Civil engineering material curing agent and preparation method

A curing agent and civil engineering technology, which is applied in the field of civil engineering and construction materials, can solve problems such as soil cracks, road cracks, and poor antifreeze performance, and achieve the effects of saving cement, reducing consumption, and improving antifreeze performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

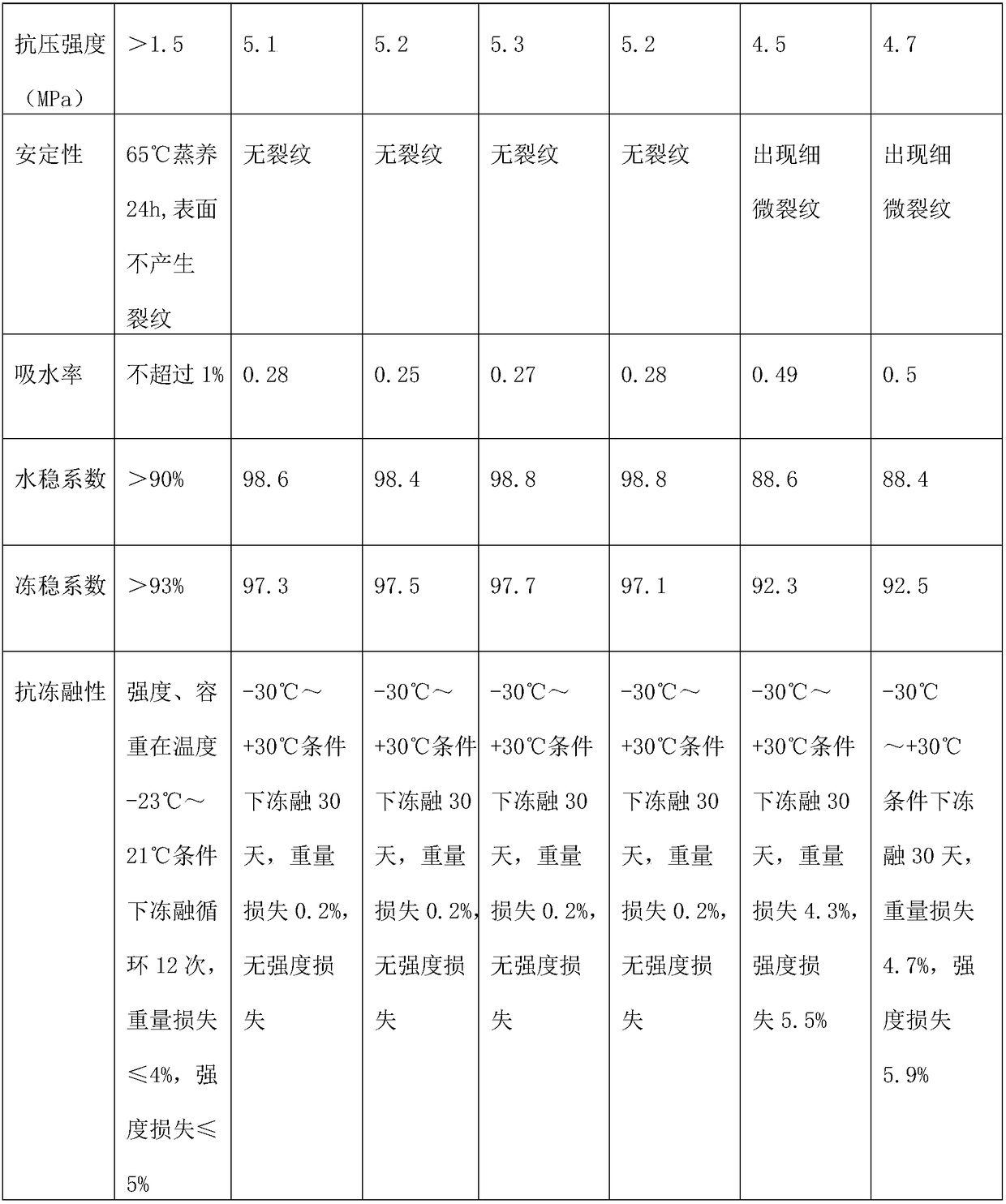

Examples

Embodiment 1

[0023] Embodiment 1: a solidifying agent for civil engineering materials, which is made by mixing the following components by weight: water reducing agent 1.3%, impermeability agent 2.5%, sodium hydroxide 1.5%, sodium oxide 1.8%, maleic acid 1.3%, Silicate 1.7%, gel material 2.5%, triethanolamine 5%, surfactant 7%, water 15%, cement 35%, quicklime powder 20%, the surfactant is sodium nitrite, fatty acid amide, alkylamine It is composed of acid phosphate ammonium salt, sodium nitrite, fatty acid amide, alkylamine and acid phosphate ammonium salt are compounded according to 2.3:1.2:1.9:1.3;

[0024] The preparation method is as follows: (1) 1.3% of water reducing agent, 2.5% of impermeable agent, 1.5% of sodium hydroxide, 1.8% of sodium oxide, 1.3% of maleic acid, 1.7% of silicate, 2.5% of gel material, 5% triethanolamine, 7% surfactant, and 15% water were added to the ball mill for grinding, the temperature was controlled at 90-120°C, the grinding fineness was 300-350 mesh, and...

Embodiment 2

[0026] Embodiment 2: a solidifying agent for civil construction materials, which is made by mixing the following components by weight: water reducing agent 3.3%, impermeability agent 4.5%, sodium hydroxide 6.5%, sodium oxide 8.5%, maleic acid 13%, Silicate 17%, gel material 15%, triethanolamine 7%, surfactant 10%, water 20%, cement 45%, quicklime powder 30%, the surfactant is sodium nitrite, fatty acid amide, alkylamine It is composed of acid phosphate ammonium salt, sodium nitrite, fatty acid amide, alkylamine and acid phosphate ammonium salt are compounded according to 2.8:1.9:2.4:1.7;

[0027] The preparation method is as follows: (1) 3.3% of water reducing agent, 4.5% of impermeable agent, 6.5% of sodium hydroxide, 8.5% of sodium oxide, 13% of maleic acid, 17% of silicate, 15% of gel material, 7% of triethanolamine, 10% of surfactant and 20% of water were added to the ball mill for grinding, the temperature was controlled at 90-120°C, the grinding fineness reached 300-350 ...

Embodiment 3

[0029] Embodiment 3: a solidifying agent for civil construction materials, which is made by mixing the following components by weight: water reducing agent 5.3%, impermeability agent 7.5%, sodium hydroxide 10.5%, sodium oxide 15.7%, maleic acid 17%, Silicate 19%, gel material 21%, triethanolamine 9%, surfactant 12%, water 25%, cement 55%, quicklime powder 35%, the surfactant is sodium nitrite, fatty acid amide, alkylamine It is composed of acid phosphate ammonium salt, sodium nitrite, fatty acid amide, alkylamine and acid phosphate ammonium salt are compounded according to 3.5:2.1:2.9:2.1;

[0030] The preparation method is as follows: (1) 5.3% of water reducing agent, 7.5% of impermeable agent, 10.5% of sodium hydroxide, 15.7% of sodium oxide, 17% of maleic acid, 19% of silicate, 21% of gel material, 9% of triethanolamine, 12% of surfactant, and 25% of water were added to the ball mill for grinding, the temperature was controlled at 90-120°C, the grinding fineness reached 300...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com