Anti-static non-firing epoxy mortar floor, and construction technology and application thereof

An epoxy mortar and anti-static technology, which is applied to floors, buildings, building structures, etc., can solve the problems that the ground cannot be anti-static, non-flammable, dust-proof, clean, and has a short service life, so that the construction process is simple and easy to use. Long life, prevent electrostatic adsorption of dust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

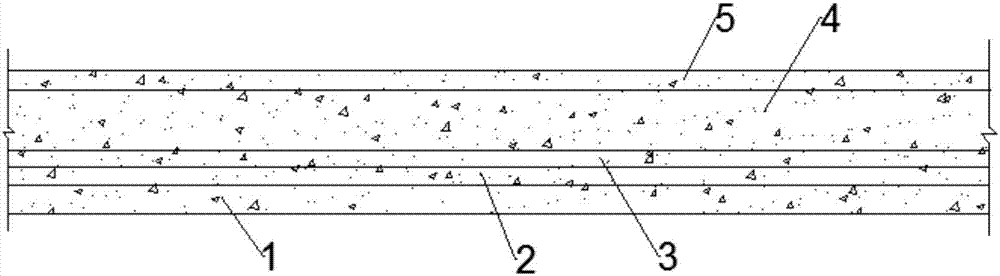

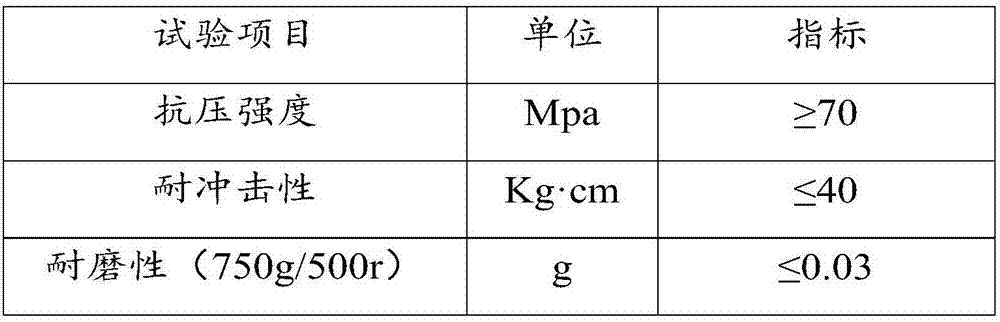

[0087] An antistatic and non-flammable epoxy mortar floor, comprising a concrete base layer, an epoxy mortar bottom layer, an epoxy mortar middle layer and an epoxy mortar surface layer laid sequentially from bottom to top, and copper wires are arranged on the epoxy mortar bottom layer , the copper wire is connected to the ground electrode;

[0088] The epoxy mortar bottom layer, the epoxy mortar middle layer and the epoxy mortar surface layer are all mainly made of epoxy mortar and conductive powder;

[0089] The epoxy mortar is mainly made of epoxy resin E-44, dolomite, No. 42.5 cement, ethylenediamine and dibutyl ester agent, epoxy resin E-44, dolomite, No. 42.5 cement, ethylenediamine and The weight ratio of dibutyl ester is 100:150:200:5:12.

Embodiment 2

[0091] A kind of antistatic non-fire epoxy mortar floor, different from embodiment 1, in the present embodiment, the weight ratio of epoxy resin E-44, dolomite, No. 42.5 cement, ethylenediamine and dibutyl ester is 100:180:280:8:15.

Embodiment 3

[0093] A kind of antistatic non-fire epoxy mortar floor, different from embodiment 1, in the present embodiment, the weight ratio of epoxy resin E-44, dolomite, No. 42.5 cement, ethylenediamine and dibutyl ester is 100:200:350:10:18.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com