Anti-static and anti-bacterial radiation-resistant patterned fabric

An anti-radiation and anti-static technology, applied in the field of textile fabrics, can solve the problems of mechanical properties such as great differences in ductility and tensile strength, fabrics without patterns, and human health hazards, so as to improve comprehensive performance and antibacterial efficiency , harm reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

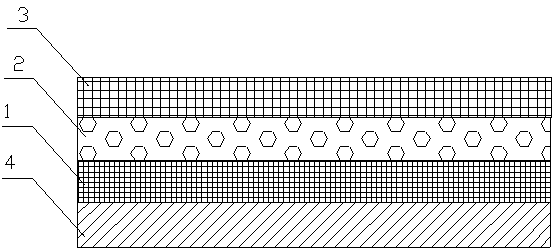

[0015] see figure 1 , the present invention relates to an antistatic, antibacterial and anti-radiation fabric with a pattern, which includes a bottom layer 4, and a base layer 1 is compounded on the surface of the bottom layer 4, and the base layer 1 is made by connecting warp yarns and weft yarns, and the warp yarns and weft yarns are made of The upper surface of the base layer 1 is bonded with a layer of aluminum alloy film 2 through an adhesive, and an antistatic layer 3 is arranged on the aluminum alloy film 2. The antistatic layer 3 is composed of warp yarns and The weft yarns are mutually woven, the warp yarns are made of cotton yarns, the weft yarns are made of conductive fibers, and the conductive fibers are striped with a spacing of 5-10mm.

[0016] In a preferred embodiment of the present invention, an antistatic agent is added to the antistatic layer 3 . It can eliminate all kinds of static electricity accumulation and bacteria caused by friction on the fabric, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com