3D (Three-dimensional) printing building material and application thereof

A technology for 3D printing and building materials, applied in the direction of additive processing, etc., can solve the problems of unpleasant and toxic gases, poor compressive performance of target buildings, poor fluidity of paste materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

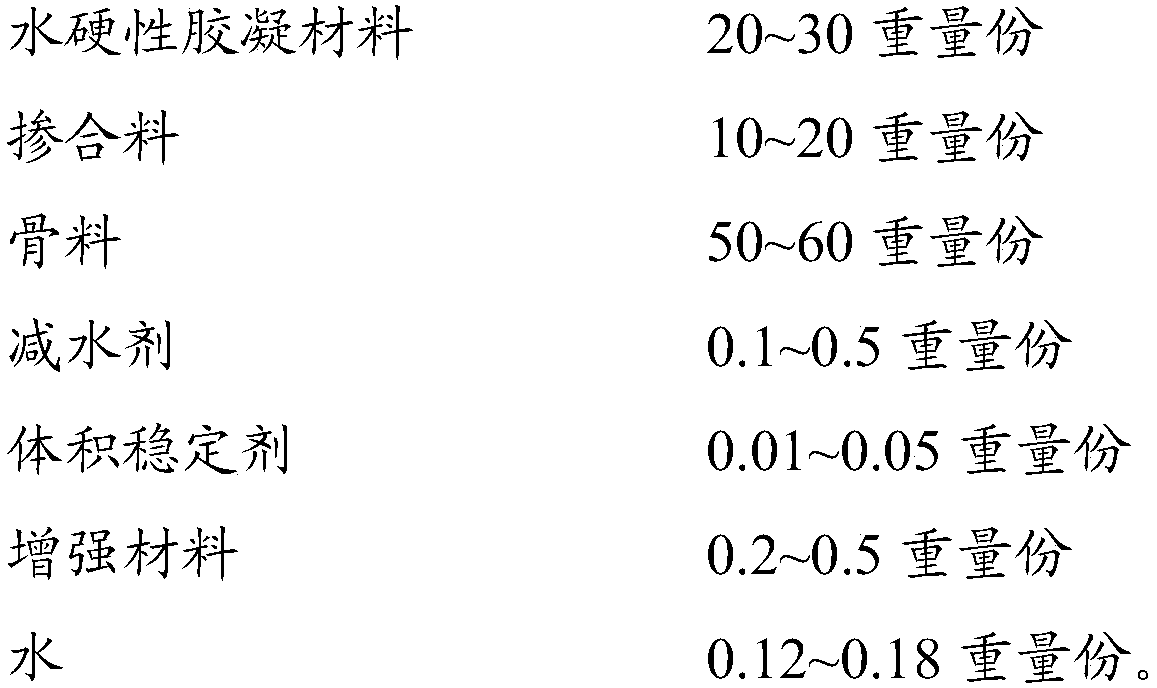

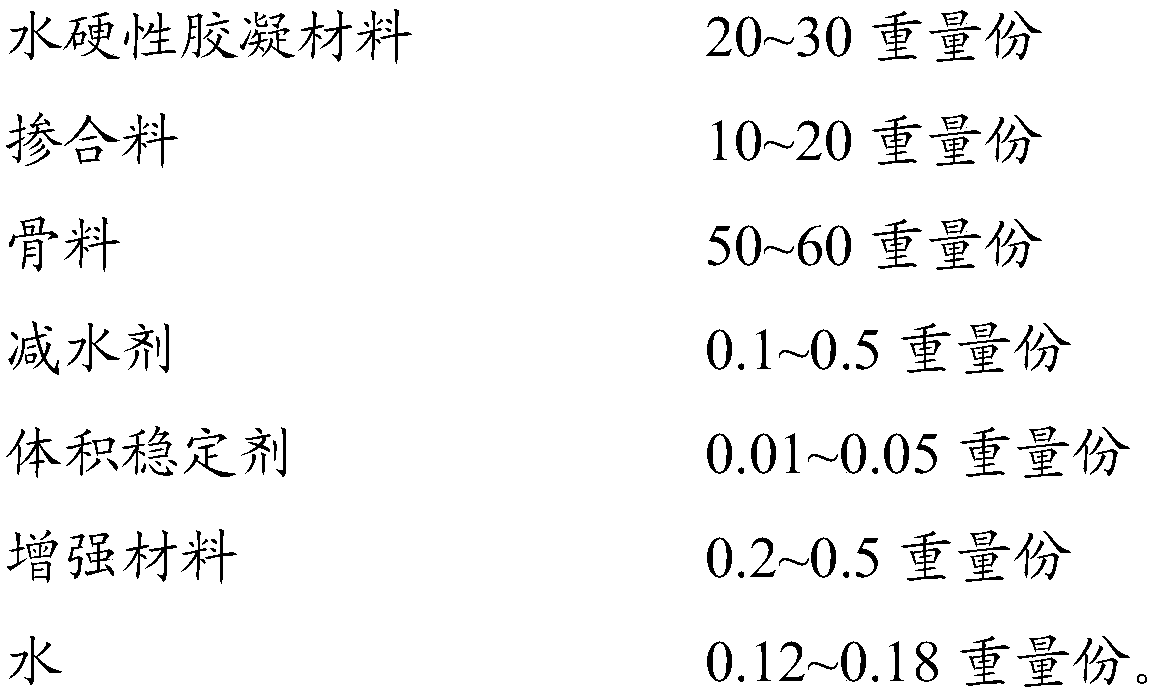

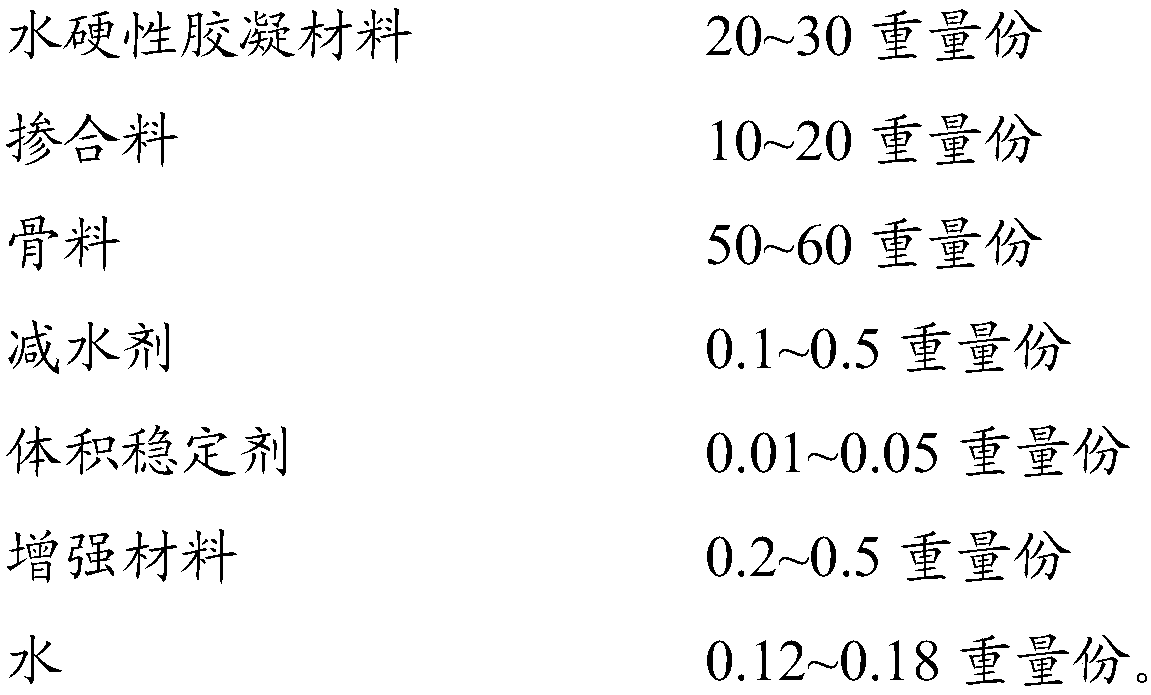

Method used

Image

Examples

preparation example Construction

[0033] The present invention has no special limitation on the preparation method of the 3D printing building material, and the 3D printing can be obtained by mixing hydraulic gelling materials, admixtures, aggregates, water reducing agents, volume stabilizers, reinforcing materials and water. building materials. In the present invention, the mixing is preferably carried out at room temperature; in the present invention, there is no special limitation on the mixing time, as long as the mixing can be achieved uniformly. In the present invention, the mixing is preferably carried out under the condition of stirring; in the present invention, there is no special limitation on the stirring rate, as long as the components can be fully mixed.

[0034] In the present invention, the mixing is preferably to mix the hydraulic gelling material, admixture, aggregate, water reducing agent, volume stabilizer and reinforcing material uniformly, and then add water for mixing; in the present inv...

Embodiment 1

[0042] Ordinary Portland cement 42.5 of 15 parts by weight, Belit cement of 15 parts by weight, mineral powder of 15 parts by weight, fly ash of 5 parts by weight, iron tailings of 40 parts by weight, sand of 10 parts by weight, 0.2 parts by weight of polycarboxylate superplasticizer, 0.01 parts by weight of carboxymethyl cellulose ether, and 0.2 parts by weight of basalt fiber are mixed until evenly stirred; add 0.12 parts by weight of water and stir for 20 minutes to obtain a 3D printing building material ;

[0043] The obtained 3D printed building materials are 3D printed, and then covered with tarpaulins for maintenance to prevent surface moisture from evaporating, and the target building is obtained.

[0044] After the obtained 3D printed building materials are cured and molded, standard samples are taken according to the GB / T 50081-2002 standard for testing the mechanical properties of ordinary concrete, and the compressive test is carried out. The compressive strength o...

Embodiment 2

[0046] 20 parts by weight of ordinary Portland cement 42.5, 10 parts by weight of Belite cement, 10 parts by weight of mineral powder, 45 parts by weight of iron tailings, 5 parts by weight of copper tailings, 0.4 parts by weight of polycarboxylate Acid high-efficiency water reducer, 0.01 parts by weight of hydroxymethyl cellulose ether, and 0.2 parts by weight of basalt fiber are mixed until uniformly stirred; add 0.14 parts by weight of water and stir for 30 minutes to obtain a 3D printing building material;

[0047] The obtained 3D printed building materials are 3D printed, and then covered and maintained with tarpaulins under natural conditions to obtain the target building.

[0048] After the obtained 3D printed building materials are cured and molded, standard samples are taken according to the GB / T 50081-2002 standard for testing the mechanical properties of ordinary concrete, and the compressive test is carried out. The compressive strength of the 28-day test is 60MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com