Water-reducing agent for concrete and preparation method thereof

A technology of concrete water reducing agent and mixture, which is applied in the field of concrete, and can solve problems such as cracking, affecting the quality and strength of concrete, and achieve the effects of avoiding cracking, improving comprehensive performance, and improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

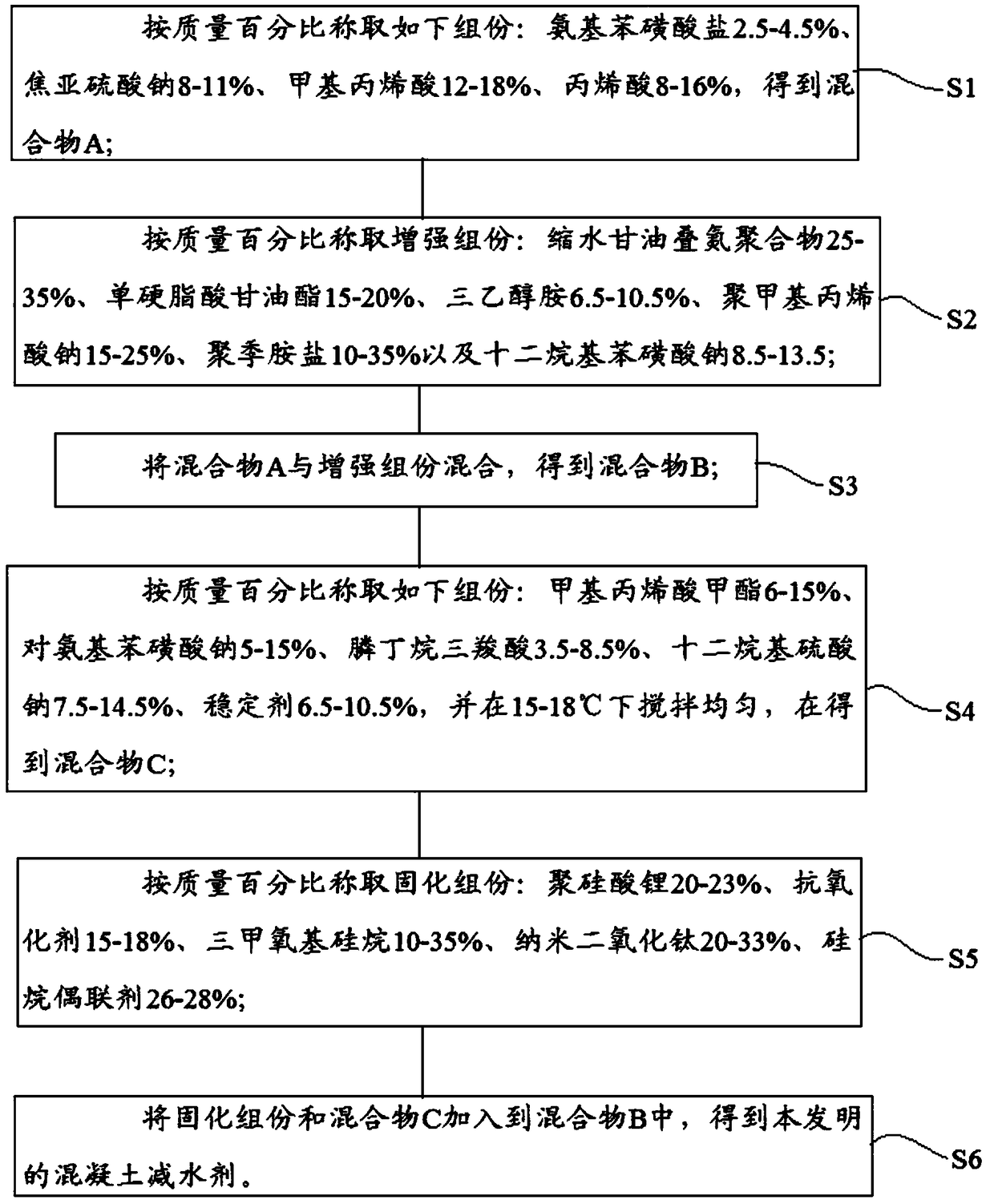

Method used

Image

Examples

Embodiment 1

[0038] Weigh the following components by mass percentage: 4.5% aminobenzenesulfonate, 8% sodium pyrosulfite, 18% methacrylic acid, and 8% acrylic acid to obtain mixture A; weigh the reinforcing component by mass percentage: glycidyl azide polymerization 25% glyceryl monostearate, 20% glyceryl monostearate, 6.5% triethanolamine, 15% sodium polymethacrylate, 35% polyquaternary ammonium salt, and 13.5% sodium dodecylbenzenesulfonate; Mix to obtain mixture B; take the following components by mass percentage: 6% methyl methacrylate, 5% sodium p-aminobenzenesulfonate, 3.5% phosphobutane tricarboxylic acid, 14.5% sodium lauryl sulfate, Stabilizer 6.5%, and stir evenly at 18°C to obtain mixture C; take the curing component by mass percentage: lithium polysilicate 23%, antioxidant 18%, trimethoxysilane 10%, nano-titanium dioxide 33% , silane coupling agent 26%; the curing component and the mixture C are added to the mixture B to obtain the concrete water reducer of the present invent...

Embodiment 2

[0040] Weigh the following components by mass percentage: 2.5% aminobenzenesulfonate, 9% sodium pyrosulfite, 18% methacrylic acid, and 8% acrylic acid to obtain mixture A; weigh the reinforcing component by mass percentage: glycidyl azide polymerization 25% glyceryl monostearate, 20% glyceryl monostearate, 8.5% triethanolamine, 18% sodium polymethacrylate, 25% polyquaternary ammonium salt and 9.5 sodium dodecylbenzenesulfonate; Mix to obtain mixture B; take the following components by mass percentage: 6% methyl methacrylate, 5% sodium p-aminobenzenesulfonate, 3.5% phosphobutane tricarboxylic acid, 8.5% sodium lauryl sulfate, Stabilizer 9.5%, and stir evenly at 18°C to obtain mixture C; take the curing component by mass percentage: lithium polysilicate 21%, antioxidant 16%, trimethoxysilane 20%, nano-titanium dioxide 25% , silane coupling agent 27%; the curing component and the mixture C are added to the mixture B to obtain the concrete water reducer of the present invention....

Embodiment 3

[0042] Weigh the following components by mass percentage: 3.5% aminobenzenesulfonate, 9.5% sodium pyrosulfite, 16% methacrylic acid, and 10% acrylic acid to obtain mixture A; weigh the reinforcing component by mass percentage: glycidyl azide polymerization 27%, glyceryl monostearate 18%, triethanolamine 9.5%, sodium polymethacrylate 18%, polyquaternary ammonium salt 28%, and sodium dodecylbenzenesulfonate 10.5; Mix to obtain mixture B; weigh the following components by mass percentage: 14% methyl methacrylate, 17% sodium p-aminobenzenesulfonate, 7.5% phosphobutane tricarboxylic acid, 10.5% sodium lauryl sulfate, Stabilizer 8.5%, and stir evenly at 18°C to obtain mixture C; take the curing component by mass percentage: lithium polysilicate 22%, antioxidant 17.5%, trimethoxysilane 28%, nano-titanium dioxide 28% , silane coupling agent 26%; the curing component and the mixture C are added to the mixture B to obtain the concrete water reducer of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com