A kind of treatment method of sewage sludge

A treatment method and technology of a sewage plant, applied in the direction of biological sludge treatment, etc., can solve problems such as air pollution, low work efficiency, and odor pollution, and achieve the effects of eliminating harmful substances and germs, fast processing speed, and short processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

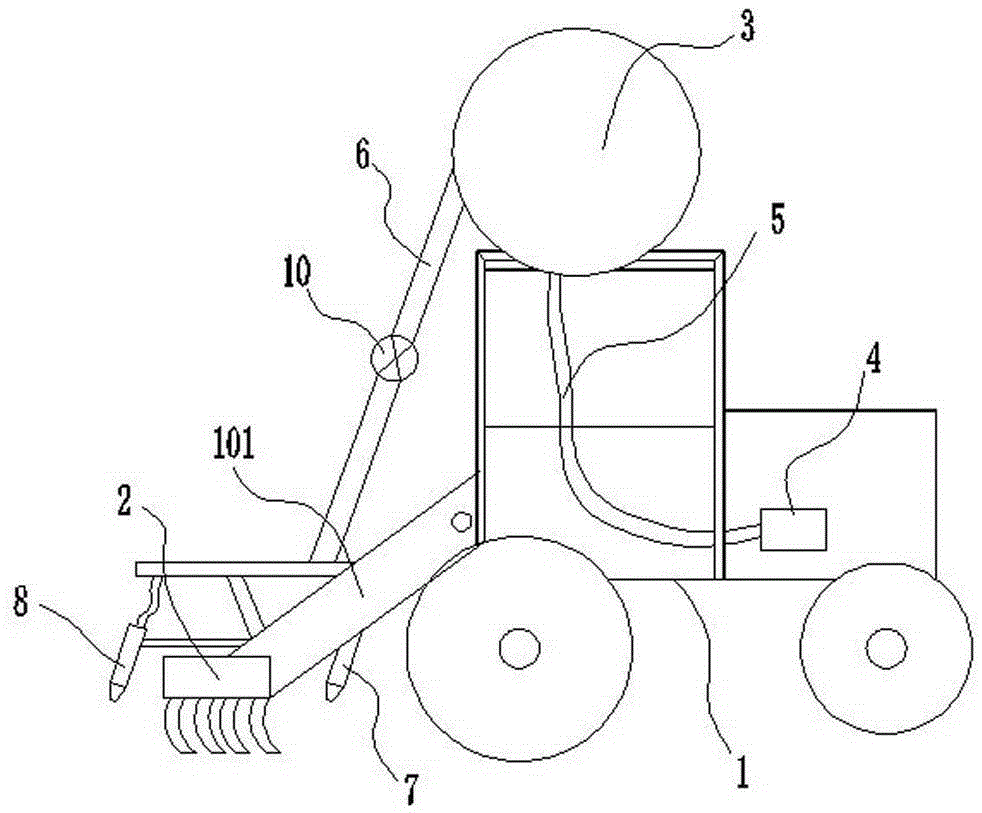

Method used

Image

Examples

Embodiment 1

[0045] A method for treating sewage sludge, comprising the following steps:

[0046] Step 1. Transport the sludge from the sewage plant into the production shed, and the loader randomly spreads it on the flat ground of the production shed with a thickness of 15cm; according to the volume ratio of deodorant and water is 1:150, the After the deodorant is diluted, the deodorant dilution is obtained for subsequent use; use sterile water, and the EM bacterial stock solution is diluted according to the volume ratio of the EM bacterial stock solution and water as 1:200 to obtain the EM bacterial dilution A for subsequent use ; Using sterile water, according to the volume ratio of the EM bacteria stock solution and water as 1:100, dilute the EM bacteria stock solution to obtain the EM bacteria dilution B, for subsequent use;

[0047] Step 2, use the rotary tillage sprayer to carry out rotary tillage to the flattened sludge and then spray the deodorant dilution, and carry out 5 rotary ...

Embodiment 2

[0054] A method for treating sewage sludge, comprising the following steps:

[0055] Step 1. Transport the sludge into the production shed, and the loader randomly spreads it on the flat ground of the production shed with a thickness of 18cm; according to the volume ratio of deodorant and water as 1:150, the deodorizing After the deodorant is diluted, the deodorant dilution is obtained for subsequent use; using sterile water, the EM bacterium stock solution is diluted according to the volume ratio of the EM bacterium stock solution and water to 1:200, and the EM bacterium dilution A is obtained for subsequent use; Sterile water, according to the volume ratio of EM bacteria stock solution and water is 1:100, dilute the EM bacteria stock solution to obtain EM bacteria dilution B, set aside;

[0056] Step 2, use the rotary tillage sprayer to carry out rotary tillage to the flattened sludge and then spray the deodorant dilution for 5 times of rotary tillage spraying; after 2.5 hou...

Embodiment 3

[0062] A method for treating sewage sludge, comprising the following steps:

[0063] Step 1. Transport the sludge into the production shed, and the loader randomly spreads it on the flat ground of the production shed with a thickness of 20cm; according to the volume ratio of deodorant and water as 1:150, the deodorant After the deodorant is diluted, the deodorant dilution is obtained for subsequent use; using sterile water, the EM bacterium stock solution is diluted according to the volume ratio of the EM bacterium stock solution and water to 1:200, and the EM bacterium dilution A is obtained for subsequent use; Sterile water, according to the volume ratio of EM bacteria stock solution and water is 1:100, dilute the EM bacteria stock solution to obtain EM bacteria dilution B, set aside;

[0064] Step 2. Rotate the flattened sludge with a rotary tillage sprayer and then spray the deodorant dilution for 5-6 times of rotary tillage spraying; after 2-3 hours, use the rotary tillag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com