High strength composite material for blast furnace cooling walls, preparation method of high strength composite material, and application of high strength composite material in protection of cooling walls

A high-strength composite material and composite material technology, applied in the field of high-strength composite materials for blast furnace staves, can solve problems such as thermal stress damage, inability to protect the stave, poor slag-hanging performance, etc., to improve adhesion, increase compactness, Excellent thermal conductivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A high-strength composite material for blast furnace staves, the composite material is prepared from component A and component B, the mass percentage of the component A is 55%, and the mass percentage of the component B is 45%;

[0041] The component A is a carbon composite fiber material;

[0042] The component B is prepared from the following raw materials in parts by weight: 30% of aluminum nitride micropowder, 8% of high-purity silicon carbide, 11% of mullite, 21% of alumina powder, 9% of silicon micropowder, montmorillonite 10%, sericite 5%, aluminate cement 4% and naphthalenesulfonate superplasticizer 2%.

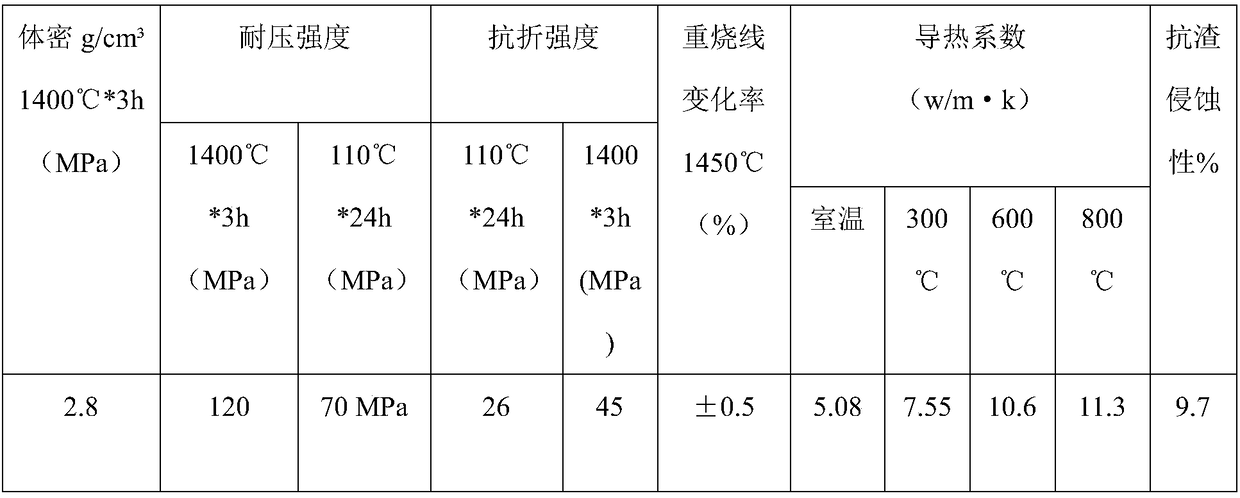

[0043] The product was tested for performance, and the results are shown in Table 1.

[0044] Among them, the specific properties of raw materials are as follows:

[0045] The tensile strength of the carbon composite fiber material is 3200Mpa, and the tensile modulus of elasticity is 33000-40000Mpa; it has small specific gravity, high temperature resistance (...

Embodiment 2

[0058] A high-strength composite material for blast furnace staves, the composite material is prepared from component A and component B, the mass percentage of the component A is 65%, and the mass percentage of the component B is 35%;

[0059] The component A is a carbon composite fiber material;

[0060] The component B is prepared from the following raw materials in parts by weight: 40% of aluminum nitride micropowder, 6% of high-purity silicon carbide, 9% of mullite, 20% of alumina powder, 9% of silicon micropowder, montmorillonite 10%, sericite 2.5%, aluminate cement 3% and naphthalenesulfonate superplasticizer 0.5%.

[0061] Described raw material specific performance is identical with embodiment 1.

[0062] The product was tested for performance, and the results are shown in Table 1.

Embodiment 3

[0064] A high-strength composite material for blast furnace staves, the composite material is prepared from component A and component B, the mass percentage of the component A is 60%, and the mass percentage of the component B is 40%;

[0065] The component A is a carbon composite fiber material;

[0066] The component B is prepared from the following raw materials in parts by weight: 35% of aluminum nitride micropowder, 7% of high-purity silicon carbide, 10% of mullite, 23% of alumina powder, 9% of silicon micropowder, montmorillonite 10.5%, Sericite 2.5%, Silicone Gel Particles 2%, and Naphthalene Sulfonate Superplasticizer 1%.

[0067] Described raw material specific performance is identical with embodiment 1. The particle diameter of the silica gel particles is 5-10 mm.

[0068] The product was tested for performance, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com