Method for repairing road surface damage

A pavement repair and pavement technology, applied in the field of pavement repair, can solve the problems of unstable driving operation, large shrinkage of new concrete, low bonding strength of ordinary concrete, etc., to improve leveling and uniformity, reduce surface tension of pavement, The effect of reducing unit water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

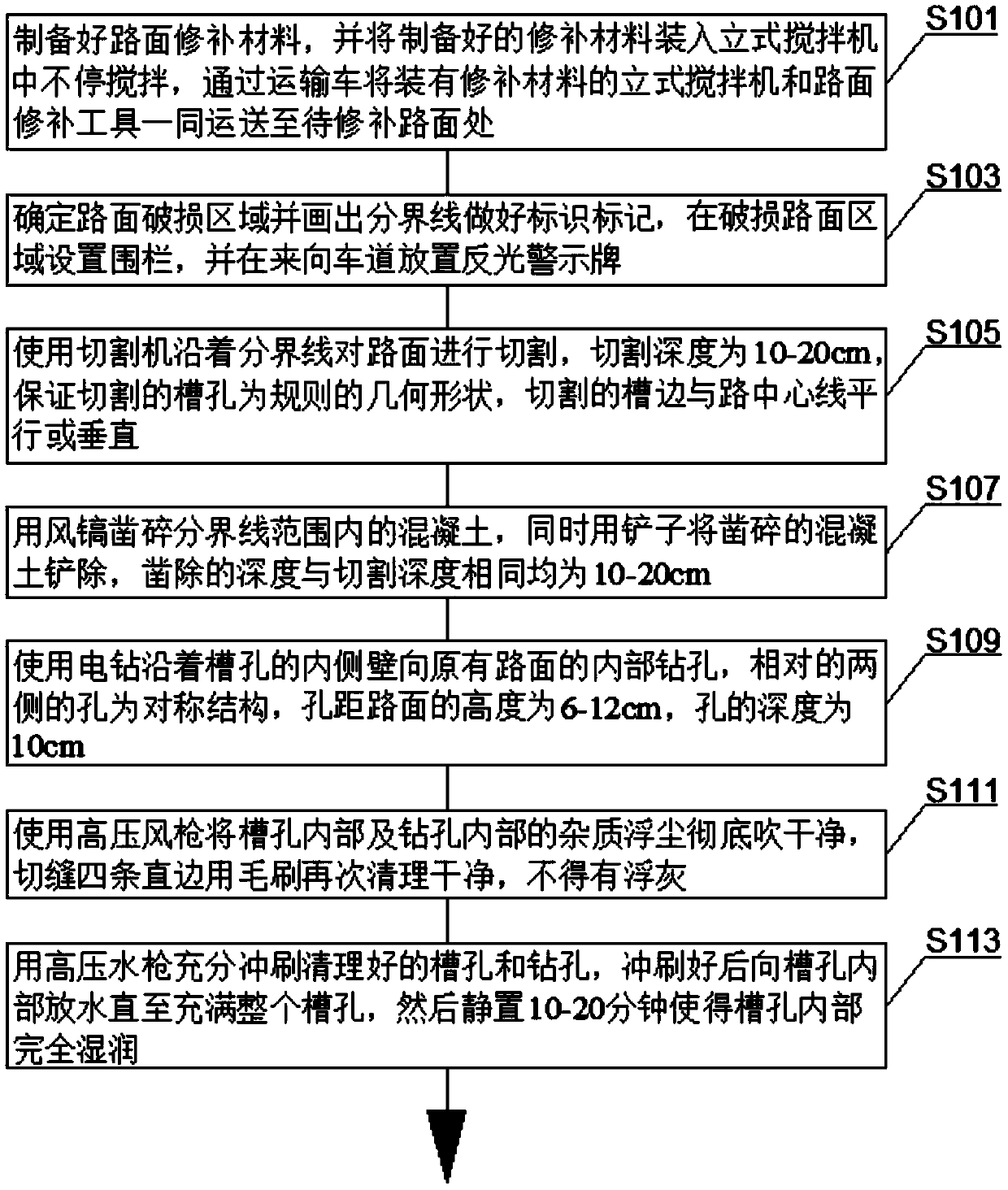

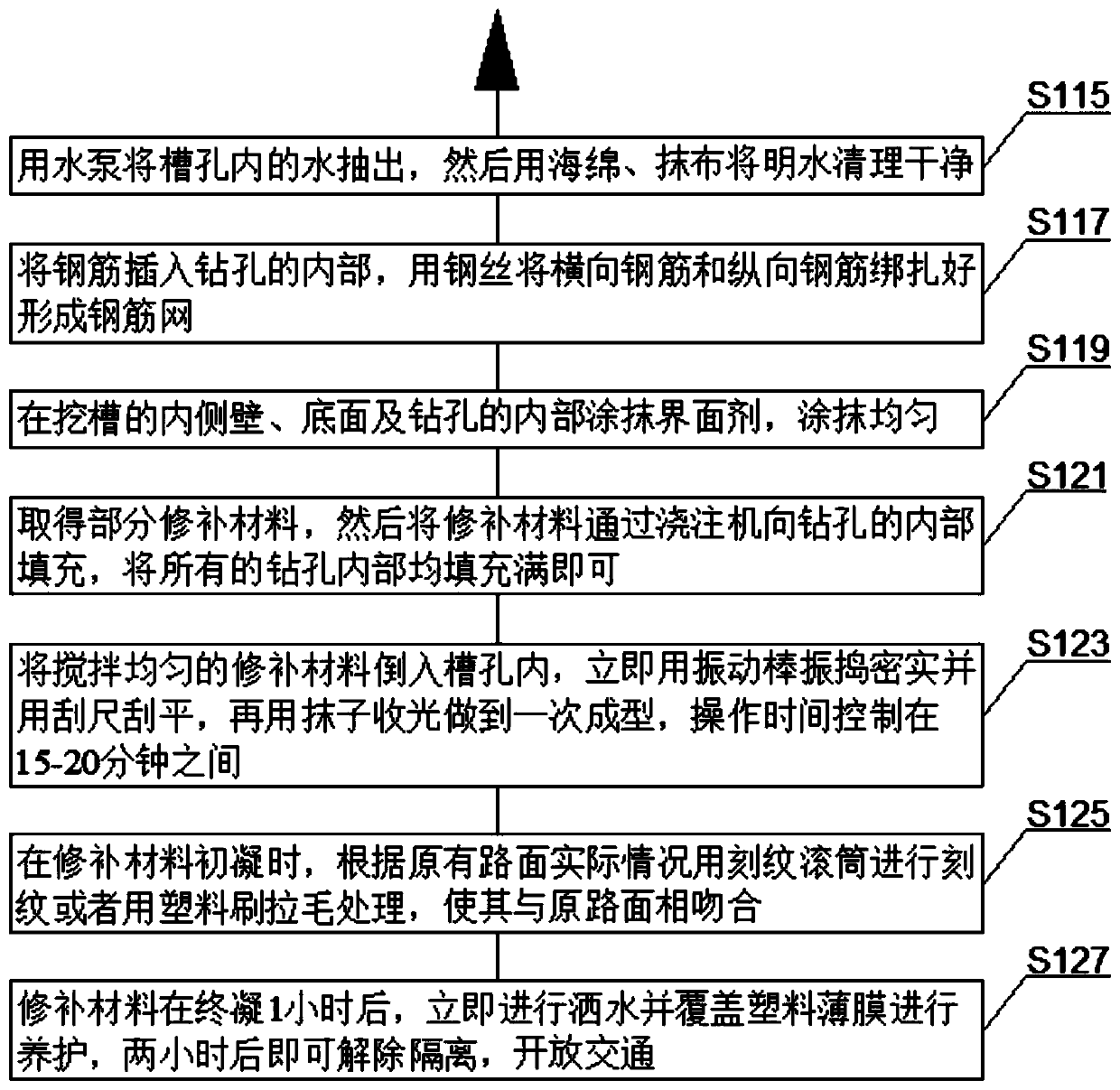

Method used

Image

Examples

Embodiment 1

[0082] A method for repairing road surface damage, wherein the road surface repair material in step S101 of the road surface damage repair method is made of the following raw materials in parts by mass:

[0083] Portland cement 35-60 parts, high alumina cement 12-20 parts, pebble crushed powder 10-20 parts, fine sand 20-30 parts, calcium stone powder 12-16 parts, water reducing agent 1-2 parts, latex powder 1 -3 parts, 1-2 parts of organic-inorganic composite fiber, 2-3 parts of nano-titanium dioxide, 1-2 parts of vinyl triethoxysilane, 2-4 parts of reinforcing particles, 1-2 parts of polyvinyl alcohol emulsion, lithium carbonate 0.5-1.5 parts, 1-1.5 parts of tartaric acid, 1-2 parts of desulfurized gypsum, 1-2 parts of inorganic dyes, 0.5-1 parts of advection agent, 2-3 parts of antifreeze, 14-18 parts of pure water.

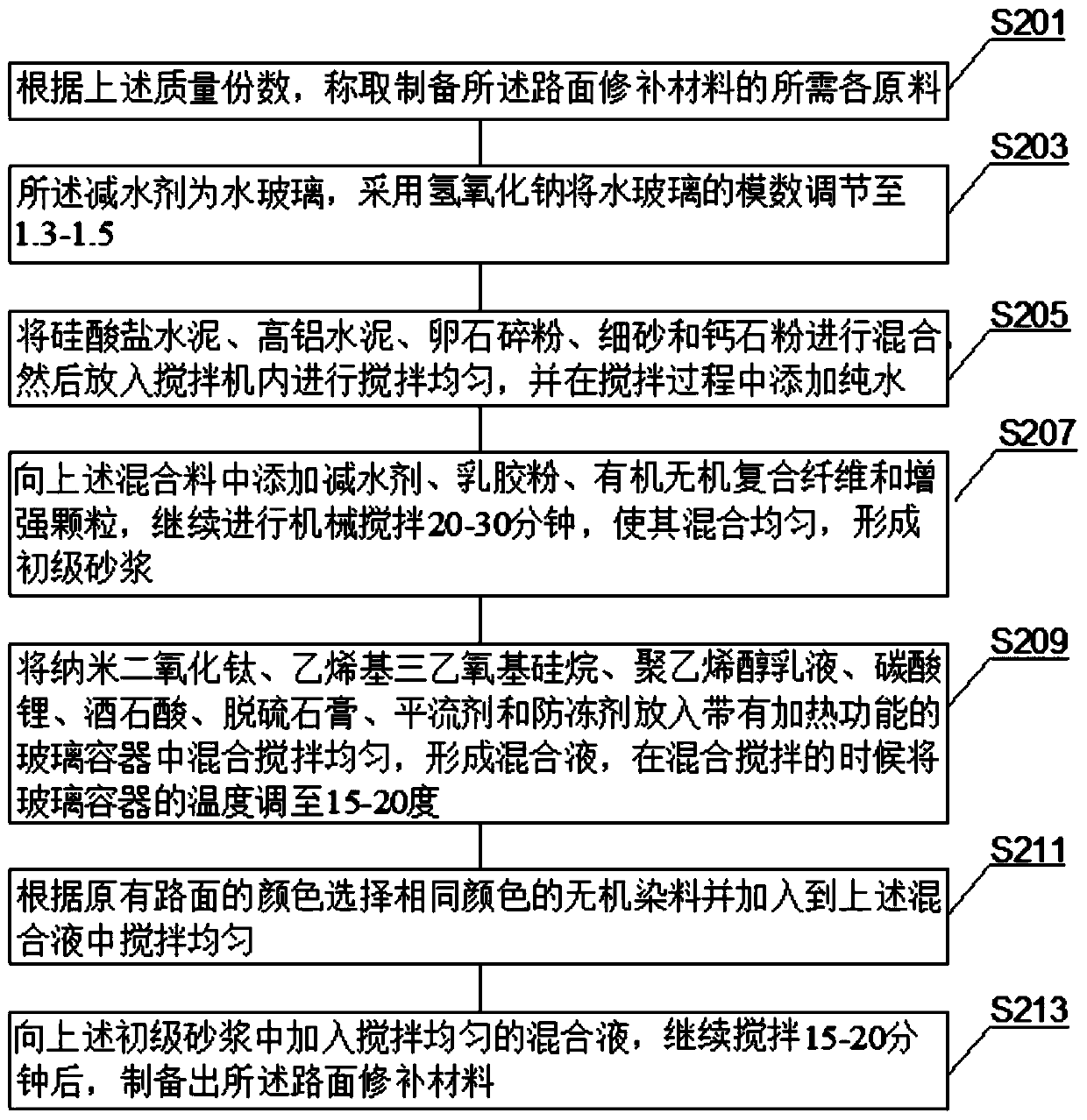

[0084] The preparation of this pavement patching material comprises the following steps:

[0085] According to the above-mentioned parts by mass, each raw mat...

Embodiment 2

[0093]A method for repairing road surface damage, wherein the road surface repair material in step S101 of the road surface damage repair method is made of the following raw materials in parts by mass:

[0094] Portland cement 35-60 parts, high alumina cement 12-20 parts, pebble crushed powder 10-20 parts, fine sand 20-30 parts, calcium stone powder 12-16 parts, water reducing agent 1-2 parts, latex powder 1 -3 parts, 1-2 parts of organic-inorganic composite fiber, 2-3 parts of nano-titanium dioxide, 1-2 parts of vinyl triethoxysilane, 2-4 parts of reinforcing particles, 1-2 parts of polyvinyl alcohol emulsion, lithium carbonate 0.5-1.5 parts, 1-1.5 parts of tartaric acid, 1-2 parts of desulfurized gypsum, 1-2 parts of inorganic dyes, 0.5-1 parts of advection agent, 2-3 parts of antifreeze, 14-18 parts of pure water.

[0095] The preparation of this pavement patching material comprises the following steps:

[0096] According to the above-mentioned parts by mass, each raw mate...

Embodiment 3

[0104] A method for repairing road surface damage, wherein the road surface repair material in step S101 of the road surface damage repair method is made of the following raw materials in parts by mass:

[0105] Portland cement 35-60 parts, high alumina cement 12-20 parts, pebble crushed powder 10-20 parts, fine sand 20-30 parts, calcium stone powder 12-16 parts, water reducing agent 1-2 parts, latex powder 1 -3 parts, 1-2 parts of organic-inorganic composite fiber, 2-3 parts of nano-titanium dioxide, 1-2 parts of vinyl triethoxysilane, 2-4 parts of reinforcing particles, 1-2 parts of polyvinyl alcohol emulsion, lithium carbonate 0.5-1.5 parts, 1-1.5 parts of tartaric acid, 1-2 parts of desulfurized gypsum, 1-2 parts of inorganic dyes, 0.5-1 parts of advection agent, 2-3 parts of antifreeze, 14-18 parts of pure water.

[0106] The preparation of this pavement patching material comprises the following steps:

[0107] According to the above-mentioned parts by mass, each raw mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com