Environmentally-friendly coal transporting and stockpiling dust inhibitor and preparation method thereof

An environment-friendly, dust-suppressant technology, applied to chemical instruments and methods, and other chemical processes, can solve the problems of coal powder scattered on the ground, coal dust prevention measures, less methods, and less dust-suppressant agents, and achieve the goal of reducing dust. Production, dust suppression effect is obvious, strong anti-weathering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

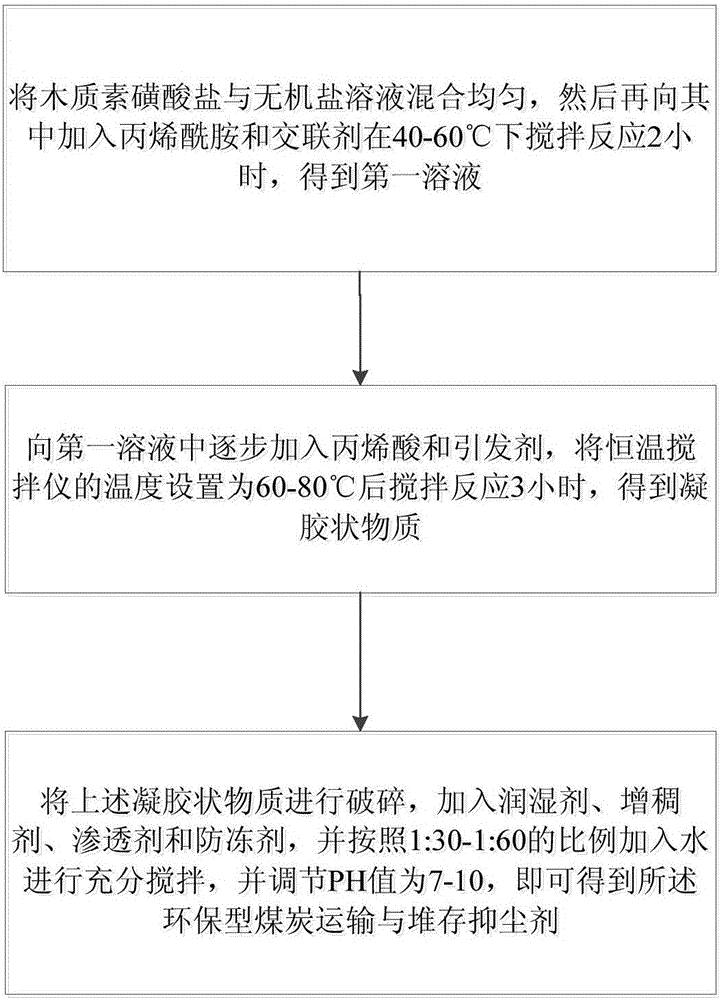

Method used

Image

Examples

Embodiment 1

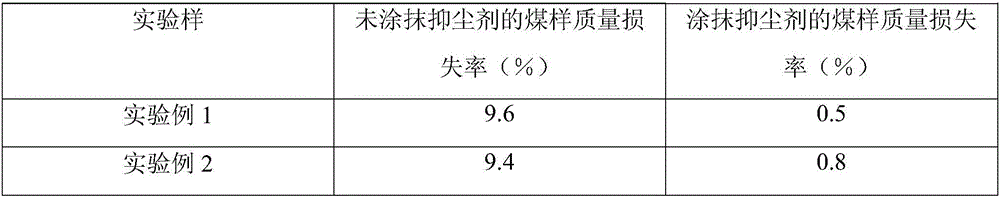

[0035] Weigh 5g of sodium lignosulfonate, 0.5g of calcium chloride, 5g of acrylamide and 0.8g of N-N methylene acrylamide, dissolve them in 100ml of water, react at a constant temperature of 50°C for 2 hours, and then add 10ml of acrylic acid and 0.06g of ammonium persulfate, react at a constant temperature of 80°C for 3 hours to obtain a gel-like substance, chop the gel-like substance, add 0.8ml of sodium secondary alkyl sulfonate, 0.3ml of hydroxyethyl cellulose, 0.3ml of castor Sesame oil polyoxyethylene ether sulfonate; 0.4ml fatty alcohol polyoxyethylene ether; 0.3ml potassium monododecyl phosphate is mixed and stirred, and the mass ratio of the obtained material and water is mixed according to the ratio of 1:50, and adjusted The PH value is 9, and the relevant performance is finally tested.

Embodiment 2

[0037] Weigh 5g of sodium lignosulfonate, 0.5g of calcium chloride, 5g of acrylamide and 0.8g of N-N methylene acrylamide, dissolve them in 100ml of water, and react at a constant temperature of 50°C for 2 hours, then add 13ml of acrylic acid and 0.06g of ammonium persulfate, react at a constant temperature of 80°C for 3 hours to obtain a gel-like substance, chop the gel-like substance, add 0.8ml of sodium secondary alkyl sulfonate, 0.3ml of hydroxyethyl cellulose, 0.3ml of castor Sesame oil polyoxyethylene ether sulfonate; 0.4ml fatty alcohol polyoxyethylene ether; 0.3ml potassium monododecyl phosphate is mixed and stirred, and the mass ratio of the obtained material and water is mixed according to the ratio of 1:50, and adjusted The PH value is 9, and the relevant performance is finally tested.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com