Rope-shaped desizing, scouring and bleaching combination machine

A descouring, bleaching and combined machine technology, which is applied in textiles and papermaking, textile material processing equipment configuration, textile material processing, etc., can solve problems such as high unit cost per 100 meters, low production efficiency, and large steam consumption. Achieve the effects of solving poor dyeing, saving energy and reducing steam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

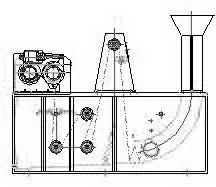

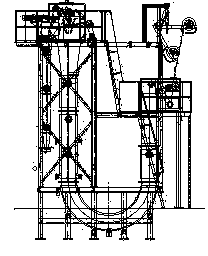

[0035] Specific embodiments: a rope-shaped descouring and bleaching combined machine, including a washing box, a rolling washing machine, a scouring box, a J-shaped box after acid rolling, and a J-shaped box after rolling hypochlorous acid. The machine is connected by the above-mentioned several devices in sequence, and the connection sequence is: washing box-rolling washing machine-scouring box-scouring box-water washing box-water washing box-water washing box-water washing box-rolling washing machine-after acid rolling J-type box-water washing box-rolling washing machine-after rolling hypochlorous acid J-type box-water washing box-water washing box.

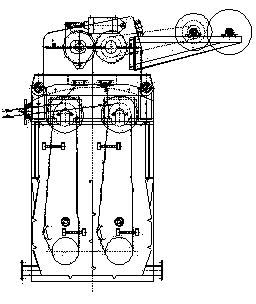

[0036] Such as figure 1 As shown, the water washing box includes a box body, two mop rollers up and down in the box body respectively constitute two mop circulation circles, and 26 spreading tugboats are arranged side by side on the upper drag rollers, and 26 groups of guide holes are arranged in the middle (the main function ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com