Light and composite multifunctional wall body and production technology thereof

A multi-functional, wall technology, applied in the field of building walls, can solve problems such as low support performance, poor wind pressure resistance, heavy wall quality, etc., achieve improved support and compression resistance, and improve wind pressure resistance , the effect of quality reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

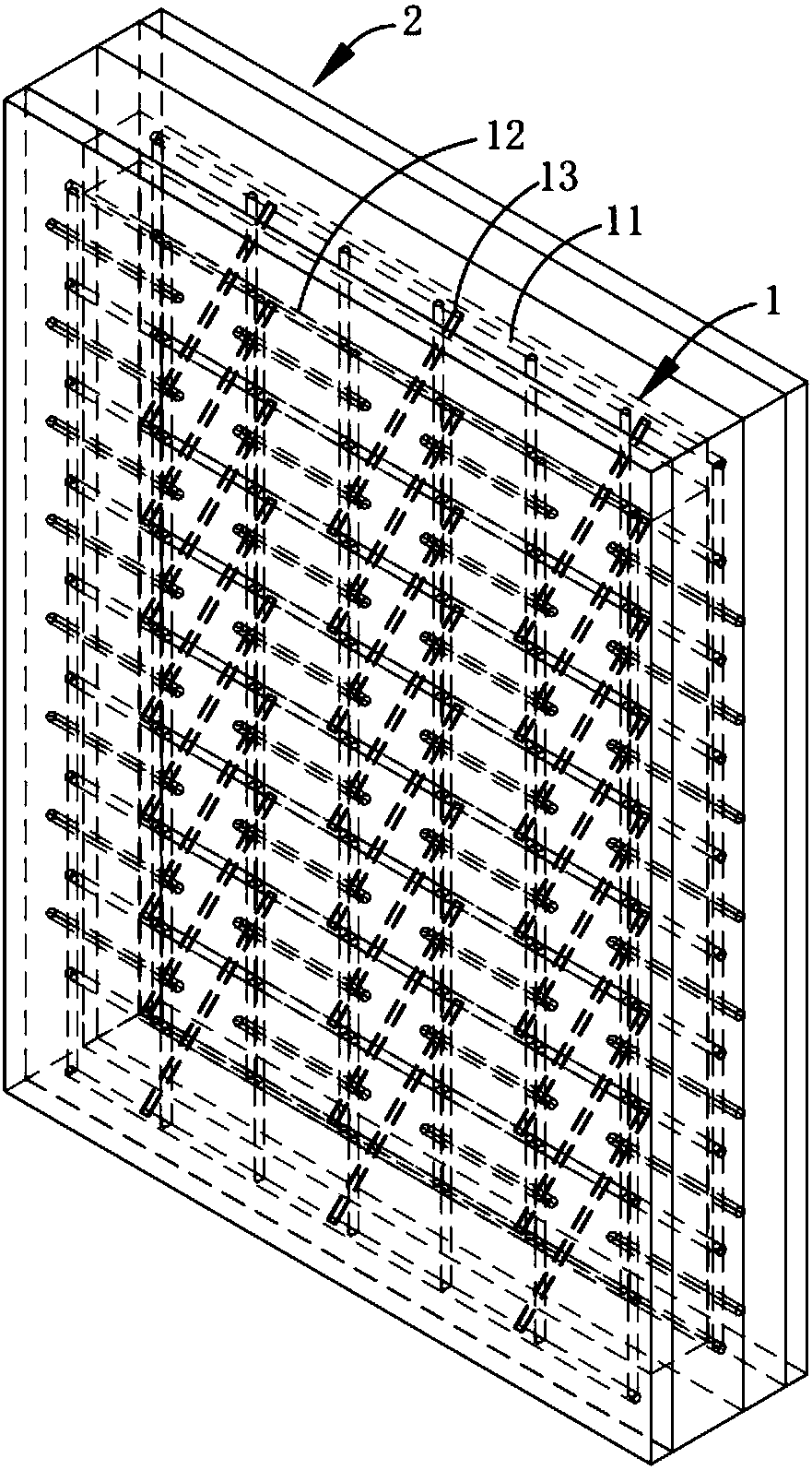

[0044] Such as figure 1 , 2 , 3 and 4, a lightweight composite multifunctional wall, including:

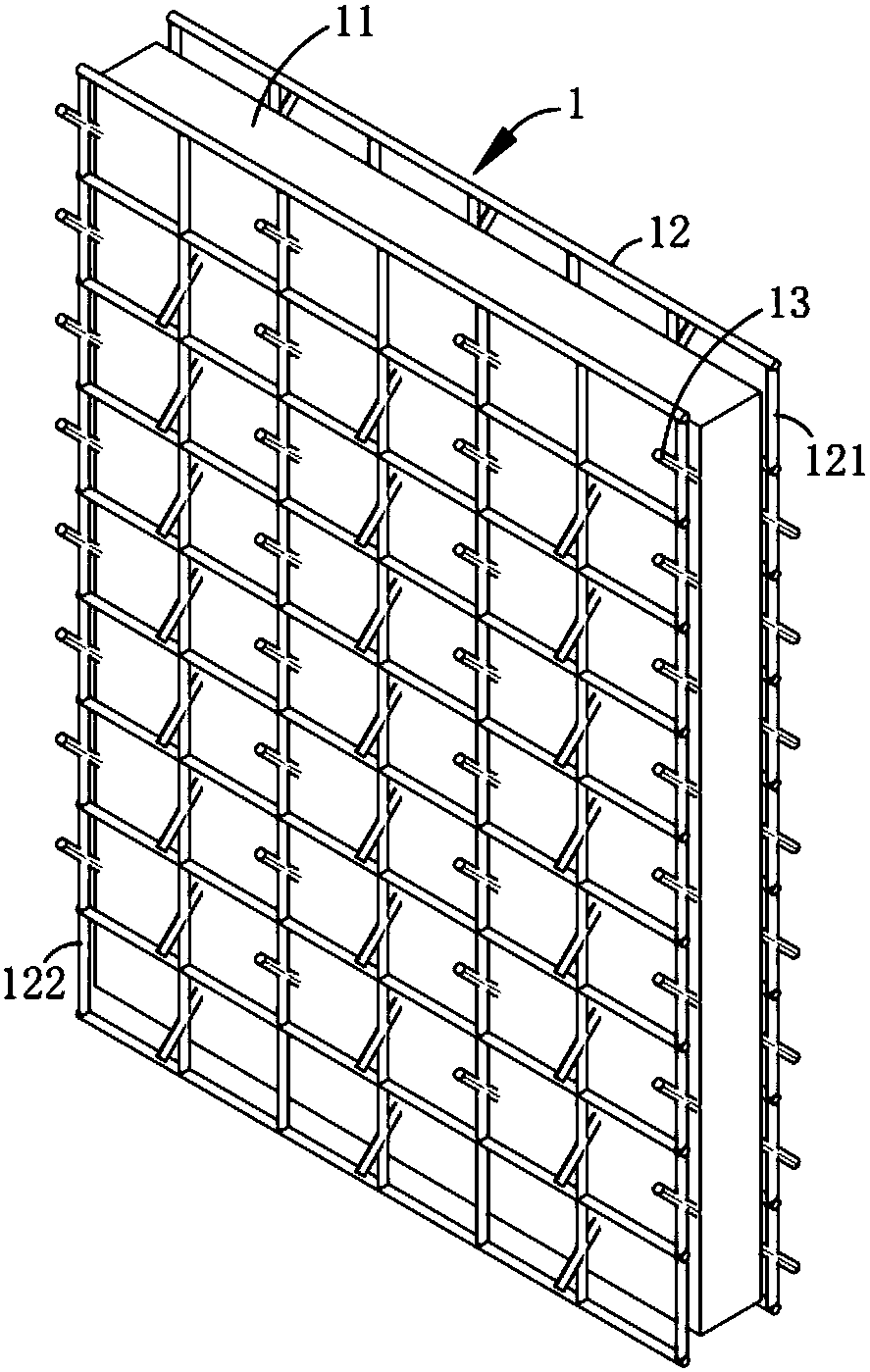

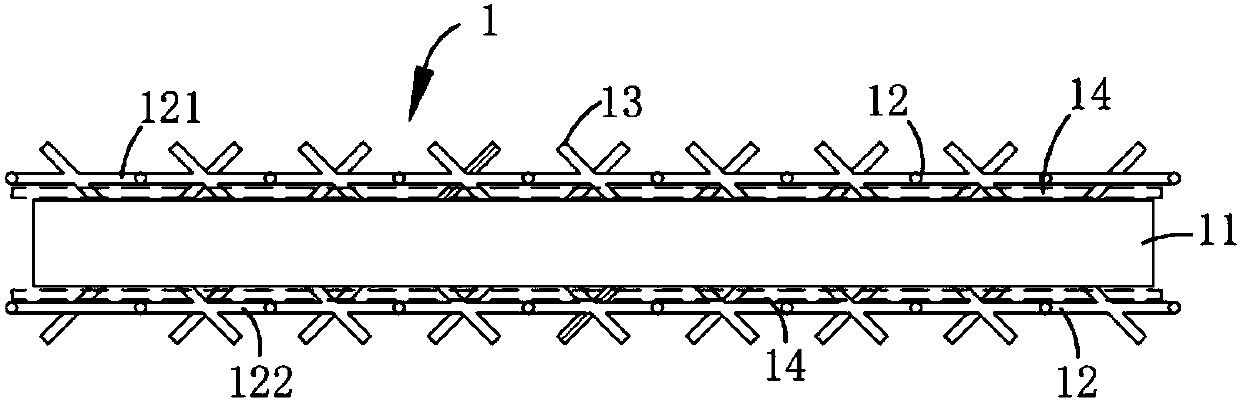

[0045] The core 1, the core 1 includes a lightweight board 11, a load-bearing structure 12 arranged on the outside of the lightweight board 11, and a plurality of support parts 13, the bearing structure 12 is formed between the surface of the lightweight board 11 An integration area 14; the support parts 13 are linearly distributed in multiple rows on the lightweight board 11, and the ends of each support part 13 respectively pass th...

Embodiment 2

[0049] Such as figure 2 , 3 and 5, wherein the same or corresponding parts with the first embodiment adopt the corresponding reference numerals with the first embodiment, and for the sake of simplicity, only the difference with the first embodiment is described below; the second embodiment is different from the first embodiment The difference is that the wall panel structure 2 includes a shell 21 cast by lightweight concrete, and the load-bearing structure 12 is a keel structure, which includes symmetrically arranged on both surfaces of the lightweight panel 11. The first frame 121 and the second frame 122, the integration area 14 formed between the first frame 121 and the second frame 122 and the lightweight board 11 are placed inside the housing 21 to form the first reinforcement part 22 respectively ; In this embodiment, the first frame 121 and the second frame 122 are grid-type frames with the same structure, and should meet the requirements in Table 1.

[0050] Table 1...

Embodiment 3

[0057] Wherein, the same or corresponding parts as in Embodiment 2 adopt the reference numerals corresponding to Embodiment 2. For the sake of simplicity, only the differences from Embodiment 2 are described below; the lightweight board 11 is foam fiber, polyester fiber One or more of cotton, plastic foam, rock wool, glass fiber wool.

[0058] Wherein, the lightweight concrete is calculated by mass percentage, and its components are: 10-30% of cement, 5-20% of yellow sand, 30-40% of filler, 0.2-1% of anti-crack auxiliary materials, 15-30% of fly ash %, additives 0.2 to 0.3%.

[0059] In addition, the filler is a spherical lightweight material, and one or more of ceramsite, aluminum granules, and high-strength plastic granules are selected; Or one or more types of metal wires.

[0060] It should be noted that lightweight concrete contains fillers and anti-crack auxiliary materials. The fillers are light materials such as spherical ceramsite, aluminum particles or high-strengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com