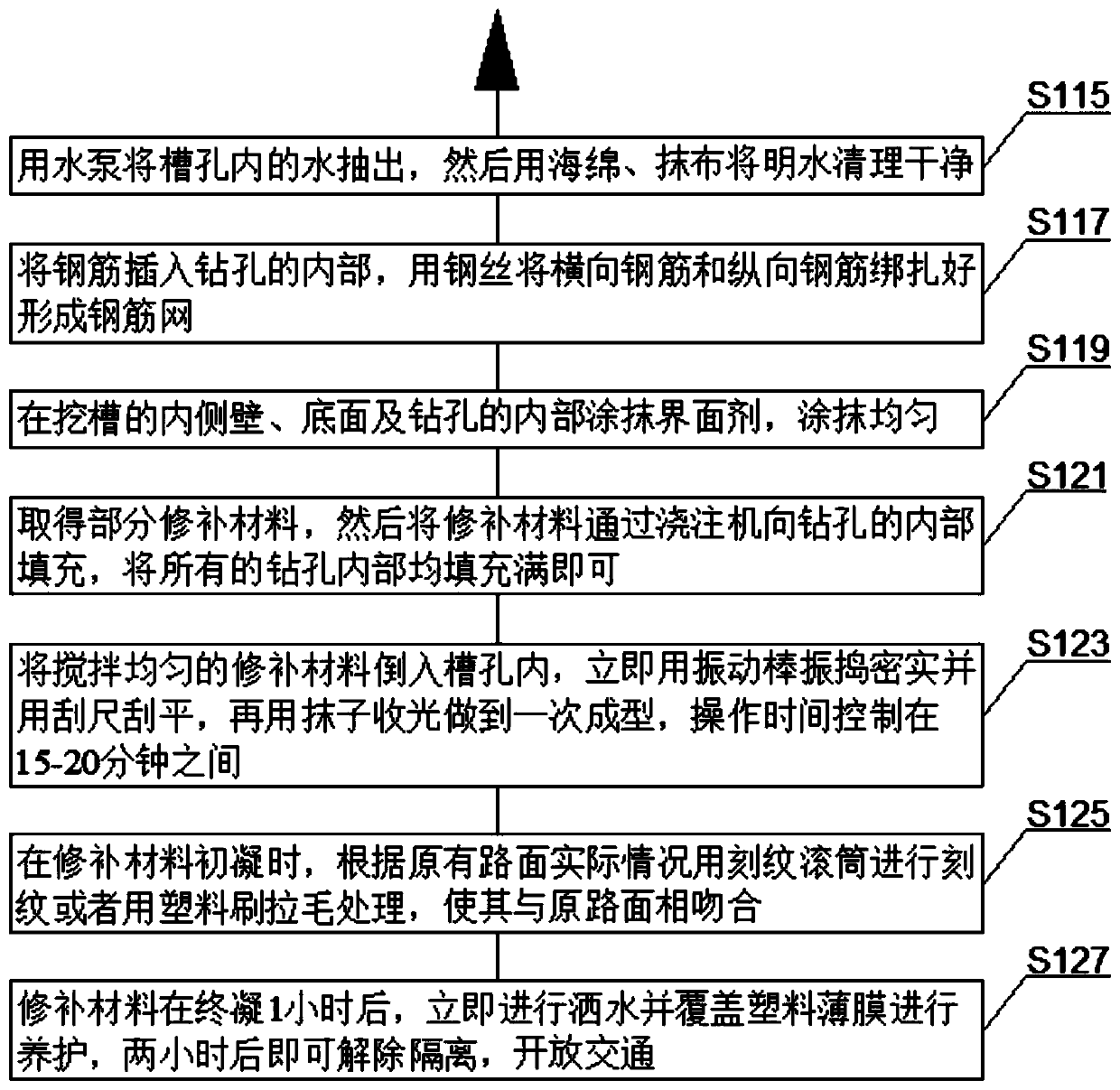

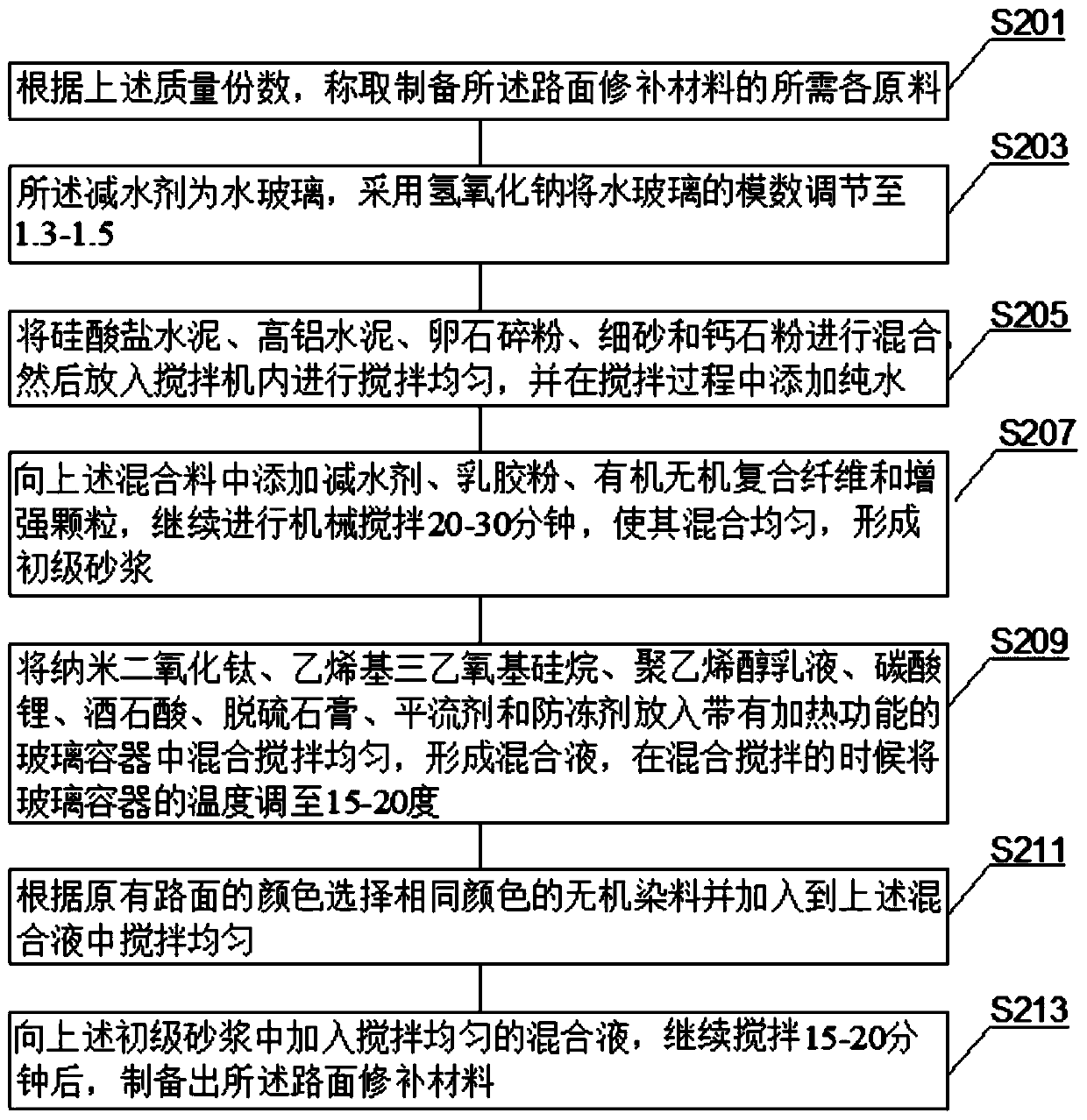

Method for repairing road surface damage

The invention discloses a method for repairing road surface damage. The road surface repairing material used in the method comprises, by mass, the following raw materials: 35-60 parts of Portland cement, 12-20 parts of high-alumina cement, 10-20 parts of gravel crushed powder, 20-30 parts of fine sand, 12-16 parts of calcium stone powder, 1-2 parts of a water reducing agent, 1-3 parts of latex powder, 2-3 parts of nano titanium dioxide, 1-2 parts of vinyl triethoxysilane, 0.5-1.5 parts of lithium carbonate, 1-1.5 parts of tartaric acid, 1-2 parts of desulfurized gypsum and 0.5-1 part of an advection agent. The method has the advantages of strong bonding property of new and old concrete, high freezing resistance, compression resistance, high bending strength, high temperature resistance andcorrosion resistance, capability of maintaining higher adhesive strength, short repairing time, long service life of a road surface, capability of adsorbing automobile exhaust and reduction of pollution.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

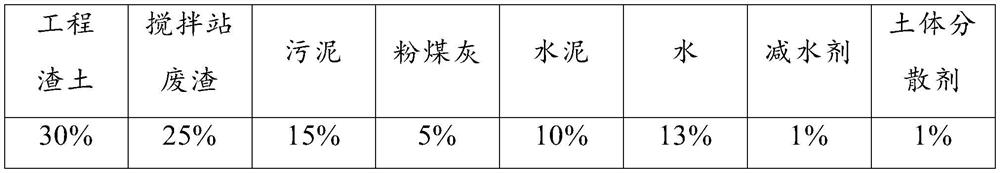

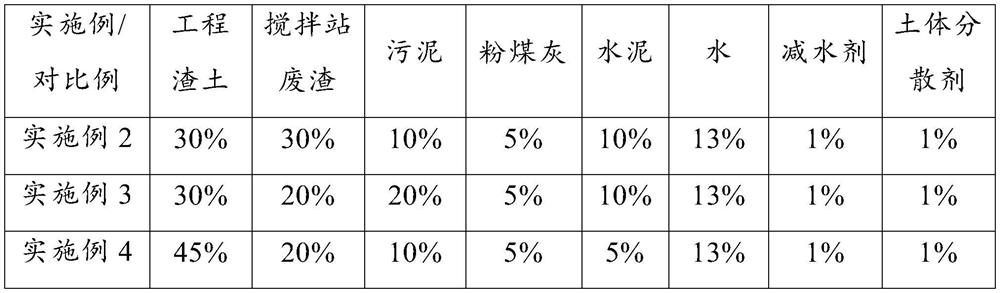

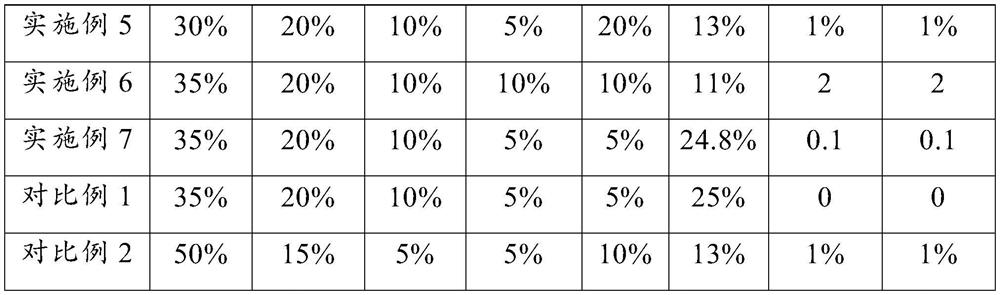

Controllable low-strength backfill material and preparation method thereof

ActiveCN113264731ACompliance with reductionIn line with resourceSolid waste managementSoil scienceSludge

The invention provides a controllable low-strength backfill material and a preparation method thereof. The controllable low-strength backfill material is prepared by adding fly ash, cement, water, a water reducing agent and a soil dispersing agent into a basic raw material and fully and uniformly mixing the mixture, wherein the basic raw material is a mixture of crushed engineering residue soil, mixing plant waste residues and sludge. The prepared controllable low-strength backfill material comprises the following components in parts by weight: 30-45 parts of engineering residue soil, 20-30 parts of mixing plant waste residues, 10-20 parts of sludge, 5-10 parts of fly ash, 5-20 parts of cement, 10-25 parts of water, 0.1-2 parts of a water reducing agent and 0.1-2 parts of a soil dispersing agent. Through the mode, the synergistic effect of all the raw materials can be fully utilized, the utilization rate of waste resources is effectively increased, meanwhile, the backfill material which is high in flow state, self-compacting and controllable in unconfined compressive strength is prepared, and the requirements of practical application are met.

Owner:WUHAN UNIV OF TECH

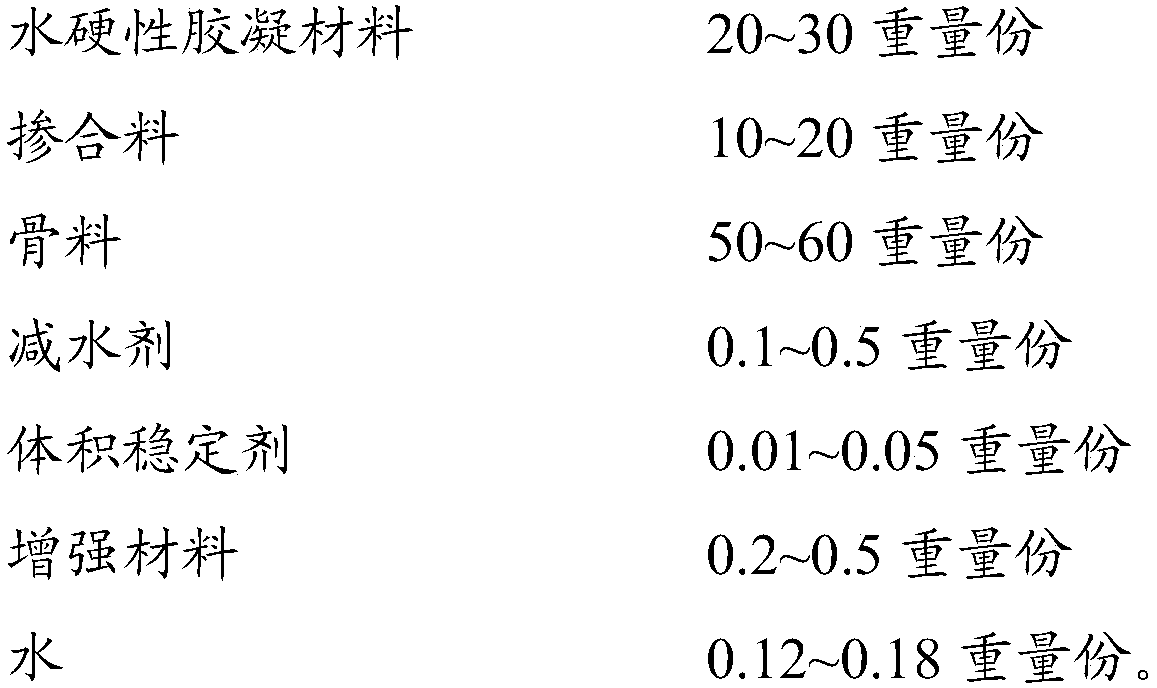

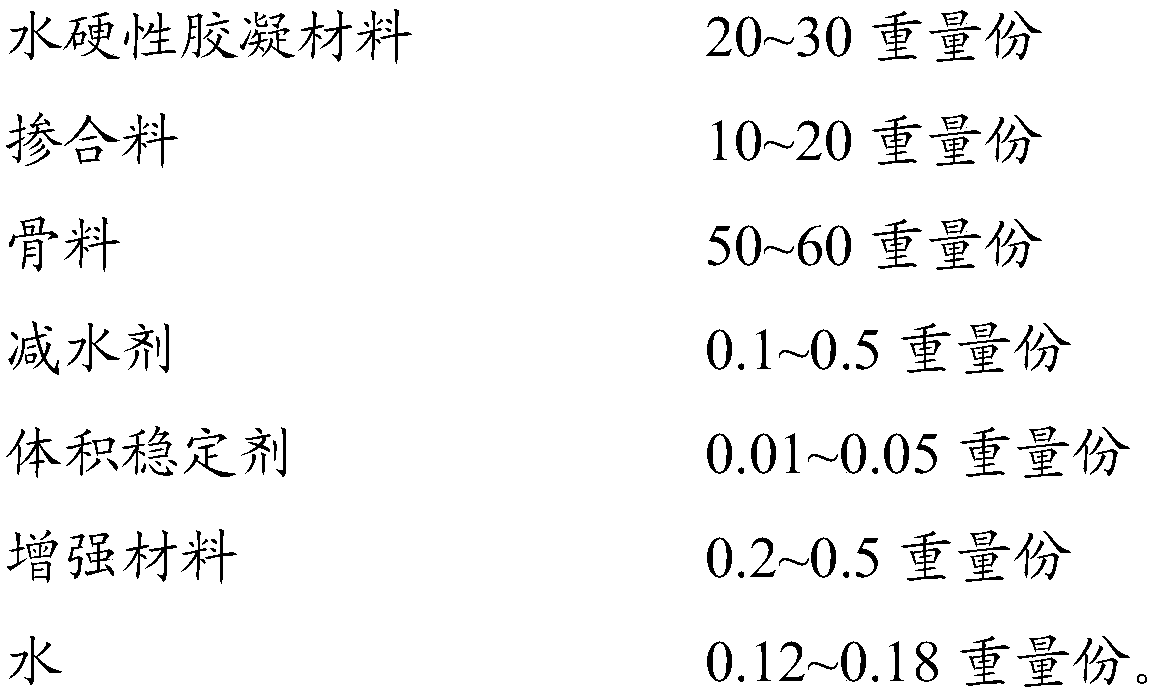

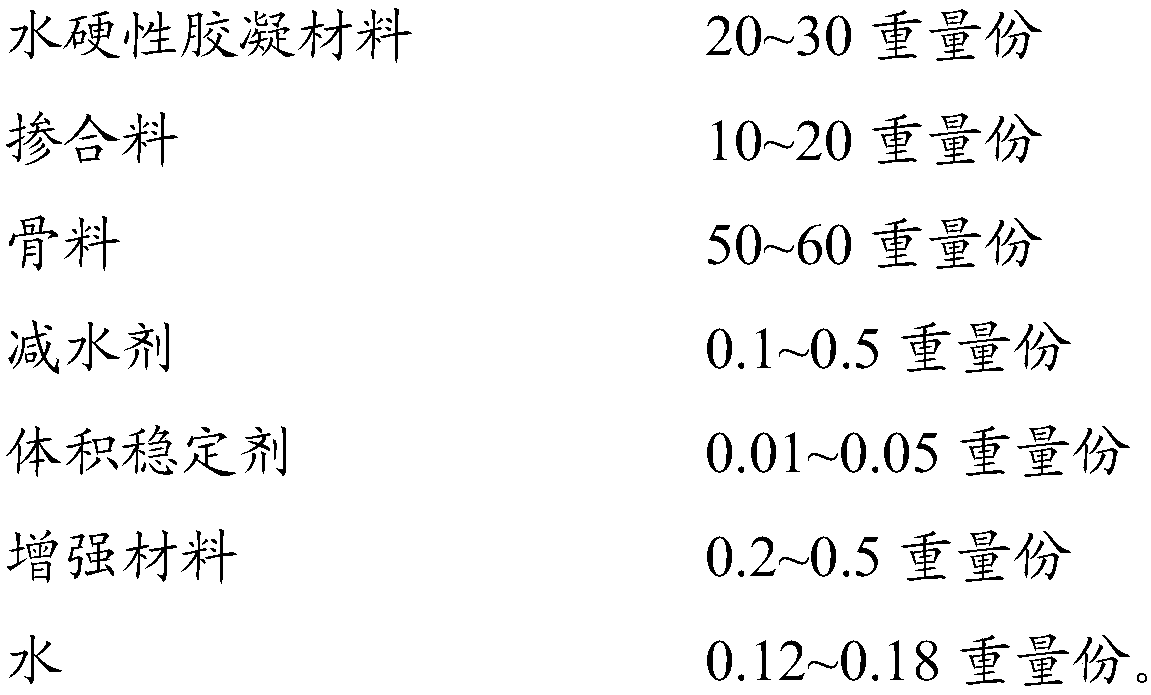

3D (Three-dimensional) printing building material and application thereof

InactiveCN108658546AImprove stress resistanceHigh strengthAdditive manufacturing apparatusCompressive strengthUltimate tensile strength

The invention provides a 3D (Three-dimensional) printing building material. The 3D printing building material is prepared from the following components in parts by weight: 20 to 30 parts by weight ofhydraulic cementing material, 10 to 20 parts by weight of admixture, 50 to 60 parts by weight of aggregate, 0.1 to 0.5 part by weight of water reducing agent, 0.01 to 0.05 part by weight of volume stabilizer, 0.2 to 0.5 part by weight of reinforcing material and 0.12 to 0.18 part by weight of water. The 3D printing building material provided by the invention is suitable for printing low-rise buildings with 1 to 3 layers; according to the record of the embodiment, the 28-day test compressive strength of the cured and molded 3D printing building material provided by the invention, can reach 60MPa or above.

Owner:北京美斯顿科技开发有限公司

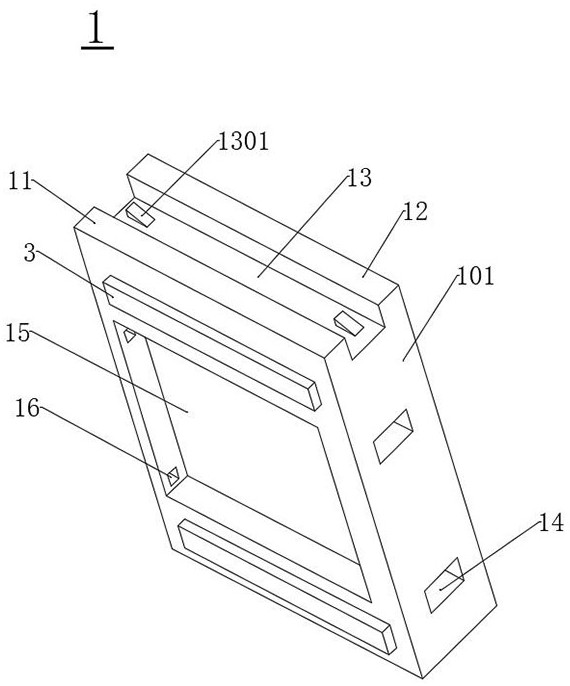

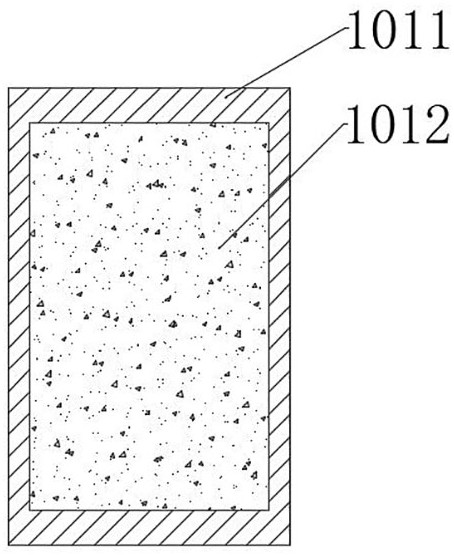

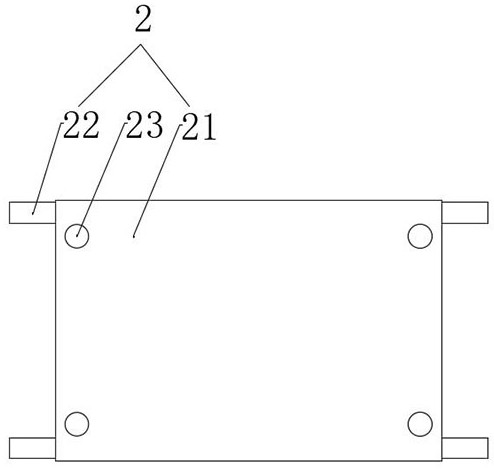

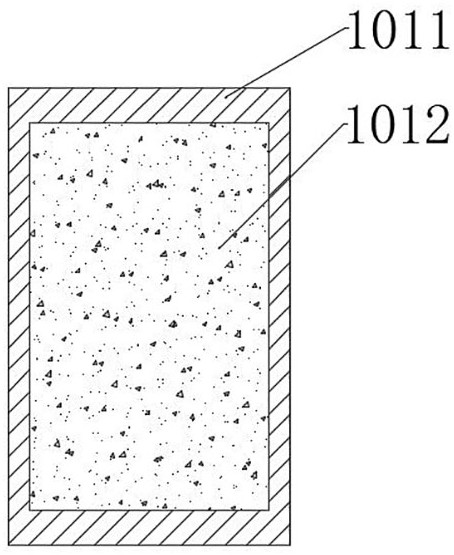

Anti-crack construction waste recycled concrete wallboard

ActiveCN113429170AImprove crack resistanceImprove liquidityBuilding componentsCrack resistanceArchitectural engineering

The invention relates to an anti-crack construction waste recycled concrete wallboard which comprises a wallboard assembly. The wallboard assembly comprises a wallboard body, and the wallboard body comprises a fireproof layer and a concrete layer. The concrete layer is prepared from the following raw materials in parts: 22-34 parts of recycled coarse aggregate, 33-43 parts of recycled fine aggregate, 46-72 parts of anti-crack cement, 1-13 parts of steel fibers, 1-3 parts of a water reducing agent, 1-4 parts of a reinforcing agent, 5-9 parts of mineral powder, 5-8 parts of nano silicon dioxide and 120-230 parts of water. The crack resistance of the concrete layer can be greatly improved; the flowability of a concrete mixture is improved, and high economic benefits are achieved; the durability and wear resistance of the concrete surface can be improved; and a wallboard installation limiting function can be achieved, and installation is convenient.

Owner:奥王建筑材料科技有限公司

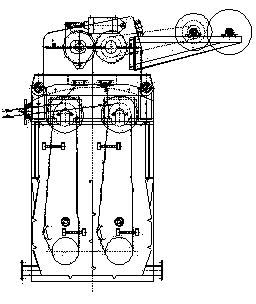

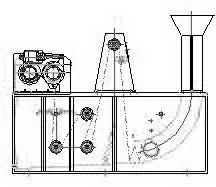

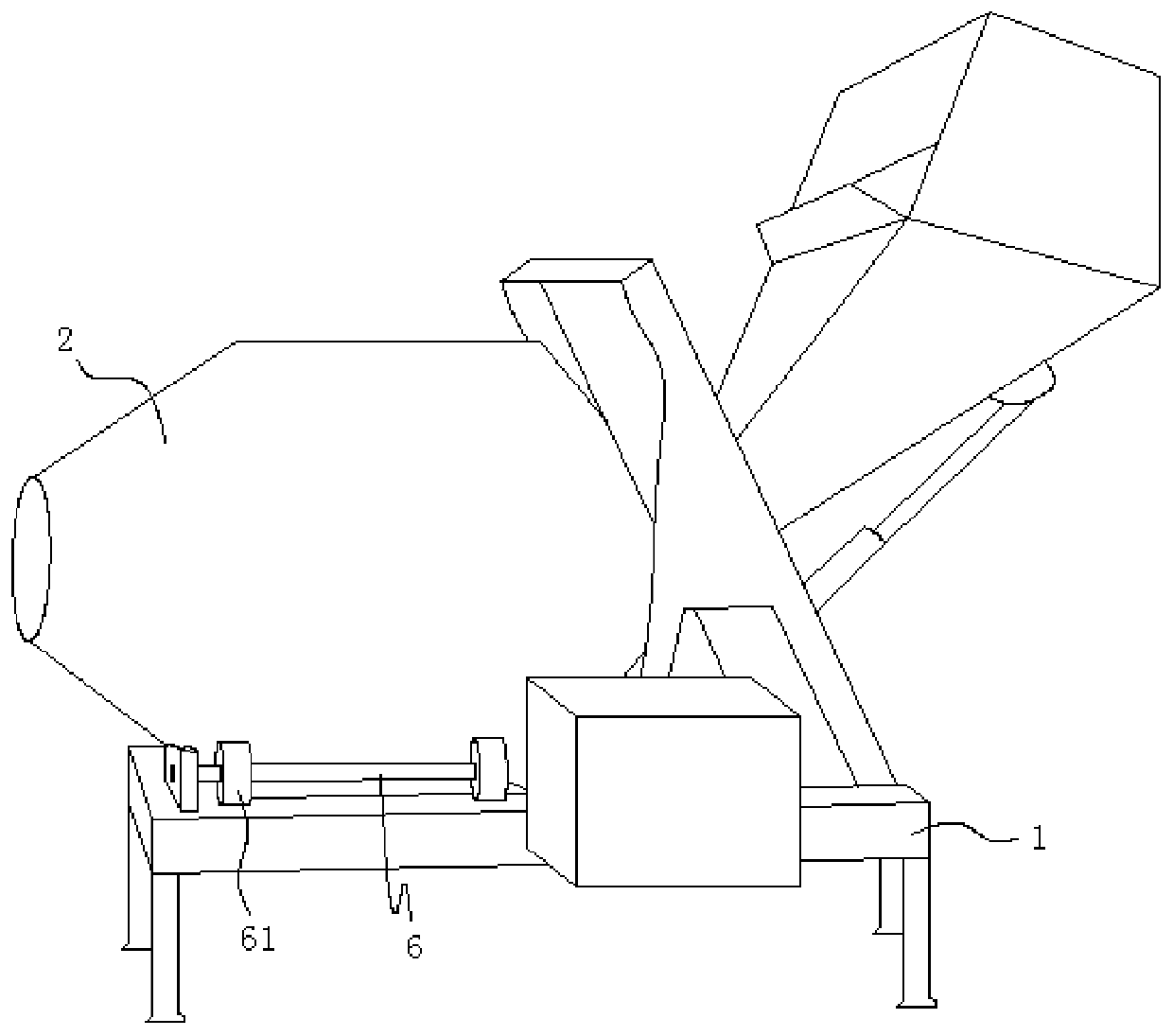

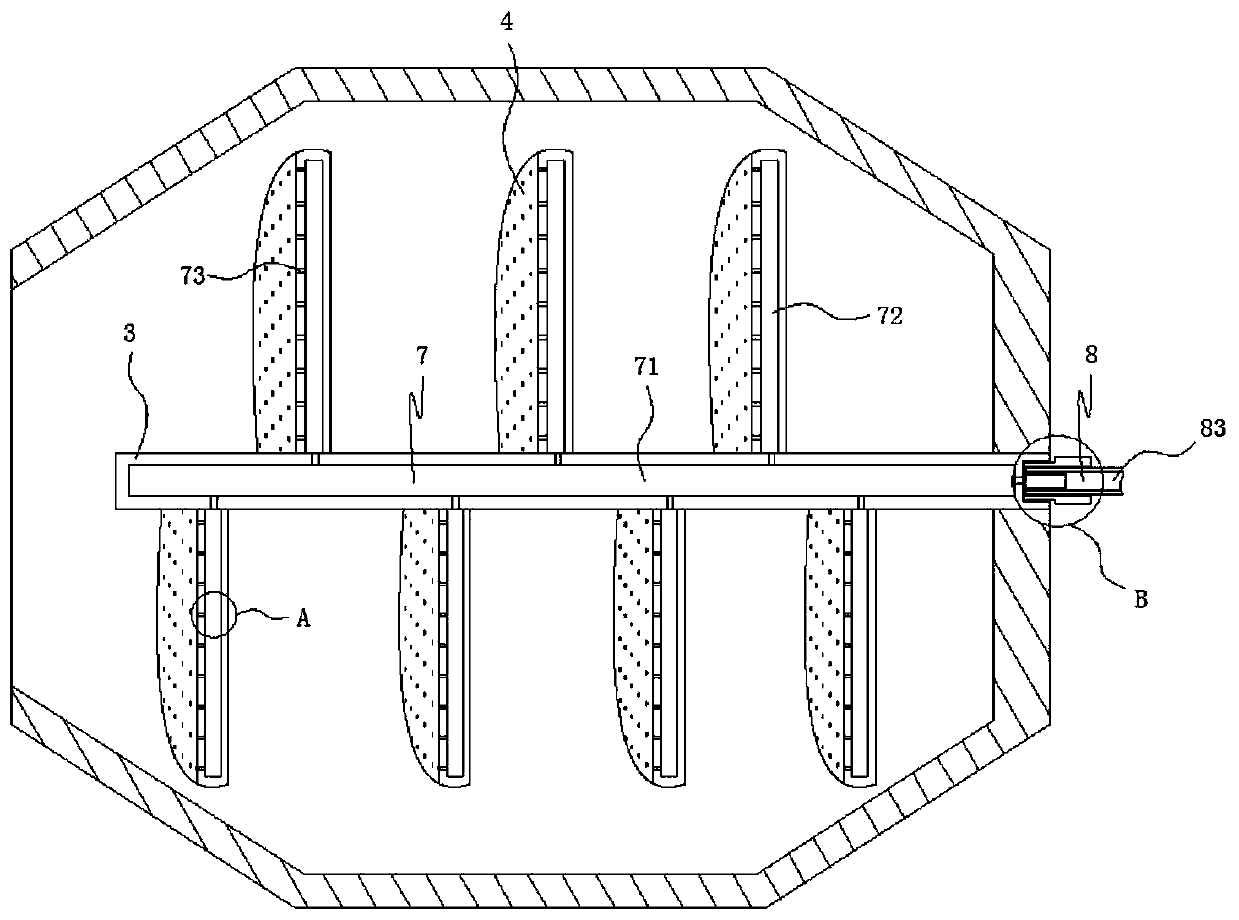

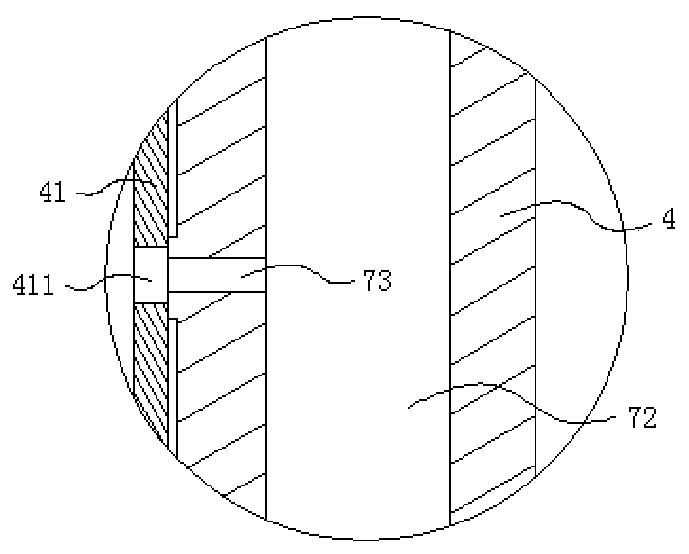

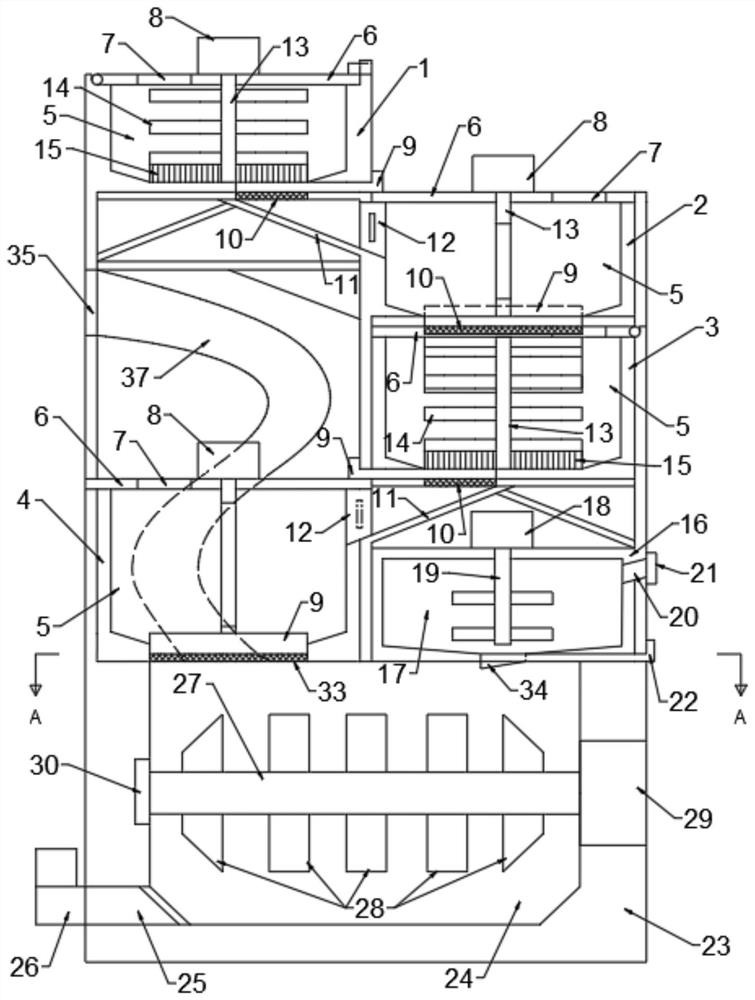

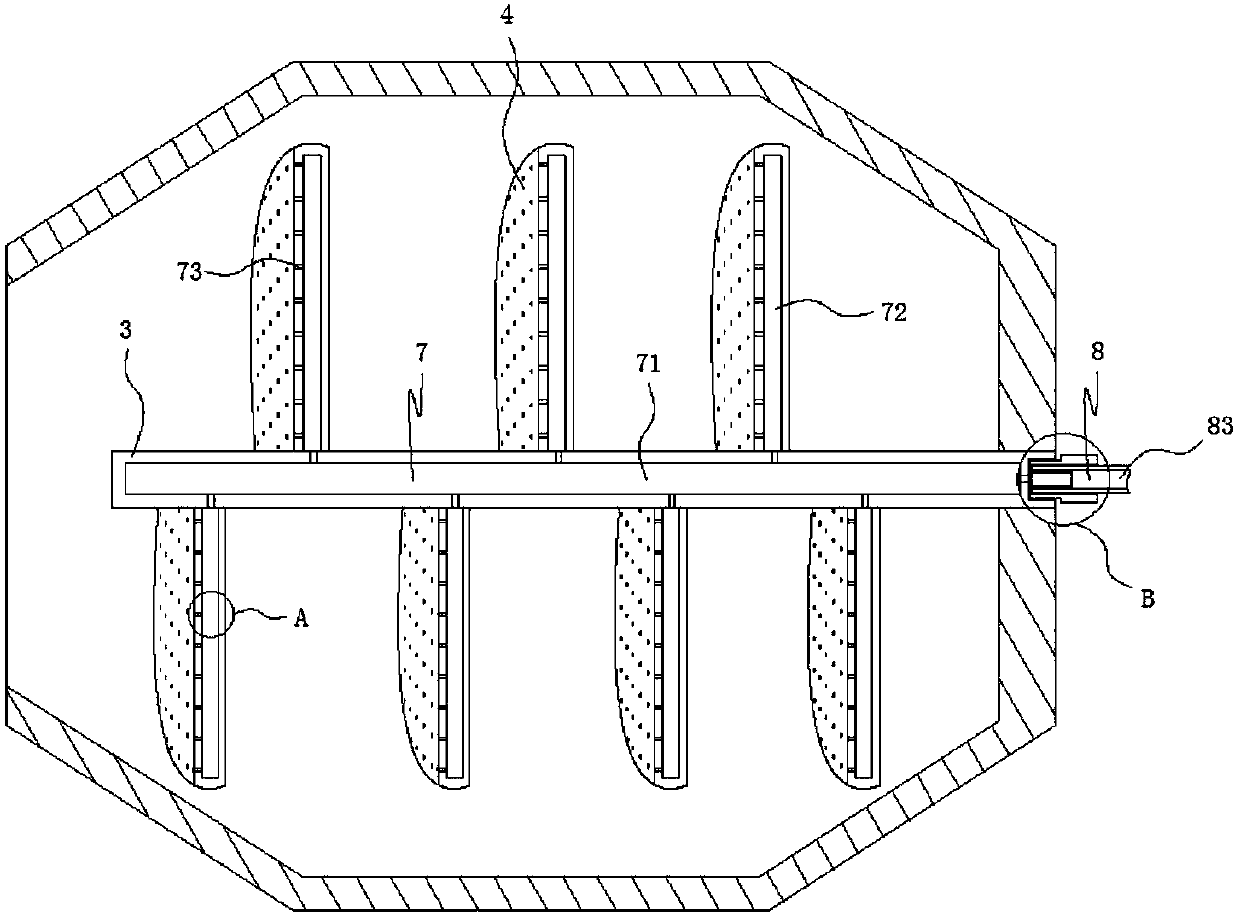

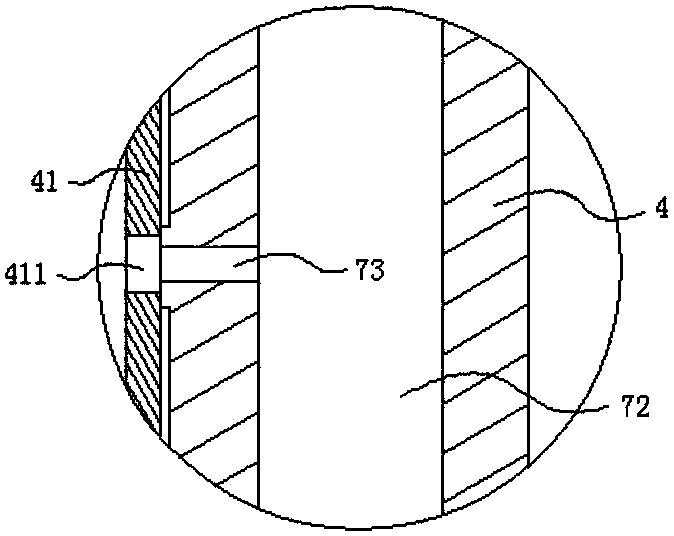

Rope-shaped desizing, scouring and bleaching combination machine

ActiveCN104328616AReduce energy consumptionImprove wettabilitySucessive textile treatmentsTextile treatment containersProcess engineeringDesizing

The invention belongs to the field of technical equipment in the fabric pre-treatment procedure in the printing and dyeing industry, and in particular relates to a rope-shaped desizing, scouring and bleaching combination machine. The rope-shaped desizing, scouring and bleaching combination machine comprises water washing tanks, rolling washing machines, scouring tanks, a J-shaped tank after acid rolling, and a J-shaped tank after hypochlorous acid rolling. The rope-shaped desizing, scouring and bleaching combination machine is characterized by being formed by connecting the water washing tank I, the rolling washing machine I, the scouring tank I, the scouring tank II, the water washing tank II, the water washing tank III, the water washing tank IV, the washing tank V, the rolling washing machine II, the J-shaped tank after the acid rolling, the water washing tank VI, the rolling washing machine III, the J-shaped tank after the hypochlorous acid rolling, the water washing tank VII and the water washing tank VIII in sequence. According to the rope-shaped desizing, scouring and bleaching combination machine, technical flow steps are simple, the operation is reliable, the maintenance is convenient, 3 persons are saved, the energy consumption is reduced by one time, the desizing effect is good, the damage to cloth is lightened, and the operation efficiency is improved by 2.5 times.

Owner:HUAFANG

High-performance concrete for building and preparation method thereof

The invention discloses high-performance concrete for building. The concrete is prepared from the following raw materials in parts by weight: 32 to 36 parts of Portland cement, 28 to 30 parts of quartz sand, 24 to 26 parts of fly ash, 22 to 24 parts of superfine mineral powder, 18 to 22 parts of bechilite powder, 14 to 16 parts of polyethylene glycol oxide, 3 to 5 parts of titanium fiber, 4 to 8 parts of fatty alcohol-polyoxyethylene ether, 8 to 10 parts of thermal stabilizers, 3 to 4 parts of anti-aging agents, 1 to 2 parts of water-reducing agents, 2 to 3 parts of waterproof agents and 20 to22 parts of water. The high-performance concrete for building has the advantages that the concrete has excellent intensity and durability; meanwhile, the raw material ingredients are safe and non-toxic and achieve the environment-friendly effects; high practical values and good application prospects are realized.

Owner:HEFEI YAKELI NEW BUILDING MATERIAL CO LTD

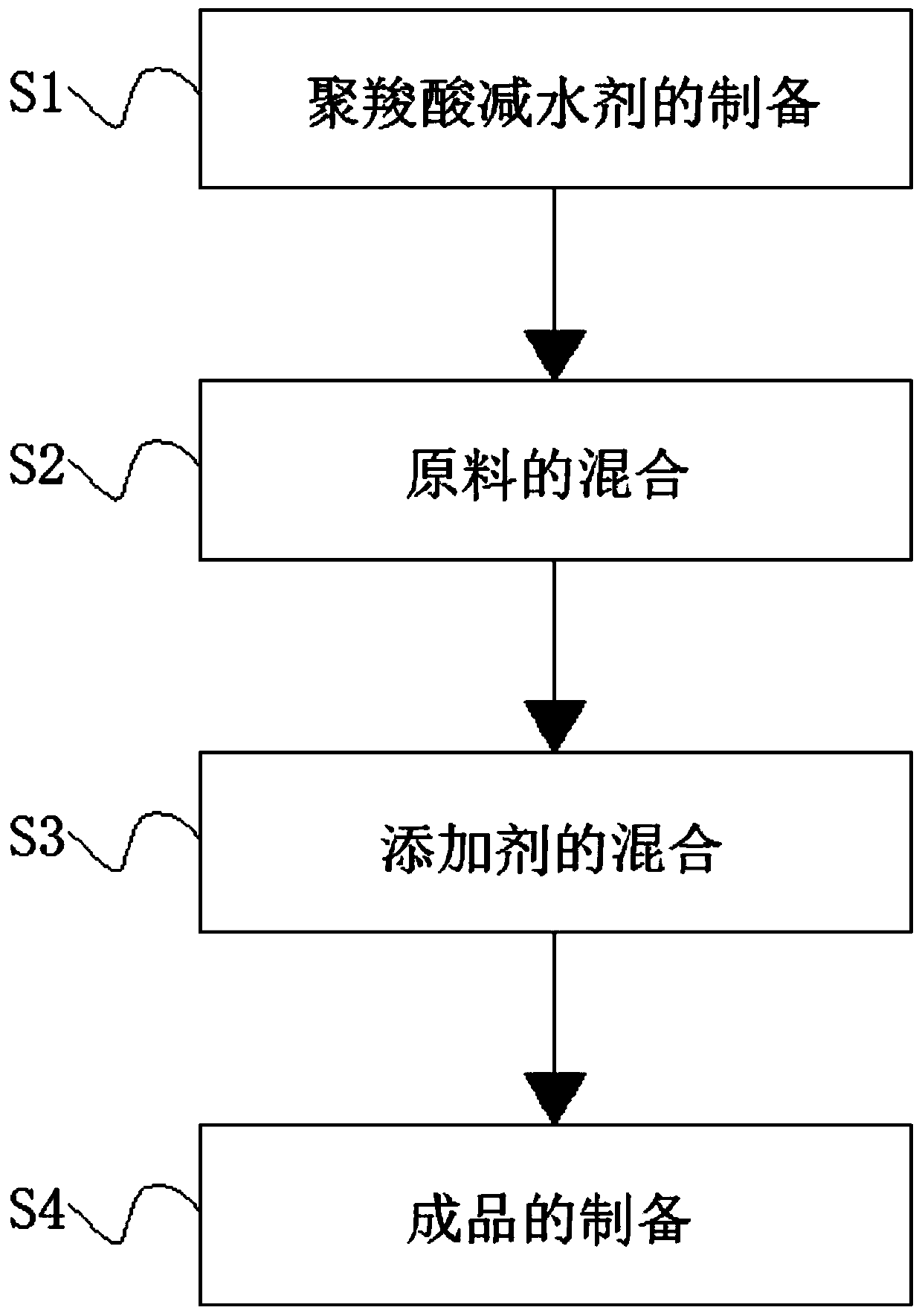

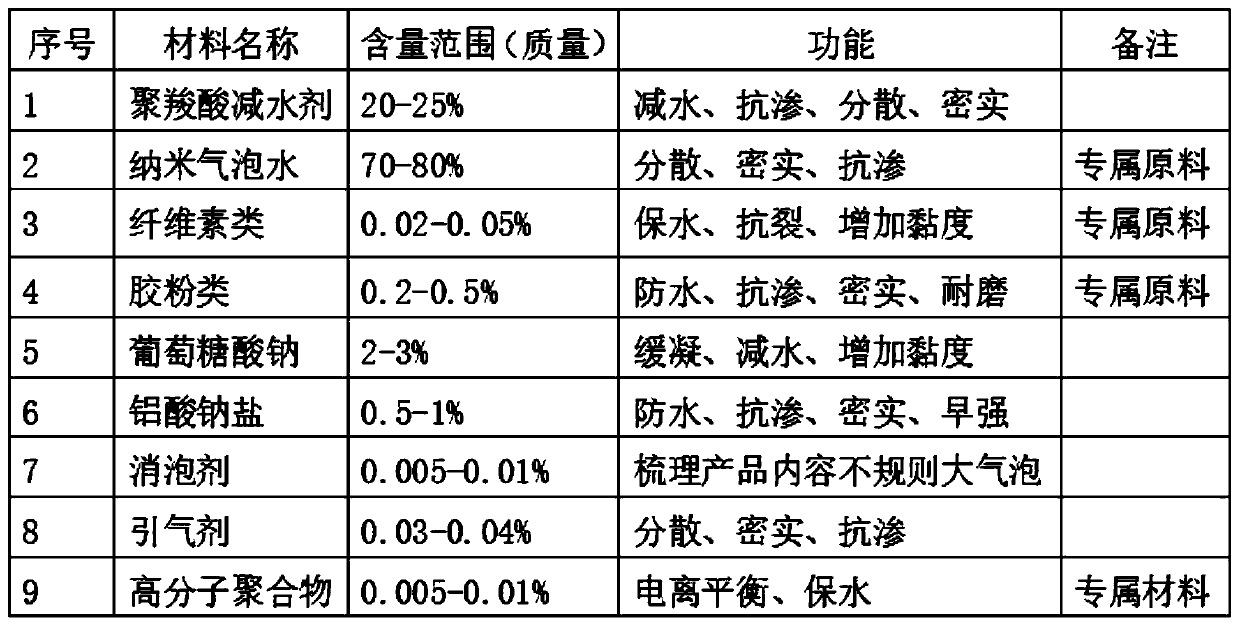

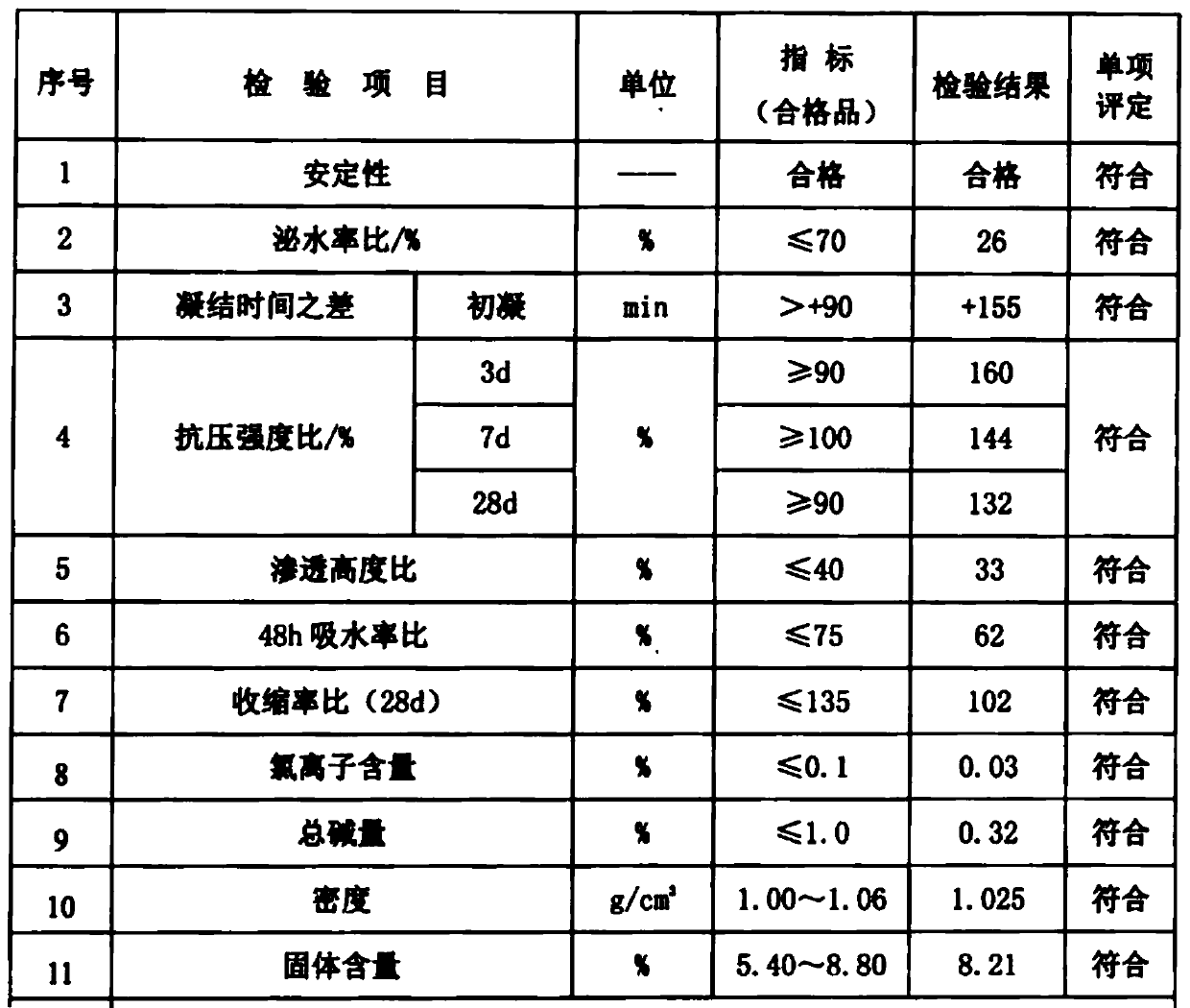

Preparation method of micro-nano porous impermeable crack-resistance concrete additive

The invention discloses a preparation method of a micro-nano porous impermeable crack-resistance concrete additive, and belongs to the technical field of building water resistance. The preparation method comprises following steps: 1, preparation of a polycarboxylic acid water reducer; 2, raw material mixing; 3, additive mixing; and 4, finished product preparation. According to the preparation method, combined water resistance is replaced by concrete structure type water resistance, water-proof material cost is reduced greatly, multi-layer water-proof construction process is avoided, so that construction time is shortened, construction working efficiency is increased greatly, artificial construction steps are reduced greatly, artificial cost is reduced, and artificial construction imbalancehidden trouble is avoided; a concrete self water-proof system is adopted, so that water resistance lasting period is as long as building service life, in the prior art, maintenance cost is extremelyhigh because of leakage caused by various factors in water proof construction, while almost no daily maintenance is needed in the invented technology.

Owner:广西北海市圣峰建材科技有限公司

Light foam soil prepared from alumina tailing and preparation method of light foam soil

The invention provides a light foam soil prepared from an alumina tailing and a preparation method of the light foam soil. The preparation method of the light foam soil comprises a cement paste liquidand a foaming system, the cement paste liquid mainly comprises the following components of cement, the alumina tailing, a water reducer and water, wherein the water cement ratio is 0.2-1.0, the massratio of the alumina tailing to the cement is (0.2-5):1, the mass of the water reducer accounts for 0.4-0.6% of the mass of the cement paste liquid; the foaming system mainly comprises the following components: 0.5-2 parts of a foaming agent, 0.1-0.3 part of a foam stabilizer, and 0.05-1 part of a micro foaming agent and 100 parts of water. The light foam soil has the characteristics of good viscosity and plasticity of the alumina tailing, and the light foam soil with high degree of density, good durability and good anti-permeability.

Owner:GUANGXI UNIV +1

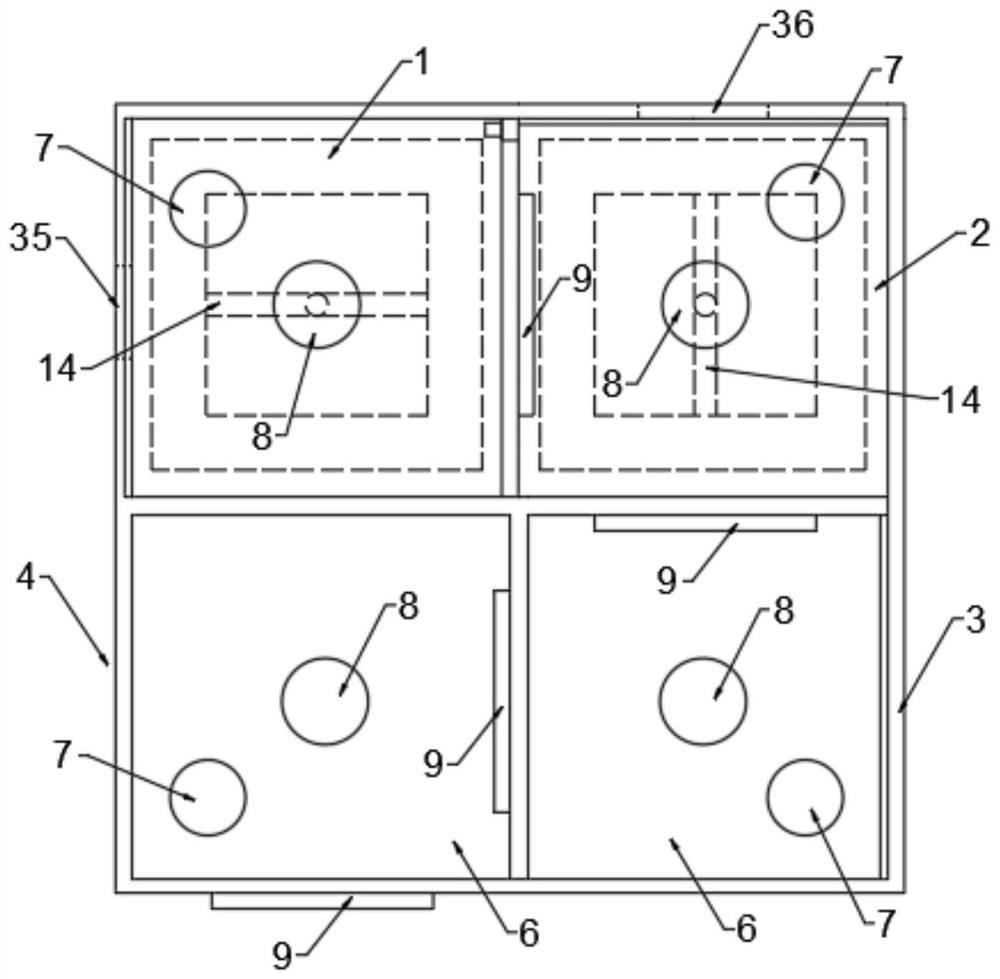

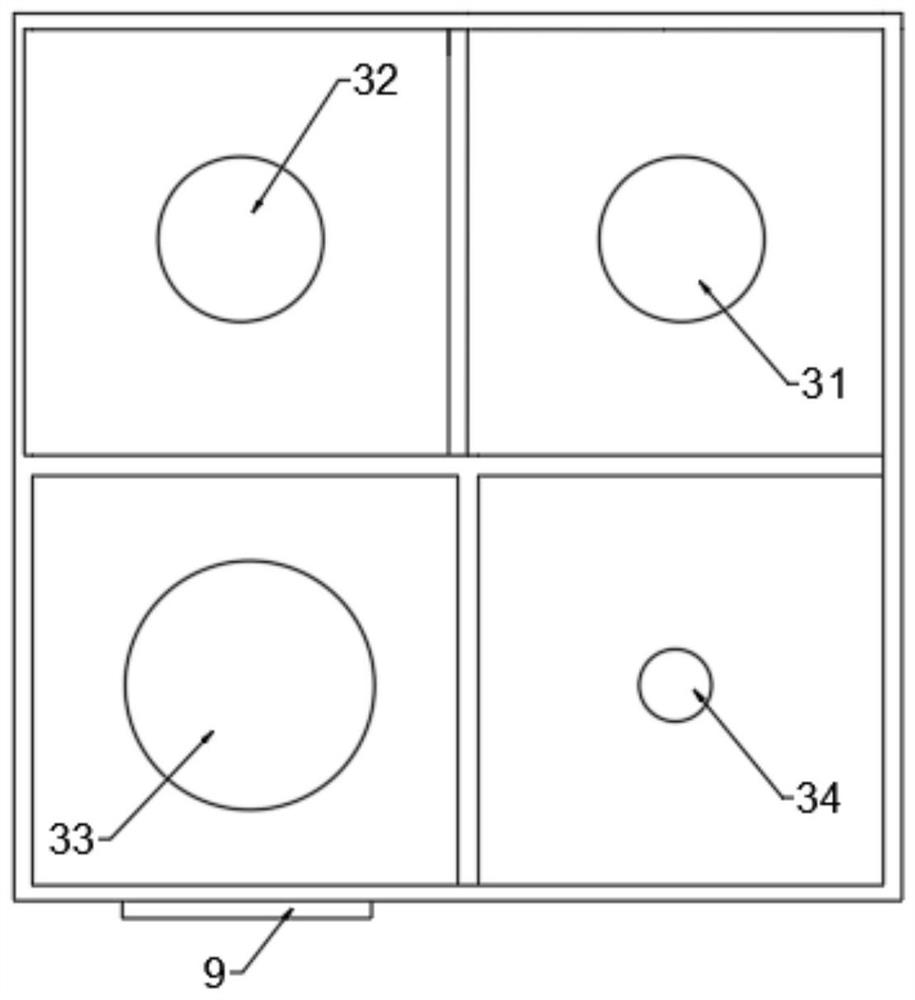

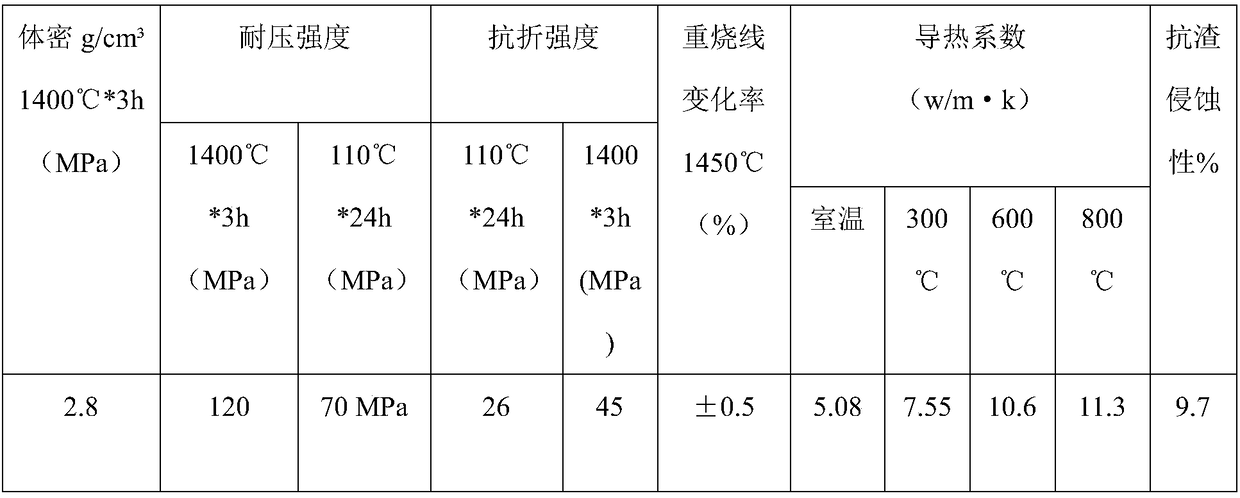

High-performance wet spray coating material for blast furnaces, and preparation method thereof

InactiveCN109251008AImprove rheologyImprove liquidityClaywaresSpray coatingUltimate tensile strength

The invention discloses a high-performance wet spray coating material for blast furnaces, wherein the high-performance wet spray coating material comprises, by weight, 45-75 parts of aggregate, 15-25parts of alumina powder, 2-7 parts of spodumene, 5-10 parts of calcium aluminate cement, 0.5-1.5 parts of Guangxi white clay, 2-8 parts of alumina micro-powder, 3-9 parts of silica fume, 1-4 parts ofbrown fused alumina, 0.05-0.5 part of a composite water reducing agent, and 0.5-4 parts of a quick-setting agent. The preparation steps comprise: weighing the raw materials according to the mass ratio; mixing and stirring the aggregate, the alumina powder, the spodumene, the calcium aluminate cement, the Guangxi white clay, the alumina micro-powder, the silica fume and the brown fused alumina to obtain a stirring material a; adding the calcium aluminate cement and the composite water reducing agent to the stirring material a, and stirring; and inspecting, and packaging. According to the present invention, the wet spray coating material has good rheological property during the use, cannot flow and shed after the wet spray coating material reaches the spray coating working surface, has characteristics of significantly reduced rebound rate and increased adhesion rate, and further has high compressive strength and high bending strength after being dried.

Owner:ANHUI RUITAI NEW MATERIALS TECH

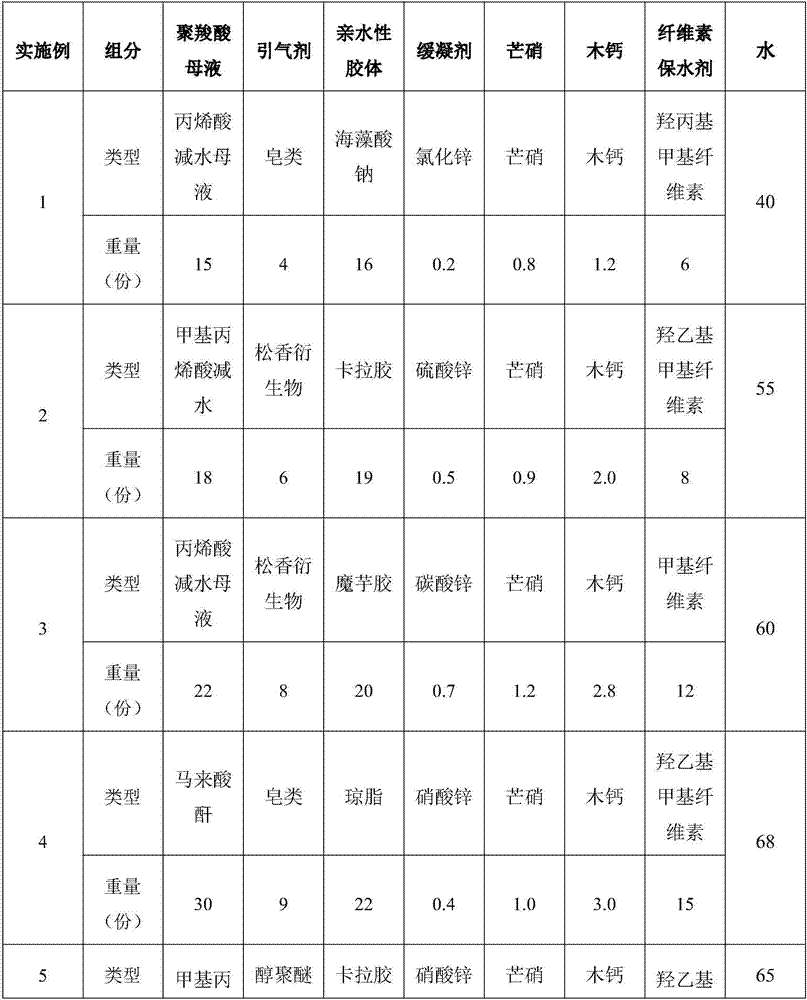

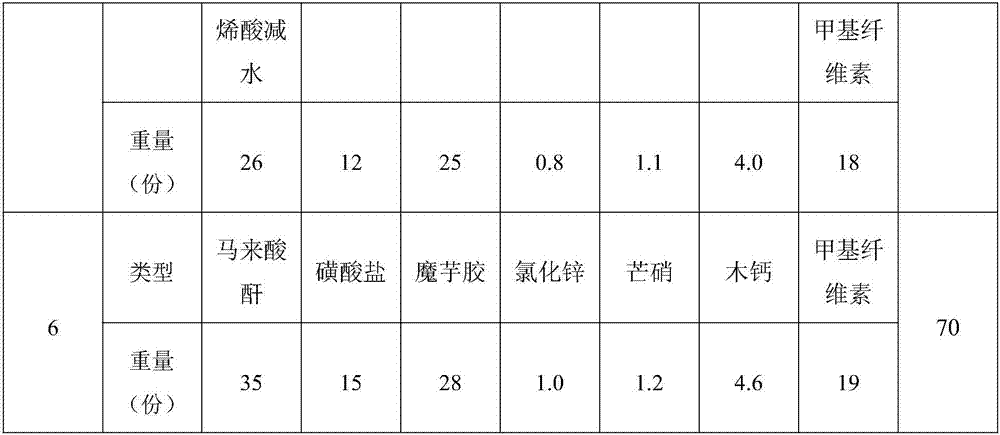

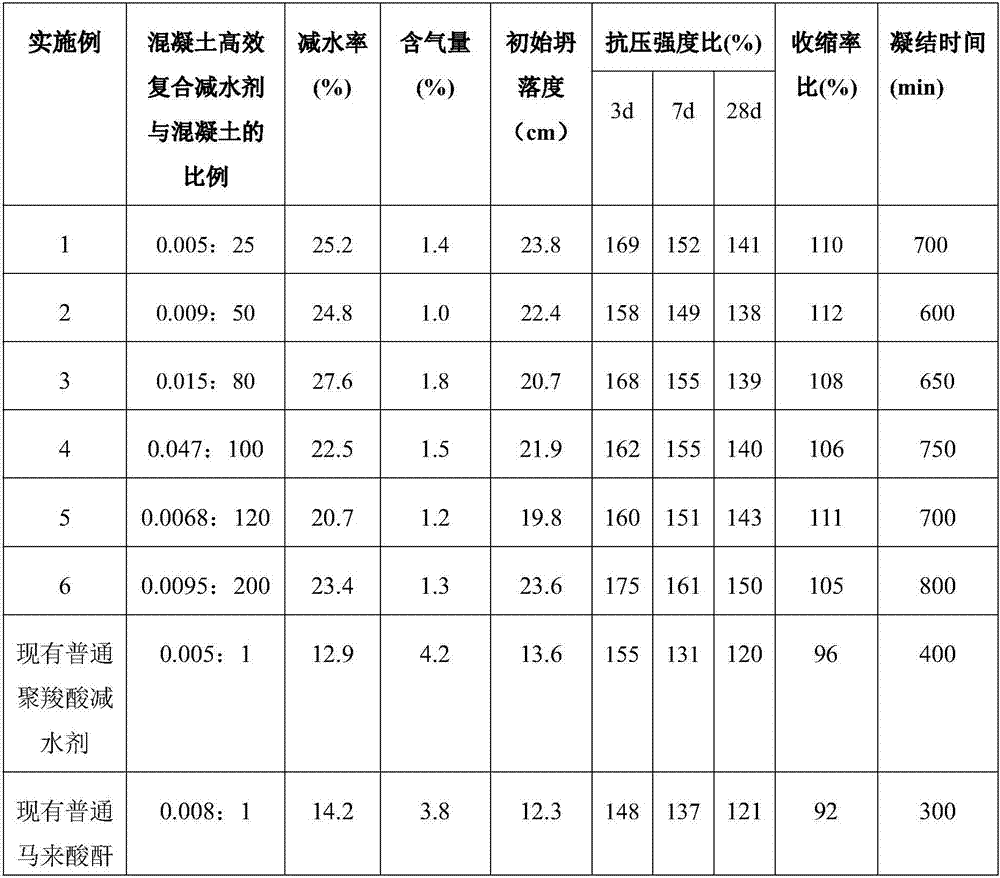

Efficient concrete composite water reducing agent and application thereof

The invention provides an efficient concrete composite water reducing agent which consists of the following components in parts by weight: 10-40 parts of a polycarboxylic acid mother liquid, 4-15 parts of an air entraining agent, 15-30 parts of lyophilic colloid, 0.1-1 part of a retarder, 0.8-2 parts of mirabilite, 1-5 parts of calcium lignosulphonate, 5-20 parts of a cellulose water retaining material and 30-70 parts of water. The efficient concrete composite water reducing agent is applied to preparation of concrete, the mass ratio of the efficient concrete composite water reducing agent to the concrete is (0.0001-0.1):(20-300). The efficient concrete composite water reducing agent has properties such as slow release, collapse prevention, high early strength and water retention, is capable of greatly reducing the unit water consumption of the concrete, improving the density of the concrete, greatly reducing the amount of cement, reducing the shrinkage and improving the stability of the concrete, has the characteristics of being low in doping quantity and remarkable in effect when being used in the concrete, in addition is environment-friendly, and has very good economic benefits and social benefits.

Owner:CHANGSHA QIUDIANBING INFORMATION TECH CO LTD

Coral reef sand concrete and preparation method thereof

ActiveCN106116281ASolve liquidity problemsSolve the strength problemWater volumeUltimate tensile strength

The invention discloses coral reef sand concrete and a preparation method thereof. A cubic meter of the concrete is prepared from the raw materials of 380-420kg of cement, 0-40kg of fly ash, 550-650kg of coral sand, 1150-1250kg of macadam, 4.5-6.5kg of an additive, 0.27-0.39kg of an anti-adsorbent, 35-45kg of additional water, and 180-190kg of net water. The preparation method comprises the following steps of adopting compact piling models comprehensively considering aggregate particle shapes, gradation and concrete working performance, to determine the sand ratio of the concrete under different flowing conditions, and determining the additional water capacity by using water absorption feature points. According to the coral reef sand concrete disclosed by the invention, the defects that the coral reef sand concrete prepared by a conventional method is poor in concrete fluidity and low in strength grade are overcome, and the prepared coral reef sand concrete has the advantages of being high in strength grade, good in fluidity, low in slump loss, not liable to crack, low in unit water consumption, and the like.

Owner:CCCC WUHAN HARBOR ENG DESIGN & RES

Retarding and water reducing agent based on boric acid or borax

The invention belongs to the technical field of water reducing agents and particularly relates to a retarding and water reducing agent based on boric acid or borax. The retarding and water reducing agent based on boric acid or borax is prepared from a water reducing agent, a retarding agent and a shrinkage reducing agent, wherein the weight ratio of the water reducing agent to the retarding agent is 6:4-9:1, the shrinkage reducing agent accounts for 0.01-0.03% of the total weight of the water reducing agent and the retarding agent, a tea sulfurate and formaldehyde condensation water reducing agent serves as the water reducing agent, SRA-3 serves as the shrinkage reducing agent, and boric acid or borax serves as the retarding agent. By means of the efficient retarding and water reducing agent, cement particles can be dispersed, and the workability of concrete can be improved; unit water use can be reduced, the strength of concrete can be improved, and the durability of concrete can be improved; unit cement use can be reduced, and the cost of concrete can be reduced. The product has the effects of retarding condensation of concrete, promoting early strength, reducing water and the like.

Owner:TIANJIN WANGJIU SCI & TECH DEV

Environmental-friendly industrial waste special anti-crack dry-mixed mortar and preparation method thereof

The invention relates to environmental-friendly industrial waste special anti-crack dry-mixed mortar. The environmental-friendly industrial waste special anti-crack dry-mixed mortar comprises the following components in percentage by mass: 55-70% of sand, 20-25% of cement, 5-10% of a mineral admixture, 0.5-0.7% of a water retaining thickener and 0.1-0.3% of a water reducer. The mineral admixture is slag, coal ash or volcanic ash, the water reducer is a polycarboxylate-type high-performance water reducer, and the water retaining thickener is a mixture of 30-40% by weight of cellulose and 60-70% by weight of a thixotropic lubricant. The mortar provided by the invention is simple in component and low in production cost, and the water retaining property and crack resistance of the mortar are greatly improved, the utilization amount of a water resource is reduced, and the application range is improved. Therefore, the mortar is particularly suitable for various building construction sites.

Owner:绍兴职业技术学院

Environment-friendly concrete water reducer and preparation method thereof

InactiveCN109279804ASimple manufacturing methodRaw materials are easy to getSuccinic acidWater reducer

The invention provides an environment-friendly concrete water reducer. The concrete water reducer comprises the following components in parts by weight: 30-40 parts of a triethanolamine oleic soap-based polyacrylic acid copolymer, 10-15 parts of modified activated clay, 5-10 parts of 4-aminophenyl fucoside, 4-6 parts of polyether amine, 10-15 parts of isopropanol and 30-40 parts of water, whereinthe triethanolamine oleic soap-based polyacrylic acid copolymer is prepared by copolymerization of triethanolamine oleic soap, (2R,3S,4S)-rel-2-carboxyl-4-(1-methylvinyl)-3-pyrrolidine acetic acid, sulfo succinic acid-1-(2-propenyl)-4-tridecylester sodium salt and N-acryloyltris(hydroxymethyl)aminomethane. The invention further discloses a preparation method of the environment-friendly concrete water reducer. The environment-friendly concrete water reducer disclosed by the invention has the advantages that comprehensive performance is excellent, the water reducing effect is more obvious, the mixing amount is smaller, plasticizing performance is more excellent, cost is lower, influence on the environment is smaller, and use is safer and more environmentally friendly.

Owner:魏菊宁

Concrete high-efficiency slow setting water reducing agent

The invention belongs to the technical field of a water reducer, and concretely relates to a concrete high-efficiency slow setting water reducing agent comprising a water reducer, a retarder and a shrinkage reducing agent. a weight ratio of the water reducer and the slow setting water reducing agent is 9:1-6:4, and the weight percentage of the shrinkage reducing agent accounts for 0.01-0.03% of gross weight percentage of the water reducer and the retarder, and the water reducer is the naphthalene sulfonic acid-formaldehyde water reducer, and the shrinkage reducing agent is SRA-4; and the retarder is one or more from ferrous sulphate, sodium fluosilicate, ferrous carbonate, cellulose ether, and cadmium sulfate. The high-efficiency slow setting high-efficiency water reducing agent is capable of dispersing the cement particles; improving the workability of the concrete, reducing the water usage amount per unit, enhancing the concrete intensity and increasing the endurance of the concrete; reducing the cement usage amount per unit, and reducing the cost of the concrete. The product has the effects of delay of the coagulation time of the concrete, high early strength, and water reduction.

Owner:TIANJIN WANGJIU SCI & TECH DEV

Silicon-manganese water-quenched slag concrete

Physical treatment and chemical modification are carried out on silicon-manganese water-quenched slag, an excitant, quartz tailings, sand, stone and other components are comprehensively utilized, andthe advantages are complementary. According to the invention, the silicon-manganese water-quenched slag contains high vitreous body, potential hydraulic property and volcanic ash activity, and the activity is excited by an exciting agent which is formed by mixing lime and sodium carbonate, so that active substances are generated in the secondary reaction of cement, and the strength of the materialis improved. The silicon-manganese water-quenched slag partially replaces cement, cement consumption is reduced, the gelling effect of the slag is used to solidify heavy metal, the slag is environmentally friendly, gaps among particles are filled, and the compactness is high. The silica content of the quartz tailings is high, the hydration reaction of silicate is promoted, secondary utilization of natural resources is achieved, the radioactivity of part of substitute sand is low, and the manufacturing cost is reduced. Compared with reference concrete, the prepared concrete has the advantagesthat the mechanical property is improved to a certain extent, and the concrete has good impermeability, freezing resistance, dry shrinkage resistance, durability and the like and can be widely appliedto engineering.

Owner:XIANGTAN UNIV

High-water-reducing-rate low-cost polycarboxylate superplasticizer and preparation method thereof

The invention discloses a high-water-reducing-rate low-cost polycarboxylate superplasticizer and a preparation method thereof, wherein the high-water-reducing-rate low-cost polycarboxylate superplasticizer is prepared from the following raw materials by weight: 3548 parts of a base material, 652.5 parts of a material A, 830 parts of a material B and 650 parts of supplemented water. According to the invention, the preparation method is simple, low in cost, convenient to operate and beneficial to large-scale industrial production; the prepared polycarboxylate superplasticizer has high water reducing effect; after a concrete mixture is added, the polycarboxylate superplasticizer has a dispersing effect on cement particles so as to improve the workability, reduce the unit water consumption, improve the flowability of the concrete mixture, improve the quality of concrete and improve the actual use effect of the concrete.

Owner:湖南加美乐素新材料股份有限公司

Durable concrete for wall columns

The invention discloses durable concrete for wall columns. The concrete is prepared from components of raw materials as follows: Portland cement, coarse sand, medium-coarse sand, gravel, water, mineral powder, coal ash, natural zeolite ultrafine powder, a polycarboxylate water reducer, stannous chloride, sodium chromate, calcium nitrate, acetamide, ethylene glycol, lignin salt, alkylbenzene sulfonate, triterpenoid saponins, sodium hexametaphosphate, citric acid, polyvinyl alcohol fibers, glass fibers and polyisobutene fibers. The durable concrete for the wall columns has the advantages of being high in strength, good in durability, wide in application range and the like.

Owner:蚌埠市宝运商品混凝土有限公司

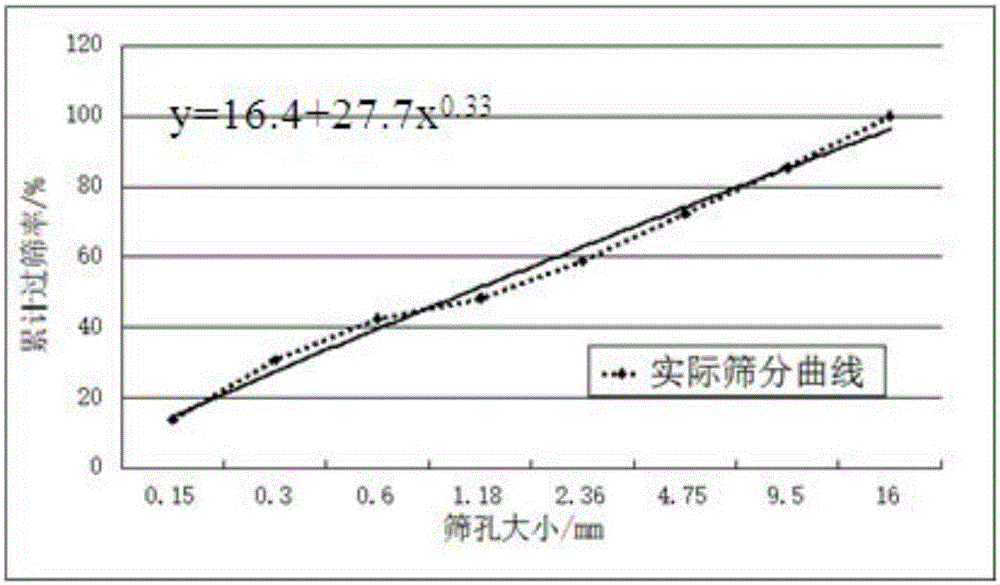

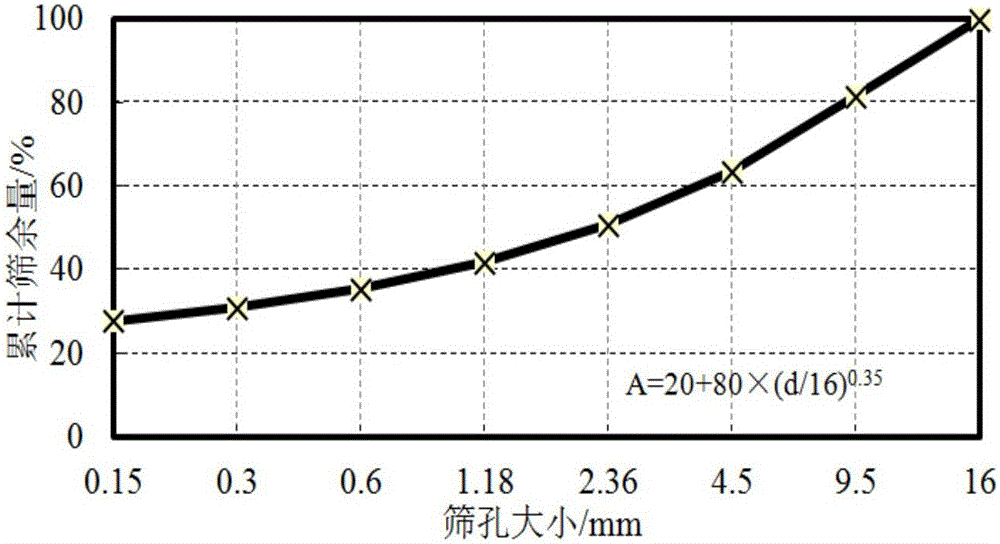

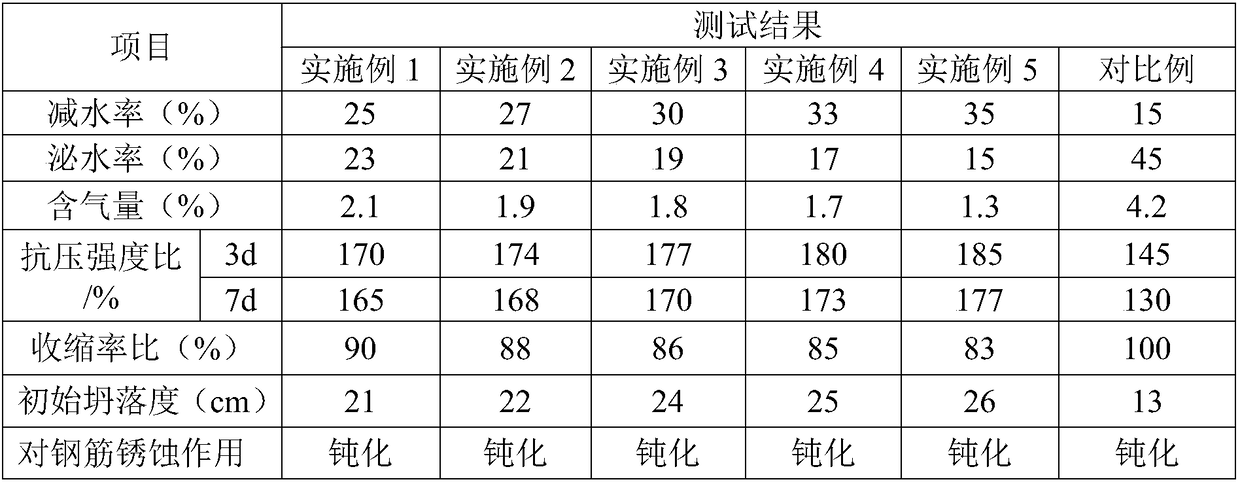

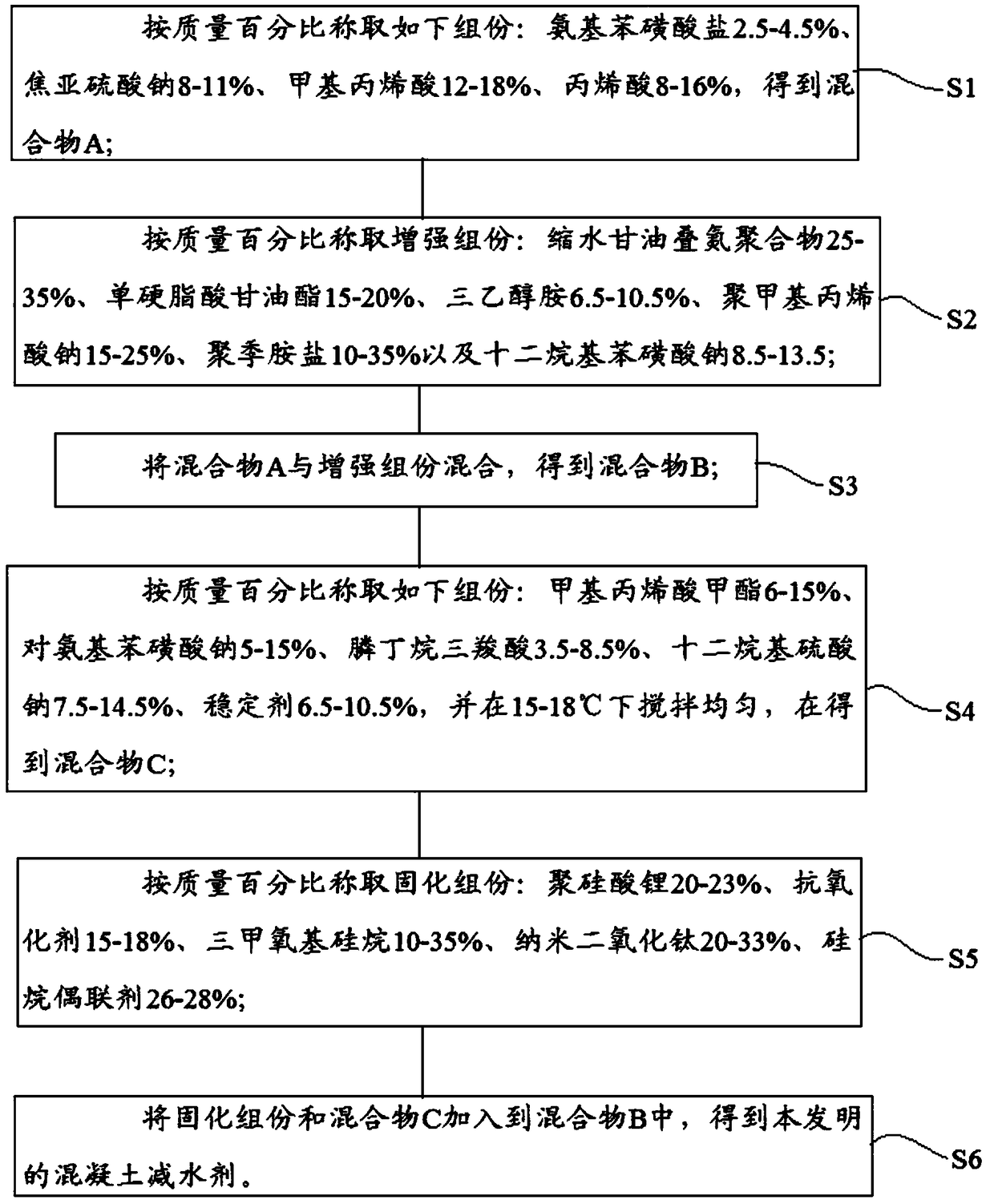

Water-reducing agent for concrete and preparation method thereof

The invention provides a water-reducing agent for concrete and a preparation method thereof. The water-reducing agent for concrete is prepared from the following components in percentage by mass: 2.5-4.5% of amino benzene sulfonate, 8-11% of sodium metabisulfite, 12-18% of methacrylic acid, 8-16% of acrylic acid, 6-15% of methyl methacrylate, 5-15% of sodium p-aminobenzenesulfonate, 3.5-8.5% of phosphinobutane tricarboxylic acid, 7.5-14.5% of lauryl sodium sulfate, 6.5-10.5% of stabilizer, 13-25% of enhancing component and 10-15% of curing component. The water-reducing agent for concrete provided by the invention has the beneficial effects that the unit consumption of water is reduced, the fluidity of concrete mixture is improved, simultaneously the strength of the cured concrete also canbe obviously enhanced, the cracking of the concrete can be avoided, the benefit for ensuring the sufficiency of concrete reaction is achieved and the comprehensive property of the concrete can be improved.

Owner:JIANGSU BAIRUIJI NEW MATERIAL

A crack-resistant construction waste recycled concrete wall panel

ActiveCN113429170BImprove crack resistanceImprove liquidityBuilding componentsCrack resistanceArchitectural engineering

Owner:奥王建筑材料科技有限公司

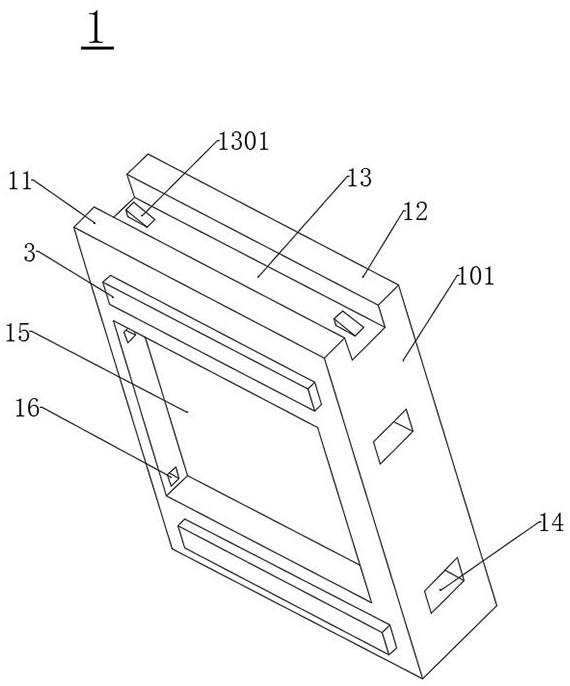

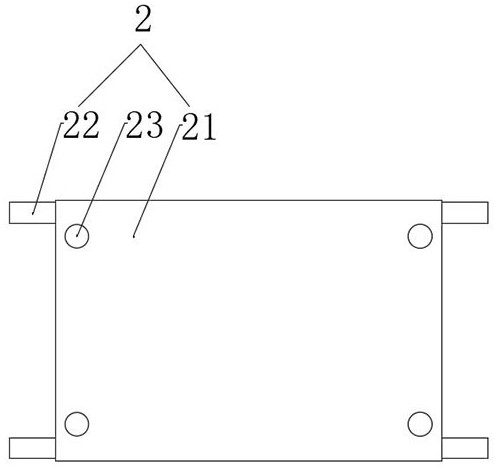

Grouting material for sound barrier backboard

InactiveCN107602006AHas fast hardeningGood adhesionNoise reduction constructionPre stressingHeat stability

The invention relates to the technical field of building materials and provides a grouting material for a sound barrier backboard. The grouting material comprises the following raw materials (by weight): 15-25 parts of Portland cement, 30-40 parts of fly ash, 50-70 parts of building rubbish, 10-15 parts of water and 0.61-1.08 parts of additives. The grouting material has advantages of wide sourcesof raw materials, high utilization rate of solid wastes, low cost, rapid hardening, early strength, slight expansion, strong bonding force, good heat stability and the like, and can be used as a binder for bonding or reinforcement of engineering equipment. The sound barrier backboard is provided with multiple reinforcing holes. after the backboard is maintained to design strength, the backboard is tensioned with pre-stress steel bars or steel strands, and then the grouting material is injected to glue the pre-stress steel bars or steel strands with the sound barrier backboard as a whole. Thus, the sound barrier backboard is safe and stable and durable.

Owner:SICHUAN SHUANGTIE TECH CO LTD

High-efficiency retarding water reducer for cement concrete and preparation method thereof

Owner:内蒙古高速公路集团有限责任公司

Efficient set-retarding and water-reducing agent for cement concrete and preparation method of efficient set-retarding and water-reducing agent

The invention provides an efficient set-retarding and water-reducing agent for cement concrete and a preparation method of the efficient set-retarding and water-reducing agent. The efficient set-retarding and water-reducing agent comprises the following components in parts by weight: 30 to 50 parts of polycarboxylic acid mother liquid, 3 to 5 parts of poly-aluminum chloride, 0.5 to 2 parts of sodium polyaspartate, 10 to 30 parts of allyl polyoxyethylene ether, 0.5 to 0.8 part of coco fatty acid diethanol amide, 5 to 10 parts of hydrogen peroxide, 0.5 to 1.2 parts of mirabilite, 3 to 10 parts of an air entraining agent, 15 to 30 parts of hydrophilic colloid, 1 to 3 parts of a set retarder, 5 to 10 parts of fiber, 1 to 5 parts of asbestos wool, 0.1 to 0.2 part of an initiator and 30 to 50 parts of deionized water. The efficient set-retarding and water-reducing agent is prepared by optimizing the components of the set-retarding and water-reducing agent, modifying part of the components and mixing, so that the efficient set-retarding and water-reducing agent has high compatibility with cement, is small in mixing amount and high in water-reducing rate, can enhance the compression resistance and the fracture resistance of concrete, has a good set-retarding effect, long concrete setting time, high strength and high construction performance, saves construction materials, can save waterand electricity and has high practical value.

Owner:内蒙古高速公路集团有限责任公司

Civil engineering material curing agent and preparation method

InactiveCN108218321ADoes not affect natureImprove frost resistancePhosphoric Acid EstersActive agent

The invention discloses a civil engineering material curing agent. The civil engineering material curing agent is characterized by being prepared from the following materials in percentage by weight:1.3 to 7 percent of a water reducer, 2.5 to 9 percent of an anti-seepage agent, 1.5 to 13 percent of sodium hydroxide, 1.8 to 25 percent of sodium oxide, 1.3 to 21 percent of maleic acid, 1.7 to 23 percent of silicate, 2.5 to 28 percent of a gel material, 5 to 11 percent of triethanolamine, 7 to 13 percent of a surfactant, 15 to 29 percent of water, 35 to 65 percent of cement and 20 to 45 percentof quick lime powder; the surfactant is prepared from sodium nitrite, fatty acid amide, alkylamine and acidic ammonium phosphate; the sodium nitrite, the fatty acid amide, the alkylamine and the acidic ammonium phosphate are compounded according to the ratio of (2.3 to 4.3) to (1.2 to 2.5) to (1.9 to 3.4) to (1.3 to 2.4). By adopting the civil engineering material curing agent, the problem that the anti-freezing performance of the curing agent is relatively poor under a severe cold climate is solved.

Owner:WENZHOU DONGHAI BUILDING INSTALLATION ENGCO LTD

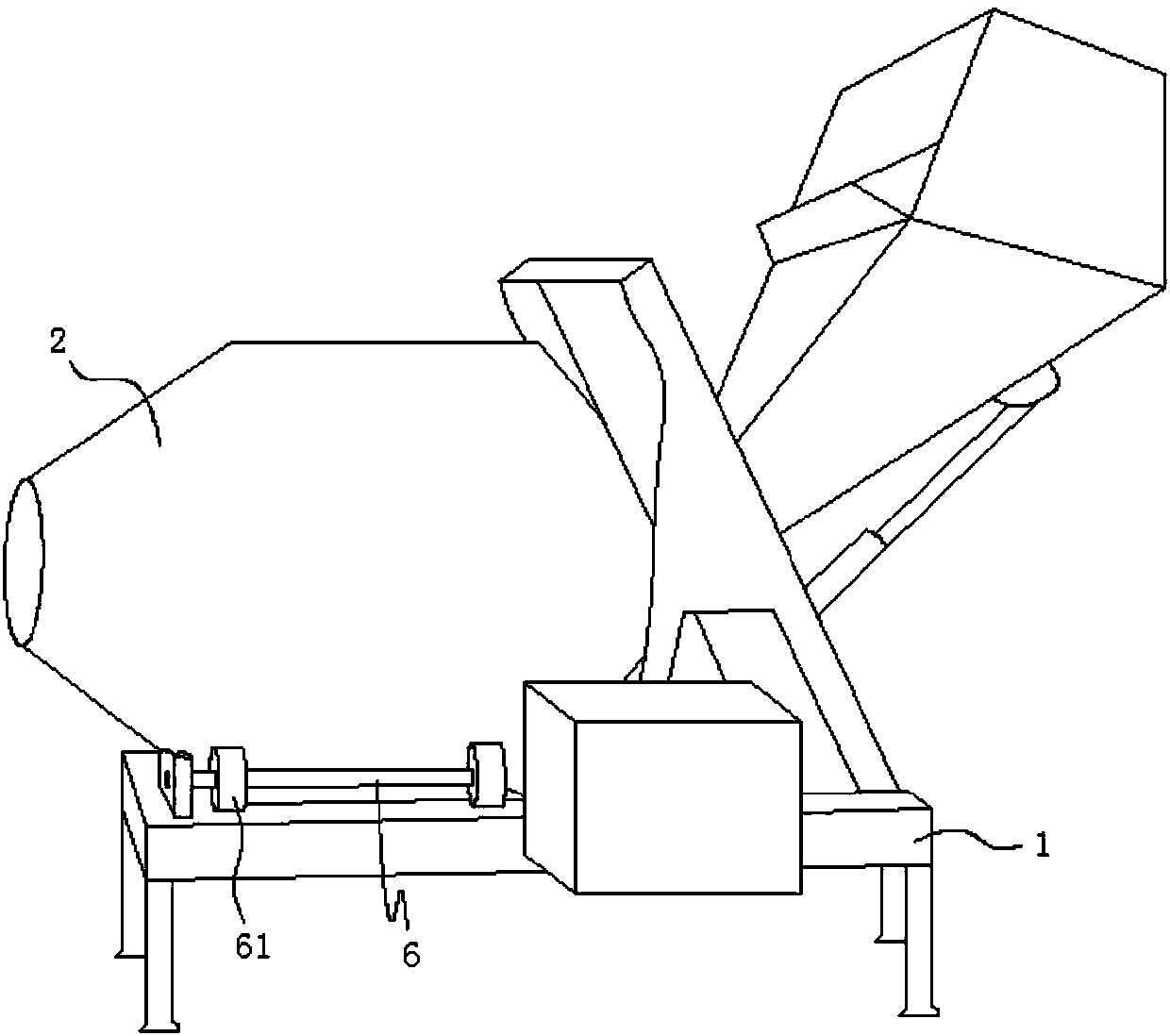

Building construction concrete preparation method based on resource reuse

The invention discloses a building construction concrete preparation method based on resource reuse. The preparation method comprises following steps: (1), acquisition of raw materials: adding sludge,construction waste, coal ash and cement to stirring equipment; (2), stirring: adding water to the stirring equipment, starting the stirring equipment, introducing air to a stirring shaft in a stirring process, and producing outwards ejected airflow on the stirring shaft and impacting materials in the stirring equipment; and (3), performance enhancement: adding reinforcing fibers to the materialsobtained by stirring in step (2), and continuing stirring to obtain a finished product. With adoption of the sludge, the construction waste and the coal ash as the raw materials, waste of non-renewable resources such as gravel, sand and the like is effectively reduced; and the stirring shaft can eject air outwards in the stirring process, the condition of caking of the materials is effectively prevented, the materials are mixed more uniformly, and therefore, the prepared concrete has better performance.

Owner:CANGZHOU DACHUAN ROAD MATERIALS CO LTD

High-strength and low-hydration-heat marine concrete and preparation method thereof

The invention discloses high-strength and low-hydration-heat marine concrete and a preparation method thereof. Limestone powder and cement are uniformly stirred to enable the gaps of the cement particles to be filled with the limestone powder, so that the compactness of a cement base system is improved; then, slag powder and fly ash are added to improve the fluidity, cohesiveness and water retention of the concrete mixture, and therefore, the concrete mixture is easy to pump, pour and mold; then, silicon powder is added to form C-S-H gel, one part of the C-S-H gel coats the surface of a cementing material, the other part of the C-S-H gel fills the pores of sand, gravels and cement particles which are added later; and the cement particles are further helped to be dispersed through a water reducing agent, the unit water consumption is reduced, and the fluidity of the concrete mixture is improved, so that the marine concrete with uniformly dispersed internal system particles and high compactness is finally obtained.

Owner:CHINA COMM 2ND NAVIGATIONAL BUREAU 2ND ENG +1

High strength composite material for blast furnace cooling walls, preparation method of high strength composite material, and application of high strength composite material in protection of cooling walls

The invention discloses a high strength composite material for blast furnace cooling walls, a preparation method of the high strength composite material, and application of the high strength compositematerial in protection of the cooling wall. The high strength composite material for the blast furnace cooling walls is prepared from a composite fiber material, aluminum nitride micro-powder, high-purity silicon carbide, mullite, alumina powder, silica powder, montmorillonite, sericite, a binding agent and a water reducing agent composite material. Practice proves that the composite material hasgood thermal conductivity, and can transfer heat to the cooling wall in time, so that the hot surface temperature is significantly reduced, and a stable slag crust is formed and does not easily falloff, that is, the slag crust can be well formed on the hot surface of the cooling wall; the high strength composite material can prevent the slag crust from falling off, so that the permanent and stable slag crust is realized, and the service life of the cooling wall is greatly prolonged. The high strength composite material is good in construction workability, is molded by pumping and self-flow forming and is free from vibration, so that a dense high-strength whole can be formed in an embedding groove of the cooling wall. The high strength composite material has a good application prospect inthe protection of the blast furnace cooling walls.

Owner:HENAN HUAXI FURNACE REFRACTORY

Method for preparing concrete

The invention discloses a method for preparing concrete, comprising the following steps: (1) material obtaining: taking sludge, construction waste, coal ash and cement and putting into stirring equipment; (2) stirring: pouring water into the stirring equipment and starting the stirring equipment, and introducing air into a stirring shaft in the stirring process, so that outwards sprayed airflow isgenerated on the stirring shaft and impacts the material in the stirring equipment; (3) performance improvement: adding reinforcing fiber to the material obtained by stirring in step (2) and furtherstirring to obtain the finished product. According to the invention, sludge, construction waste and coal ash are adopted as materials, so that waste of non-renewable resources such as gravels and sandis effectively reduced; and the stirring shaft can spray air to outwards in the stirring process, so that the condition of caking of the material is effectively prevented, the material is mixed moreuniformly, and therefore, the prepared concrete is better in performance.

Owner:兴业县银基混凝土有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com