Anti-static anti-radiation fireproof textile fabric with patterns

A fire-resistant fabric and anti-radiation technology, applied in the field of textile fabrics, can solve the problems of human loss, fabrics without patterns, endangering lives, etc., and achieve the effects of good anti-static performance, improved comprehensive performance, and enhanced safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

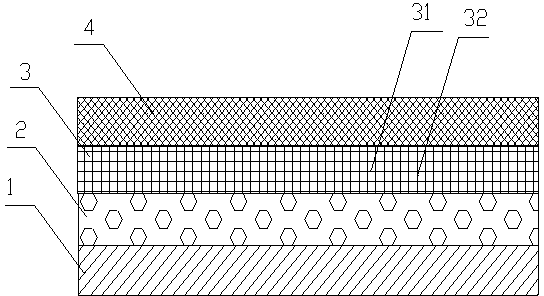

[0017] see figure 1 , the present invention relates to an antistatic anti-radiation fireproof fabric with a pattern, which includes a base layer 1, the upper surface of the base layer 1 is bonded with a layer of aluminum alloy film 2 through an adhesive, and on the aluminum alloy film 2 An antistatic layer 3 is provided, and the antistatic layer 3 is woven with warp yarns 31 and weft yarns 32. The warp yarns 31 are made of cotton yarns, and the weft yarns 32 are made of conductive fibers. 5-10mm, and the outer surface of the antistatic layer 3 is provided with a fireproof layer 4, and the fireproof layer 4 is made of CVC flame-retardant fabric.

[0018] In a preferred embodiment of the present invention, an antistatic agent is added to the antistatic layer 3 . It can eliminate all kinds of static electricity accumulation and bacteria caused by friction on the fabric, and prevent static electricity interference and dust adhesion.

[0019] The base layer is made of fabric, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com