Volumetric wheat blender

A wheat blender, volumetric technology, applied in mixer accessories, chemical instruments and methods, dissolution and other directions, can solve the problems of high cost, high manufacturing cost, low durability, etc., and achieve high proportioning accuracy, simple structure, and cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

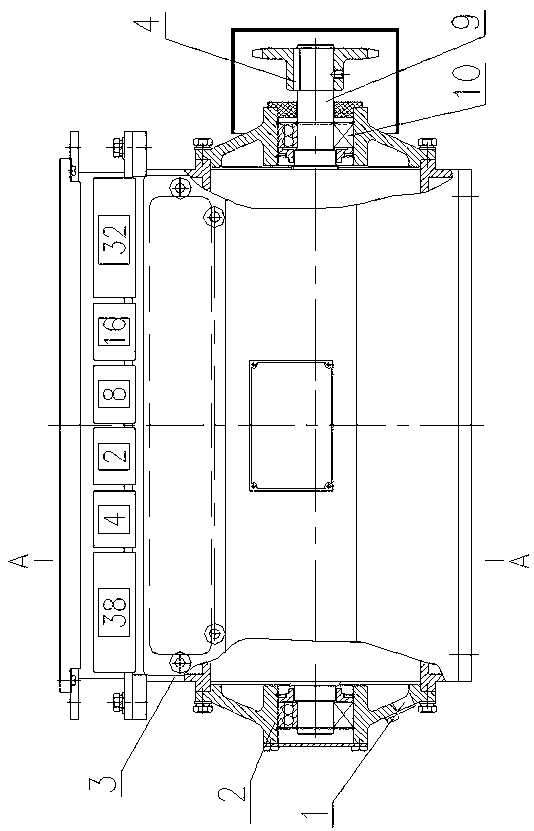

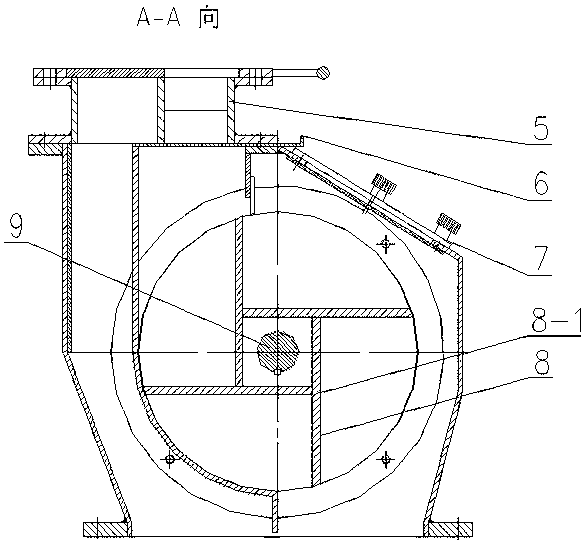

[0012] Such as figure 1 , 2 As shown, it is a volumetric microphone blender, which includes a casing 3, an observation window 7 is arranged on the upper front side of the casing 3, and a distributing body 5 is connected to the top of the casing 3, and the front side of the distributing body 5 is connected to the front side of the casing 3. Insert six matching boards 6 between the front sides. A main shaft 9 is placed on the casing 3, and the two ends of the main shaft 9 are respectively connected to the end caps 2 through bearings 10. The air supply port 1 is set, and one end of the main shaft 9 is connected with the sprocket 4 . The main shaft 9 in the casing 3 is connected to the rotor 8. The rotor 8 includes six sets of steel plate assemblies 8-1, and the six sets of steel plate assemblies 8-1 are respectively connected to the main shaft 9 along the axial direction of the main shaft 9. Each set of steel plate assemblies 8-1 They are respectively arranged under the corres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com