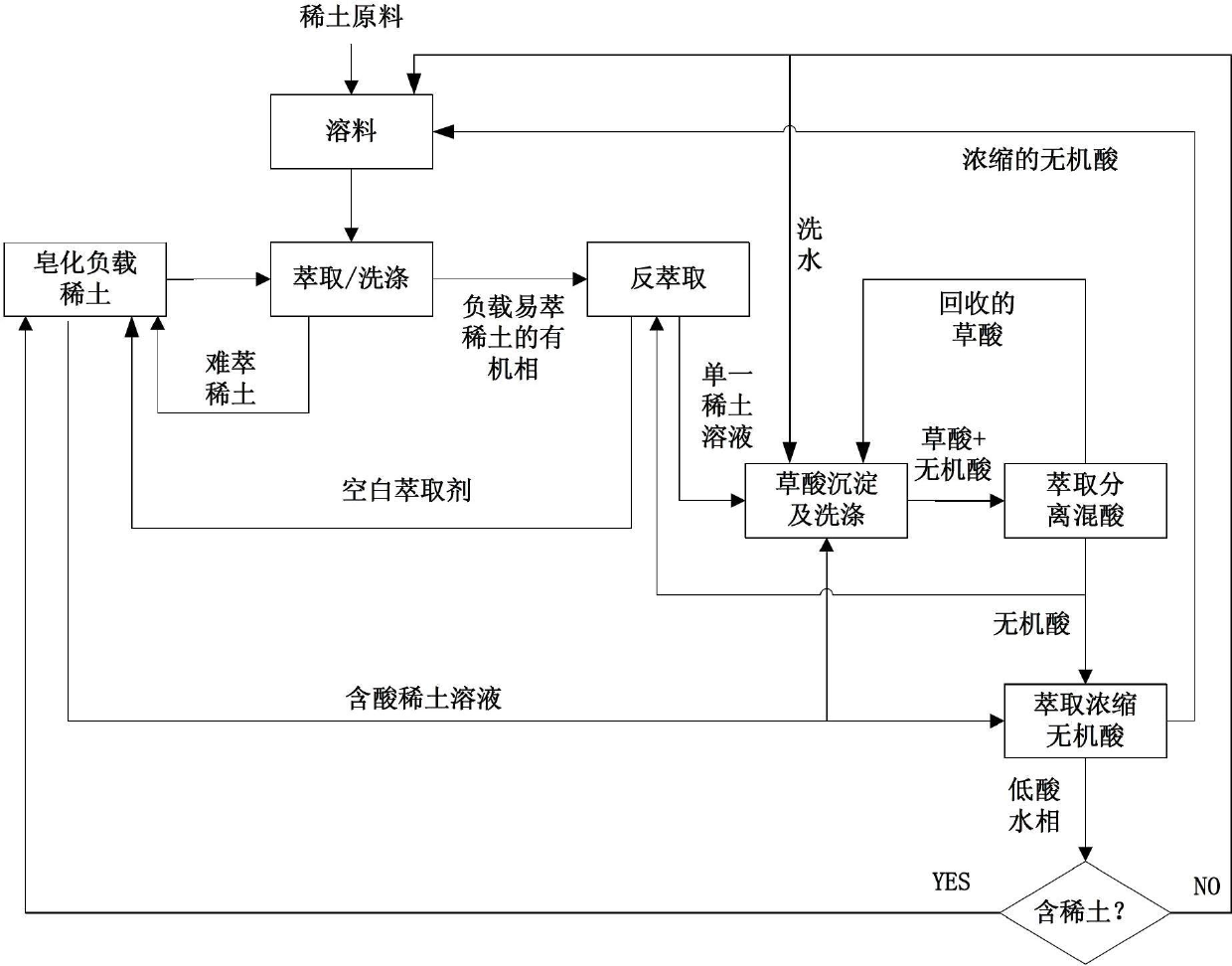

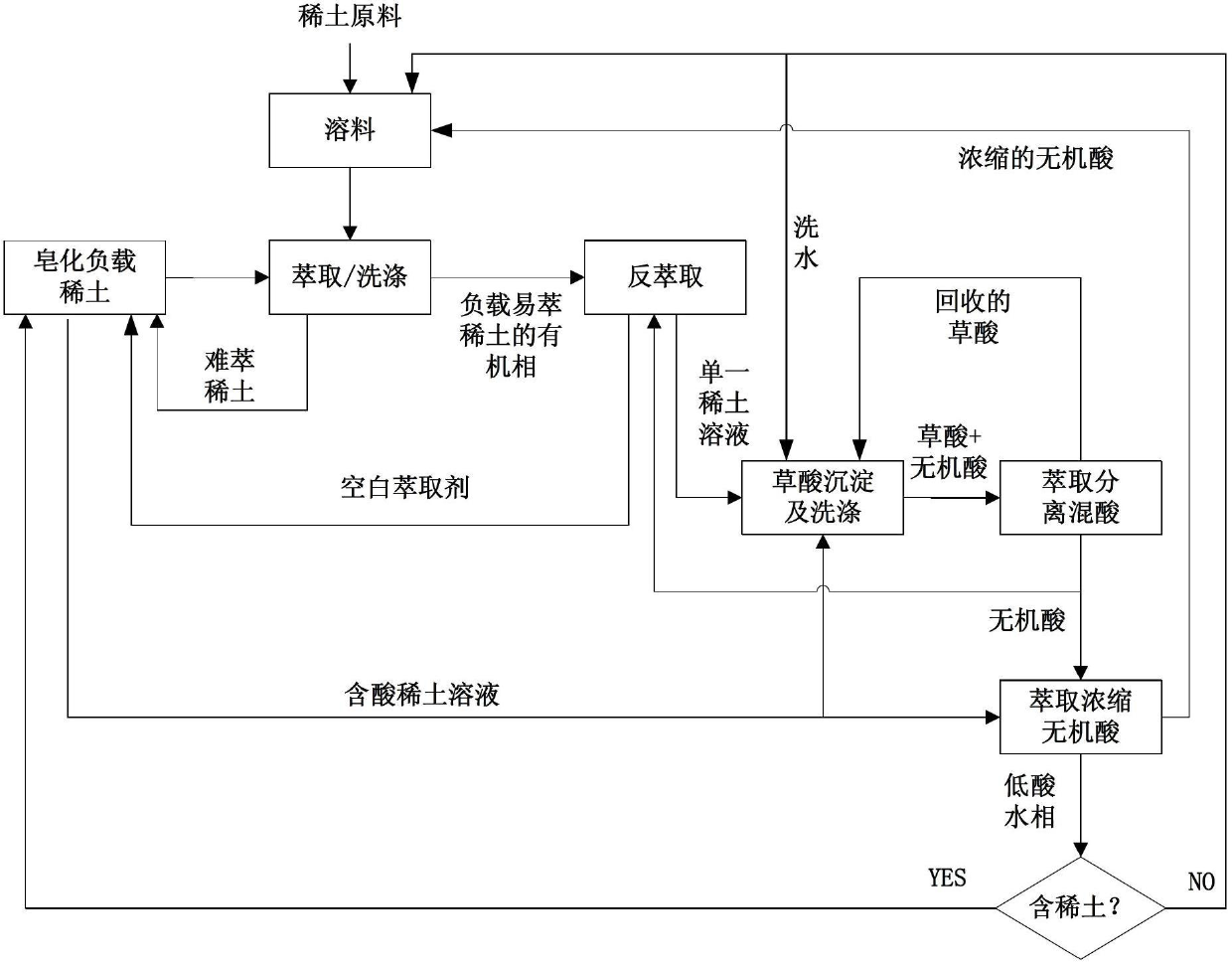

Rare earth separation method with material linkage cyclic utilization function

A separation method and rare earth technology, which are applied in the field of rare earth separation for the linkage and recycling of materials, can solve the problems of not considering the recycling of hydrochloric acid and oxalic acid, the linkage between the production and utilization of reagents, and the inability to eliminate the environmental pressure of rare earth separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Use hydrochloric acid to dissolve lanthanum cerium carbonate (the molar ratio of La to Ce is 60:40), and the solution obtained by dissolving is used as the raw material to be extracted. Using P204 as the extractant, the La / Ce separation is carried out in the 60-level 30L main extraction tank. The organic phase flow rate is 6L / min and the concentration is 1.5mol / L (diluted with a mixed organic solvent of 30% secondary octanol + 70% sulfonated kerosene). There is also a 10-stage 30L auxiliary extraction tank for acid extraction and recovery, using trialkylmethylamine as the extractant, with a flow rate of 5L / min and a concentration of 1.0mol / L (diluted with sulfonated kerosene). The organic phases of the two extraction tanks all flow from front to back.

[0059] (LaCe)Cl in the main extraction tank 3 The feed liquid concentration is 1mol / L, and it is added from the 30th stage at a flow rate of 1.5L / min, the 3.0mol / L washing acid is added from the 50th stage at 0.4L / min, and ...

Embodiment 2

[0064] Use hydrochloric acid to dissolve lanthanum cerium carbonate (the molar ratio of La to Ce is 60:40), and the resulting solution is used as the raw material to be extracted. Using 60% P204 and 40% P507 as extractants, the La is carried out in a 60-level 30L main extraction tank. / Ce separation, organic flow rate is 6L / min, concentration is 1.2mol / L (diluted with No. 200 solvent oil). In addition, a 10-stage 30L auxiliary extraction tank is set up for acid extraction and recovery, using N,N-bis(1-methylheptyl)acetamide as the extractant, with a flow rate of 5L / min and a concentration of 0.8mol / L (using 20% No. 200 Solvent oil + 40% isooctanol + 40% industrial kerosene dilution). The organic phases of the two extraction tanks all flow from front to back.

[0065] The addition of stripping acid and washing acid, the exit of La and Ce liquid and the rare earth saponification process are the same as in Example 1. The lanthanum chloride soap material is saponified with the bla...

Embodiment 3

[0068] Use nitric acid to dissolve lanthanum and cerium oxide (the molar ratio of La to Ce is 60:40), and the resulting solution is used as the raw material to be extracted. P507 is used as the extractant, and the extractant concentration is 1.8mol / L (20% 200# solvent oil + 40 % Industrial kerosene + 40% sec-octanol dilution), La / Ce separation is carried out in the 60-level 30L main extraction tank, and the organic flow rate is 6L / min. A 10-stage 30L auxiliary extraction tank is also set up for acid extraction and recovery, using trilaurylamine as the extractant, with a flow rate of 5L / min and a concentration of 1.5mol / L (20% 200# solvent oil + 80% sulfonated kerosene dilution). The organic phases of the two extraction tanks all flow from front to back.

[0069] In the main extraction tank (LaCe) (NO 3 ) 3 The feed liquid concentration is 1mol / L, added from the 30th stage at a flow rate of 1.5L / min, 3.0mol / L washing acid is added from the 50th stage at a flow rate of 0.4L / min, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com