Multi-component proportional paint supply system and painting robot

A distribution ratio and robot technology, applied in the directions of manipulators, spray devices, manufacturing tools, etc., can solve the problems of wasting paint, stuck, and difficult to clean the pipeline, and achieve the effect of reducing system cost and high proportioning accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

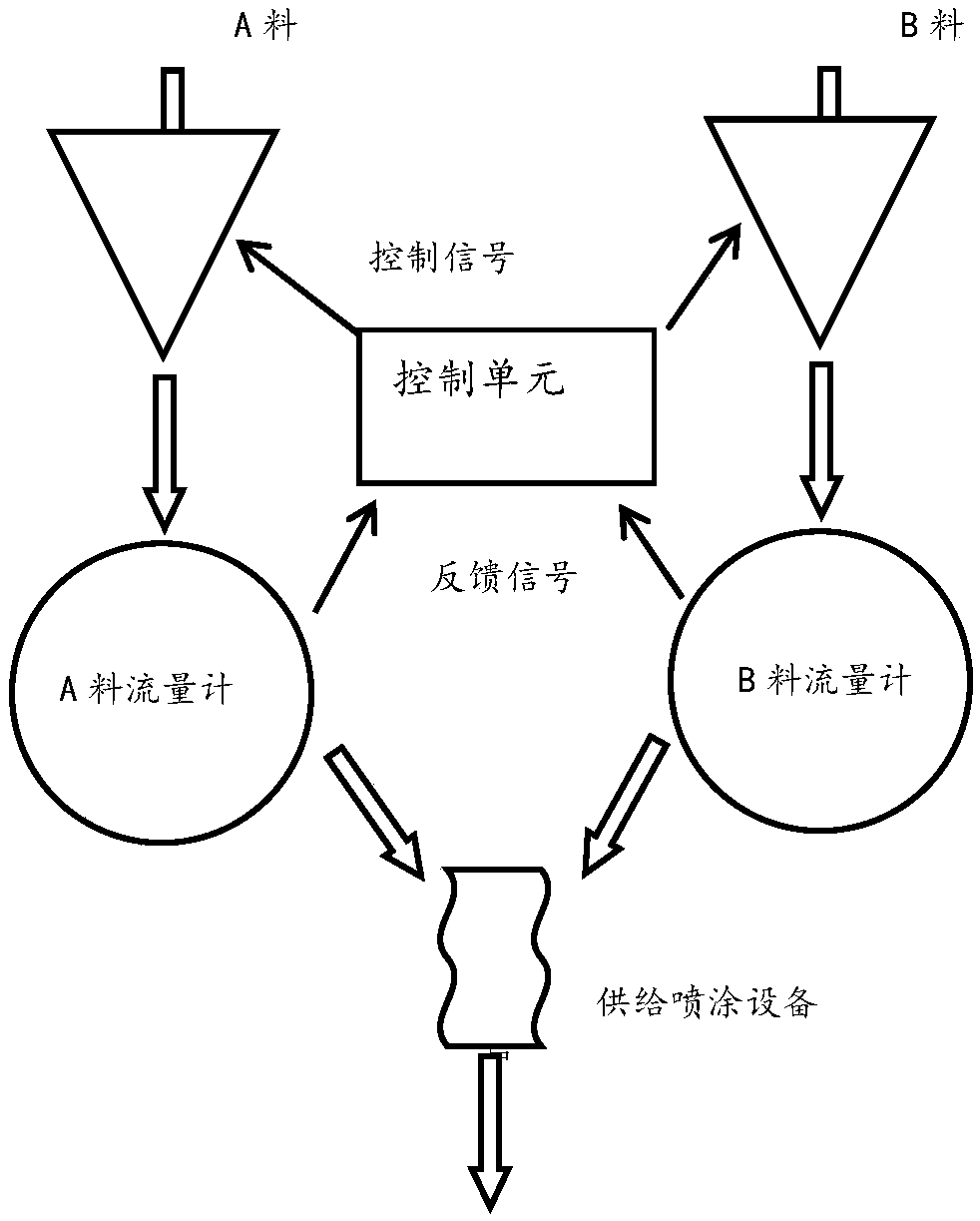

Problems solved by technology

Method used

Image

Examples

Embodiment 1

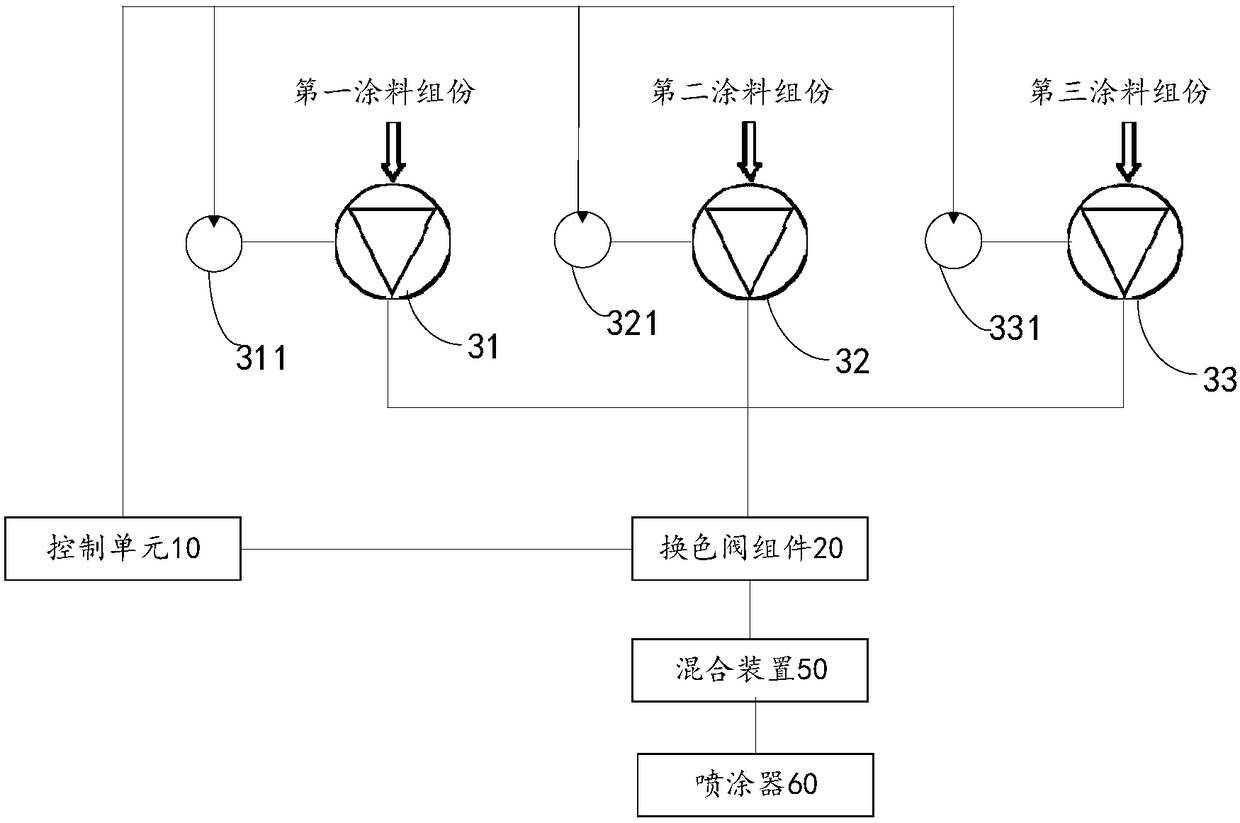

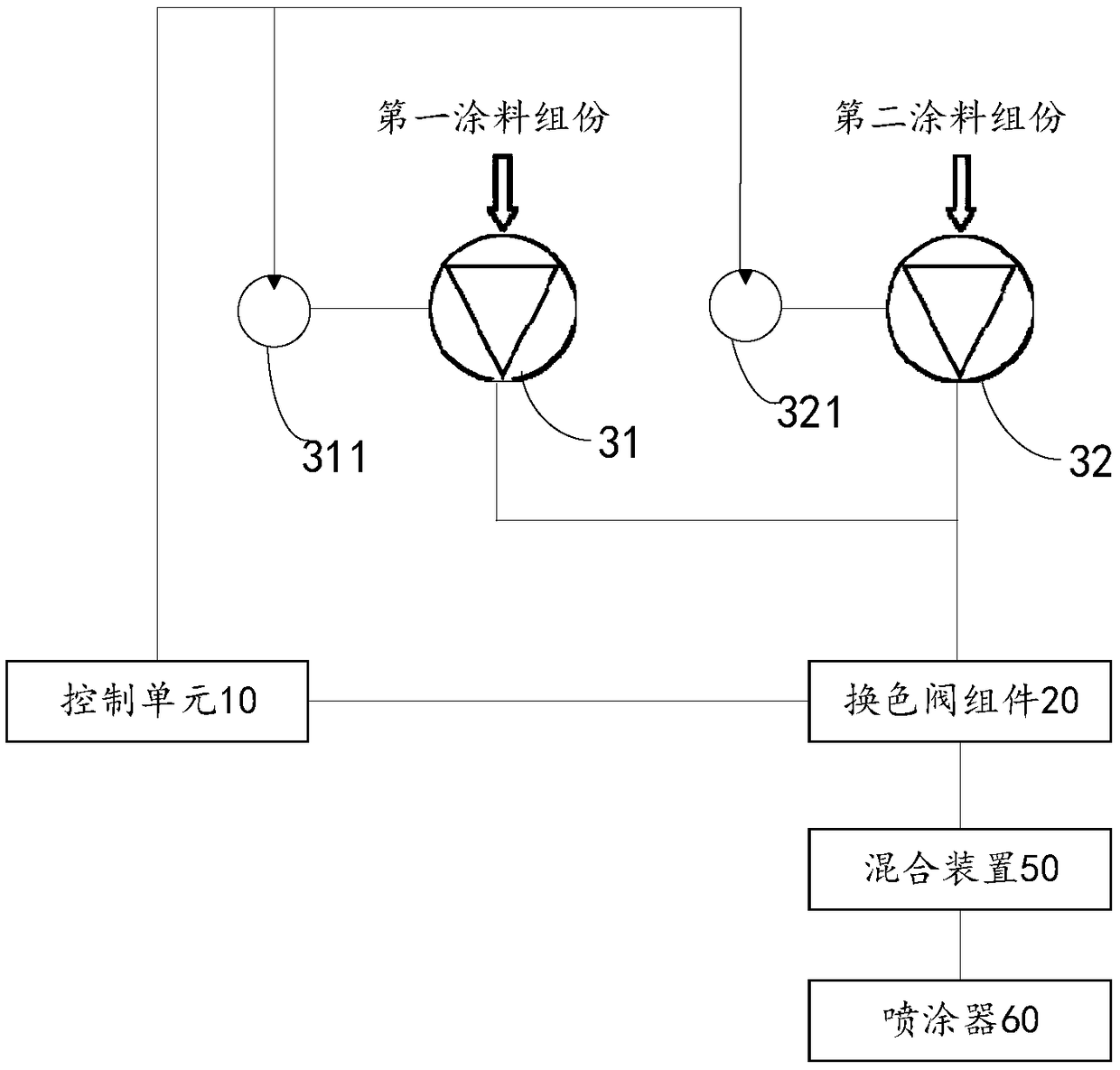

[0033] Please refer to image 3 , The multi-component distribution ratio paint supply system of this embodiment is a two-component distribution ratio paint supply system. The paint is formed by mixing two paint components, including a first paint component and a second paint component. It can be understood that the mixed paint components can be injected with more paint components according to specific spraying requirements, for example, in addition to the first paint component and the second paint component, the third paint component can also be injected in proportion , the fourth coating component, and so on. This embodiment is illustrated by taking a two-component proportional paint supply system as an example, but is not limited by paint components.

[0034] The two-component ratio paint supply system in this embodiment includes a control unit 10, and a first gear pump 31, a second gear pump 32 and a mixing device 50 set corresponding to the first paint component and the ...

Embodiment 2

[0052] The painting robot of this embodiment is used to automatically complete the painting work. The spraying robot is equipped with a spraying device 50, and the spraying device includes a spray gun. The painting robot sprays the workpiece to be sprayed.

[0053] The painting robot includes a base, a multi-dimensional motion mechanism fixed on the base, a manipulator mounted on the multi-dimensional motion mechanism, and a spraying device mounted on the manipulator. The spraying device is connected to the aforementioned multi-group distribution ratio paint supply system. During specific implementation, the spray gun is connected to the three-stage stirring pipe 56 of the mixing device 50 of the multi-component ratio paint supply system described in Embodiment 1.

[0054] Wherein, the multi-dimensional motion mechanism, the spraying device and the multi-group distribution ratio paint supply system are connected to the control unit 10 .

[0055] The control unit 10 controls d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com