Coral reef sand concrete and preparation method thereof

A coral reef and concrete technology, applied in the field of coral reef sand concrete and its preparation, can solve the problems of poor fluidity, large difference in performance of ordinary river sand, poor gradation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

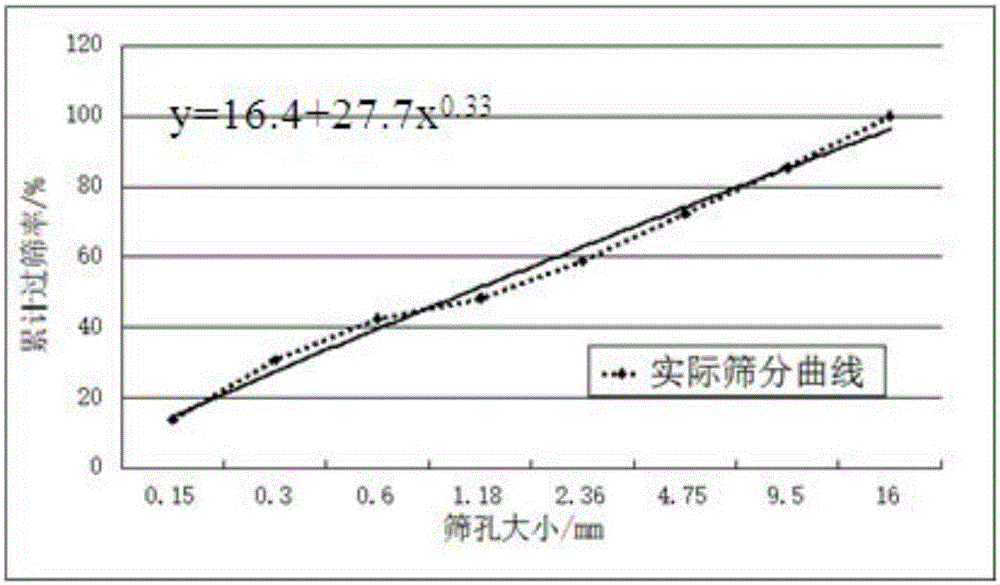

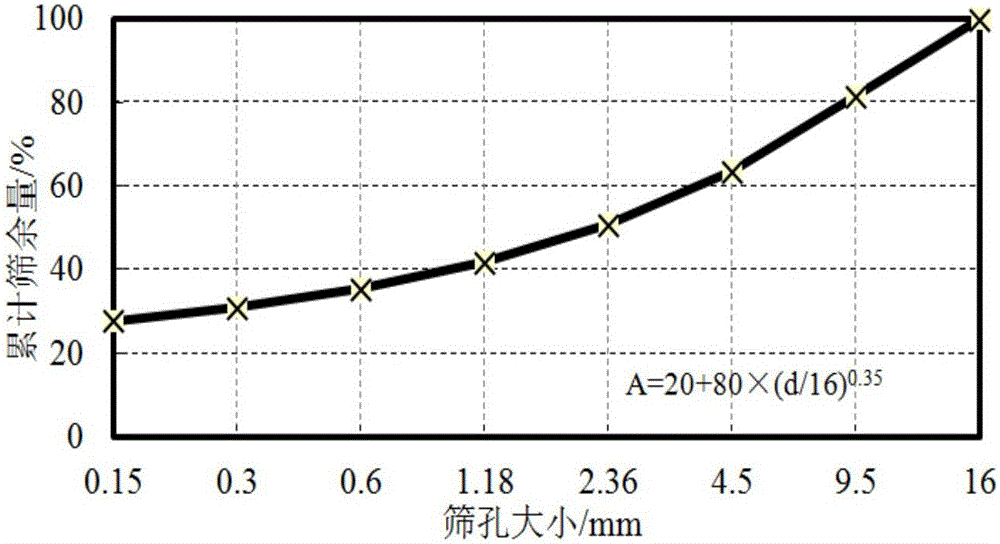

[0035] Aiming at the characteristics of poor gradation and irregular particle shape of coral reef sand, a compact packing model that comprehensively considers aggregate particle shape, gradation and concrete work performance is used to determine the sand ratio of concrete under different flow states. The formula of the compact packing model is:

[0036] Among them, A is the percentage of solid particles passing through the sieve hole d; D is the maximum particle size of the system; b is the percentage of the gelling system in the total system, which depends on the workability requirements of concrete; n is the distribution index.

[0037] Step 1) Determine the sand ratio of coral sand concrete

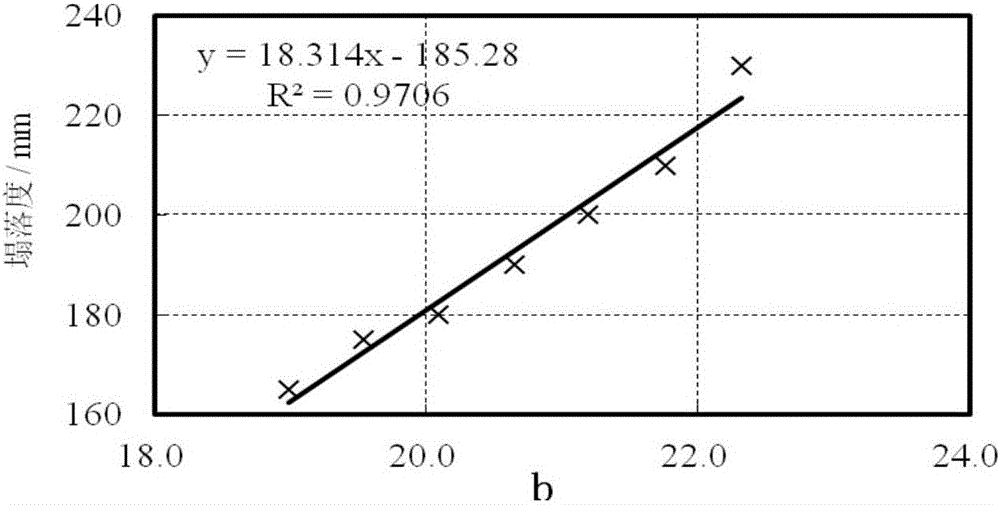

[0038] ① Determine b value

[0039] Under the same water-binder ratio, by adjusting the amount of cementing materials (cement, fly ash, etc.), coral reef sand was used to prepare 7 groups of normal concrete from S1 to S7, and the relationship between the expansion degree of concrete ...

Embodiment 1

[0061] Example 1: single material consumption, cement 380kg, fly ash 20kg, coral sand 630kg, gravel 1222kg, admixture 4.5kg, anti-adsorbent 0.28kg, additional water 36kg, net water 175kg.

Embodiment 2

[0062] Example 2: single material consumption, cement 400kg, fly ash 20kg, coral sand 600kg, gravel 1164kg, admixture 5.0kg, anti-adsorbent 0.30kg, additional water 36kg, net water 180kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

| sand rate | aaaaa | aaaaa |

| sand rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com