A crack-resistant construction waste recycled concrete wall panel

A technology for recycled concrete and construction waste, which is applied in construction, building components, building structures, etc., can solve the problems of insufficient crack resistance and strength of recycled concrete, unfavorable fluidity of fresh concrete, and increased cement consumption, and achieve crack resistance. The effect of increasing the stability, realizing the installation limit and reducing the water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The preparation method of the concrete layer 1012 comprises the following steps:

[0047] Put the corresponding parts of the regenerated coarse aggregate, the regenerated fine aggregate, the water, the crack-resistant cement and the reinforcing agent into a mixer for mixing and stirring for 10-15 minutes;

[0048] Add corresponding parts of the steel fiber, the mineral powder, the nano silicon dioxide, and the water reducing agent into a mixer for mixing and stirring, and the stirring time is 5-15 minutes.

Embodiment 1

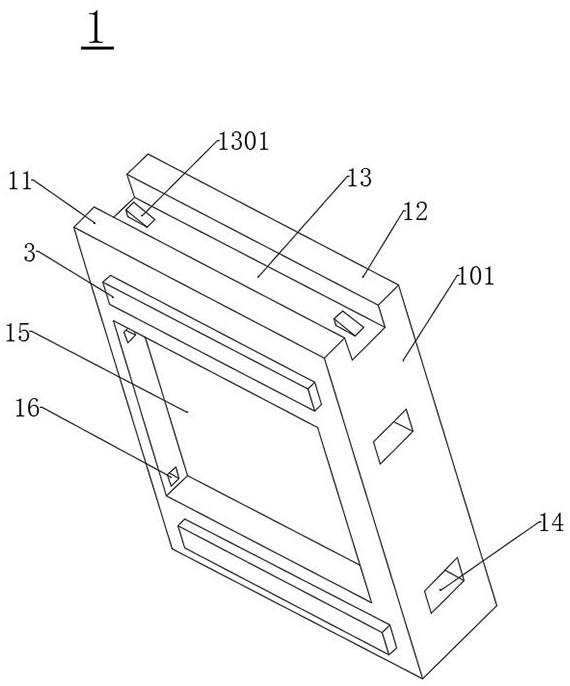

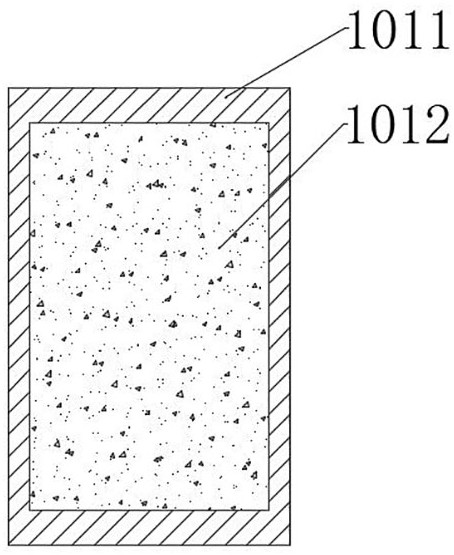

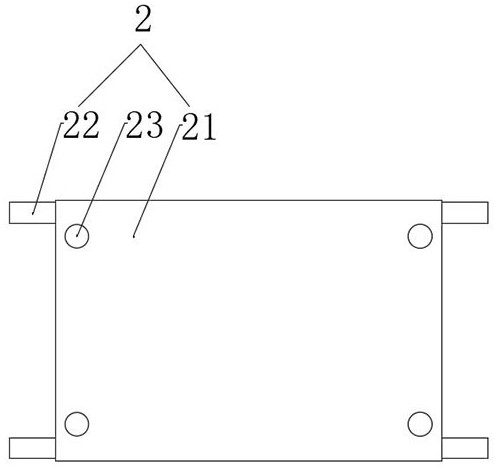

[0050] Such as figure 1 with figure 2 As shown, the present invention provides a crack-resistant construction waste recycled concrete, including a wall panel assembly 1, the wall panel assembly 1 includes a wall panel body 101, and the wall panel body 101 includes a fireproof layer 1011 and a concrete layer 1012, The concrete layer 1012 is made of the following raw materials: 25 parts of recycled coarse aggregate, 35 parts of recycled fine aggregate, 50 parts of crack-resistant cement, 5 parts of steel fiber, 1 part of water reducing agent, and 1 part of reinforcing agent , 5 parts of mineral powder, 5 parts of nano silicon dioxide, 150 parts of water.

[0051] The crack-resistant cement is made of the following raw materials: 40 parts of cement, 10 parts of river sand, 8 parts of mixed fiber, 11 parts of fly ash, and 55 parts of water; wherein, the mixed fiber includes glass fiber and sword Hemp fiber, the ratio of the glass fiber to the sisal fiber is 1:1.5.

[0052] The...

Embodiment 2

[0060] Such as figure 1 with figure 2 As shown, the present invention provides a crack-resistant construction waste recycled concrete, including a wall panel assembly 1, the wall panel assembly 1 includes a wall panel body 101, and the wall panel body 101 includes a fireproof layer 1011 and a concrete layer 1012, The concrete layer 1012 is made of the following raw materials: 24 parts of recycled coarse aggregate, 33 parts of recycled fine aggregate, 56 parts of crack-resistant cement, 7 parts of steel fiber, 1 part of water reducing agent, and 2 parts of reinforcing agent , 7 parts of mineral powder, 6 parts of nano silicon dioxide, 180 parts of water.

[0061] The crack-resistant cement is made of the following raw materials: 55 parts of cement, 13 parts of river sand, 13 parts of mixed fiber, 15 parts of fly ash, and 60 parts of water; wherein, the mixed fiber includes glass fiber and sword Hemp fiber, the ratio of the glass fiber to the sisal fiber is 2:2.5.

[0062] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com