Treatment method for waste acid containing iron and zinc and water purifying agent and zinc product obtained through treatment method

A treatment method and technology of water purifying agent, applied in metallurgical wastewater treatment, chemical instruments and methods, extraction water/sewage treatment, etc., can solve the problems of difficult treatment, secondary pollution, large amount of solid slag, etc., and achieve stable product quality , The production process is environmentally friendly and the use value is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

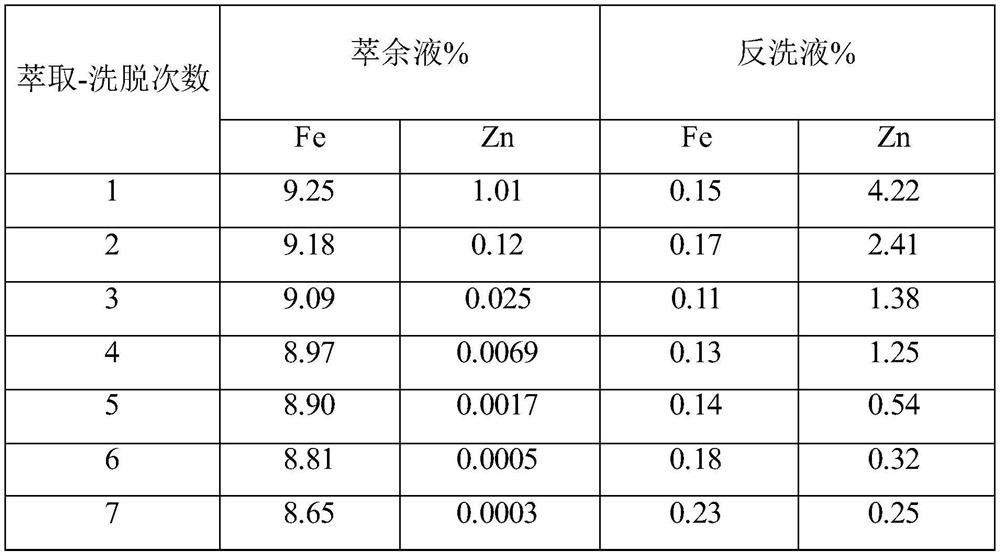

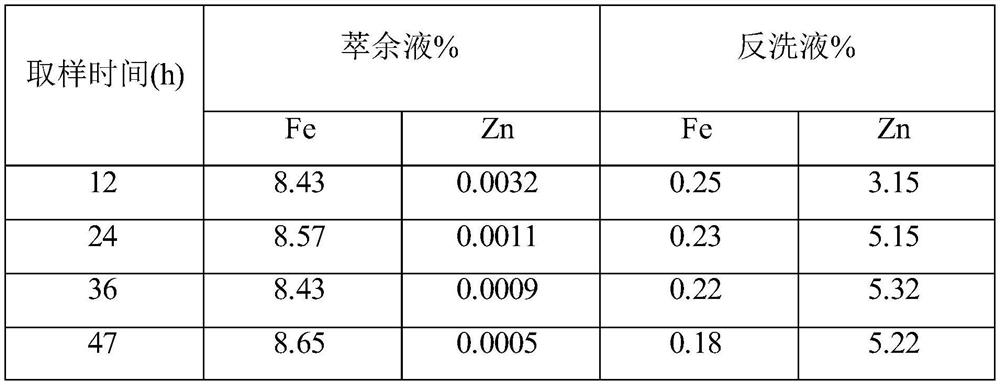

Embodiment 1

[0054] The purpose of this embodiment is to provide a kind of treatment method of iron-containing, zinc waste acid, specifically as follows:

[0055] After the stock solution is pretreated, the organic matter is removed to obtain the first liquid to be treated; after the extraction mixture is pretreated, it is mixed with the first liquid to be treated, and after stirring for 5 minutes, the liquid is separated to obtain the raffinate and the liquid to be treated. 2, wherein the volume of the liquid to be treated and the extraction mixed liquid is 1:2, specifically, the volume of the liquid to be treated is 200mL, and the volume of the mixed liquid to be extracted is 400 mL; after mixing the liquid to be treated with the washing liquid, liquid separation is performed again , the backwash solution and the recovery solution are obtained, wherein the volume ratio of the second solution to be treated and the washing solution is 4:1, and specifically, the volume of the washing solutio...

Embodiment 2

[0061] The purpose of this embodiment is to provide a kind of treatment method of iron-containing, zinc waste acid, specifically as follows:

[0062] After the stock solution is pretreated, the organic matter is removed to obtain the liquid to be treated; the extraction mixture is pretreated, mixed with the liquid to be treated, and after stirring for 4 minutes, the liquid is separated to obtain the raffinate and the liquid to be treated. 2, wherein the volume of the liquid to be treated and the extraction liquid mixture is 1:1, specifically, the volume of the liquid to be treated is 200mL, and the volume of the extraction liquid mixture is 200mL; after mixing the liquid to be treated with the washing liquid, the liquid separation is carried out again. , the backwash solution and the recovery solution are obtained, wherein the volume ratio of the second solution to be treated and the washing solution is 3:1, and specifically, the volume of the washing solution is 65mL;

[0063...

Embodiment 3

[0068] The purpose of this embodiment is to provide a kind of treatment method of iron-containing, zinc waste acid, specifically as follows:

[0069] After the stock solution is pretreated, the organic matter is removed to obtain the liquid to be treated; the extraction mixture is pretreated, mixed with the liquid to be treated, and after stirring for 7 minutes, the liquid is separated to obtain the raffinate and the liquid to be treated. 2, wherein the volume of the liquid to be treated and the extraction liquid mixture is 1:3, specifically, the volume of the liquid to be treated is 200mL, and the volume of the extraction liquid mixture is 600mL; after mixing the liquid to be treated with the washing liquid, liquid separation is performed again , the backwashing liquid and the recovery liquid are obtained, wherein the volume ratio of the second liquid to be treated and the washing liquid is 5:1, and specifically, the volume of the washing liquid is 120 mL;

[0070] Then, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com