Online measurement method for NOx emission of coal-fired boiler

A technology of a coal-fired boiler and a measurement method, applied in the electric power field, can solve the problems of large deviation between the calculated value and the actual value, difficult to obtain data, time-consuming and labor-intensive acquisition, etc., and achieves complete model fitness, high operational reliability, and low input cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

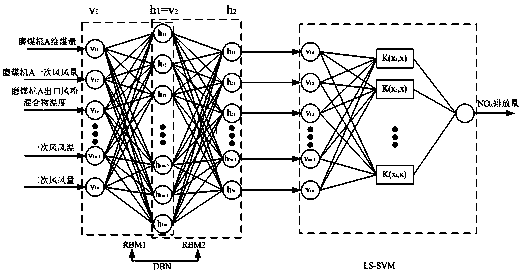

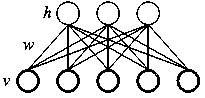

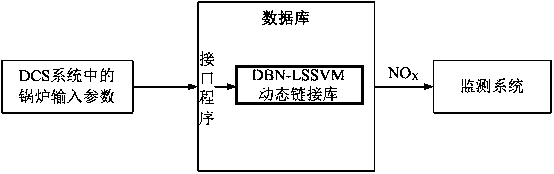

Method used

Image

Examples

Embodiment Construction

[0047] The present invention is illustrated below by way of examples.

[0048] 1. Get sample data

[0049] Establish a multi-working-condition model data set based on test data, composed of test data, simulation optimization data and DCS data. The input parameters of the data set include: the coal feed rate of each coal mill, the particle size of coal powder, the primary air volume of each coal mill, the temperature of the air-powder mixture at the outlet of each coal mill, the secondary air volume of the furnace, and the primary and secondary air volume. temperature, pulverized coal particle size, and overfire air rate. The input parameters of the sample data set are denoted as x i , the corresponding NO X The emission value is the sample data label, denoted as y i , get the sample data set The sample data set is divided into a test set and a training set, where the training set accounts for 80% of the total data set and the test set accounts for 20%.

[0050] 2. Offli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com