Preparation method of micro-nano porous impermeable crack-resistance concrete additive

A concrete admixture, micro-nano technology, applied in the field of building waterproofing, can solve the problems of increased material cost and labor cost, loss of waterproof function, low construction efficiency, etc., and achieve the effect of saving construction time, improving work efficiency, and wide application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

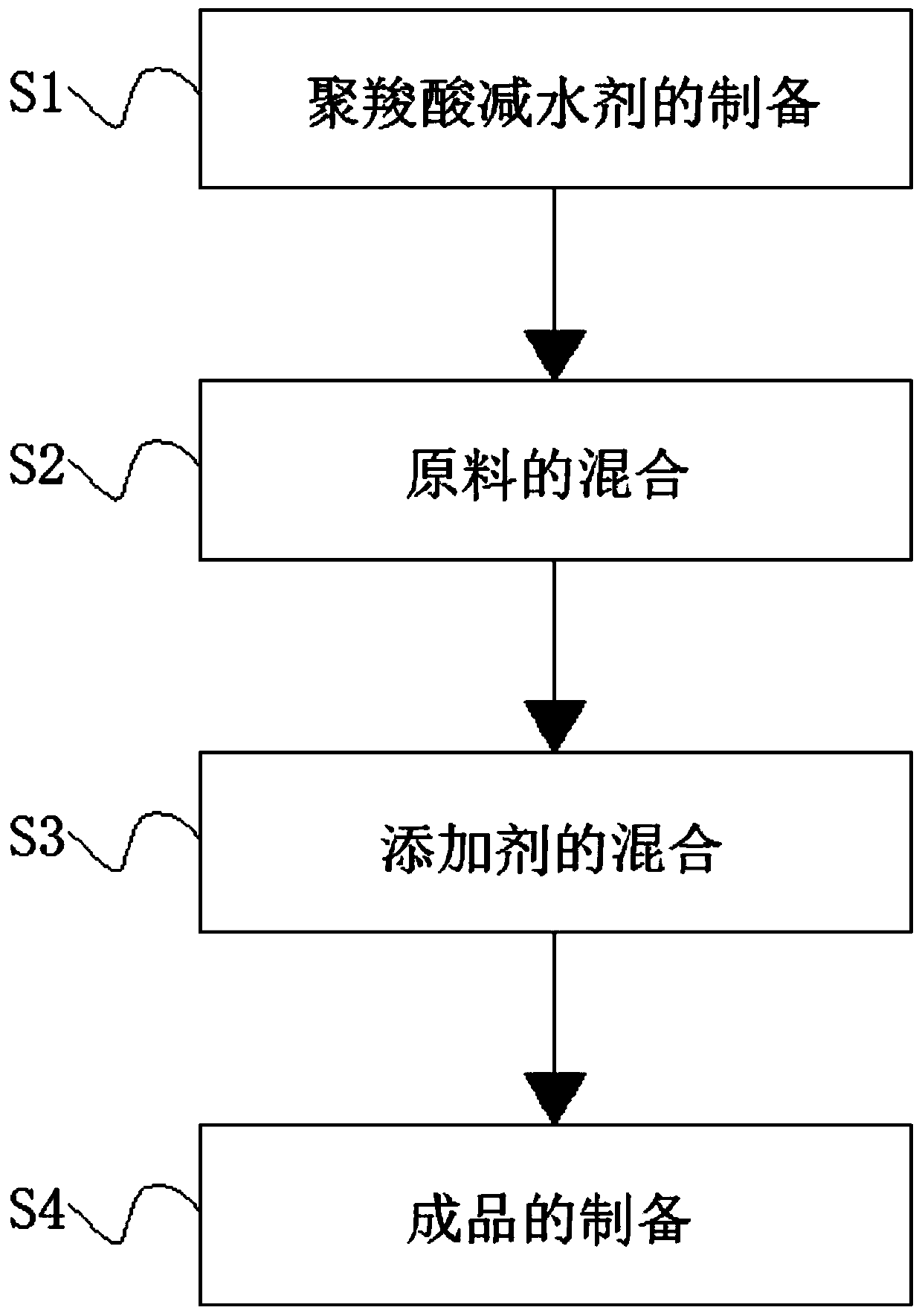

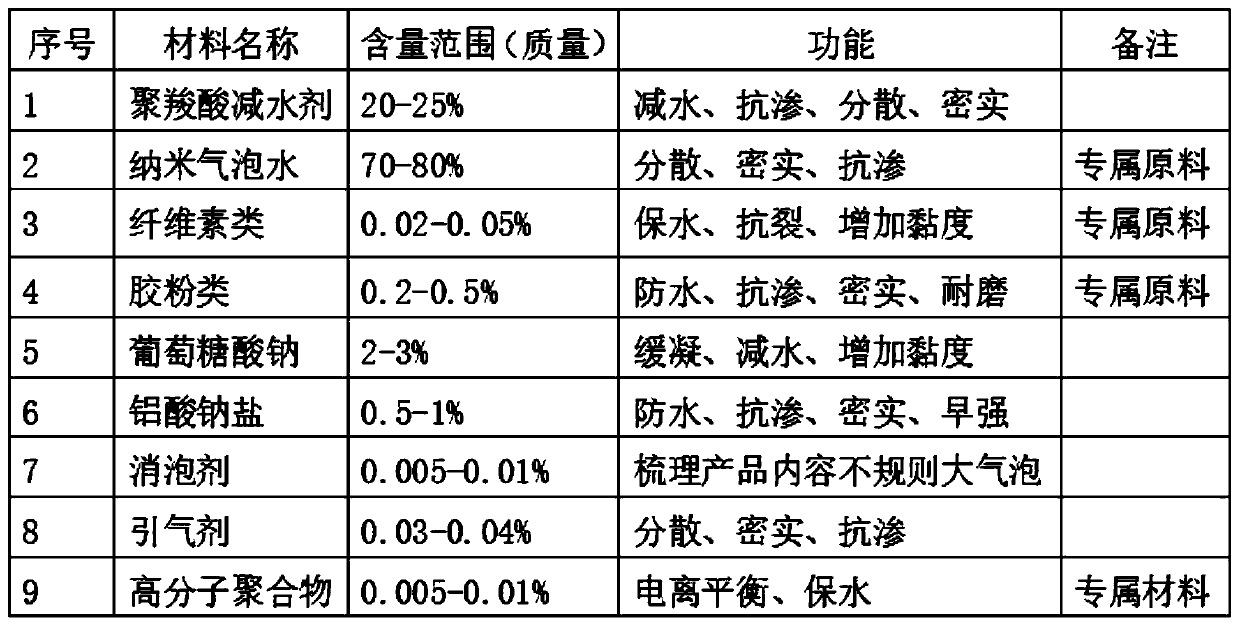

[0040] S1. Preparation of polycarboxylate water reducer: first, put the weighed 23% polycarboxylate water reducer mother liquid into the enamel reaction kettle, and then turn on the stirring equipment to stir, so that the stirring blade is kept at 60r / min, stirring for 1.5 h, the reduction ratio of the mixing reducer is 23 times, and the molecular weight of the polycarboxylate superplasticizer mother liquor is 2400;

[0041] S2. Mixing of raw materials: after the stirring is started, 0.007% high molecular weight polymer, 2.5% sodium gluconate, 0.7% sodium aluminate, 0.3% latex powder and 0.035% cellulose are put into the corresponding weight ratio in sequence, each raw material The feeding time interval is 2.5min, and the stirring is continued;

[0042] S3, mixing of additives: After all the raw materials in step S2 are put in, continue to stir for 13 minutes, then put in 0.01% defoamer, and then put in 0.035% air-entraining agent after 5 minutes;

[0043] S4. Preparation of ...

Embodiment 2

[0045] S1. Preparation of polycarboxylate superplasticizer: first put the weighed 20% polycarboxylate superplasticizer mother liquor into the enamel reaction kettle, and then turn on the stirring equipment to stir so that the stirring blade keeps 60r / min, and stir for 1h , the reduction ratio of the stirring reducer is 23 times, and the molecular weight of the polycarboxylate superplasticizer mother liquor is 2400;

[0046] S2. Mixing of raw materials: after the stirring is started, 0.005% high molecular weight polymer, 2% sodium gluconate, 0.5% sodium aluminate, 0.2% latex powder and 0.02% cellulose are put into the corresponding weight ratio in turn, each raw material The feeding time interval is 2 minutes, and the stirring is continued;

[0047] S3, mixing of additives: After all the raw materials in step S2 are put in, continue to stir for 10 minutes, then put in 0.005% defoamer, and then put in 0.03% air-entraining agent after 5 minutes;

[0048] S4. Preparation of finis...

Embodiment 3

[0050] S1. Preparation of polycarboxylate superplasticizer: first put the weighed 25% polycarboxylate superplasticizer mother liquor into the enamel reaction kettle, and then turn on the stirring equipment to stir so that the stirring blade keeps 60r / min and stir for 2h , the reduction ratio of the stirring reducer is 23 times, and the molecular weight of the polycarboxylate superplasticizer mother liquor is 2400;

[0051] S2. Mixing of raw materials: after the stirring is started, 0.01% high molecular polymer, 3% sodium gluconate, 1% sodium aluminate, 0.5% latex powder and 0.05% cellulose are put in the corresponding parts by weight in sequence, each raw material The feeding time interval is 3 minutes, and the stirring is continued;

[0052] S3, mixing of additives: After all the raw materials in step S2 are put in, continue to stir for 15 minutes, then put in 0.01% defoamer, and then put in 0.04% air-entraining agent after 5 minutes;

[0053] S4. Preparation of finished pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com