Controllable low-strength backfill material and preparation method thereof

A low-intensity, basic raw material technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problem of difficult utilization of soil-containing waste, and achieve good recycling, good economic and environmental benefits , the effect of reducing the preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a method for preparing a controllable low-strength backfill material, comprising the following steps:

[0026] S1. Mix a predetermined amount of engineering slag, mixing plant waste and sludge, and crush it to a predetermined particle size as the basic raw material;

[0027] S2. Add a predetermined amount of fly ash, cement, water, water reducer and soil dispersant to the basic raw material obtained in step S1, and stir well until the mixture is uniform to obtain a controllable low-strength backfill material.

[0028] In step S1, the particle size of the basic raw material is less than 4.75mm; the mass ratio of the engineering dregs, mixing station waste and sludge is (30-45):(20-30):(10-20).

[0029] In step S2, the mass ratio of the basic raw material to the fly ash, cement, water, water reducer and soil dispersant is (60-75):(5-10):(5-20): (10~25):(0.1~2):(0.1~2).

[0030] The present invention also provides a controllable low-strength backfi...

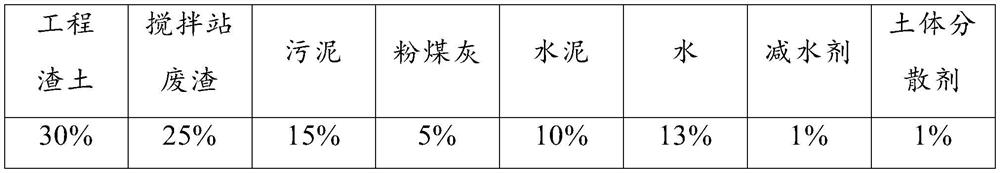

Embodiment 1

[0038] This embodiment provides a method for preparing a controllable low-strength backfill material, comprising the following steps:

[0039] S1. Mix a predetermined amount of engineering slag, mixing plant waste and sludge, and crush it until the particle size is less than 4.75mm, as the basic raw material;

[0040] S2. Add a predetermined amount of fly ash, cement, water, water reducer and soil dispersant to the basic raw material obtained in step S1, and stir well until the mixture is uniform to obtain a controllable low-strength backfill material.

[0041] In this embodiment, the engineering dregs used are mixed by subway shield spoil, pipeline engineering dregs and roadbed dregs in a mass ratio of 1:1:1, the mixing station waste is concrete mixing station waste, and the sludge is For the sludge from the waterworks, the fly ash is Class I fly ash, the cement is ordinary Portland cement, the water reducer is sulfonated lignin, and the soil dispersant is sodium metasilicate...

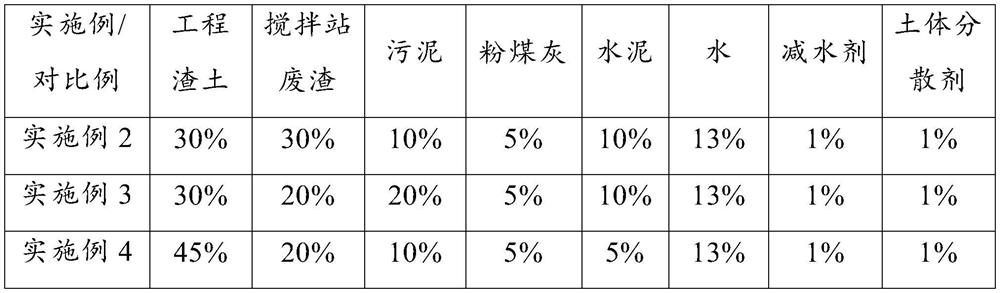

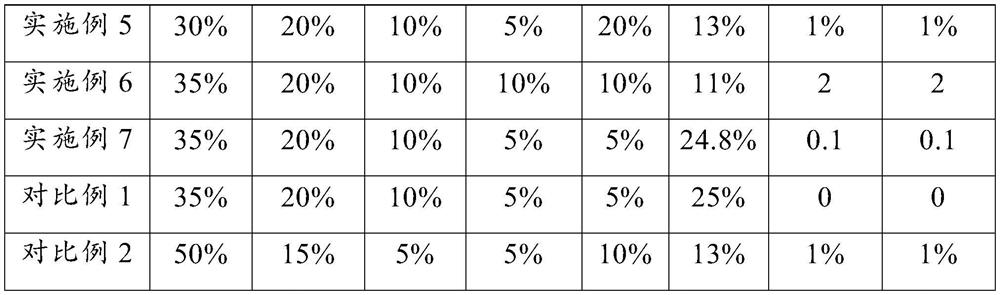

Embodiment 2~7 and comparative example 1~2

[0046] Examples 2-7 and Comparative Examples 1-2 respectively provide a controllable low-strength backfill material. Compared with Example 1, the difference is that the amount of each raw material is changed, and the preparation method is consistent with Example 1. , which will not be repeated here. Table 2 shows the mass percentages of each raw material in the controllable low-strength backfill material provided in each embodiment and comparative example.

[0047] Table 2 The mass percent of each raw material in the controllable low-strength backfill material prepared in Examples 2 to 7 and Comparative Examples

[0048]

[0049]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com