Preparing process for optical fibre bio-sensor of acetylcholinesterase

A technology of acetylcholinesterase and biosensor, which is applied in the field of preparation of acetylcholinesterase optical fiber biosensor, can solve the problems of non-reusable use, long time, complicated process, etc., and achieve the effect of mechanization, accurate identification and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

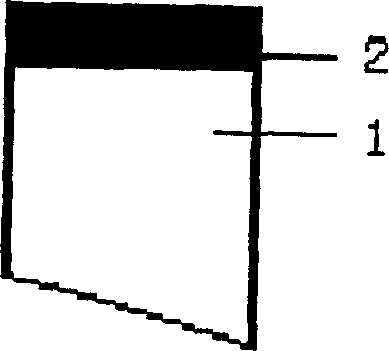

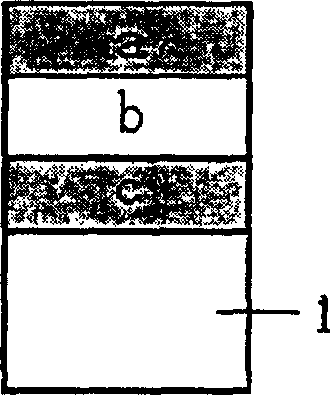

[0031] Embodiment 1: The diameter of the Y-shaped optical fiber 1 is 1 mm, and the sensing film 2 has a three-layer structure. The first layer is a Nafion polymer membrane a, the middle is a choline oxidase layer b, and the third layer is a polymer layer modified with an oxidation indicator c, and the oxygen indicator is Tris(2,2'-bipyridyl)ruthenium(II )chlorideHexahydrate. The sensing film 2 is fixed to the surface of the optical fiber head of the Y-shaped optical fiber 1 by means of covalent bonding.

Embodiment 2

[0032] Embodiment 2: The diameter of the Y-shaped optical fiber 1 is still 1 mm, and the sensing film 2 has a two-layer structure. Choline oxidase membrane and oxygen indicator membrane. The oxygen indicator membrane is 5mm(bpy) 3 2+ 1.25wt% Nafion ethanol solution was dropped onto the end face of the optical fiber and dried at room temperature. Choline oxidase solution is Nafion solution with 90%

[0033]Ethanol was diluted to a final concentration of 1%, and 3mg of choline oxidase (10 units / mg) was added to 50ul% Nafion solution. The prepared choline oxidase liquid is dropped onto the surface of the optical fiber to dry to prepare a sensing film.

Embodiment 3

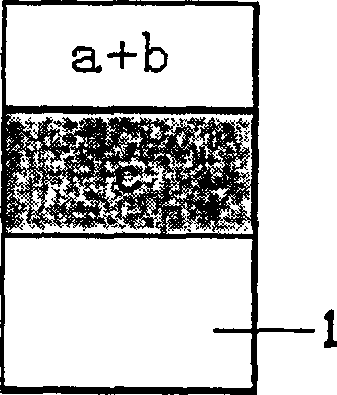

[0034] Embodiment 3: The Y-shaped optical fiber 1 has a diameter of 1 mm, and the sensing film 2 has a single-layer structure. The solutions of oxygen indicator C, choline oxidase b and PDMS polymer material a are mixed and condensed to form a monolayer film. The above-mentioned single-layer sensing film 2 is fixed to the surface of the optical fiber head of the Y-shaped optical fiber 1 by means of adsorption.

[0035] According to the acetylcholinesterase optical fiber sensor that embodiment 1 to embodiment 3 make, combine light source 3, detector 4, computer 5 and image display 6 (such as Figure 5 ), the properties of the nerve bundles of the nerve trunk 7 can be quickly, intuitively and accurately determined. The light source can be laser, light-emitting diode, mercury lamp, etc. When using a light source with a wide spectrum such as a mercury lamp, use the corresponding color filter to obtain the excitation light of the required wavelength, and the wavelength selection ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com