Patents

Literature

185results about How to "Meet production and processing needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

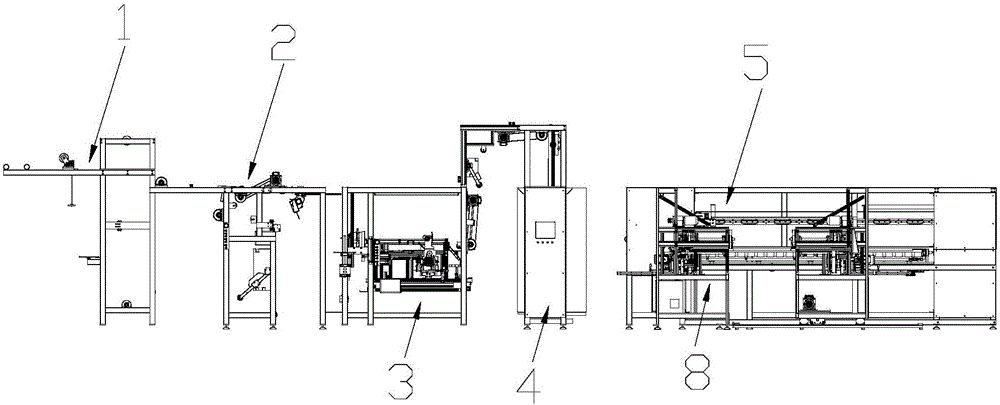

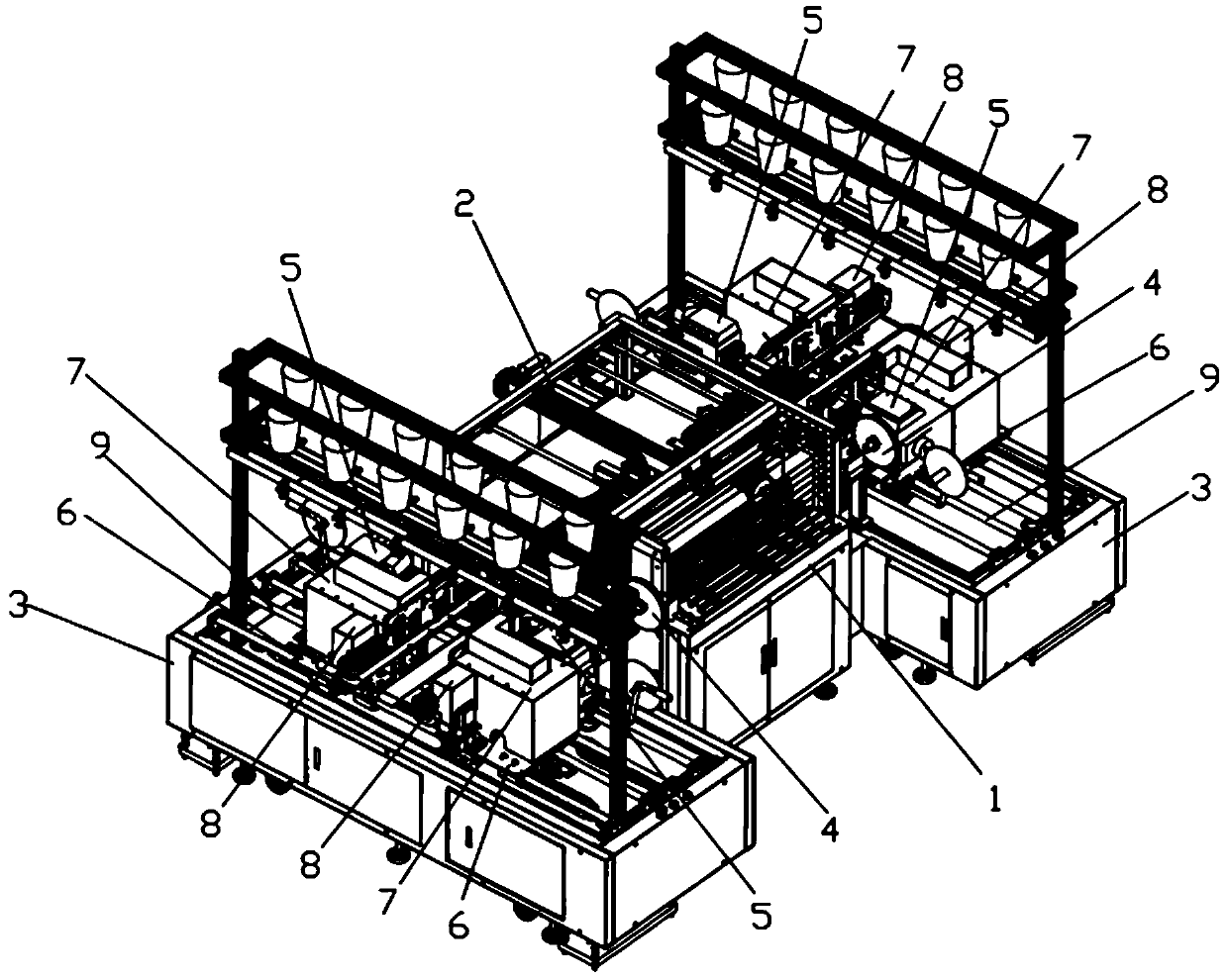

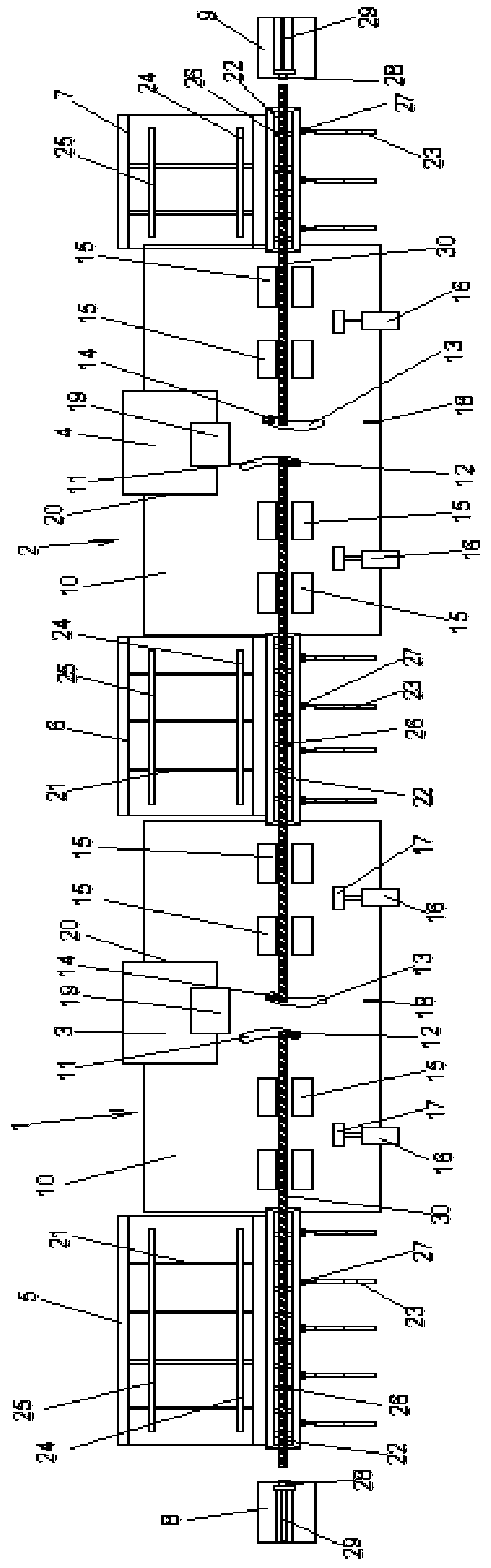

Full-automatic pillowcase machine

ActiveCN107435189AReasonable structure layoutMeet production and processing needsMechanical cleaningPressure cleaningEngineeringAssembly line

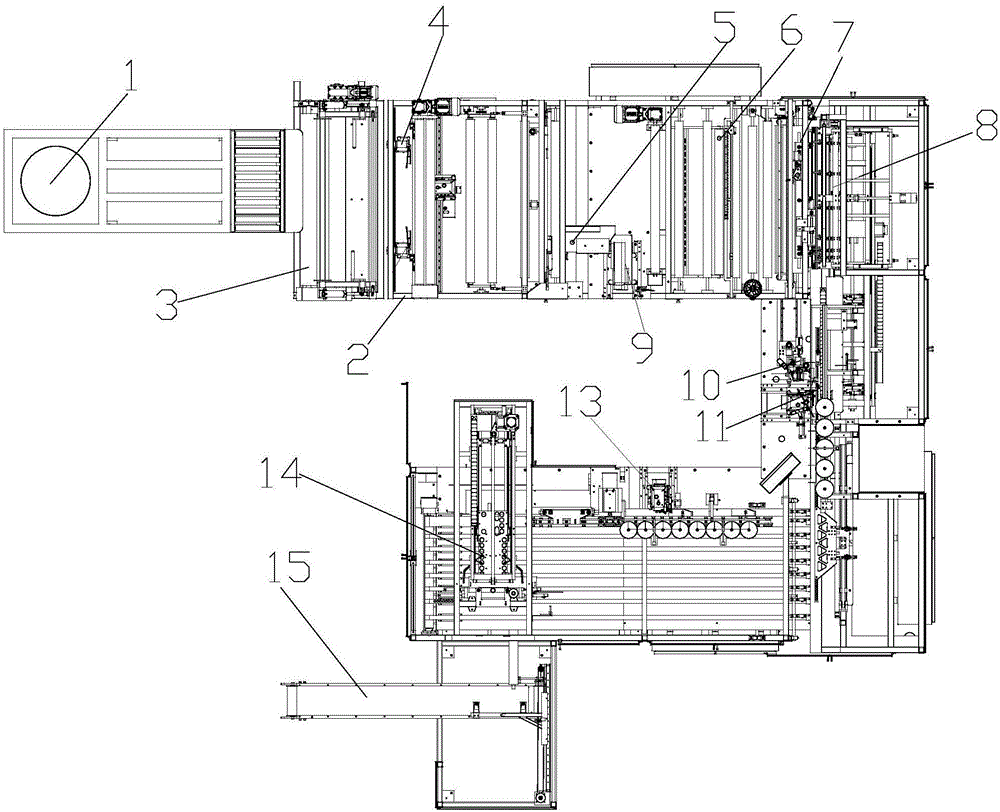

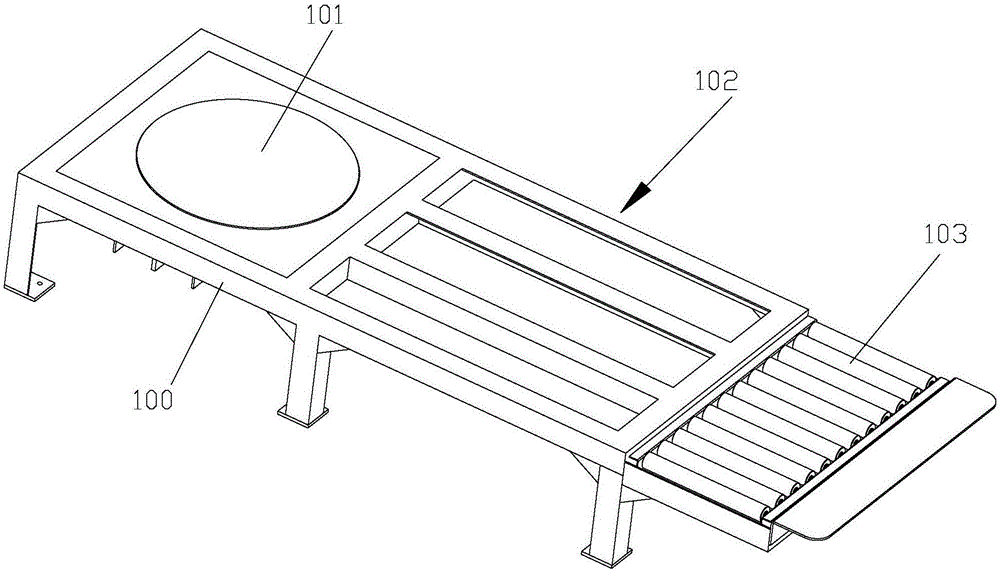

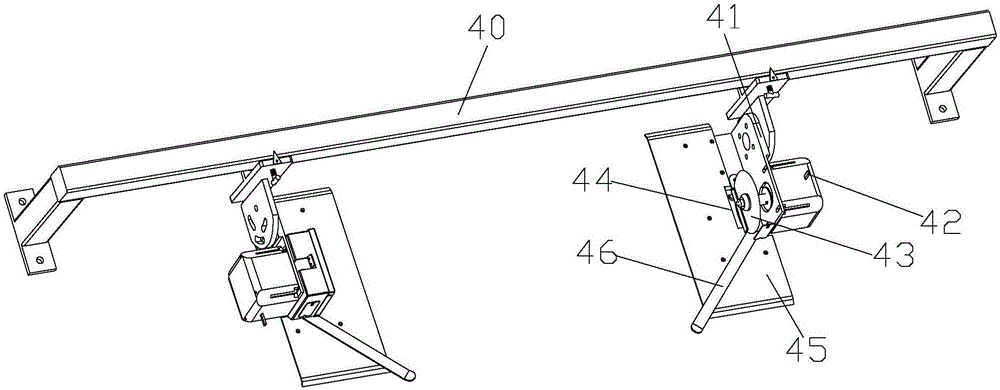

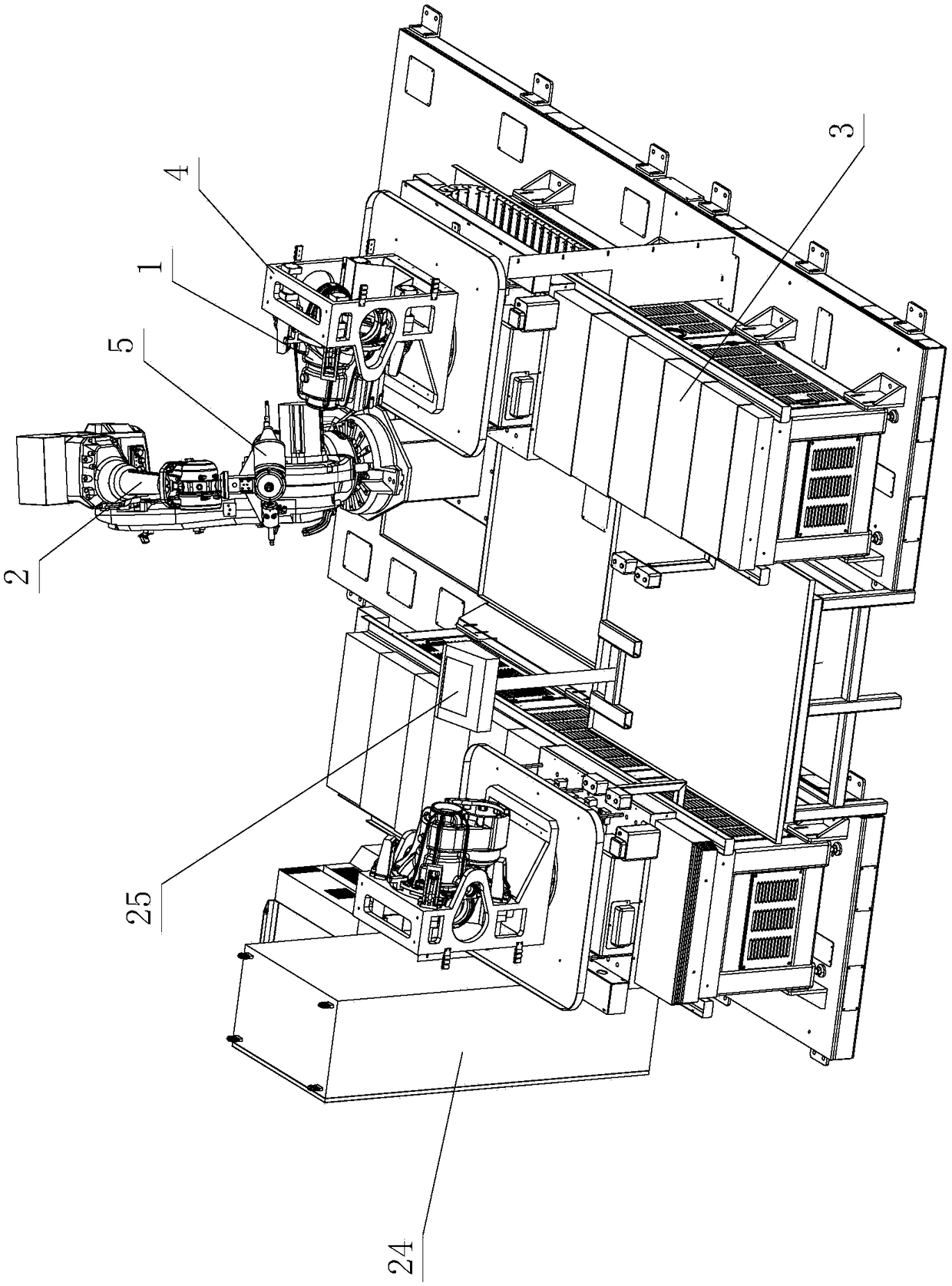

The invention relates to a full-automatic pillowcase machine. The machine comprises a feeding buffer area, a machine frame, a feeding component, a trimming device, an edge folding device, a sewing machine, a cloth slow storing mechanism, a correction device, a fixed-length cloth cutting-off mechanism, a label feeding device, a first binding-off device, a second binding-off device, a bag turning device and a collecting device, wherein the feeding component, the trimming device, the edge folding device, the sewing machine, the cloth slow storing mechanism, the correction device, the fixed-length cloth cutting-off mechanism, the label feeding device, the first binding-off device, the second binding-off device, the bag turning device and the receiving device are arranged on the machine frame; the feeding buffer area is located on one side of the machine frame; the feeding component, the trimming device, the edge folding device, the cloth slow storing mechanism, the correction device and the fixed-length cloth cutting-off mechanism are sequentially distributed on the machine frame; the label feeding device and the first binding-off device which are longitudinal distributed are arranged at the lower end of the fixed-length cloth cutting-off mechanism; the second binding-off device and the bag turning device are transversely distributed are arranged on one side of the lower end of the first binding-off device; the collecting device is arranged at the lower end of the bag turning device. The full-automatic pillowcase machine is reasonable in overall structural layout, assembly line processing of pillowcases can be automatically completed, the production efficiency is high, and the machine meets actual production and processing requirements.

Owner:SUZHOU TRANSPARENT TECH CO LTD

Food cutting equipment

The invention discloses a food cutting device, which comprises a working box and a belt. A hot water tank is fixedly connected to the left side of the top of the working box. Both sides of the hot water tank are fixedly connected with heating blocks, the bottom of the hot water tank is connected with a nozzle, the bottom of the nozzle penetrates the top of the working box and extends to the inner cavity of the working box, and the left side of the working box is provided with a feeding port The bottom on the right side of the feed inlet is fixedly connected with a slanting block, the left side of the feed inlet is fixedly connected with a feed hopper, and the inner cavity of the working box is respectively movably connected with a first roller shaft and a second roller shaft through bearings. The present invention can efficiently and evenly cut meat through the cooperation of working box, belt, hot water tank, feed port, conveyor belt, blade, first motor, turntable, connecting rod structure, discharge port and discharge box. Into small pieces, which reduces the labor cost of the production enterprise and can meet the production and processing needs of the enterprise.

Owner:翟端

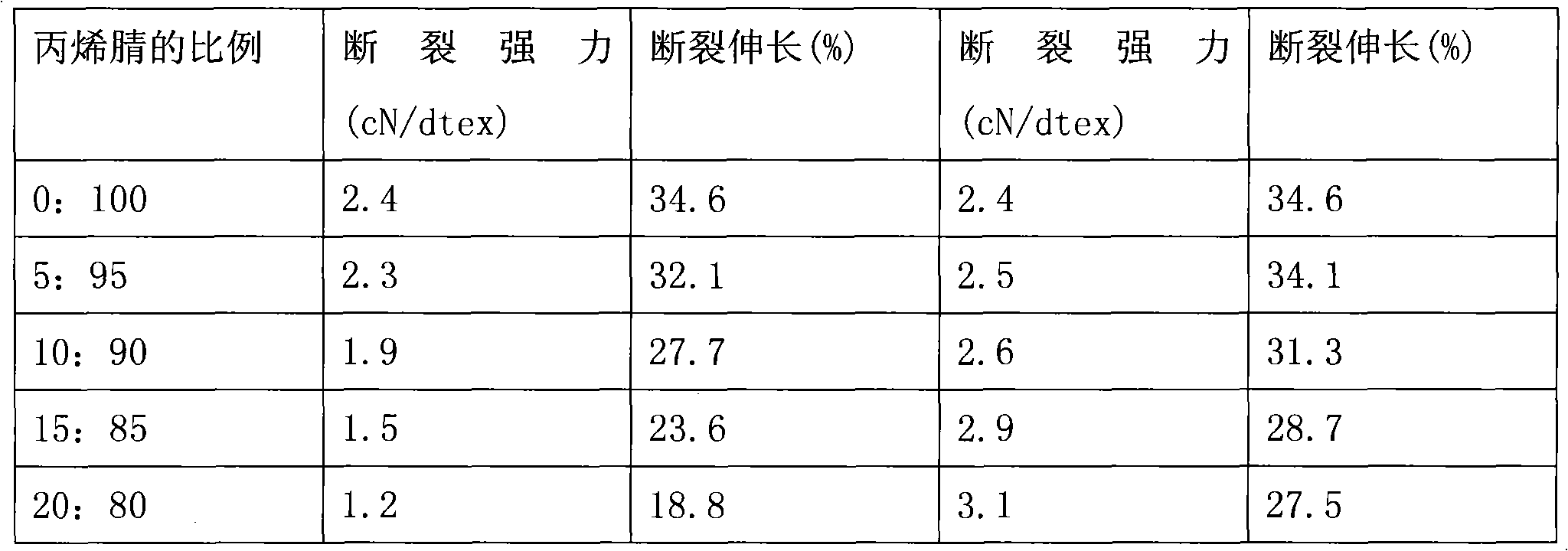

Complex fiber modified by keratin whiskers and preparation method thereof

InactiveCN101525781APlay a reinforcing roleMeet the needs of production and processingWet spinning methodsMonocomponent synthetic polymer artificial filamentFiberPolymer science

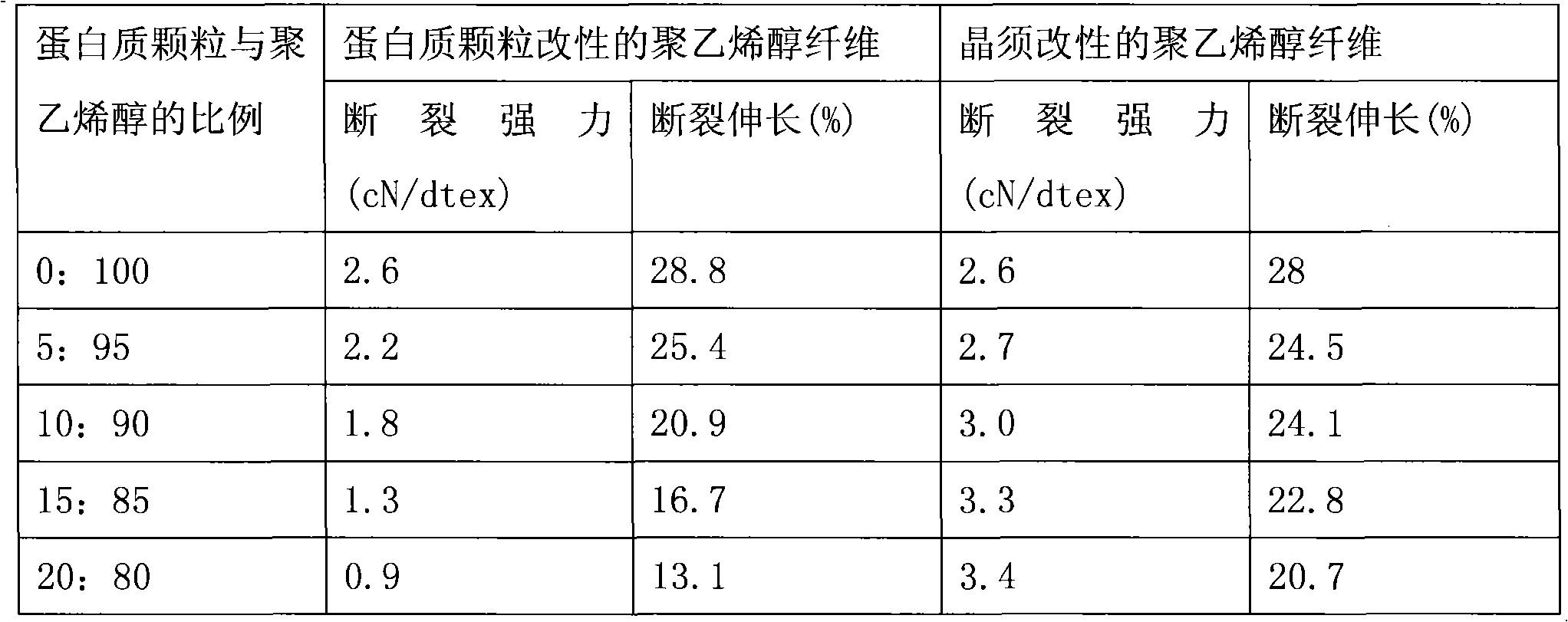

The invention provides complex fiber modified by keratin whiskers and a preparation method thereof. The complex fiber modified by keratin whiskers consists of a high molecular material and the keratin whiskers extracted from natural keratin fiber and distributed in the high molecular material, wherein, weight ratio of the keratin whiskers to the high molecular material is 5-20:80-95, and the keratin whiskers are oriented along an axial direction of the fiber in the complex fiber. The complex fiber has mechanical properties meeting production and processing needs, and obviously improved hygroscopicity, dyeability, ultraviolet resistance and static resistance properties. Protein whiskers can be prepared from waste wool or other animal fiber materials without spinning value, and has wide sources of raw materials, low cot and simple processing. The production of whiskers modified complex fiber by wet spinning or dry spinning has the same processing course as the traditional process, is easy to be industrialized and has significant economic benefit.

Owner:DONGHUA UNIV

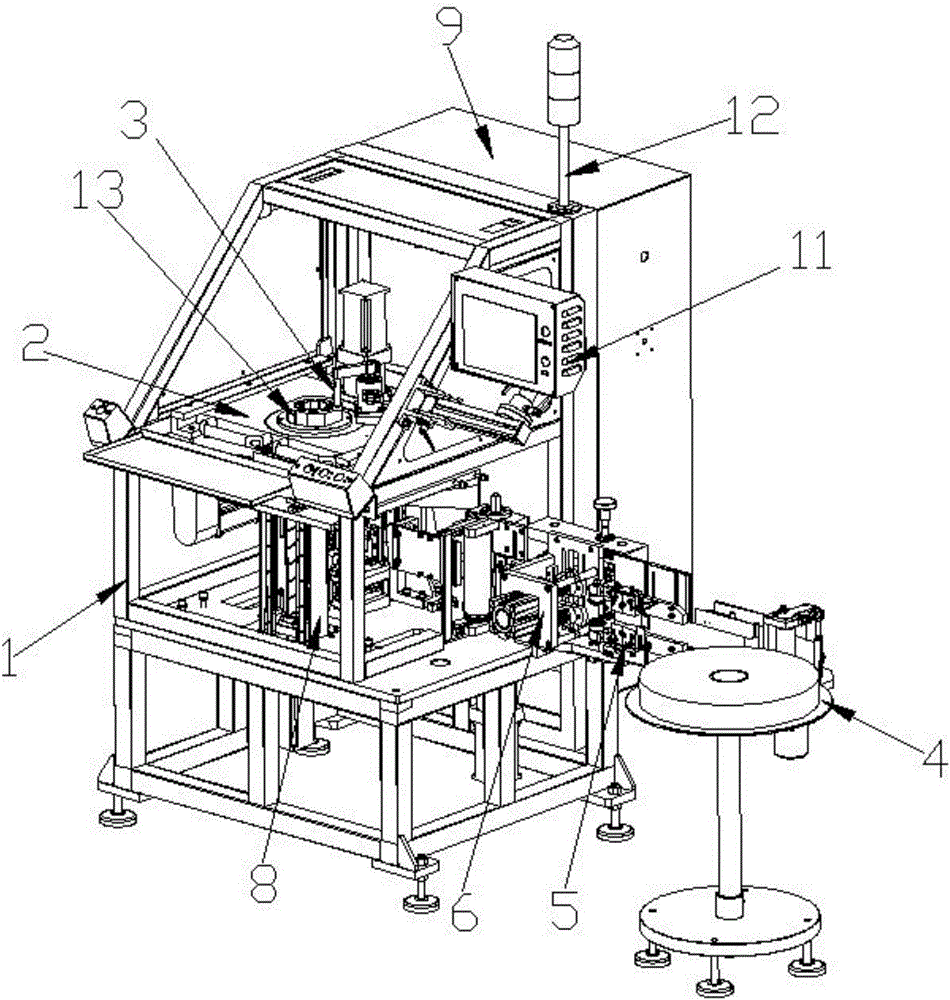

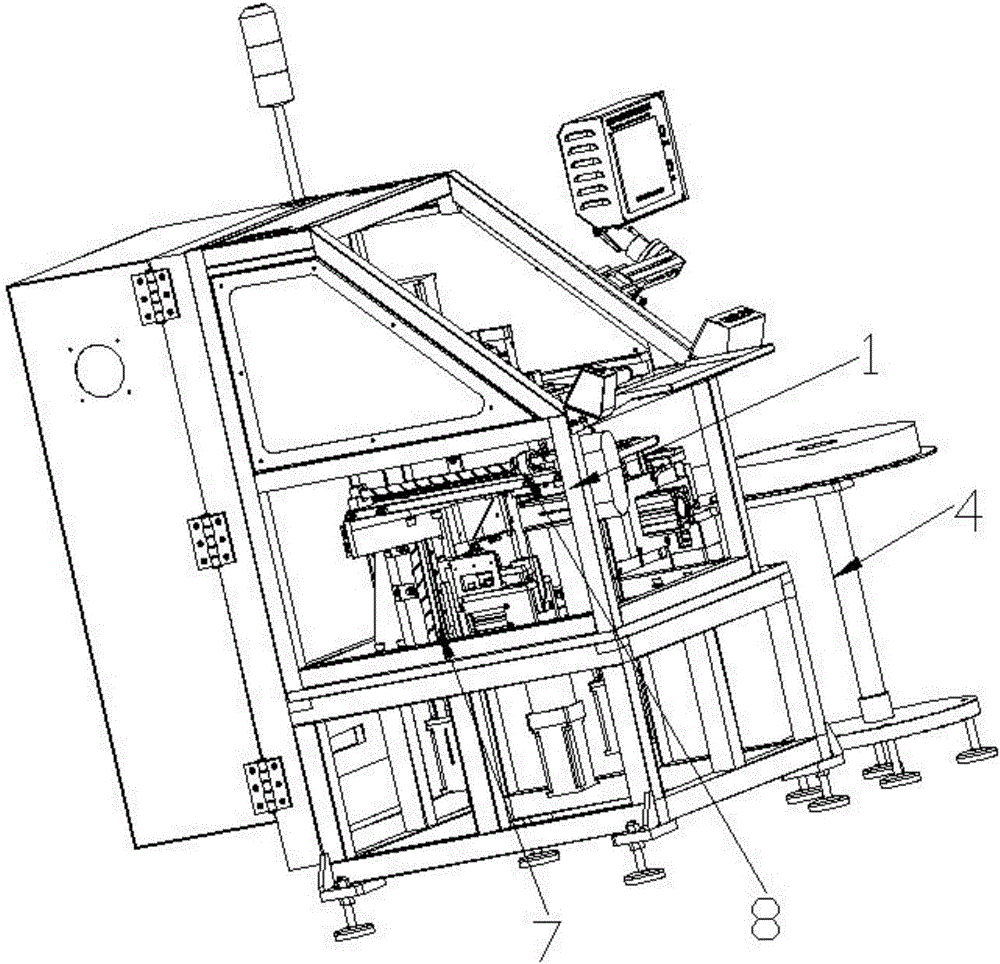

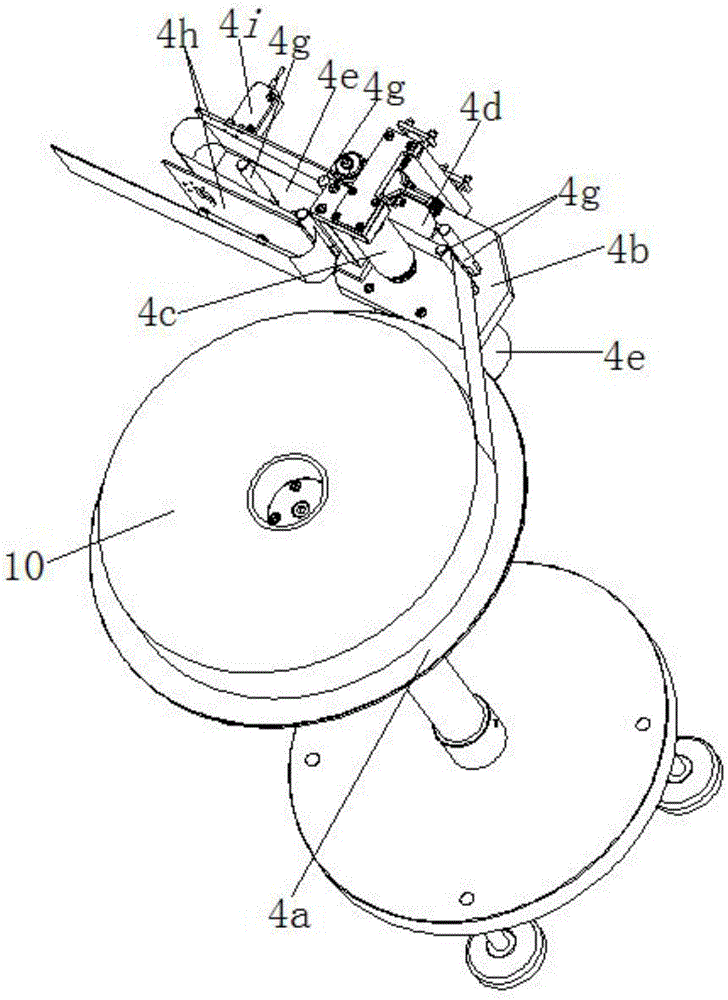

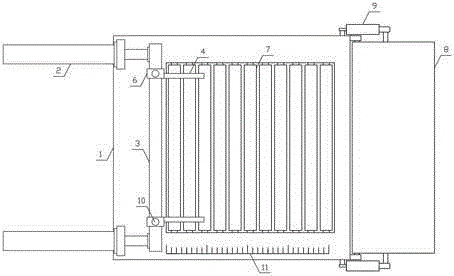

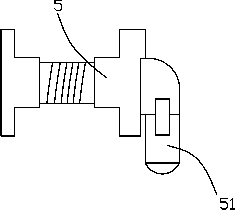

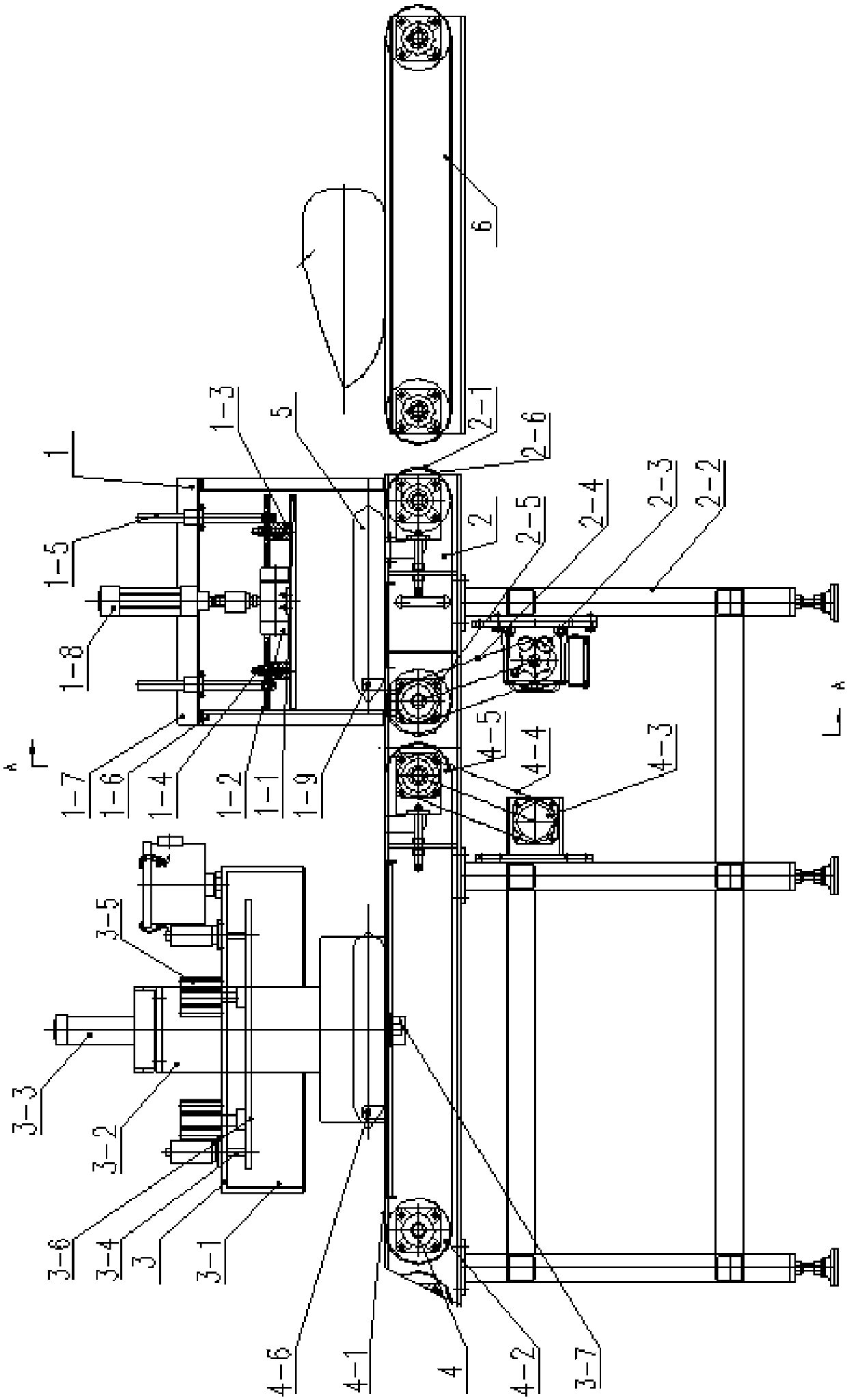

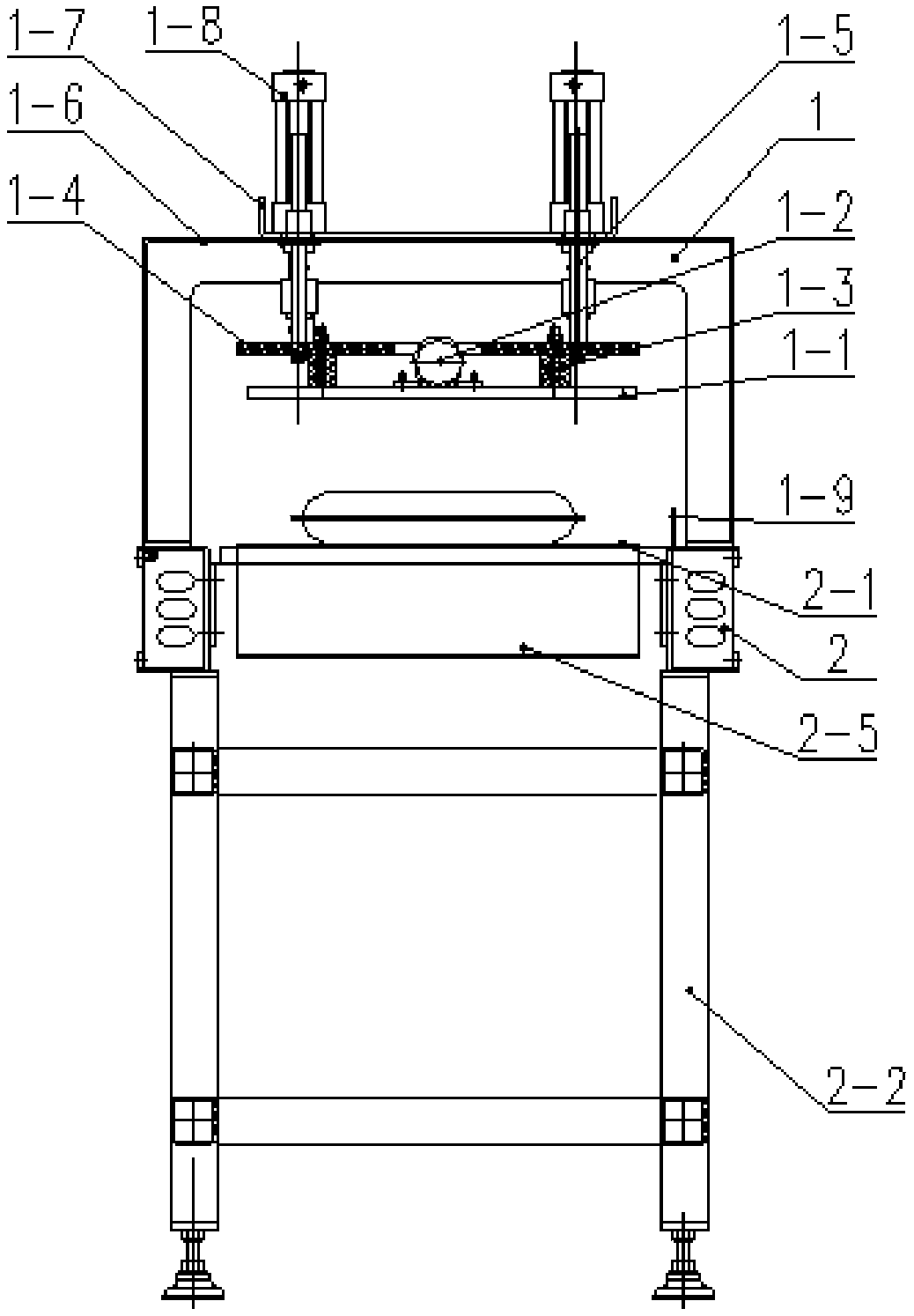

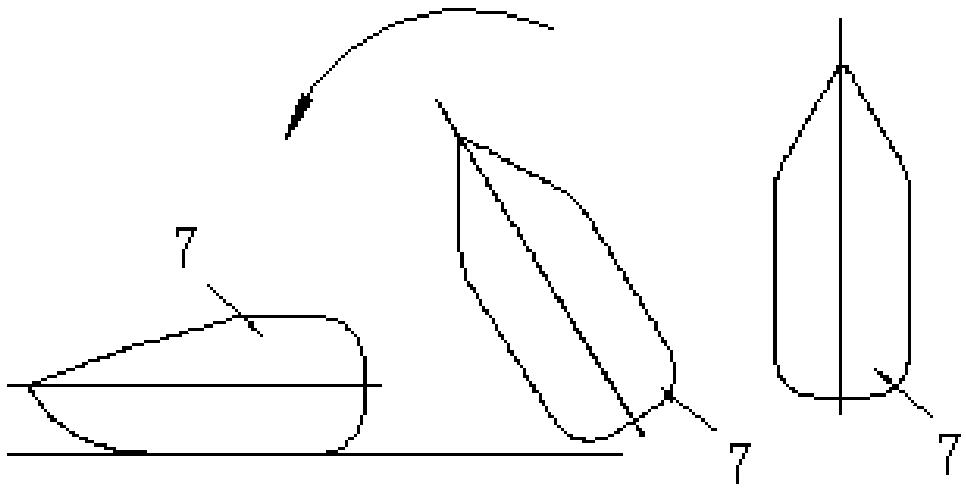

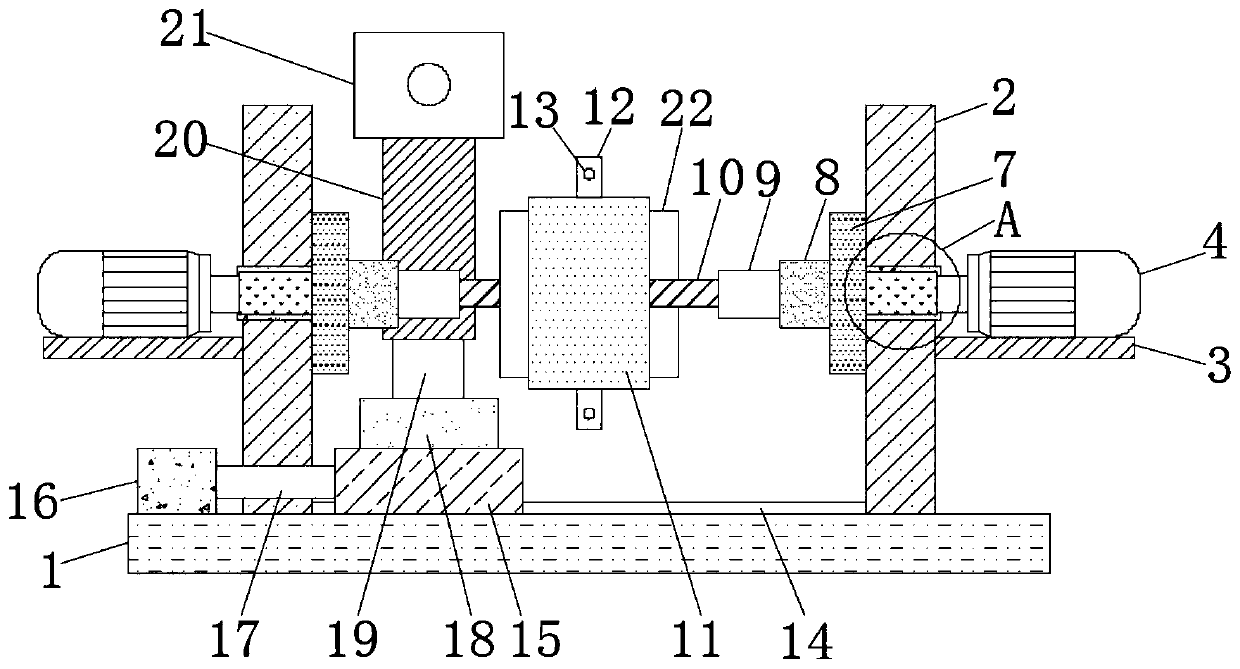

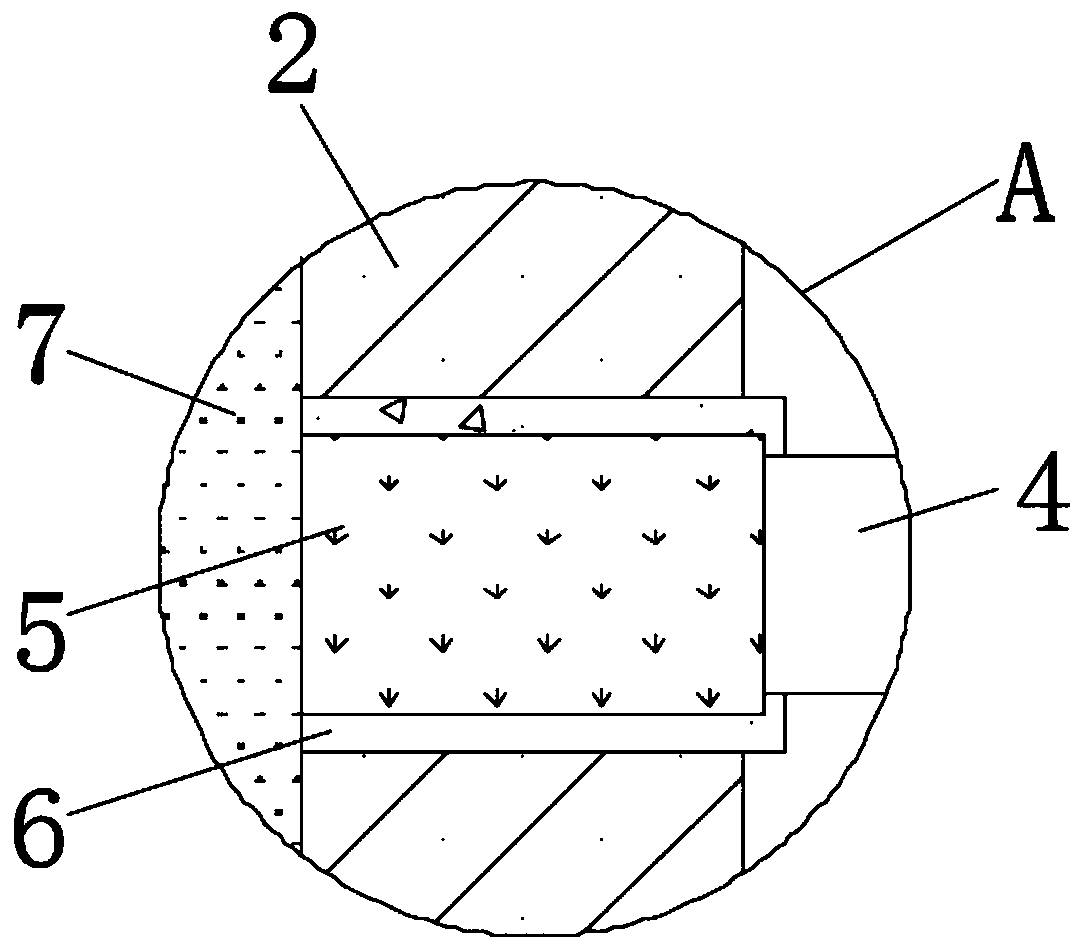

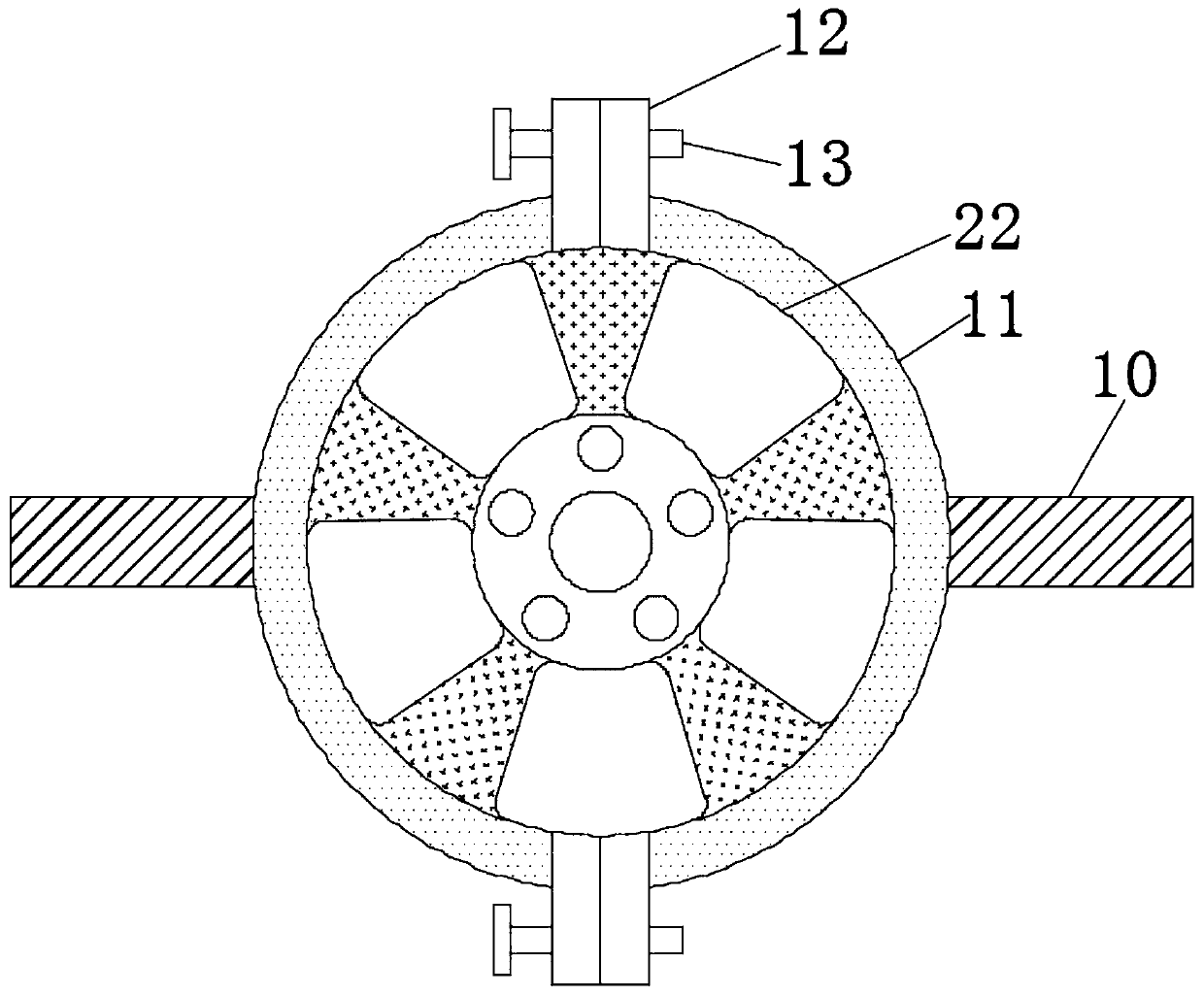

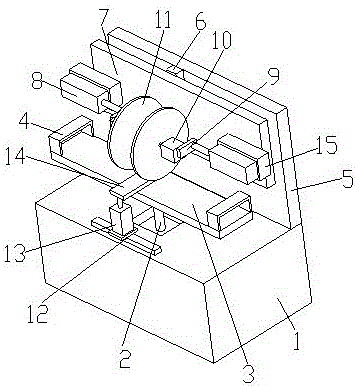

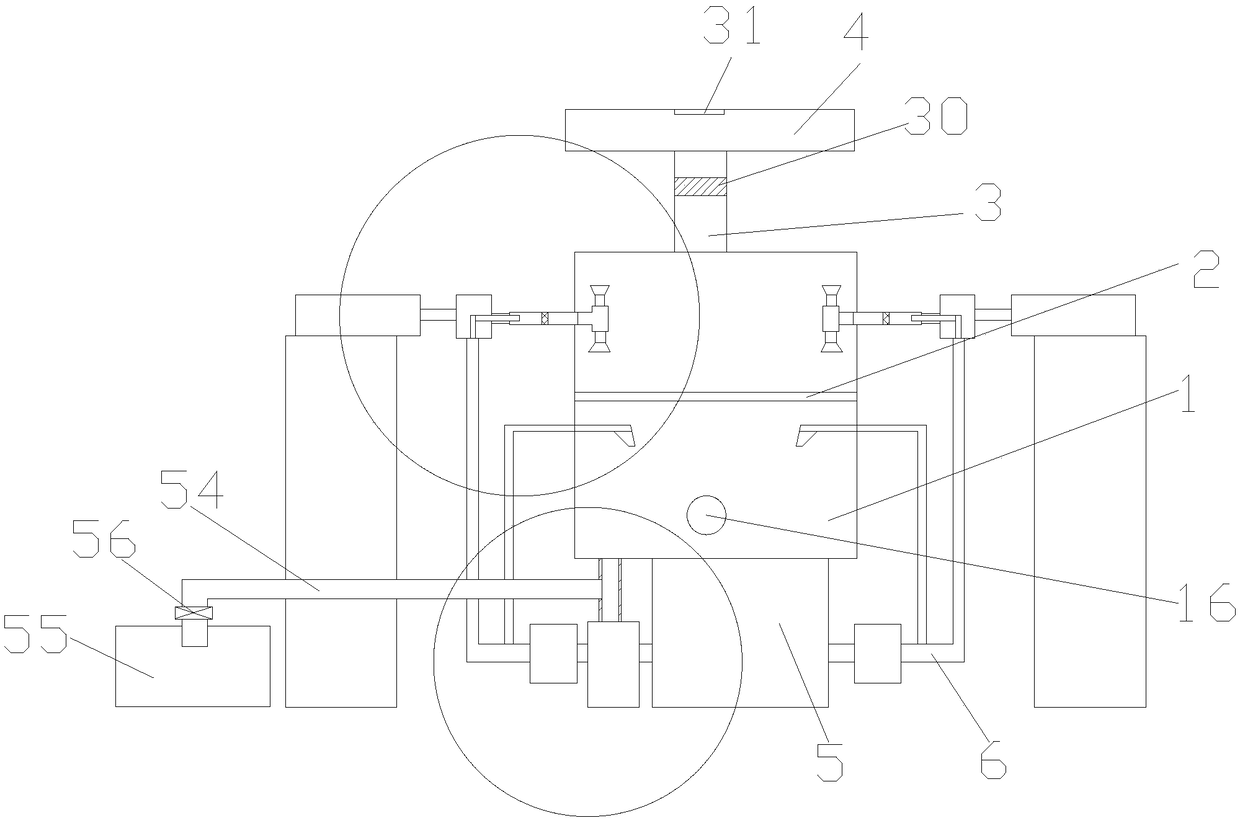

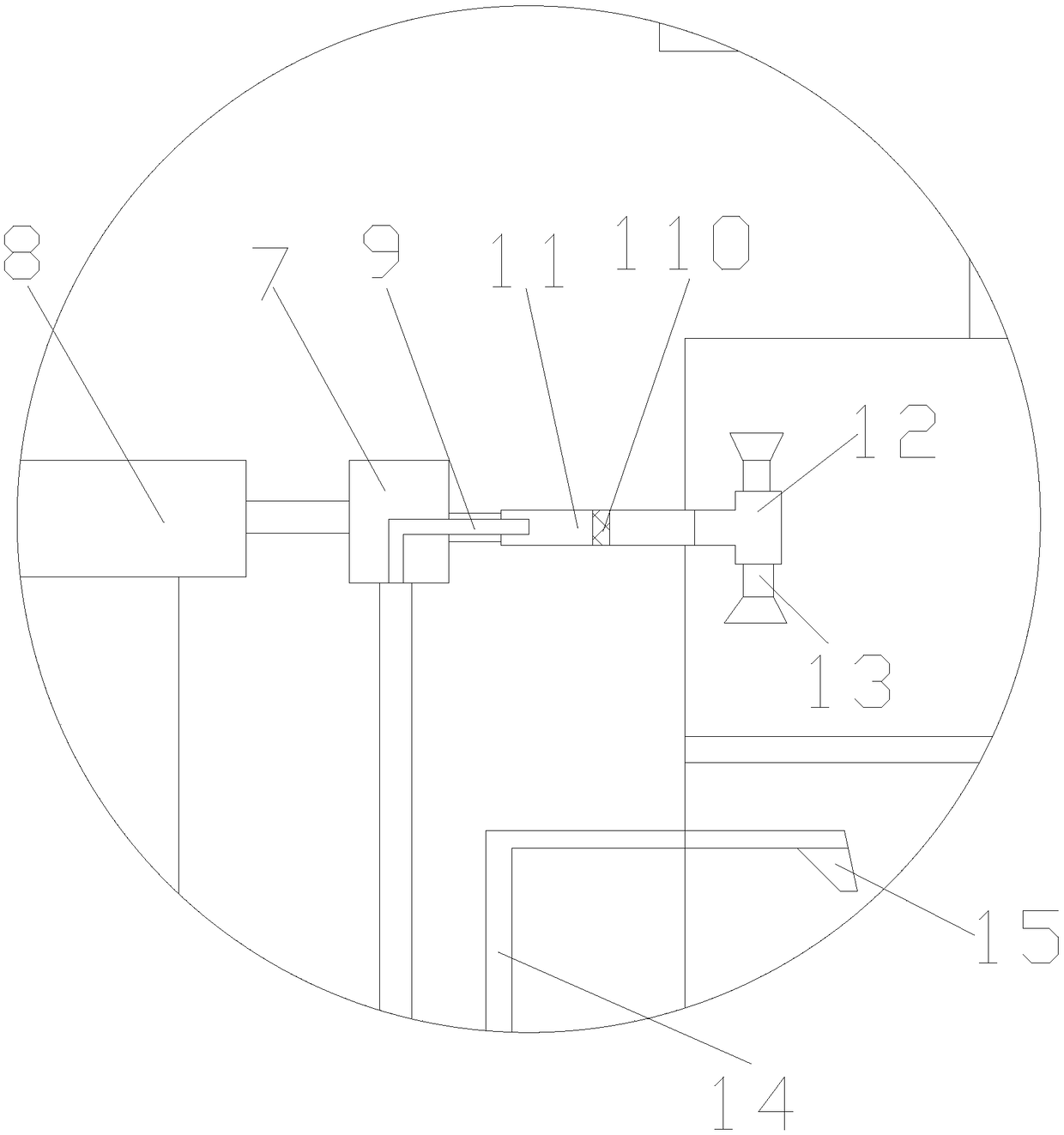

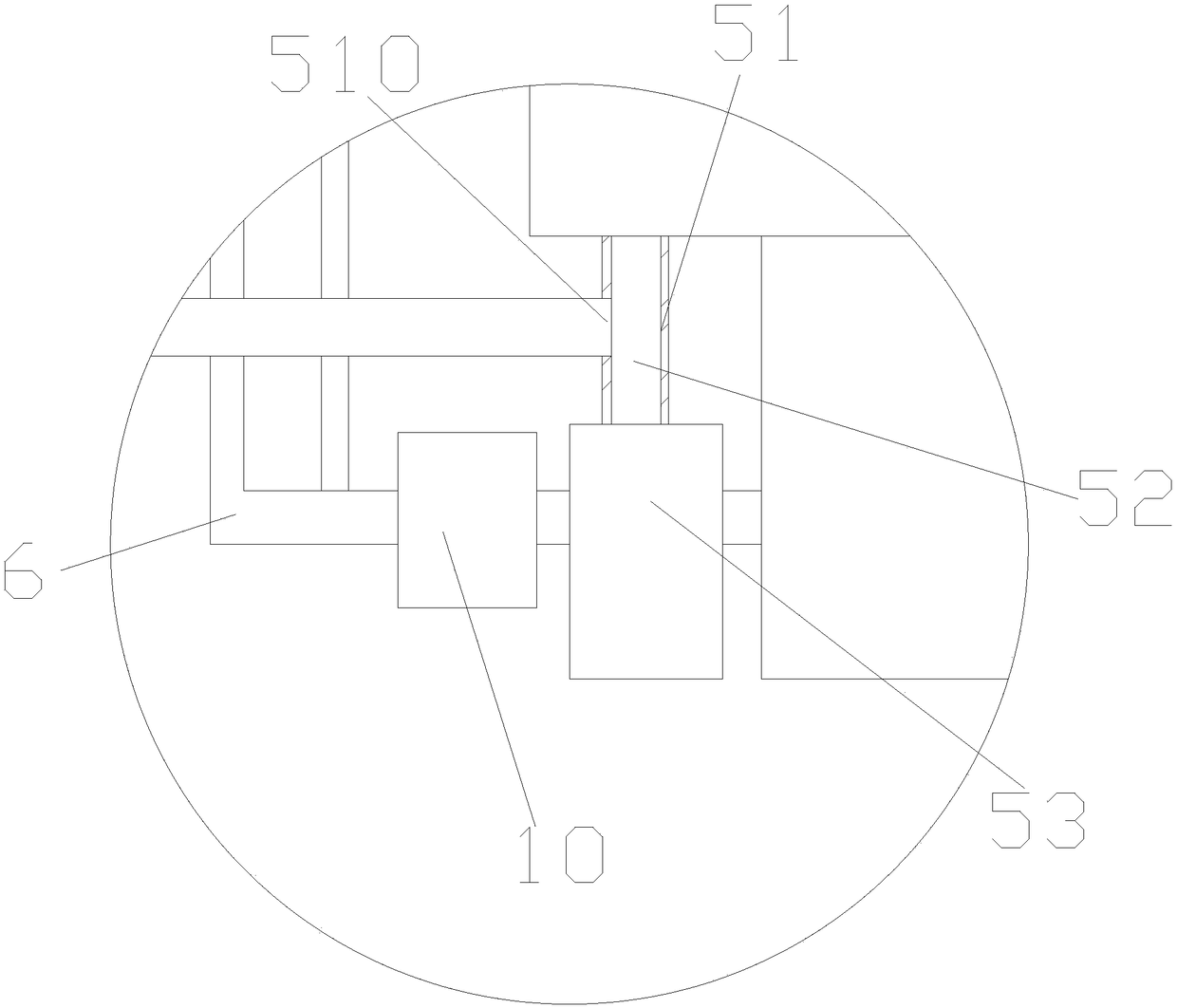

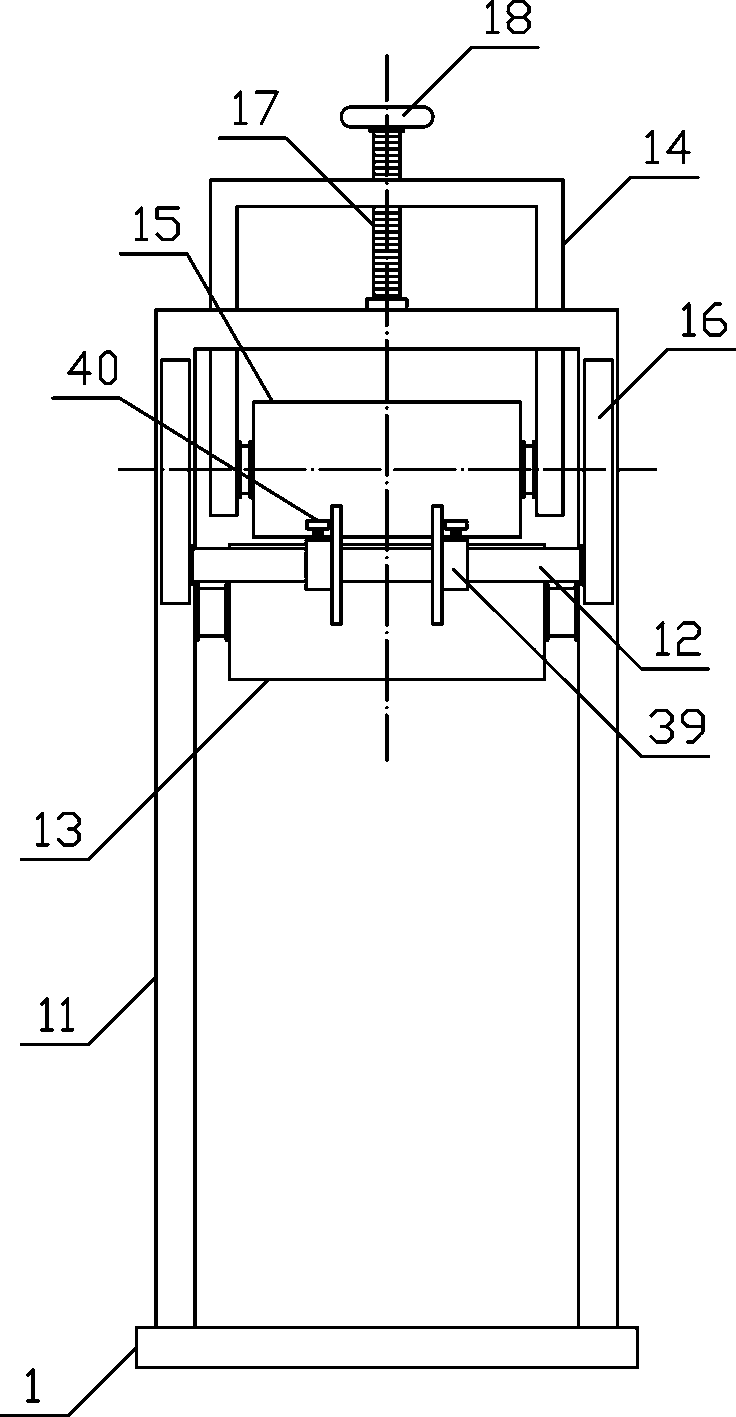

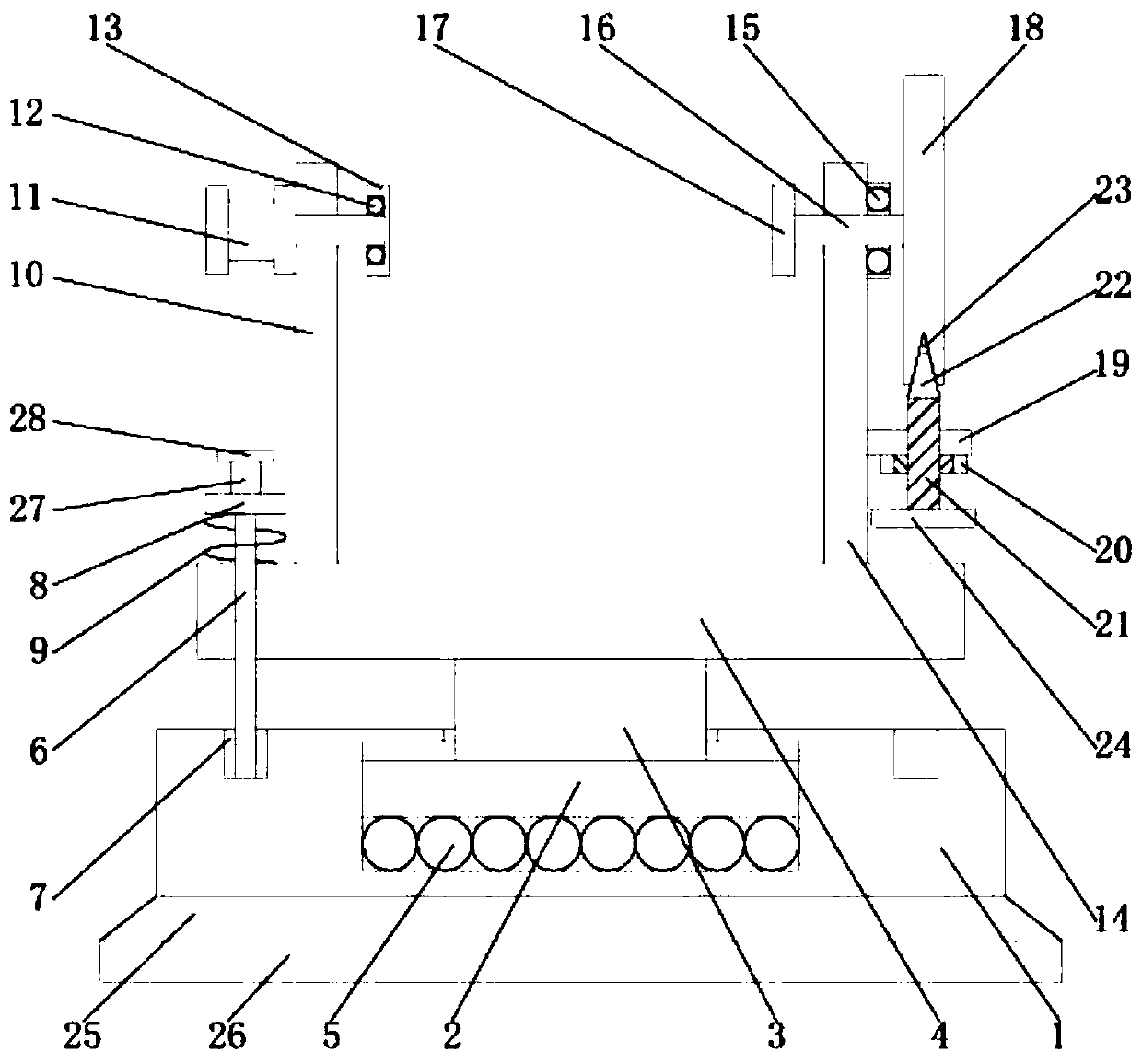

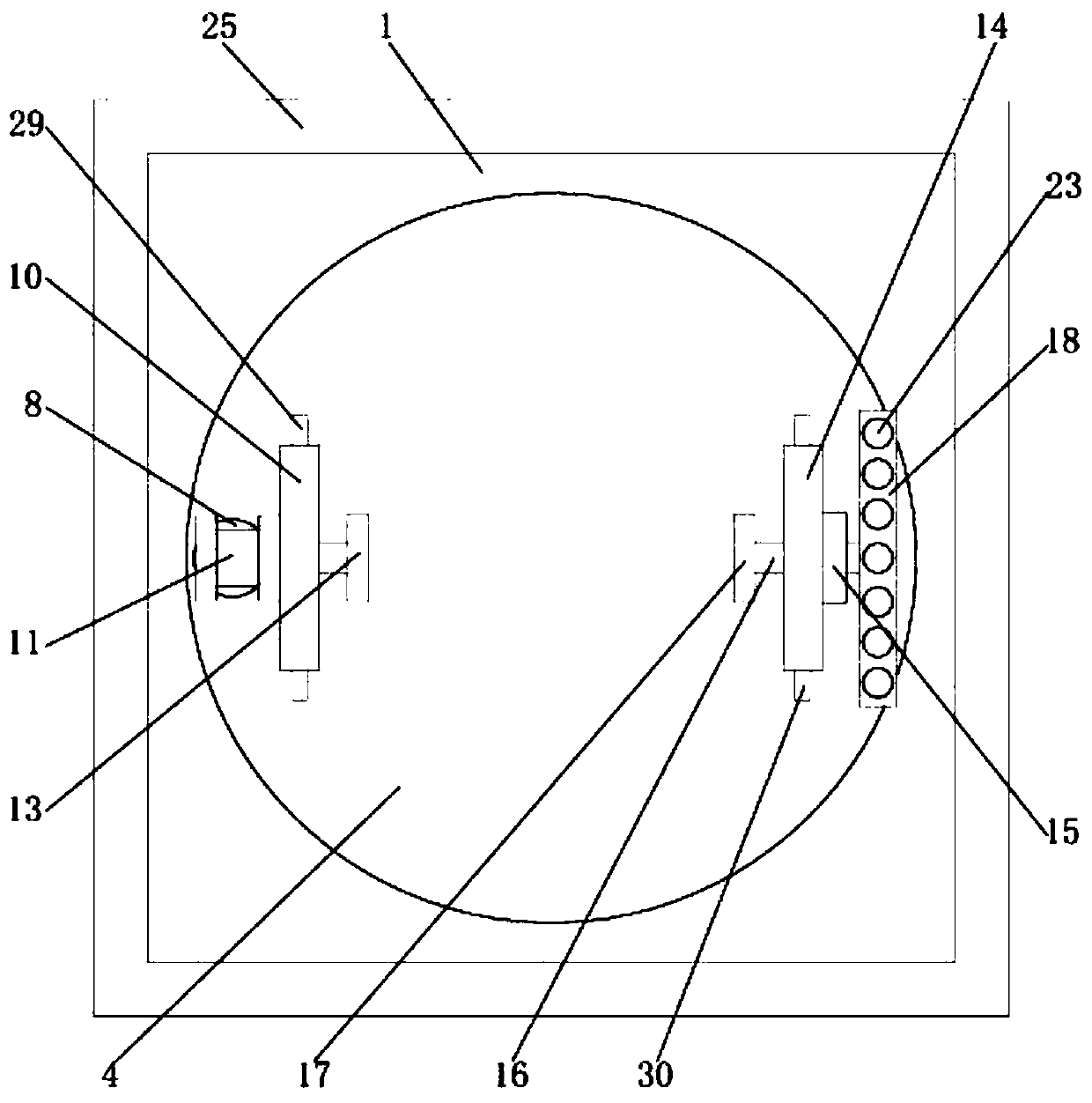

Insulating paper insertion machine

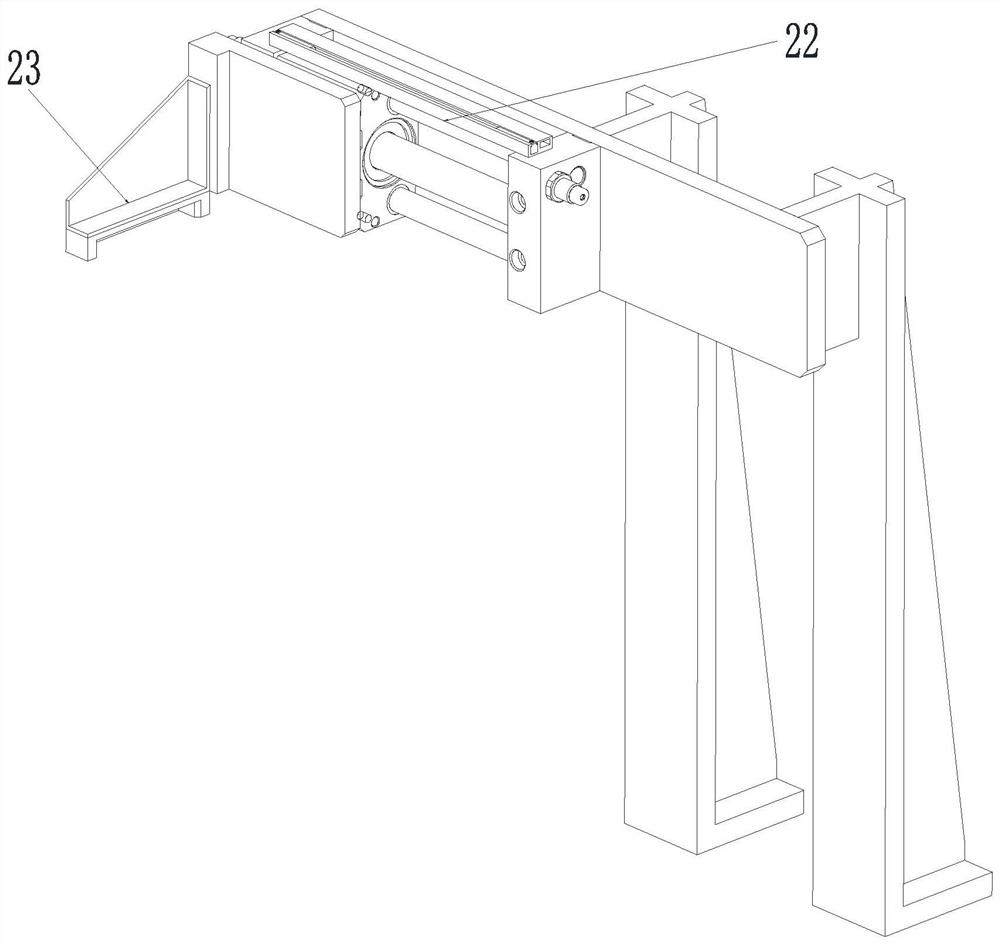

PendingCN106451953AEasy to operateImprove processing efficiencyApplying solid insulationFinal product manufacturePulp and paper industryPaper sheet

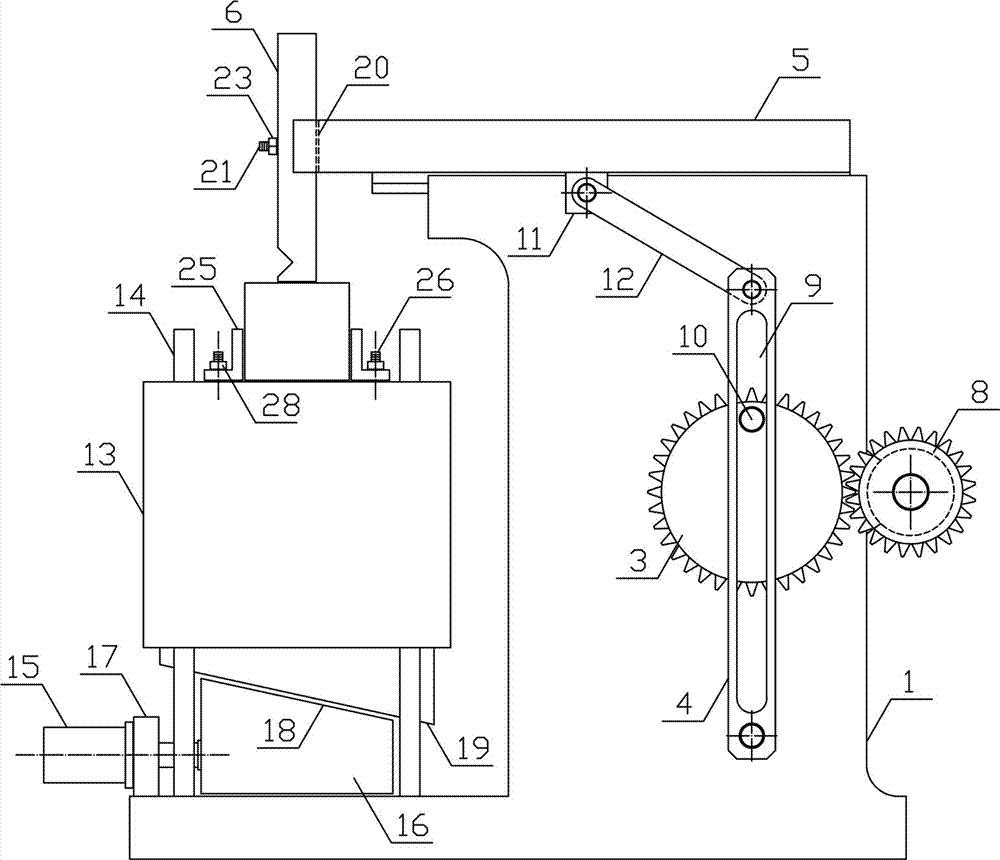

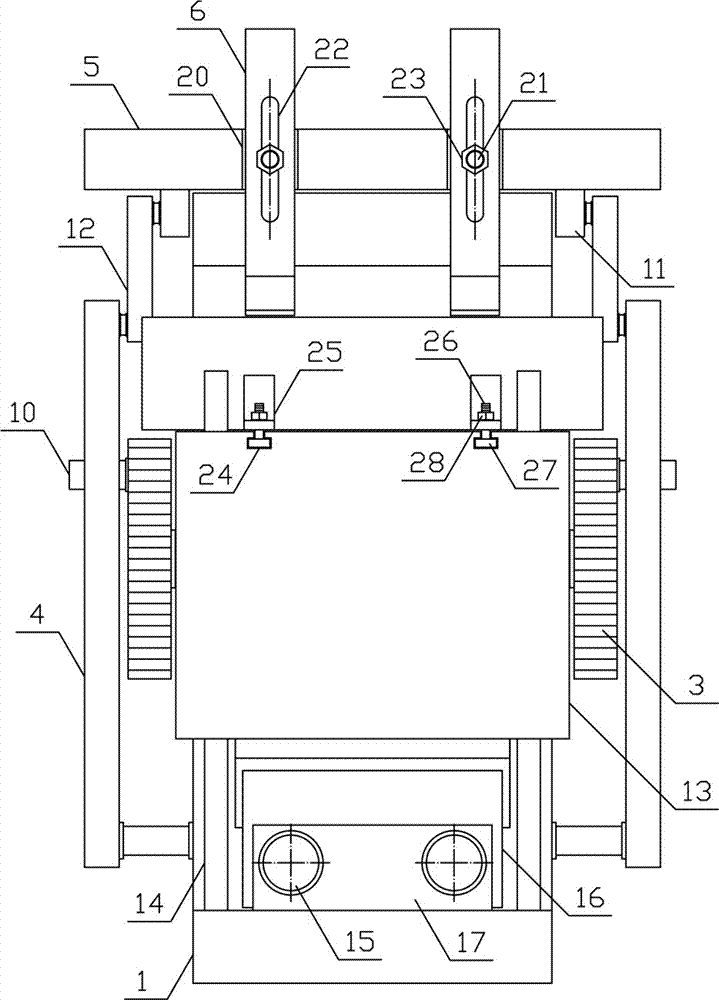

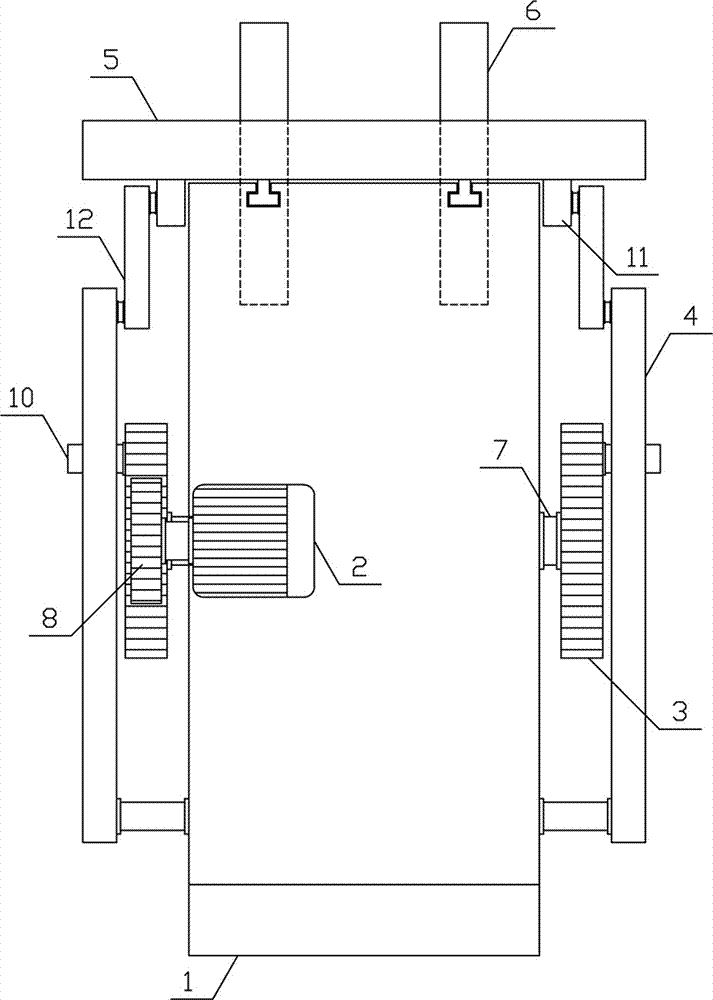

The invention relates to an insulating paper insertion machine. A worktable is provided with an indexing die device, a paper pre-feeding device is provided on one side of the rack, and a folding device and a punch transmitting device which are sequentially distributed and matched with the paper pre-feeding device are arranged in the rack. A cutting and forming device matched with the punch transmitting device is arranged at the lower end of the worktable. A paper moving and pushing device is arranged above the cutting and forming device. Insulating paper sequentially passes the folding device, the punch transmitting and the cutting and forming device after being fed by the paper pre-feeding device, and is pushed into a motor stator fixed in the indexing die device through the paper moving and pushing device. The insulating paper insertion machine has the advantages of convenient operation, high processing efficiency, and reliable and stable operation, interlocking protection and high degree of automation, which can meet the actual production and processing needs and have high promotional value, and inserting the insulating paper into the motor stator can be completed automatically.

Owner:NIDE MECHANICAL EQUIP

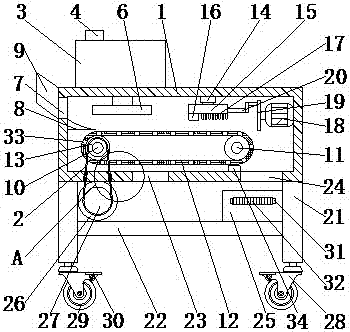

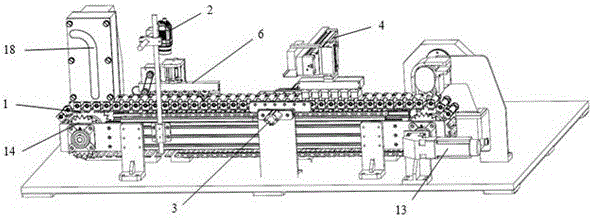

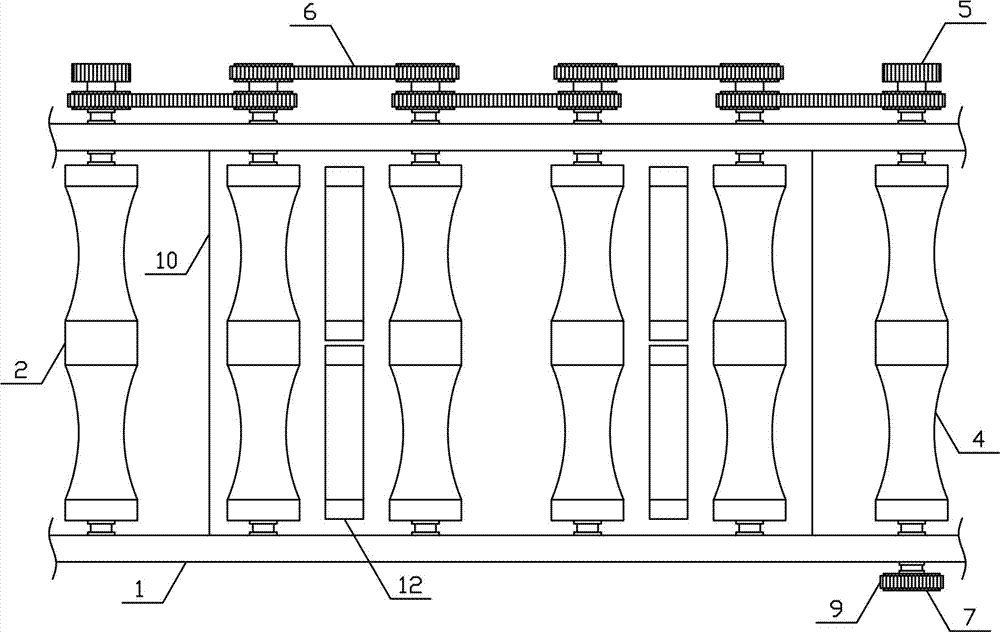

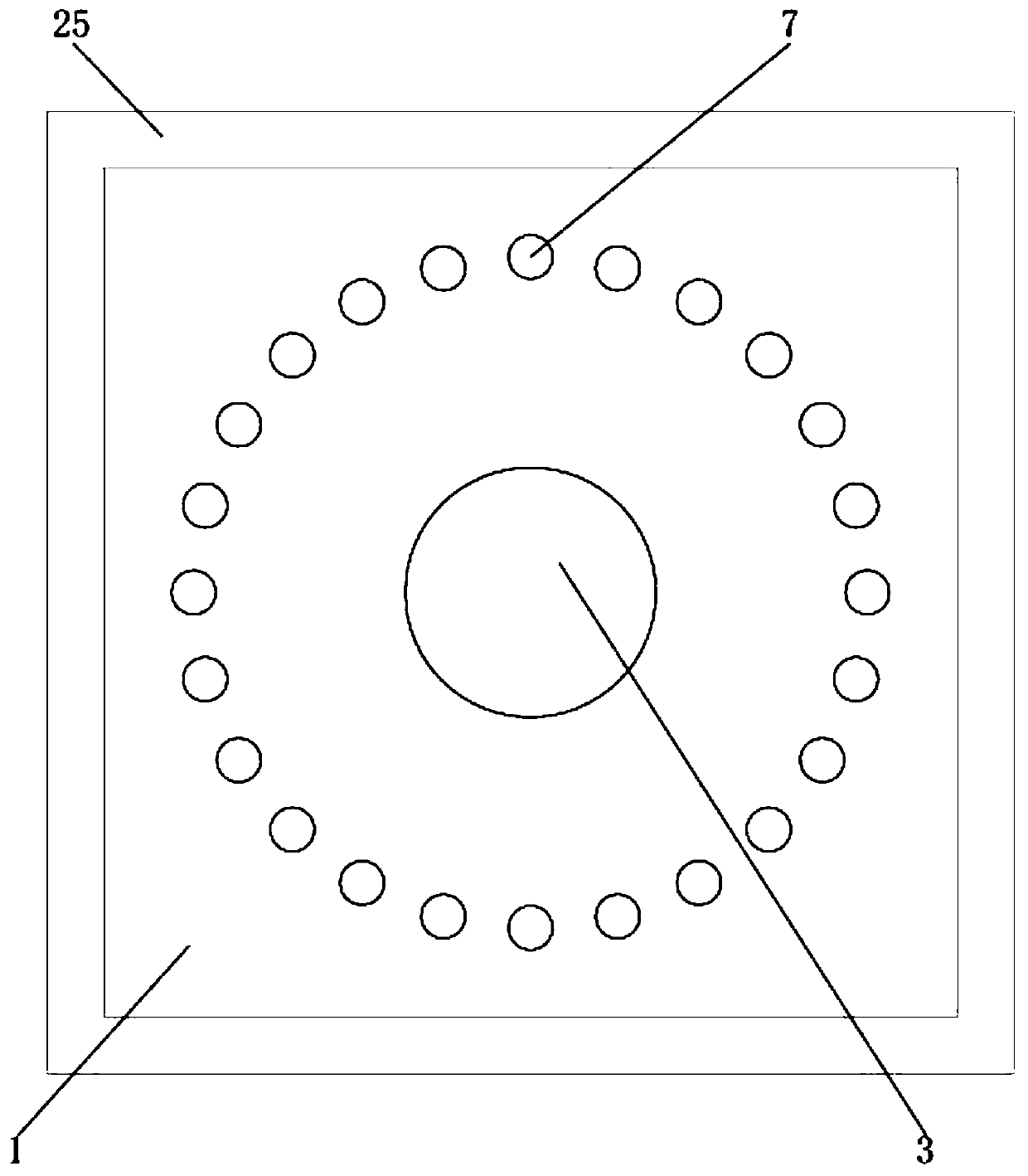

Battery detection machine

The invention relates to a battery detection machine. The battery detection machine comprises a conveying device. A code scanning device, a detection device and a sorting device are arranged in the conveying direction. The code scanning device comprises a code scanner and an auxiliary code scanning device body. The detection device comprises detection probes which are installed on a pressing device. An eliminating device comprises an eliminating bracket. A transporting device is installed on the eliminating bracket. Material taking heads are installed on the transporting device. According to the battery detection machine, code scanning, detecting and eliminating of battery cores are synchronously achieved, and meanwhile the efficiency is high, so that the requirements for production and processing of an automated assembly line are met.

Owner:WUXI AOTEWEI INTELLIGENT EQUIP CO LTD

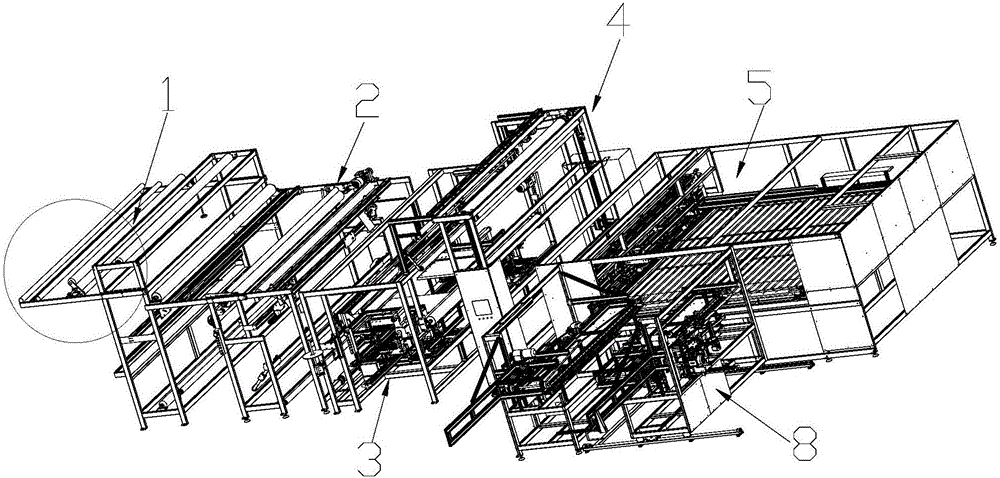

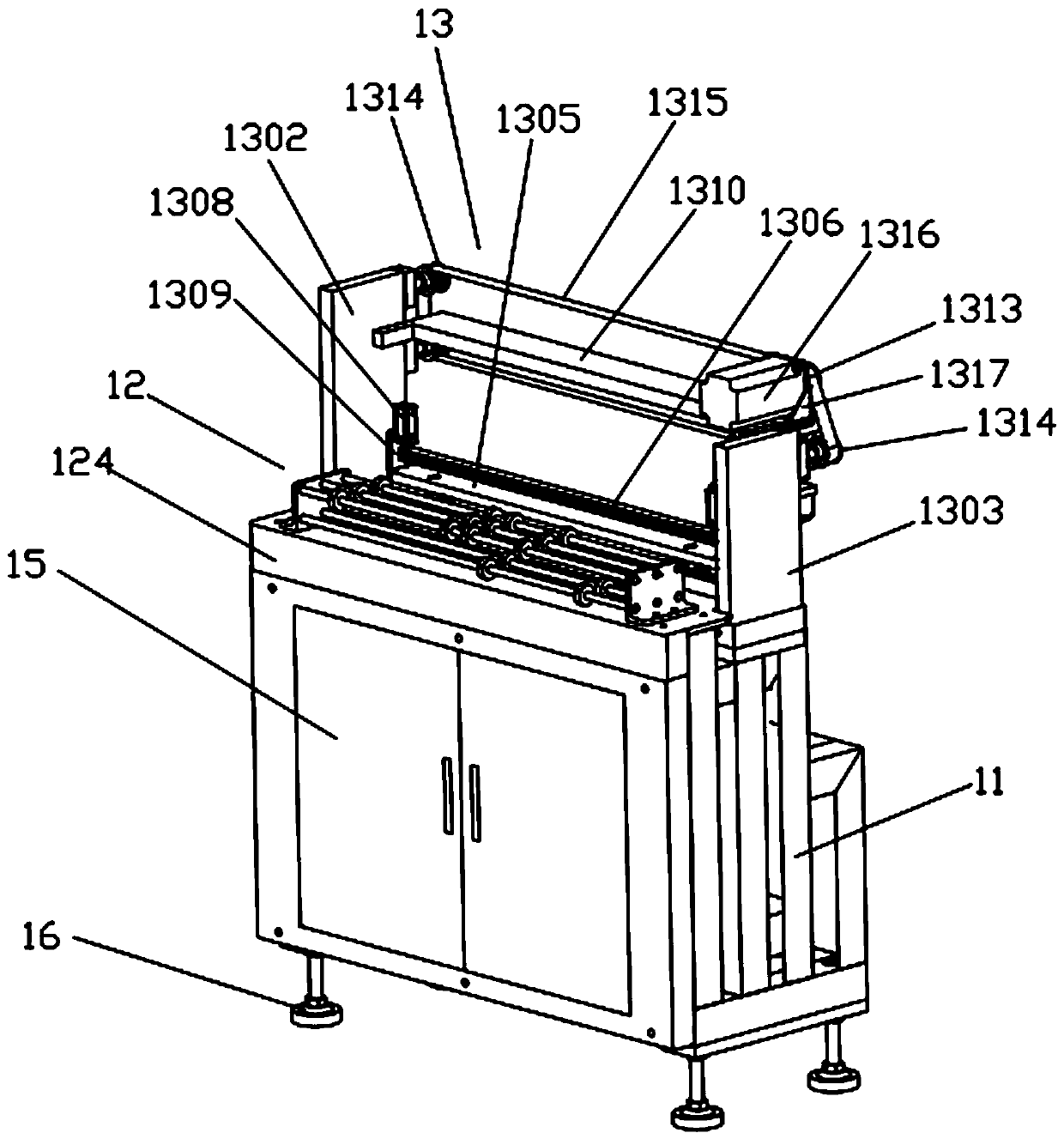

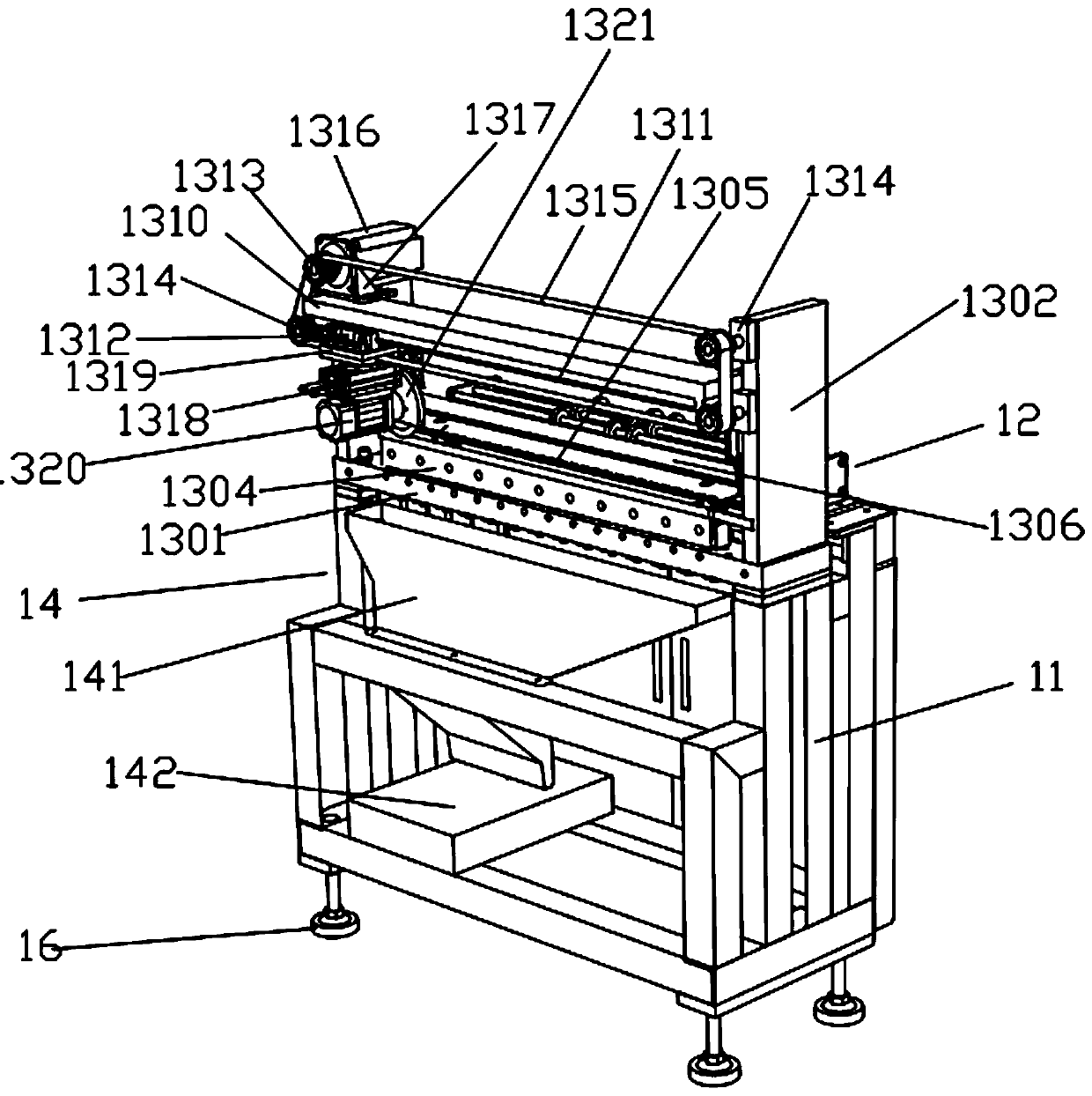

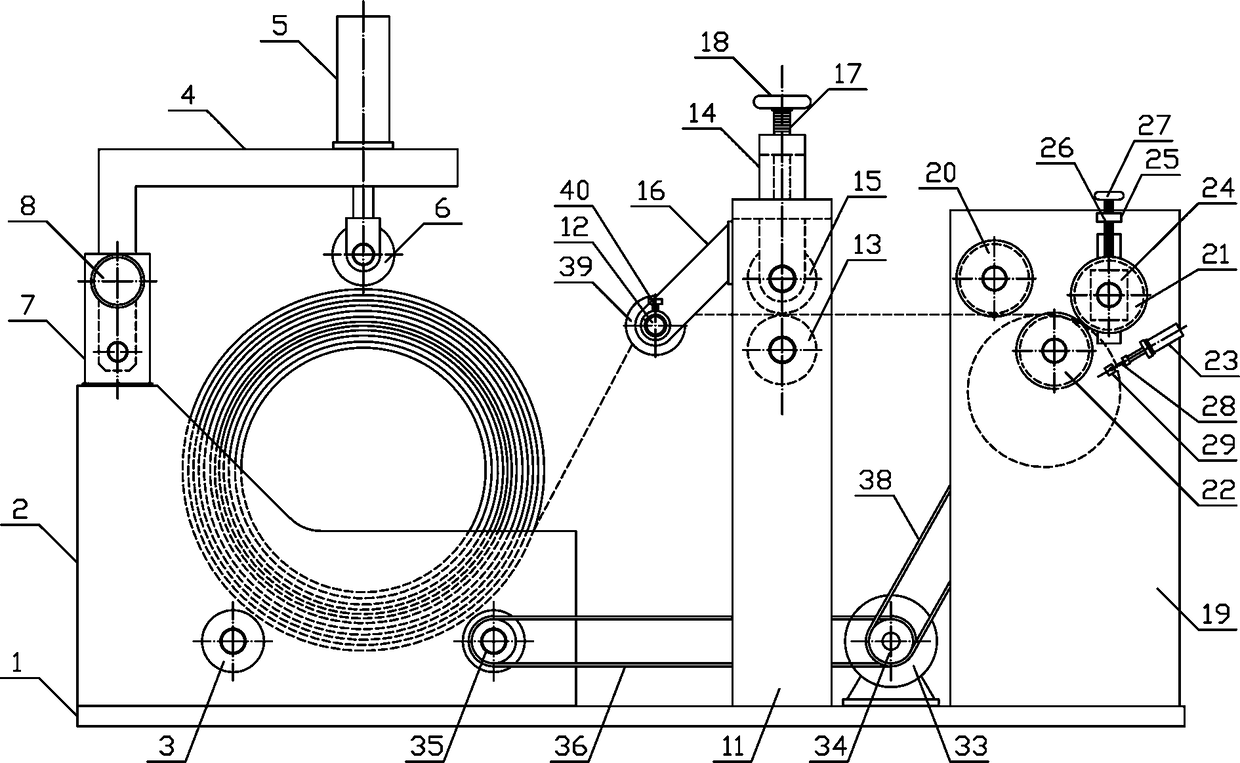

Full-automatic bed sheet machine

The invention relates to a full-automatic bed sheet machine. The full-automatic bed sheet machine comprises a feeding device, a correcting mechanism, a longitudinal folding mechanism, a buffering device, a material grasping cutter device, a labeling and transferring device and a horizontal folding mechanism; the feeding device, the correcting mechanism, the longitudinal folding mechanism, the buffering device and the material grasping cutter device are oppositely placed in sequence; one side of the material grasping cutter device is provided with the labeling and transferring device; the labeling and transferring device is connected with the horizontal folding mechanism. The full-automatic bed sheet machine is compact in integral structure and reasonable in layout and can automatically complete processing of cloth into bed sheets, full-process automation is achieved, the processing efficiency is high, the occupied space is small, the number of workers is small, the production cost is low, and actual production and processing needs are met.

Owner:SUZHOU TRANSPARENT TECH CO LTD

Board machining push mechanism

InactiveCN105083974APush level is accurateImprove processing efficiencyConveyor partsHydraulic cylinderWood processor

The invention discloses a board machining push mechanism, and belongs to the field of wood machining mechanical equipment. The board machining push mechanism comprises a main bracket, translation hydraulic cylinders, a push plate and a limiting plate, wherein multiple brake universal wheels are uniformly arranged at the lower side of the main bracket; two translation hydraulic cylinders are horizontally arranged at the two sides of one end of the main bracket; the push plate is horizontally arranged at output ends of the two translation hydraulic cylinders; limiting sleeves are respectively arranged at the two sides of the push plate; the limiting plate is horizontally arranged at one sides of the limiting sleeves; the upper side of the main bracket is horizontally and rotationally connected with multiple wood guide rollers; the upper end of a wood guide bracket is hinged to the main bracket; wood guide hydraulic cylinders are respectively arranged between the two sides of the wood guide bracket and the main bracket; the tail ends of the wood guide hydraulic cylinders are hinged with the main bracket; and the output ends of the wood guide hydraulic cylinders are hinged to the middle part of the wood guide bracket. The board machining push mechanism is simple in structure, can quickly and efficiently move boards horizontally and accurately, improves the board machining efficiency and quality, and satisfies the production and use demands.

Owner:徐阳

Recycled color yarn produced from waste polyester fabric and manufacturing method of recycled color yarn

InactiveCN110273197ANo need to dyeNo pollution in the processChemical industryPigment addition to spinning solutionYarnPolyester

The invention discloses a recycled color yarn produced from waste polyester fabric and a manufacturing method of the recycled color yarn. The recycled color yarn comprises the waste polyester fabric, esterified products, color masterbatches, brightening agents and chain extenders. The manufacturing method includes (1) pretreating the waste polyester fabric to form a foam material; after the foam material is put into a melting furnace to be smelted into a molten state, filtering the melt to remove non-melted impurities, extracting bubbles and oligomers in the melt through negative pressure to obtain a granulated semi-finished product, and subjecting the granulated semi-finished product to depolymerization, chain extension and ester exchange re-polymerization in a reaction kettle to obtain a granulated raw material; (2) subjecting the esterified products, the color masterbatches and the brightening agents to melt blending for extrusion granulation to obtain an esterified masterbatch; (3) adding the products of the step (1) and the step (2) into a reaction-type vented screw extruder for extrusion granulation to obtain a raw material of the recycled color yarn; (4) subjecting the product of the step (3) to melt spinning. The recycled color yarn and the manufacturing method thereof have the advantages that the waste polyester fabric is recycled, the printing and dyeing process of the recycled color yarn is simplified, environmental pollutants such as printing and dyeing wastewater are avoided, and the recycled color yarn is energy saving and environment friendly.

Owner:FUQING BRANCH OF FUJIAN NORMAL UNIV

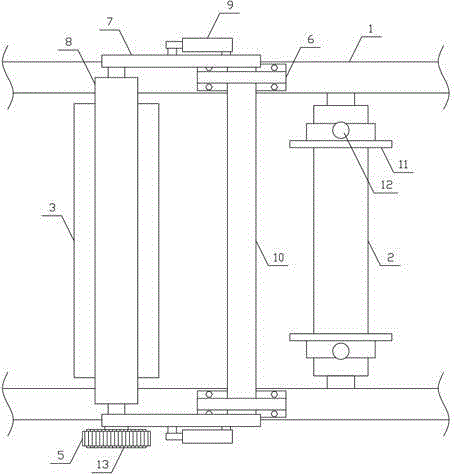

Edge cutting mechanism for airbrushed fabric

ActiveCN104960966AImprove trimming efficiencyImprove trimming qualityUnfolding thin materialsArticle deliveryMotor driveEngineering

The invention discloses an edge cutting mechanism for airbrushed fabric, and belongs to the field of advertisement processing mechanical equipment. The edge cutting mechanism comprises a main support, an unfolding roller, a transmission motor, a fabric sending roller, an edge cutting mechanism and a material guiding mechanism; the unfolding roller rotates horizontally to be connected to the upper side of the main support, the transmission motor drives the unfolding roller, the fabric sending roller rotates horizontally to be connected to the lower side of the main support, and the edge cutting mechanism is arranged on the main support horizontally; the edge cutting mechanism comprises an edge cutting roller and a fabric bearing roller which rotate horizontally to be connected to the main support respectively, two sides of the edge cutting roller are provided with edge cutting knives respectively and symmetrically, and two sides of the fabric bearing roller are provided with limiting knife grooves matched with the edge cutting knives respectively and symmetrically; the material guiding mechanism comprises translation rods and material guiding pipes, two sides of the translation rods are horizontally provided with translation sleeves matched with the translation rods respectively, and the material guiding pipes are arranged on one sides of the translation sleeves. According to the edge cutting mechanism, the structure is simple, transmission and edge cutting can be rapidly, efficiently and conveniently carried out on the airbrushed fabric, and requirements for producing and machining are met.

Owner:徐州辰耀针织有限公司

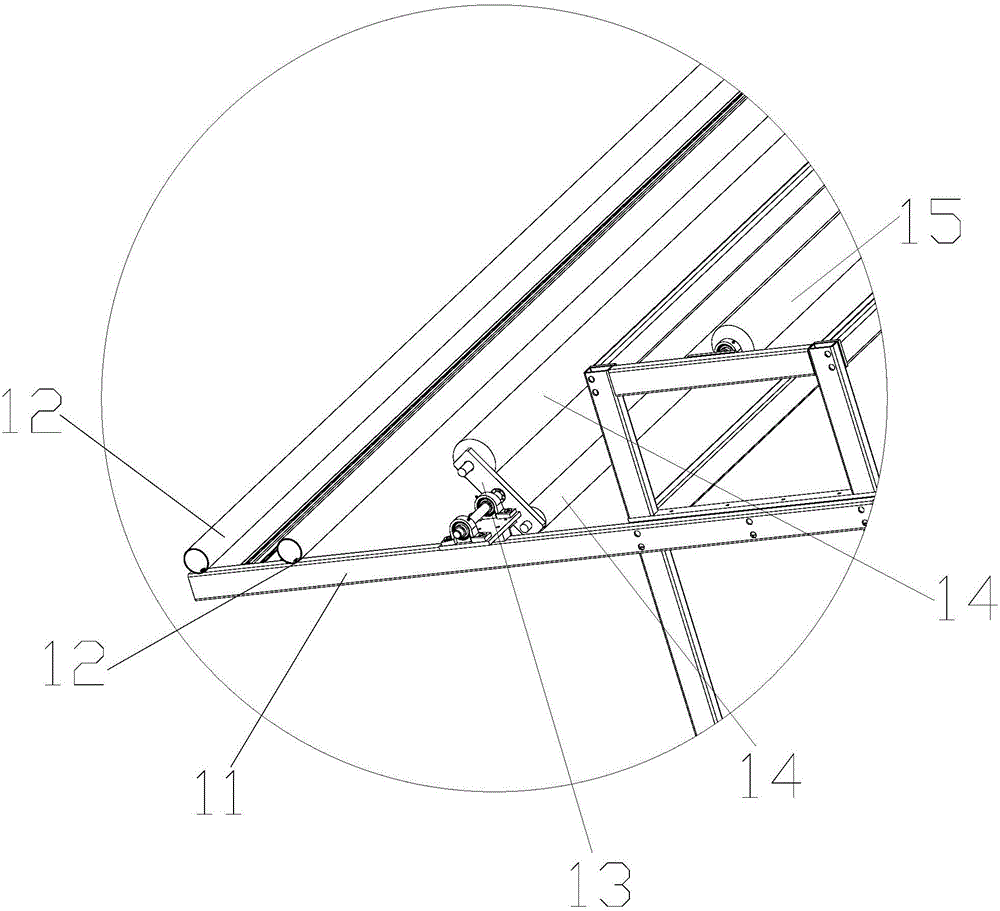

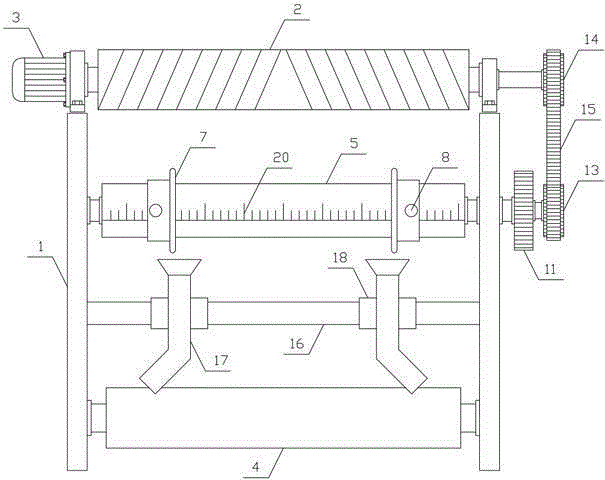

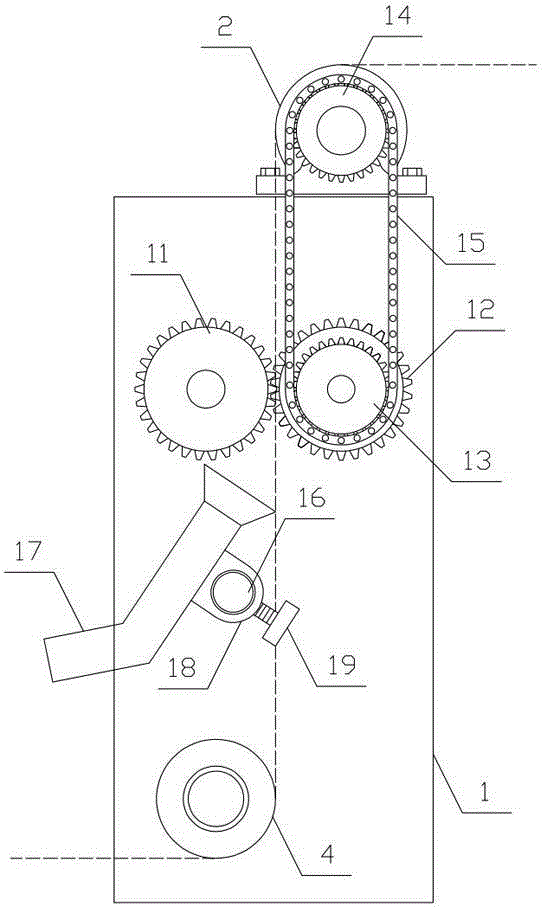

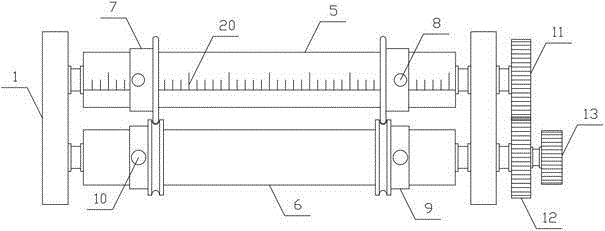

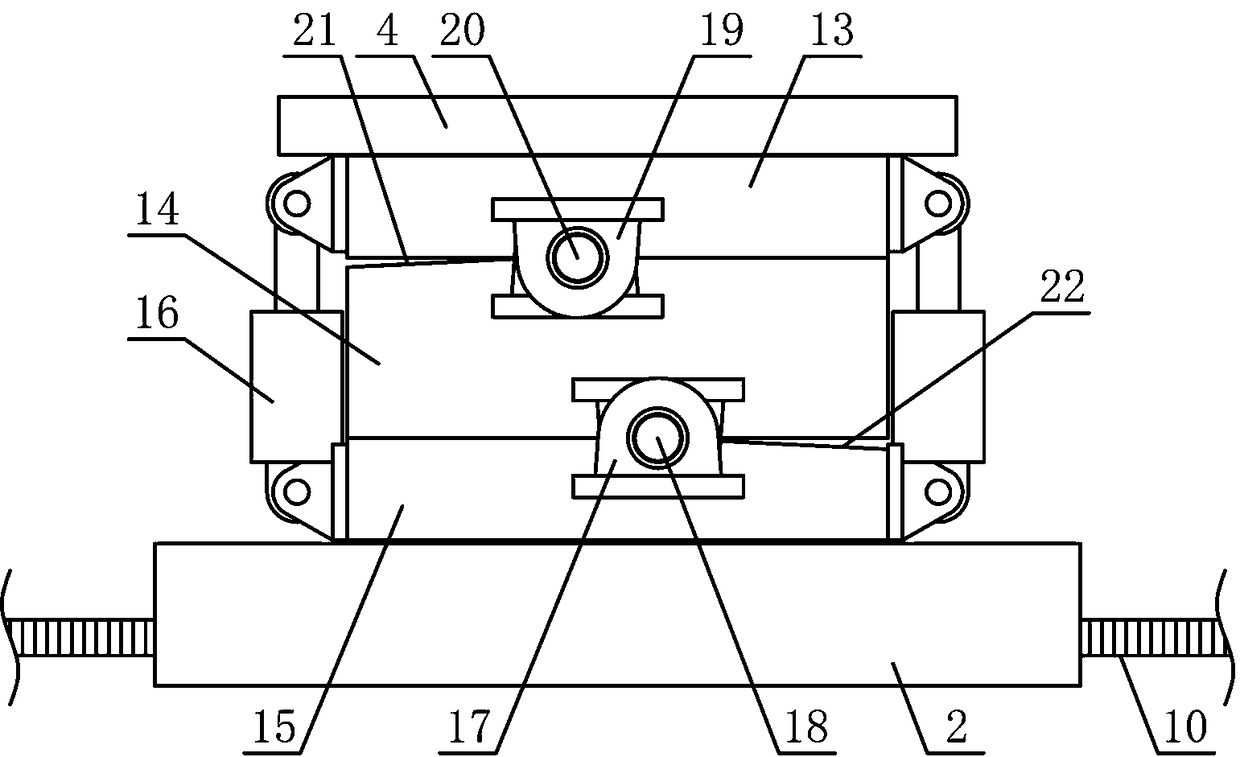

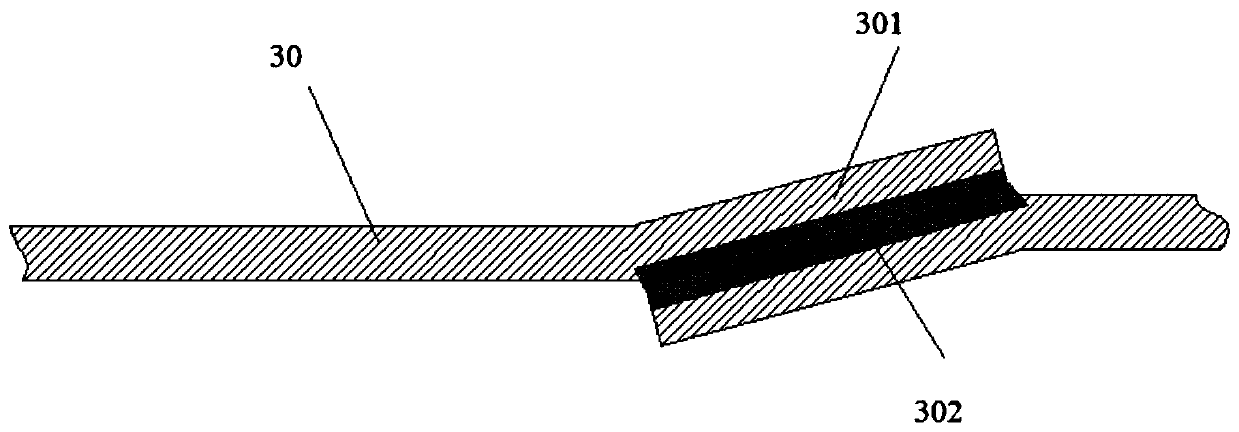

Fabric translation and traction mechanism

InactiveCN109162055AEnsure translational pullReasonable structural designStretchingMechanical equipmentEngineering

The invention discloses a fabric translation and traction mechanism and belongs to the field of fabric processing mechanical equipment. A translation screw rod is in horizontal threaded connection with a translation guide plate; a rotation adjusting mechanism is arranged on the upper side of the translation guide plate; a rotation connecting plate is fixedly arranged on the upper side of the rotation adjusting mechanism; a lifting base is fixedly arranged on the upper side of the rotation connecting plate; a lifting bracket is arranged on the lifting base in a sliding manner in the vertical direction; a fabric pressing mechanism is fixedly arranged in the middle of the upper side of the lifting bracket; the output end of a lifting cylinder is fixedly connected with both sides of the lowerpart of the lifting bracket; a translation push block is arranged at the output end of a fabric pressing cylinder in a horizontal sliding manner; a fabric pressing inclined surface is arranged on thelower side of the translation push block in an inclined manner; both sides of a lifting pressing plate are arranged on the fabric pressing guide rod in the sliding manner in the vertical direction. The fabric translation and traction mechanism is reasonable in structure, an end part of a fabric can be conveniently and efficiently pressed and fixed, then the fabric can be stably and accurately translated and tracked, the processing automation degree of the fabric can be increased, and requirements of production and processing can be met.

Owner:桐乡市富利来针织股份有限公司

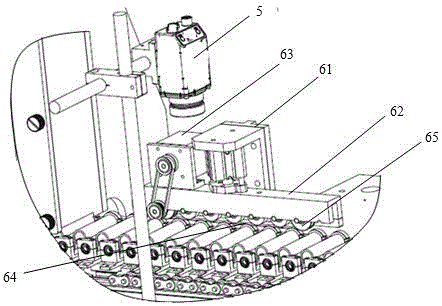

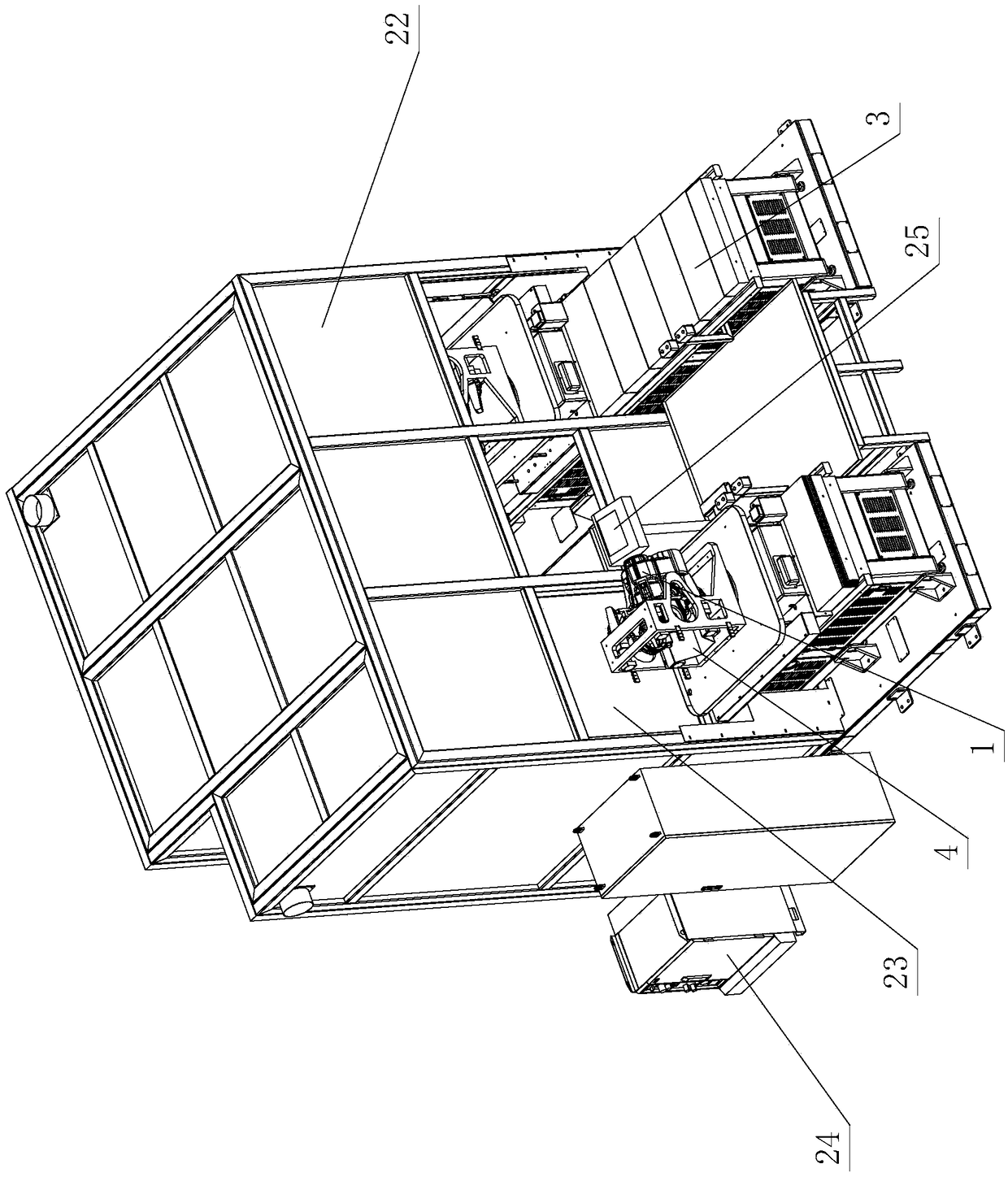

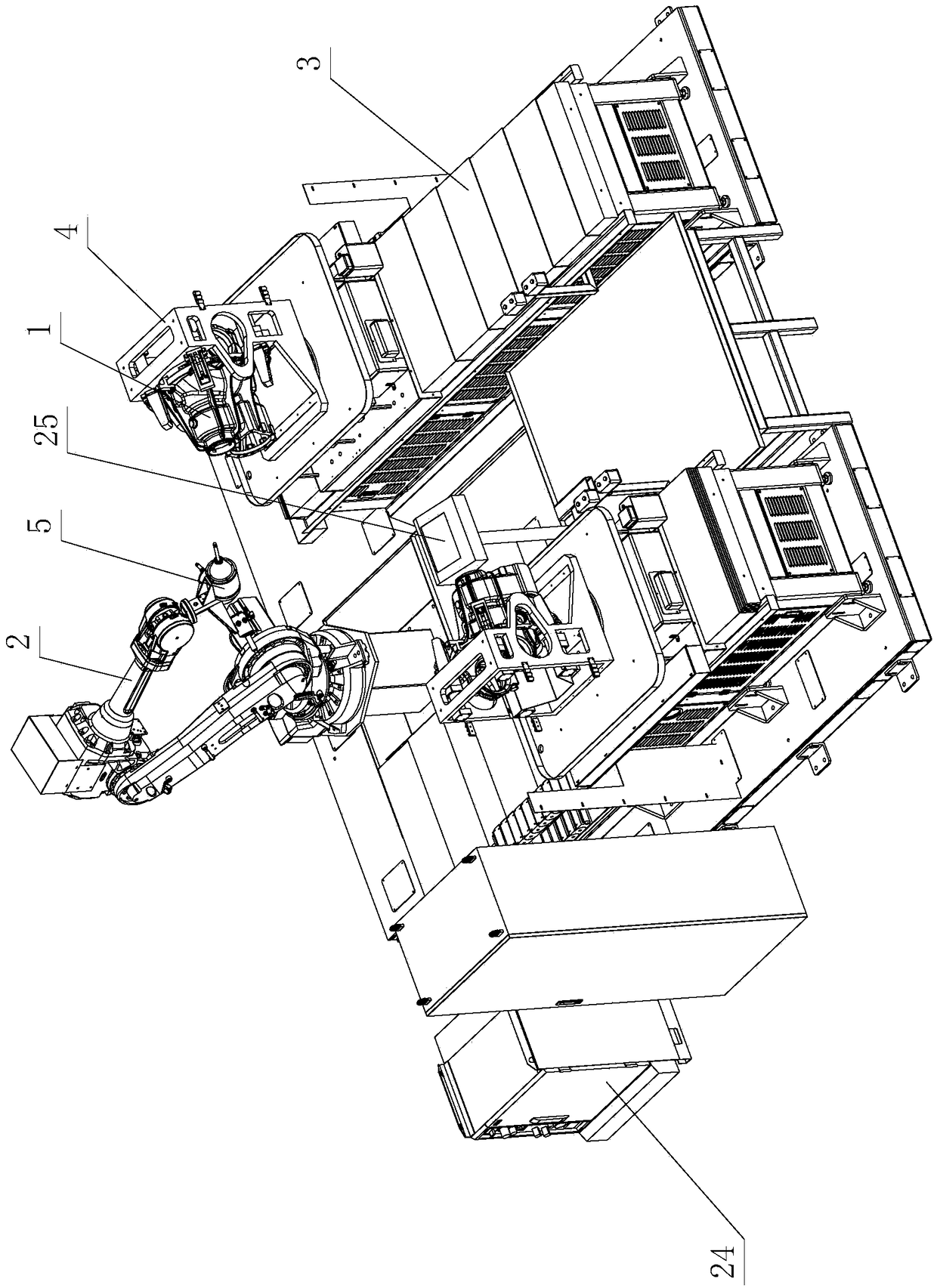

Reducer shell polishing equipment with robot

PendingCN109202615AImprove grinding efficiencyImprove grinding accuracyGrinding machinesGrinding feedersReduction driveReducer

Reducer shell polishing equipment with a robot comprises a piece to be polished, the six-axis robot and two feeding and discharging conveying platforms. The two feeding and discharging conveying platforms are provided with fixture assemblies. The fixture assemblies slide back and forth on the feeding and discharging conveying platforms, and a feeding and discharging station and a polishing stationare formed. The six-axis robot is arranged between the two feeding and discharging conveying platforms and is provided with three rotary floating polishing assemblies. The piece to be polished is fedto the fixture assemblies through the feeding and discharging station and slides to the polishing station through the fixture assemblies. The six-axis robot carries out polishing machining on the piece to be polished through the three rotary floating polishing assemblies, and the polished and machined piece to be polished slides to the feeding and discharging station through the fixture assemblies and is discharged. By means of the improvement of the structure, the reducer shell polishing equipment with the robot has the advantages of being simple and reasonable in structure, stable in quality, safe, reliable, capable of achieving full-automatic production, high in production efficiency and the like and is high in practicality.

Owner:GUANGDONG LXD ROBOTICS CO LTD

Profile surface slotting device

InactiveCN107088674AStable and firmSmooth and accurate promotionPlaning/slotting machinesEngineeringMechanical equipment

The invention discloses a profile surface groove cutting device, which belongs to the field of material processing mechanical equipment. The invention includes a fixed bracket, a translation motor, a translation gear, a swing guide rod, a translation bracket, a grooving tool and a material receiving mechanism. The swing guide rods are arranged symmetrically on both sides of the fixed bracket, and the translation bracket is slid on the fixed bracket along the horizontal direction. A translation connecting rod is installed obliquely between the translation push plate and the swing guide rod, and the two sides of one end of the translation support are respectively vertically and symmetrically provided with grooving knives. On the lower side of the material bearing bracket, a push plate slope is arranged on the upper side of the lifting push plate, and a lifting slope compatible with the push plate slope is arranged on the lower side of the material bearing bracket. The invention has a reasonable structural design, can quickly, efficiently and accurately perform groove cutting on profiles, improves the efficiency and quality of profile processing, and meets the needs of production and processing.

Owner:海宁市波菲特进出口有限公司

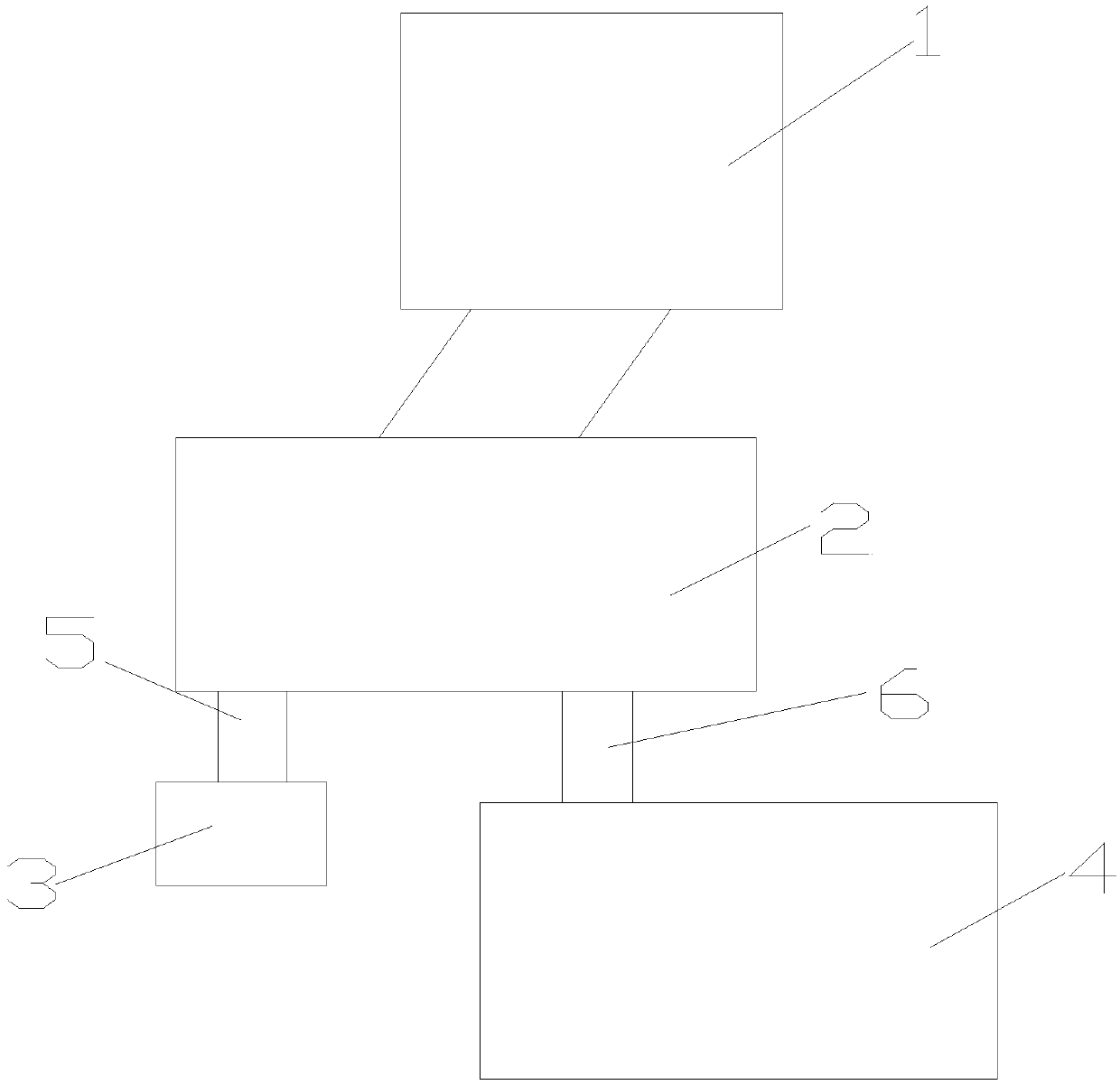

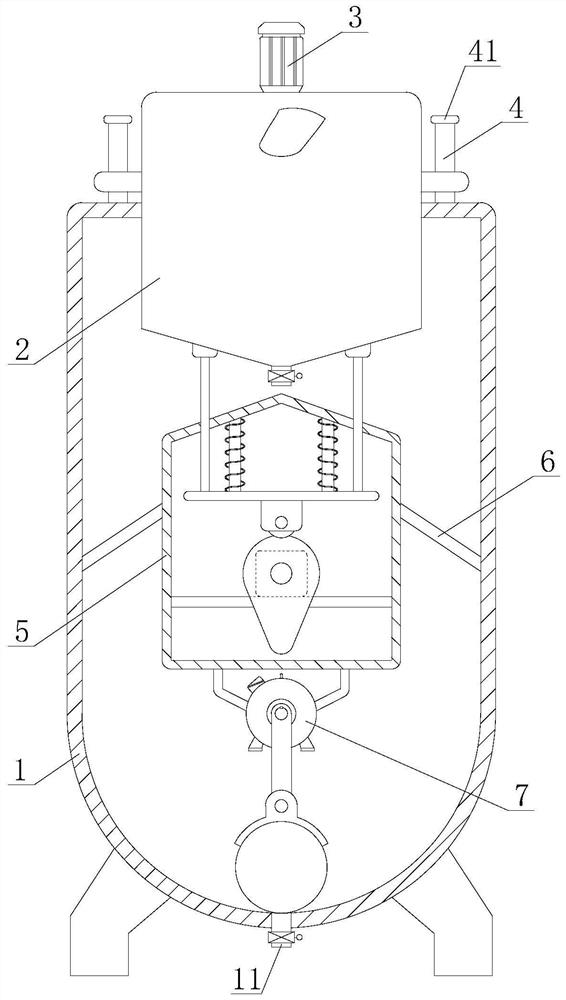

Treatment equipment for kitchen waste

InactiveCN107626719AEasy to operate and labor-savingEasy to operateFeeding-stuffSolid waste disposalOil–water separatorLiquid waste

The invention relates to treatment equipment for kitchen waste. The treatment equipment comprises a stirring device, a solid-liquid separation device, a solid processing treatment device and an oil-water separator; the stirring device is positioned above the solid-liquid separation device; the lower end of the solid-liquid separation device is provided with a solid outlet pipe and a liquid outletpipe; the solid processing treatment device is arranged at the lower end of the solid outlet pipe; and the oil-water separator is arranged at the lower end of the liquid outlet pipe. According to thetreatment equipment for the kitchen waste, the kitchen waste can be automatically stirred evenly and cut, then solid waste and liquid waste are separated through the solid-liquid separation device, the liquid waste is discharged through the oil-water separator, the solid waste is converted into feed used for fowl after being processed by the solid processing treatment equipment, operation is convenient and labor-saving, and actual production and processing requirements are met.

Owner:SUZHOU MEIJIESHENG ENVIRONMENTAL PROTECTION ENG CO LTD

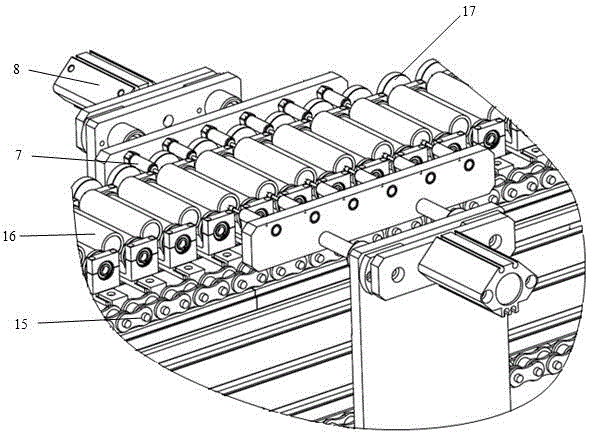

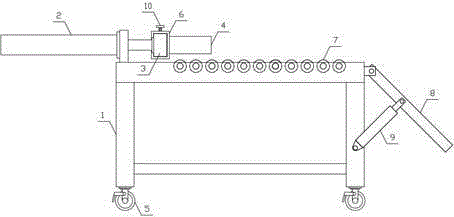

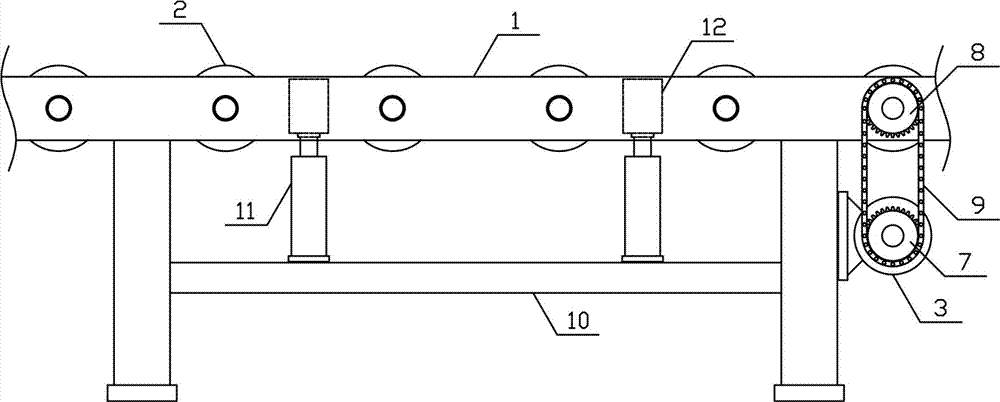

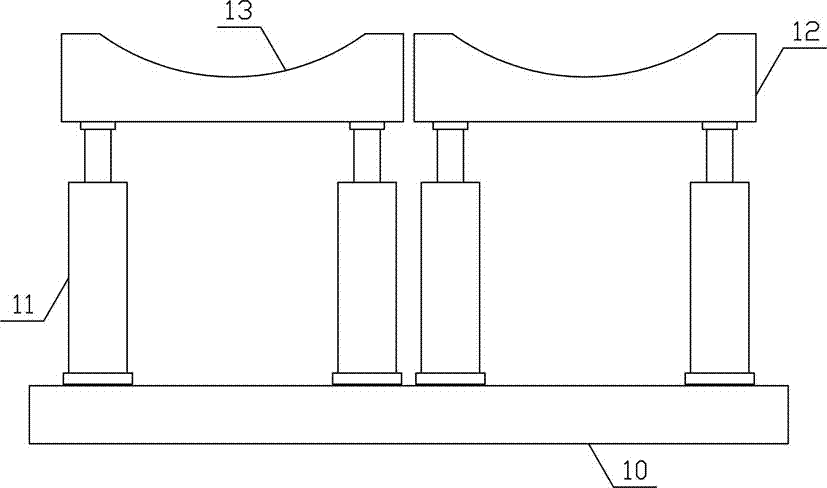

Pipe conveying and lifting mechanism

InactiveCN107082222AImprove efficiencyQuality improvementConveyorsConveyor partsElectric machineryMachining

The invention discloses a pipe transferring and lifting mechanism and belongs to the field of transferring mechanical devices. The pipe transferring and lifting mechanism comprises a transferring support, transferring rollers, a transferring motor and a pipe lifting mechanism. The transferring support is sequentially and rotatably connected with the multiple transferring rollers in the horizontal direction, every two adjacent transferring rollers are connected in a transmission mode through a connecting chain, and the upper side of a fixed plate is provided with the pipe lifting mechanism; and the pipe lifting mechanism comprises lifting air cylinders and pipe bearing plates, the two pipe bearing pates are sequentially arranged between every two adjacent transferring rollers in the horizontal direction, and the lifting air cylinders are vertically arranged between the two sides below the pipe bearing plates and fixed plate. According to the pipe transferring and lifting mechanism, structural design is reasonable, pipes can be horizontally and stably lifted in the transferring process, the pipes on the transferring support can be subjected to respective transferring one by one and multiple synchronous transferring according to the machining needs, the quality and efficiency of pipe transferring are improved, and the requirements for pipe production and machining are met.

Owner:蔡燕

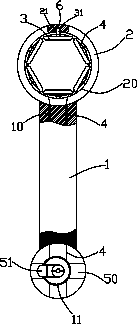

Opening size adjustable spanner

ActiveCN104626020AMeet the needs of production and processingEasy to operateSpannersWrenchesEngineeringMachining

The invention discloses an opening size adjustable spanner and relates to the spanner. The opening size adjustable spanner comprises a handle portion, wherein one end of the handle portion is provided with a head portion; the head portion comprises a ring; six first through holes are uniformly formed in the inner side wall of the ring in the periphery direction; each first through hole is internally provided with a cylinder; one end of each cylinder is provided with a baffle board; second through holes are symmetrically formed in the two ends of each baffle board; a steel rope penetrates through the second through holes in the six baffle boards. Compared with the prior art, the opening size of the opening size adjustable spanner can be adjusted according to the actual requirements, the requirements of production and machining are met, the structure is reasonable, the operation is convenient, the working efficiency is greatly improved, and the industrial production is achieved.

Owner:重庆新捷诚精密机械制造有限公司

Vibration flattening mechanism

PendingCN107554893AReasonable structural designMeet the needs of production and processingWrapper twisting/gatheringEngineeringMachine press

The invention discloses a vibration flattening mechanism which comprises a conveyor, a flattening conveyor and a vacuum conveyor which are mutually independent, are aligned sequentially and convey circularly; the conveyor is located at the feed end of the flattening conveyor; the vacuum conveyor is located at the discharge end of the flattening conveyor; a flattening machine is erected above the flattening conveyor; the flattening machine comprises a pressing plate driven by driving air cylinders; a vibration motor is arranged on the pressing plate; a vacuum mechanism is erected above the vacuum conveyor and comprises a vacuum cover driven by a vacuum air cylinder; and a movable pressurization plate is mounted in the vacuum cover and is driven by a pressurization air cylinder on the vacuumcover. Conveying operation is completed through the conveyor, the flattening conveyor and the vacuum conveyor, the flattening machine presses down a material and vibrates at the same time, the material is compressed and vacuumized by the vacuum mechanism and a vacuumizing action is completed, thus exhausting and flattening actions are completed in one process, the production efficiency is improved, and the requirements of production and processing are met.

Owner:ANHUI YONGCHENG ELECTRONICS & MECHANICAL TECH

Punching device for automobile hub machining

InactiveCN111112677AEasy to processEasy to holdWork clamping meansPositioning apparatusCouplingElectric machinery

The invention relates to the technical field of hub machining, and discloses a punching device for automobile hub machining. The punching device comprises a base, the top of the base is fixedly connected with a positioning seat, one side of the positioning seat is fixedly connected with a supporting plate, the top of the supporting plate is fixedly connected with a motor, an output shaft of the motor is fixedly connected with a rotating shaft through a coupler, the outer wall of the rotating shaft is movably connected with a bearing body, one end of the rotating shaft is fixedly connected witha rotating disc, one side of the rotating disc is fixedly connected with a first pneumatic cylinder, and the output end of the first pneumatic cylinder is fixedly connected with a first pneumatic rod. According to the punching device for automobile hub machining, the purpose of conveniently and stably clamping the hub can be achieved, the problem that a common punching device for automobile hub machining is unstable in clamping is solved, the hub machining stability is improved, the machining precision is guaranteed, meanwhile, the clamping angle is conveniently adjusted, the machining equipment can conveniently machine the automobile hub, and the practical performance is good.

Owner:JIAXING TANGDONG AUTO PARTS CO LTD

Intelligent automatic double-sided sewing equipment

PendingCN109763267ARealize adjustableMeet the requirements of automation equipmentWorkpiece carriersWork-feeding meansEngineeringMirror image

The invention discloses intelligent automatic double-sided sewing equipment. The equipment comprises a cloth cutting disc cutter, a two-way cloth pulling and feeding machine, two auxiliary racks, label cutting, folding and feeding integrated machines, sewing machines, adjusting platforms, synchronous belt conveying movement structures and tangent thermal bonding mechanisms, wherein the two-way cloth pulling and feeding machine is arranged behind the cloth cutting disc cutter, the two auxiliary racks are arranged on the left and right sides of the two-way cloth pulling and feeding machine in mirror images respectively, one label cutting, folding and feeding integrated machine, two sewing machines, two adjusting platforms, two synchronous belt conveying movement structures and two tangent thermal bonding mechanisms are arranged on each auxiliary rack. Accordingly, the intelligent automatic double-sided sewing equipment can be adjusted arbitrarily within the adjustment range according tospecifications of to-be-produced products, meets requirements of automatic equipment, does not need complicated manual adjustment, has high automation degree, and meets production requirements.

Owner:苏州大喆智能科技有限公司

Aluminum material punching mechanism

InactiveCN107199272AAvoid distortionSmooth and easy removalMetal-working feeding devicesStripping-off devicesPunchingEngineering

The invention discloses an aluminum material punching mechanism, and belongs to the field of material processing mechanical equipment. The aluminum material punching mechanism comprises a fixed bracket, a punching air cylinder, a lifting pushing plate, a translation punching plate, a material pressing air cylinder and a material supporting bracket, wherein the lifting pushing plate is horizontally arranged at an output end of the punching air cylinder; the translation punching plate is horizontally arranged on the fixed bracket at the lower side of the lifting pushing plate; a plurality of translation guide rods are horizontally and uniformly arranged below one side of the translation punching plate; translation springs are arranged on the translation guide rods between a translation baffle block and the fixed bracket; a punching circular rod which is horizontally arranged is arranged in a mounting machine head; the output end of the material pressing air cylinder is horizontally equipped with the material pressing plate; the material supporting bracket is horizontally arranged on the fixed bracket at the lower side of the material pressing plate; and a lifting spring is arranged on a lifting guide rod at the upper side of the fixed bracket. The aluminum material punching mechanism disclosed by the invention is reasonable in structural design, and can be used for quickly and conveniently punching an aluminum material accurately and efficiently, so that punching efficiency and punching quality are improved, and producing processing needs are met.

Owner:张雅婷

Aluminum profile cutting device high in cutting efficiency

InactiveCN106624111ACompact structureEasy to operateShearing machinesShearing machine accessoriesMachiningEngineering

The invention relates to an aluminum profile cutting device high in cutting efficiency. A lifting air cylinder is arranged in a base, and a telescopic rod of the lifting air cylinder penetrates out of the base. An accommodating plate is connected to the upper end of the telescopic rod of the lifting air cylinder. The two ends of the accommodating plate are provided with pressing blocks. One side of the accommodating plate is provided with a pressing mechanism located on the base. A positioning plate is fixedly arranged at one end of the base and provided with a slide rail. The slide rail is provided with a movable plate capable of sliding up and down. The movable plate is provided with two movable air cylinders arranged oppositely. Telescopic rods of the movable air cylinders are connected with rotary motors through adapter blocks. The rotary motors are connected with cutter knives. The cutter knives are located above the accommodating plate. The aluminum profile cutting device high in cutting efficiency is compact in overall structure, convenient to operate and capable of saving effort and cutting an aluminum profile into three sections at a time according to actual demands, so that the cutting efficiency is greatly improved; moreover, the quality of a cut surface is good, and actual production machining demands are met; and the aluminum profile cutting device has high practical value.

Owner:江苏隆基铝业有限公司

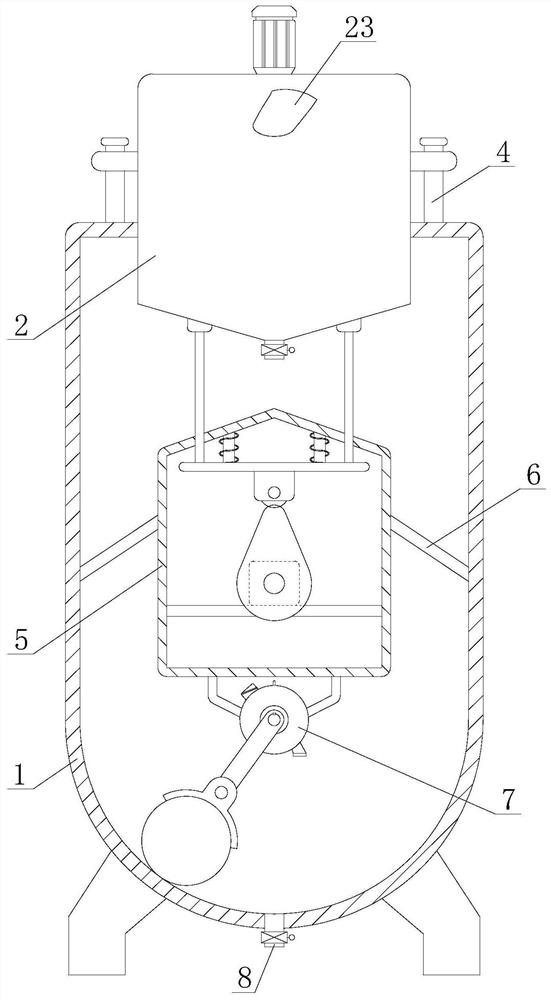

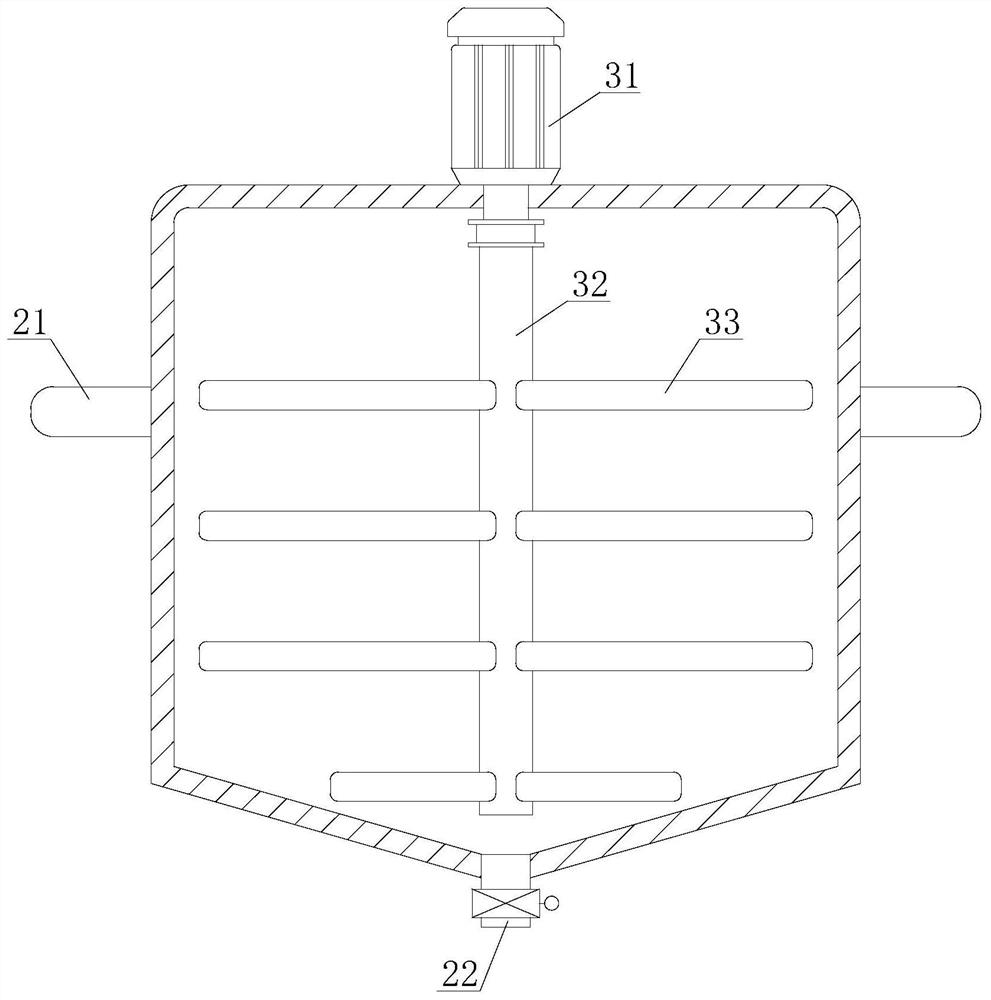

Lithium battery composite negative electrode material preparation device

InactiveCN112295484AMeet production and processing needsImprove the mixing effectElectrode manufacturing processesShaking/oscillating/vibrating mixersElectric machineEngineering

The invention discloses a lithium battery composite negative electrode material preparation device, and belongs to the technical field of lithium batteries. The device comprises a box body, the upperend of the box body is provided with a material mixing box, the material mixing box is provided with a stirring mechanism, the inner side of the box body is provided with a shaking mechanism, and theshaking mechanism is fixed on the inner wall of the box body through a support rod. The shaking mechanism is connected with the material mixing box and shakes the material mixing box, and a grinding and material mixing mechanism is further arranged on the shaking mechanism. According to the lithium battery composite negative electrode material preparation device, a negative electrode material is stirred and mixed through rotating stirring blades, and meanwhile, a second driving motor drives an eccentric wheel to rotate, so that the eccentric wheel pushes the material mixing box to shake up anddown, the negative electrode material is uniformly mixed in the material mixing box, and the mixing effect of the negative electrode material is good; and the negative electrode material can be mixedagain through a rotating grinding and mixing roller, so that the granularity of the negative electrode material is uniform, the negative electrode material mixing effect is good, and the production and processing requirements of the lithium battery can be met.

Owner:惠州市枫叶电子科技有限公司

Exhaust spray tower

InactiveCN108905584AEasy to handleSimple structureCombination devicesPulp and paper industrySpray tower

The invention relates to an exhaust spray tower. An exhaust pipe is arranged at an upper end of the tower body. An exhaust outlet pipe is arranged on the exhaust pipe. Two ends of the exhaust outlet pipe are provided with gas outlets. The lower part of the tower body is provided with an exhaust inlet. The middle of the tower body is provided with a filter layer. The tower body is divided into a first spraying chamber and a second spraying chamber. The lower end of the tower body is provided with a spraying liquid tank. Two ends of the spraying liquid tank are connected to a motor through connection pipes. One end of the motor is connected to a telescopic cylinder. The connection pipes are communicated with a rotation shaft of the motor through a communication pipe in the motor. The rotation shaft of the motor is hollow. The rotation shaft of the motor is connected to a spraying pipe of the first spraying chamber. The spraying pipe is provided with a three-way joint. The three-way jointis provided with a first nozzle. The connection pipe is provided with a flowing pipe. The flowing pipe is communicated with a second nozzle. The tower body is provided with a waste liquid collectingmechanism. The first nozzle can spray the liquid into the first spraying chamber so that the full reaction of exhaust and sodium hydroxide is guaranteed and the waste liquid can be collected.

Owner:SUZHOU HUAXI ENVIRONMENTAL TECH CO LTD

Airbag pressing ring forming device

PendingCN108188748AReasonable structural designAccurate transmissionMetal-working feeding devicesShearing machinesEngineeringMechanical equipment

The invention discloses an airbag pressing ring forming device, and belongs to the field of water heating equipment machining mechanical equipment. The airbag pressing ring forming device comprises afixed base, an unwinding mechanism, a guide mechanism and a forming and collecting mechanism. Roll bearing wheels are vertically and symmetrically arranged on the inner sides of the two ends of the lower portion of a roll clamping support correspondingly. A roll pressing support is vertically arranged on the upper side of the roll clamping support, and a guide support is vertically arranged in themiddle of the upper side of the fixed base. A guide roll is horizontally and rotationally connected to a guide supporting plate, and a pressing roll is horizontally arranged over a bearing roll. Theforming and collecting mechanism comprises a forming support, a guide wheel, a bending wheel, a pull wheel and a cut-off air cylinder. A cutting blade is horizontally arranged at the output end of thecut-off air cylinder, and a collecting ring guide rod is obliquely arranged at the upper end of a fixed round rod upwards. The airbag pressing ring forming device is reasonable in structural design,metal strap rolls can be fast and efficiently conveyed, machined and bent into rings stably, the formed rings can be continuously cut off and collected one by one, and the needs of production and machining are met.

Owner:ZHEJIANG TANKPRO IND

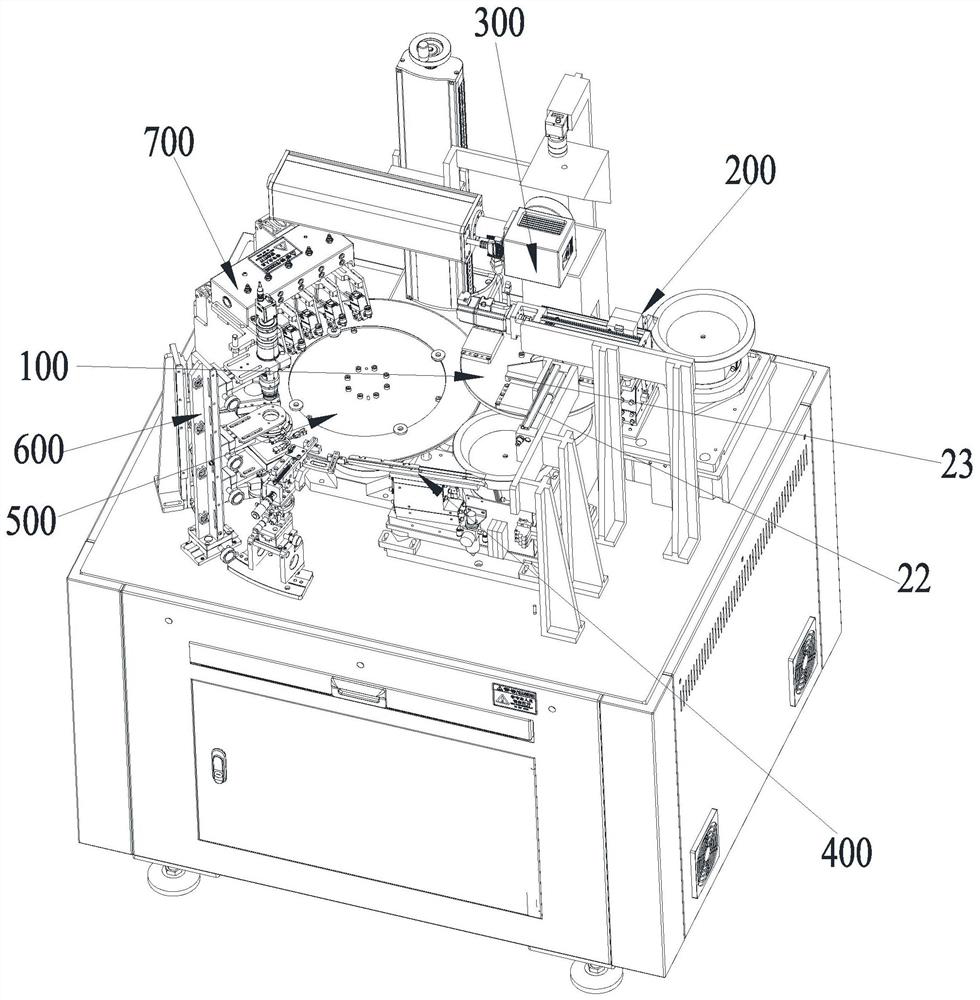

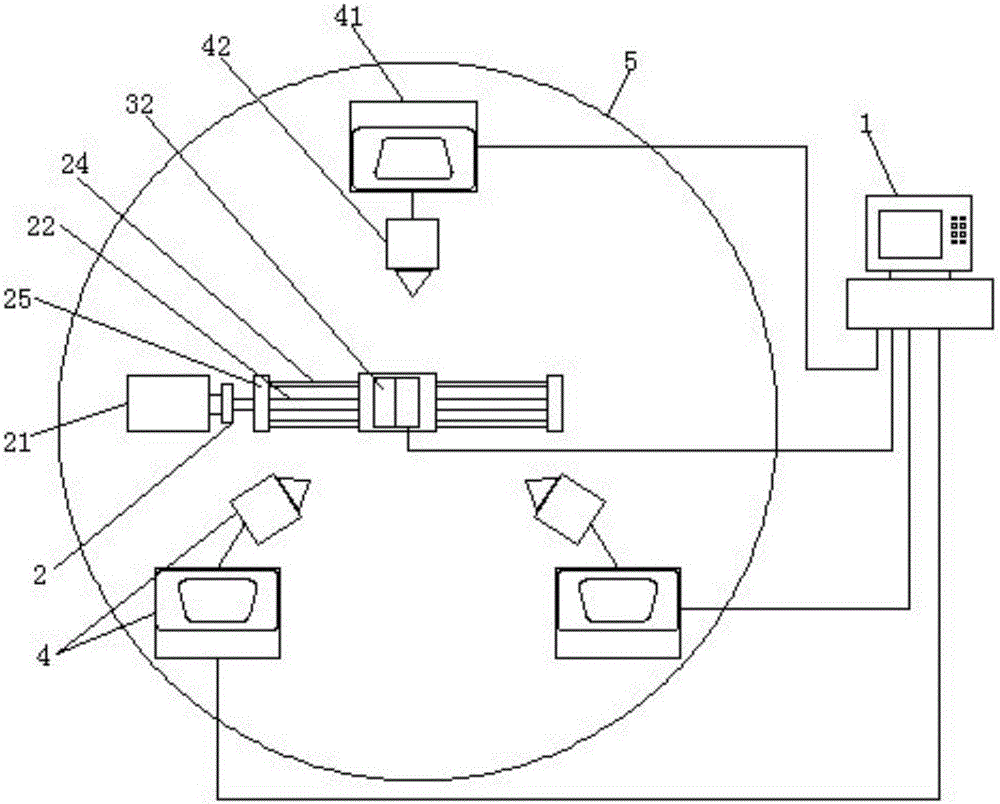

Integrated inductor automatic feeding and paint stripping optical screening machine

PendingCN113560741AMeet production and processing needsShortened process chainInductances/transformers/magnets manufactureSortingVisual screeningMechanical engineering

The invention discloses an integrated inductor automatic feeding and paint stripping optical screening machine. The machine comprises a first rotary disc, and a plurality of rotatable jigs are arranged on the first rotary disc; a feeding mechanism is arranged on one side of the first rotary disc and used for feeding inductors to the jigs of the first rotary disc in an array mode; an inductor paint stripping assembly is arranged above the first rotary disc; a product pushing guide mechanism is arranged on one side of the first rotary disc; a second rotary disc is arranged on one side of the product pushing mechanism; a visual screening detection system is arranged on one side of the second rotary disc; and a classified material collecting mechanism is arranged on one side of the visual screening detection system and used for conducting classified collection on qualified products and defective products through the second rotary disc. According to the integrated inductor automatic feeding and paint stripping optical screening machine, automatic feeding and arrangement of the inductors, automatic paint stripping, visual screening of related sizes and appearances after paint stripping, automatic judgment of final non-defective products and automatic separation and material collection are realized, and meanwhile, multi-station synchronous operation is adopted, so that the process chain is shortened, the cost is effectively saved, and the production efficiency is greatly improved.

Owner:苏州诠泰智能装备有限公司

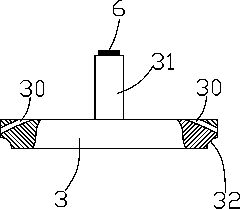

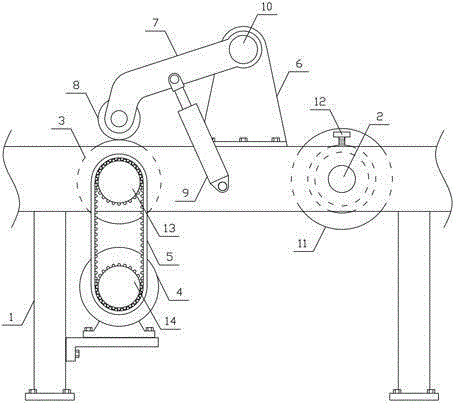

Spray painting cloth conveying metering device

InactiveCN105034615ASimple structurePrevent slippingOther printing apparatusElectric machineryLeather belt

The invention discloses a spray painting cloth conveying metering device, and belongs to the field of mechanical equipment for printing. The device includes a main support, a conveying mechanism and a metering mechanism, the metering mechanism is horizontally arranged on the main support at an upper side of the conveying mechanism, the conveying mechanism includes a cloth guiding roller, a cloth feeding roller and a cloth feeding motor, the cloth guiding roller and the cloth feeding roller are horizontally rotatably connected to the main support in sequence along a spray painting cloth conveying direction, a conveyer belt is arranged between the cloth feeding motor and the cloth feeding roller for transmission connection, the metering mechanism includes a rotary support, rotary plates, a metering roller and a compressing cylinder, a rotating shaft is horizontally rotatably connected on the rotary support, the two rotary plates are symmetrically arranged at two ends of the rotating shaft, the metering roller is horizontally rotatably connected to the other ends of the rotary plates, the compressing cylinder is arranged between the main support and the rotary plates, and an antiskid rubber layer is arranged on the surface of the metering roller. The spray painting cloth conveying metering device provided by the invention is simple in structure and convenient to operate, and can rapidly, efficiently and accurately convey and meter spray painting cloth, thereby satisfying requirements of production and machining.

Owner:TONGXIANG TANGCHAO ADVERTISEMENT CO LTD

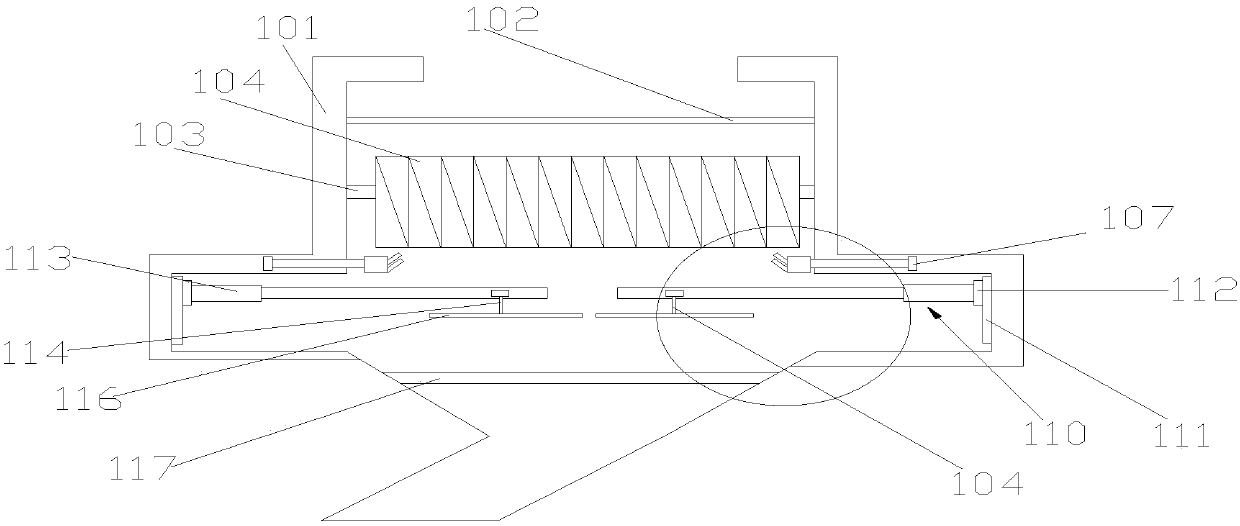

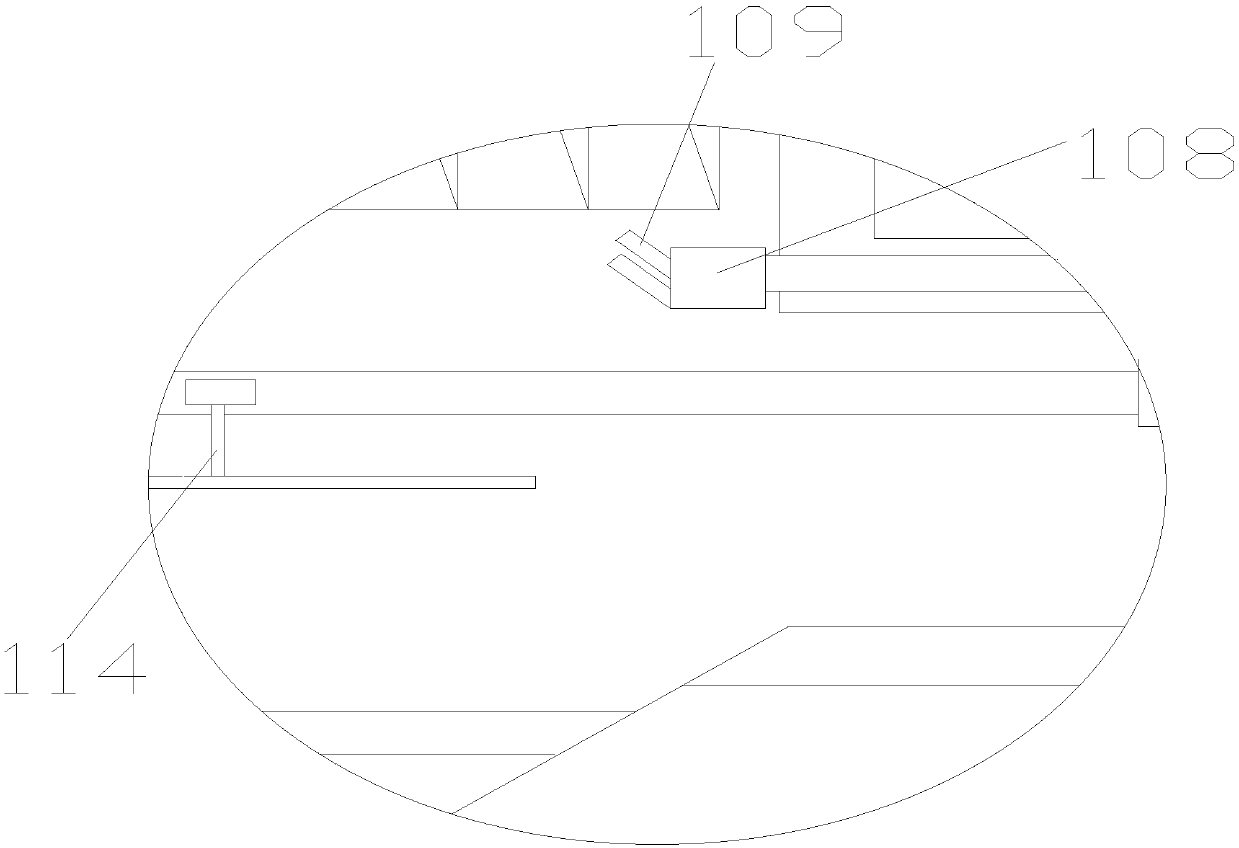

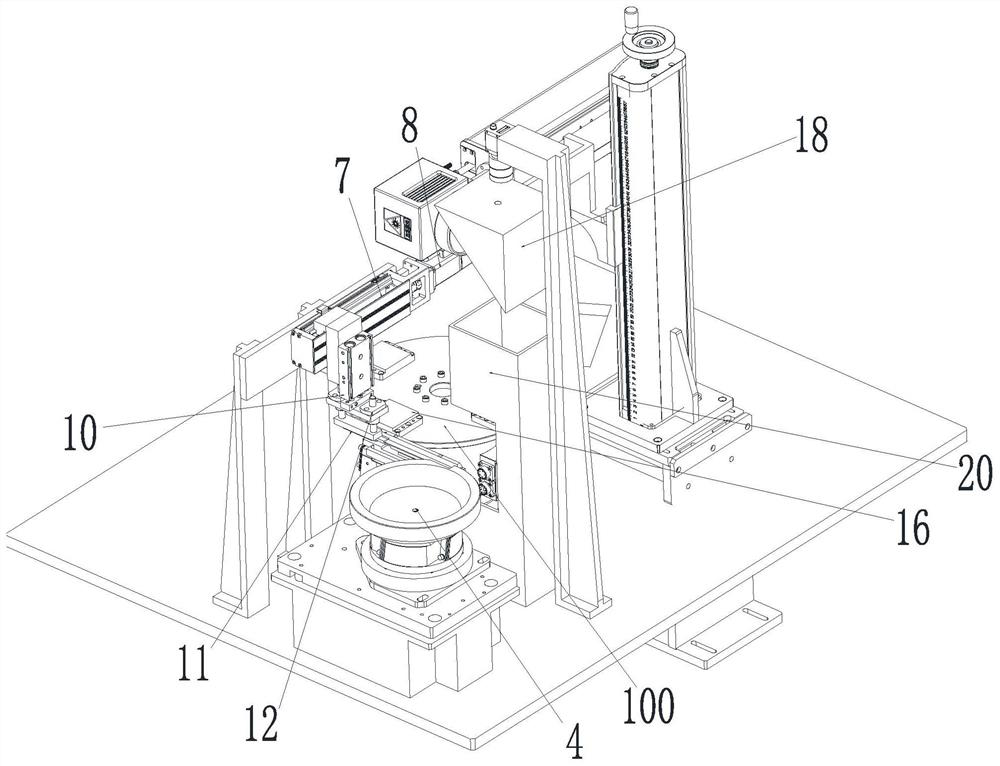

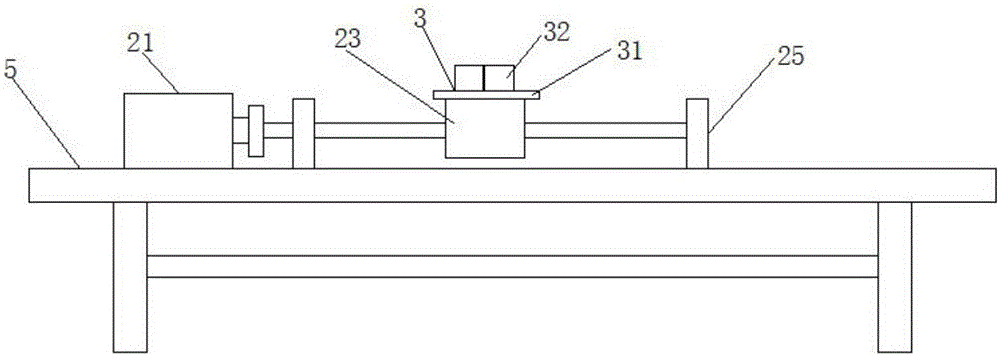

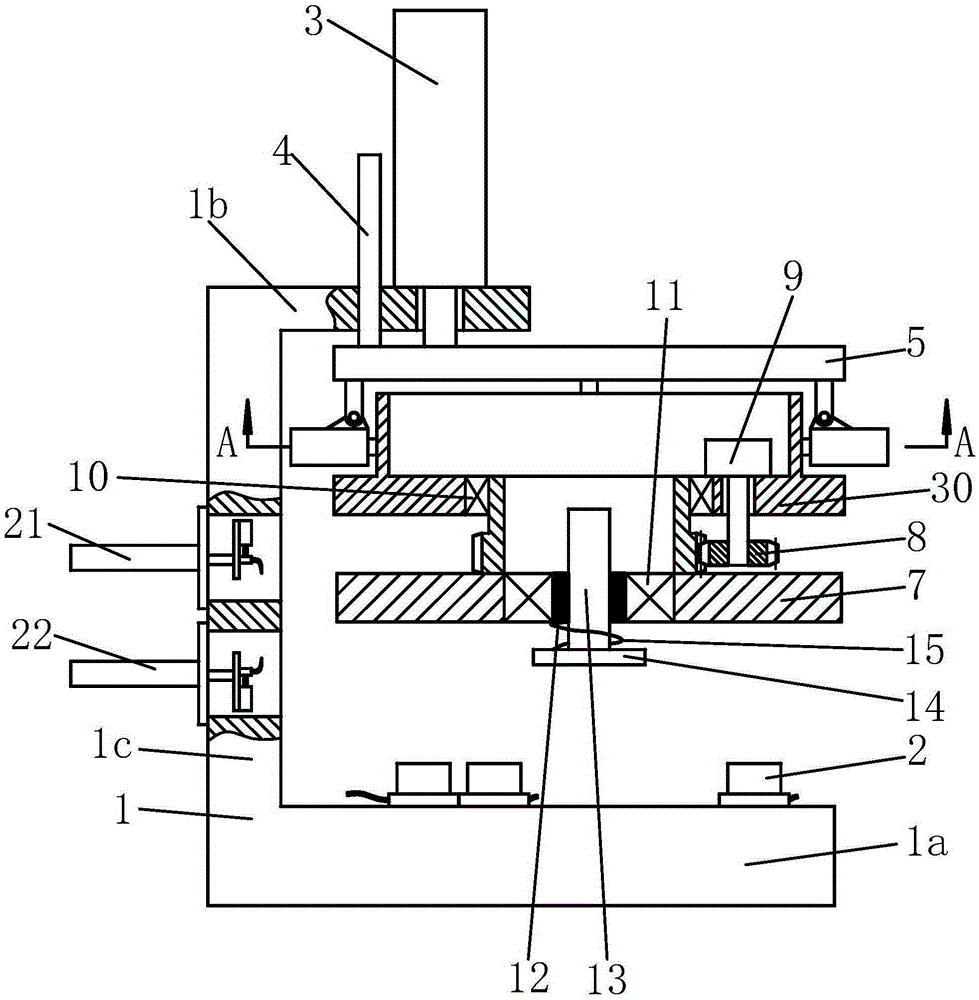

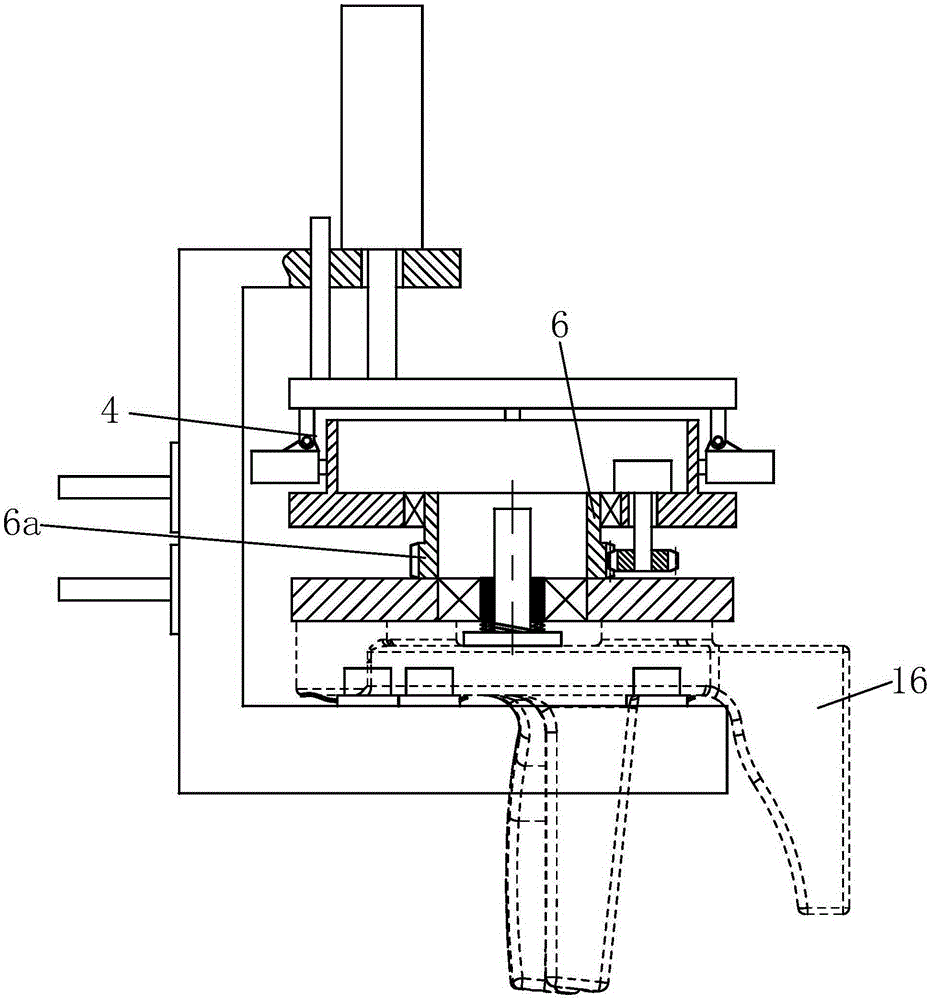

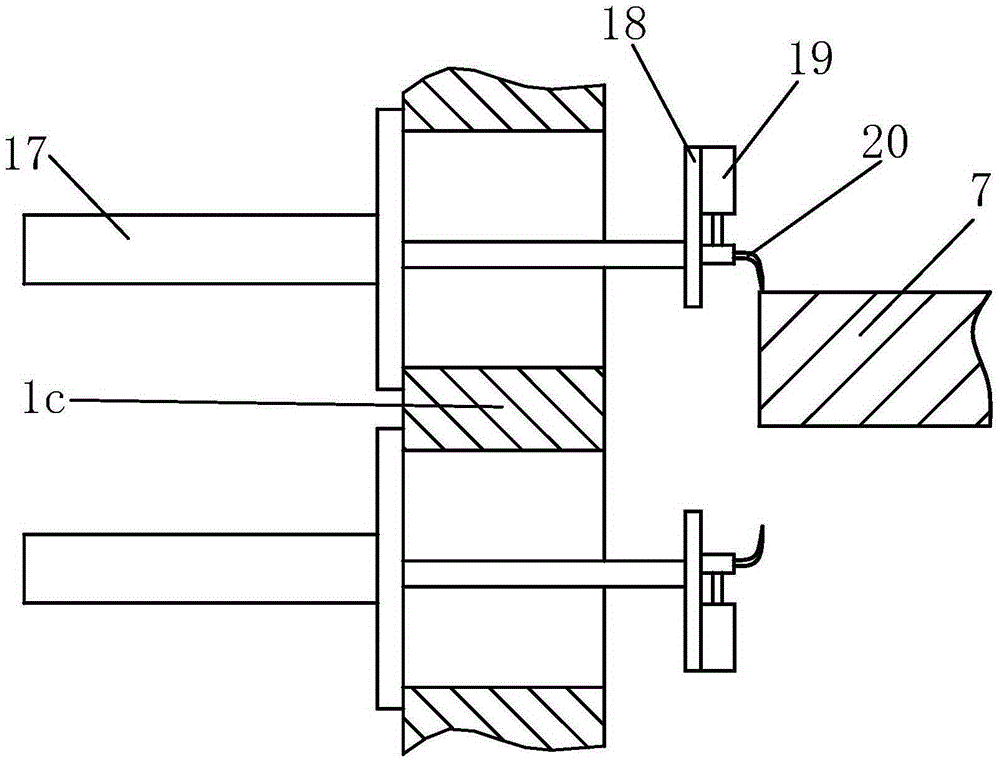

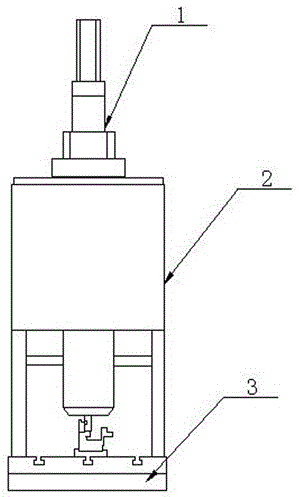

Laser cleaning device for inductor pins

ActiveCN105032849ASimple structureEasy to useCleaning processes and apparatusLaser transmitterGalvanometer

A laser cleaning device for inductor pins comprises an industrial personal computer, a flexible transmission mechanism, a clamp tray mechanism, three laser emitter assemblies and a workbench, wherein the flexible transmission mechanism is installed on the workbench and connected with the industrial personal computer through a line; the clamp tray mechanism is fixed to the flexible transmission mechanism and connected with the industrial personal computer through a line; the three laser emitter assemblies are installed on the workbench; each laser emitter assembly comprises a laser generator and a laser galvanometer connected with the laser generator; the laser generators are connected with the industrial personal computer through lines; the laser galvanometers of the three laser emitter assemblies are evenly distributed on the same horizontal plane and are all used in cooperation with an electromagnetic clamp. The laser cleaning device for inductor pins has the beneficial effects that the structure is simple, use is convenient, manpower and material resource are saved, and the machining efficiency is improved; the unit cost for cleaning of pins of electronic elements is dramatically reduced, and the requirements of people for production and machining are met.

Owner:武汉拓尔奇光电技术有限公司

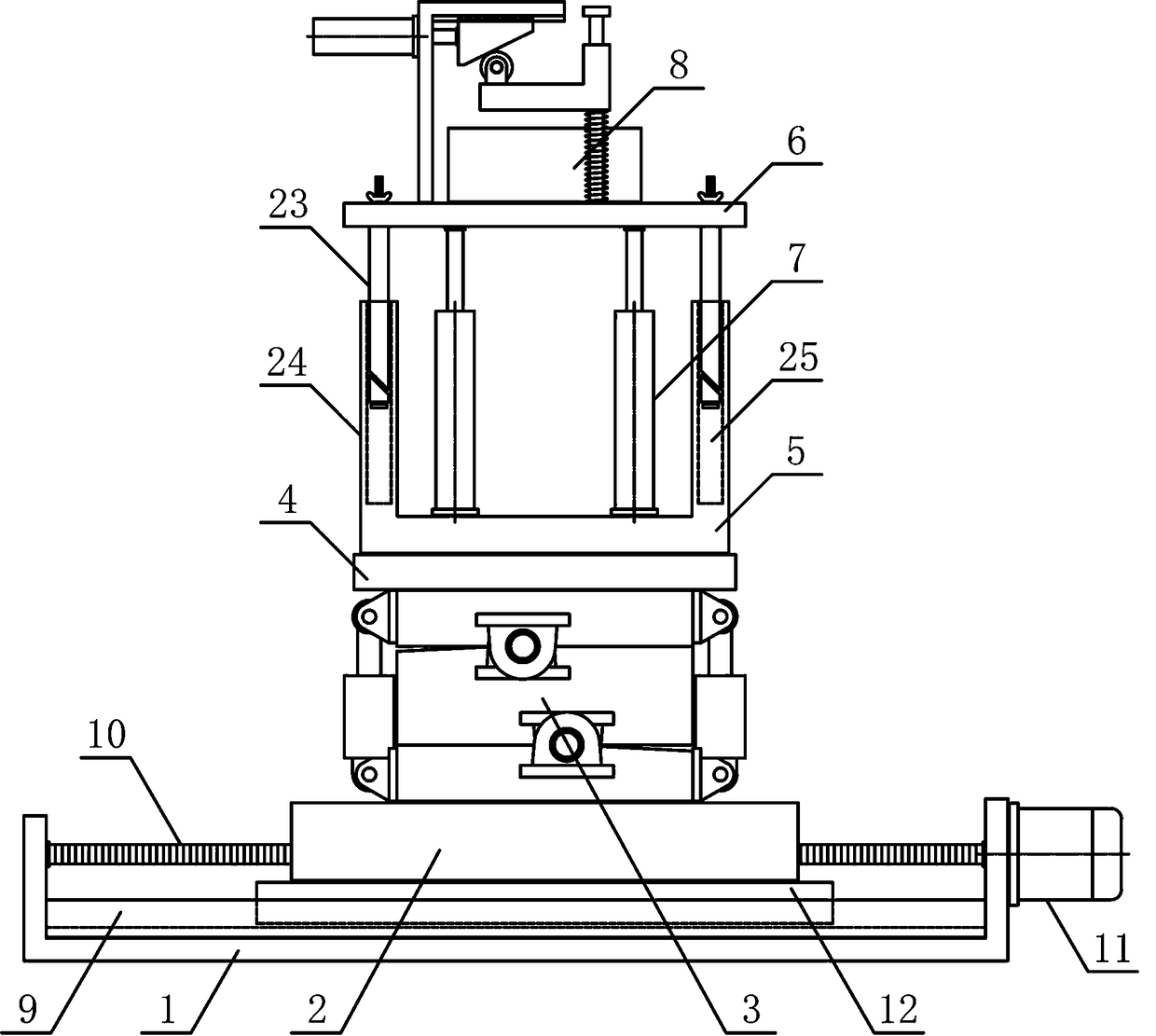

Automatic end surface milling device for automobile flexible shaft brackets

InactiveCN105345107AReasonable structural designReduce production costMilling equipment detailsPositioning apparatusMechanical engineeringEngineering

The invention relates to an automatic end surface milling device for automobile flexible shaft brackets. The automatic end surface milling device comprises a base, a locating device, a lifting regulation device, a milling position regulation device, a rotary milling device, a pressing device and an abrasion detector. The locating device is placed on the upper end surface of a work table, the lifting regulation device is installed on a cross beam, the milling position regulation device is installed in the middle of the lower end of the lifting regulation device, the rotary milling device is installed in the middle of the milling position regulation device, the pressing device is installed in the middle of the lower end of the rotary milling device, the abrasion detector is installed in the middle of a supporting beam, and the lower left part of the rotary milling device is located in the middle of the abrasion detector. The automatic end surface milling device has the advantages of being reasonable in structural design, low in producing and manufacturing cost, convenient to operate, capable of milling the upper end surfaces of the flexible shaft brackets and greatly improving the milling efficiency of the automobile flexible shaft brackets, capable of compensating for abrasion so as to guarantee the machining precision, capable of being regulated according to the automobile flexible shaft brackets of different dimensions, high in flexibility and wide in application range.

Owner:WUHU YINXING AUTO PARTS

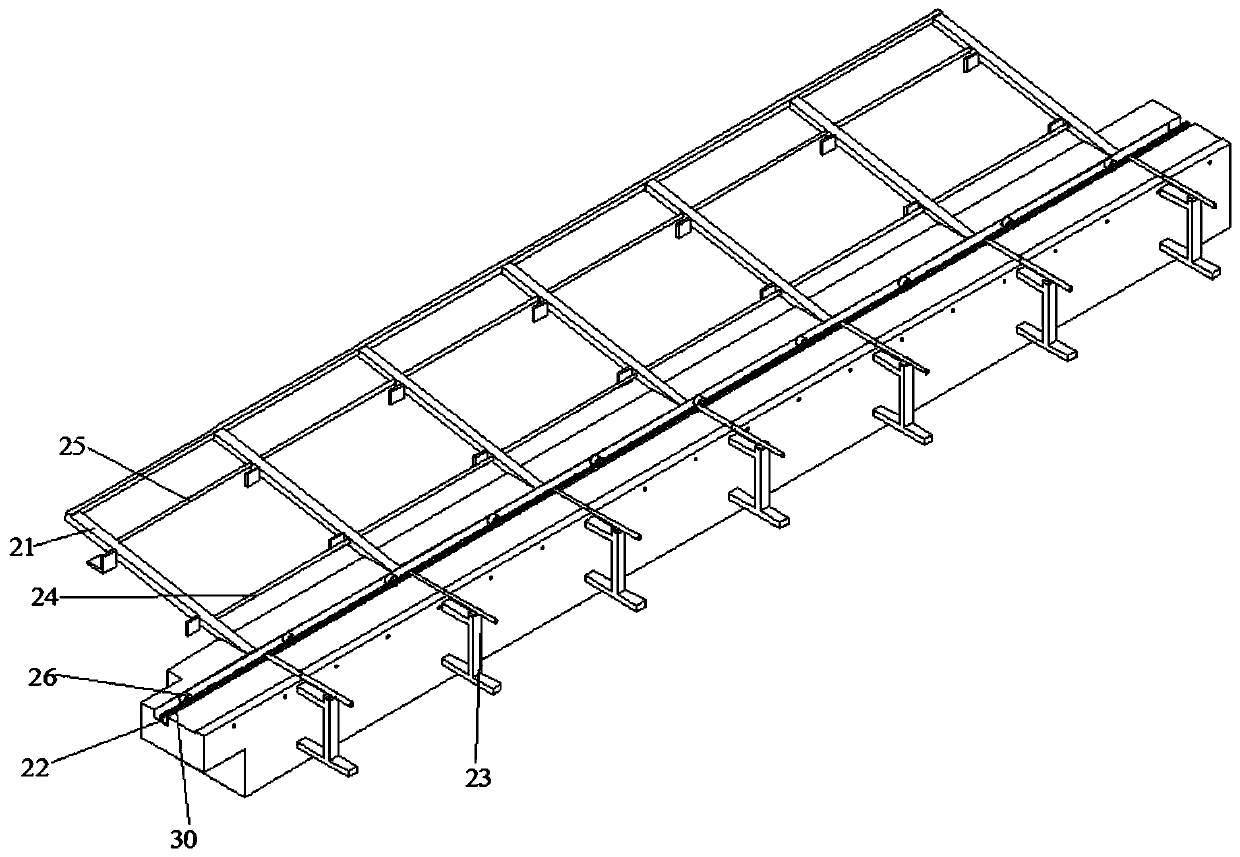

Automatic transmission, bending and welding integrated device used for large span box beam main reinforcement

The invention discloses an automatic transmission, bending and welding integrated device used for large span box beam main reinforcement. The automatic transmission, bending and welding integrated device used for the large span box beam main reinforcement comprises bending platforms, welding devices, transmission devices and rotating devices, wherein the welding devices, the transmission devices and the rotating devices are arranged on the bending platform; the bending platforms comprise N bending platform bodies arranged at intervals, and N is greater than or equal to 2; a welding device is arranged on each bending platform; the corresponded set number transmission devices is N+1, a bending platform is arranged between every two adjacent sets of transmission devices; and two sets of rotating devices are correspondingly arranged at the tail end of the transmission device arranged at the end of the bending platform. According to the schemes of the automatic transmission, bending and welding integrated device used for the large span box beam main reinforcement, labor intensity of workers is lowered, the production efficiency is improved, the actual using effect is good, and production requirements are met; the bending mechanism, the welding mechanism and the transmission mechanism of rebar are combined into a whole, the structure is compact, the volume is decreasing, the automatic transmission, bending and welding integrated device used for the large span box beam main reinforcement is suitable for manufacturing of the large span box beam main reinforcement, standard pieces are adopted, and the cost is greatly lowered.

Owner:THE SECOND CONSTR OF CTCE GROUP

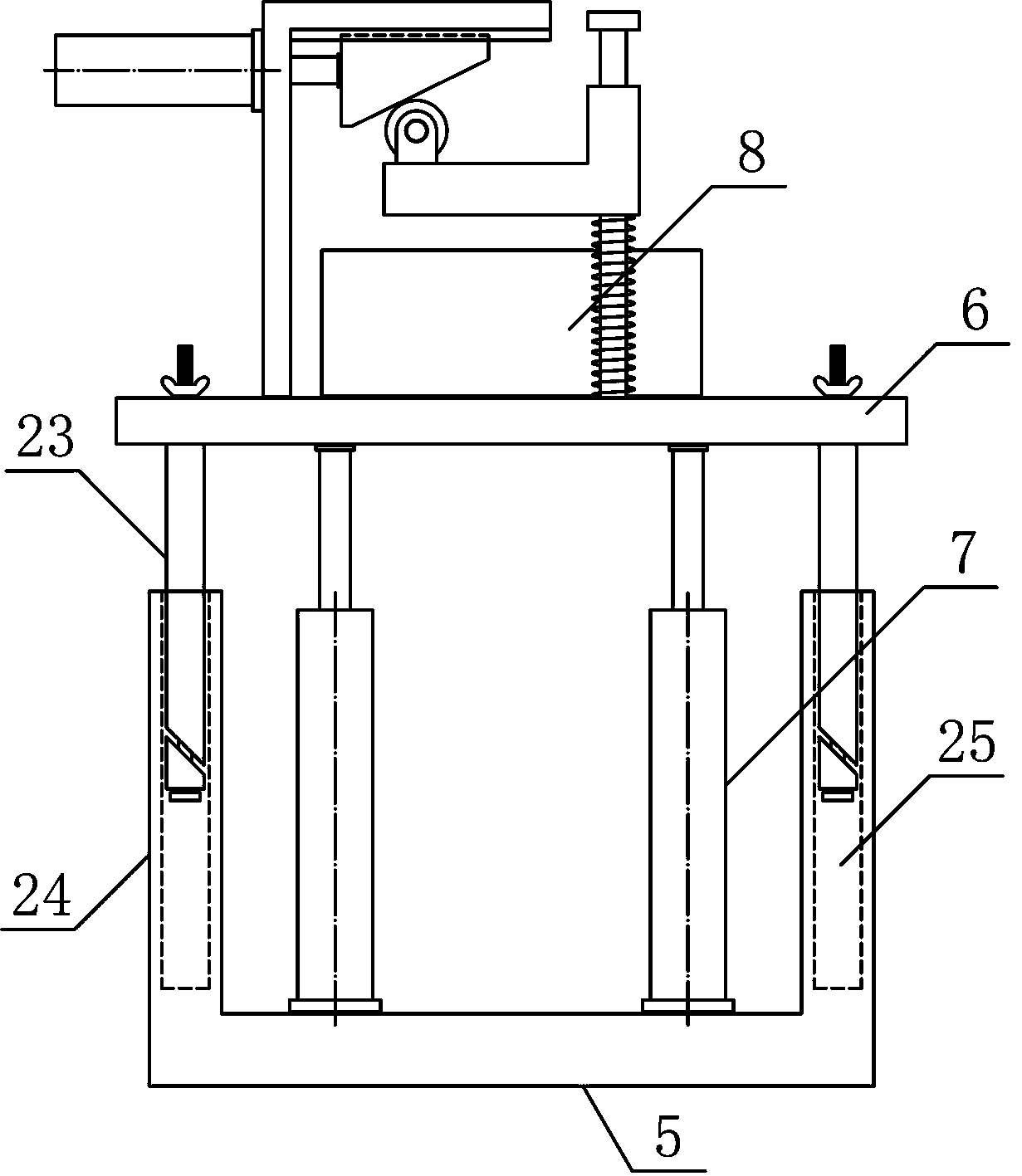

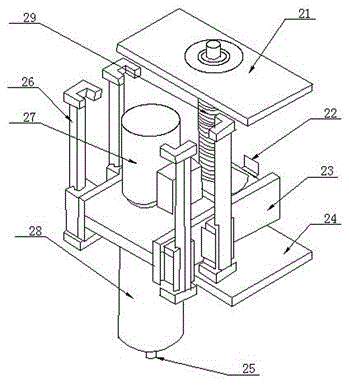

Intelligent precise die device

InactiveCN110153291AMeet production and processing needsSpeed up the production processShaping toolsNon-rotating vibration suppressionEngineeringMechanical engineering

The invention relates to an intelligent precise die device which comprises a bottom plate, wherein a rotary block is arranged in a groove in the top of the bottom plate; a rotary column is fixedly connected with the top of the rotary block; the top of the rotary column penetrates through the bottom plate, extends out of the bottom plate and is fixedly connected with a rotary plate; a ball at the bottom of the rotary block is arranged in the groove in the top of the bottom plate; and a stabilizing rod is movably connected with the left side of the top of the rotary plate. Through mutual cooperation of the rotary block, the rotary column, the rotary plate, the ball, the stabilizing rod, a stabilizing groove, a movable plate, a limiting spring, a first bearing, a second bearing, a rotary rod,a second fixed plate, a rotary disc, a support plate, a nut, a threaded rod, a limiting block and a limiting groove, the intelligent precise die device can conveniently adjust the angle, so that thedie producing and processing demand is better met, the production progress of the precise die is accelerated, and great convenience is brought for die production.

Owner:HEFEI UNIV

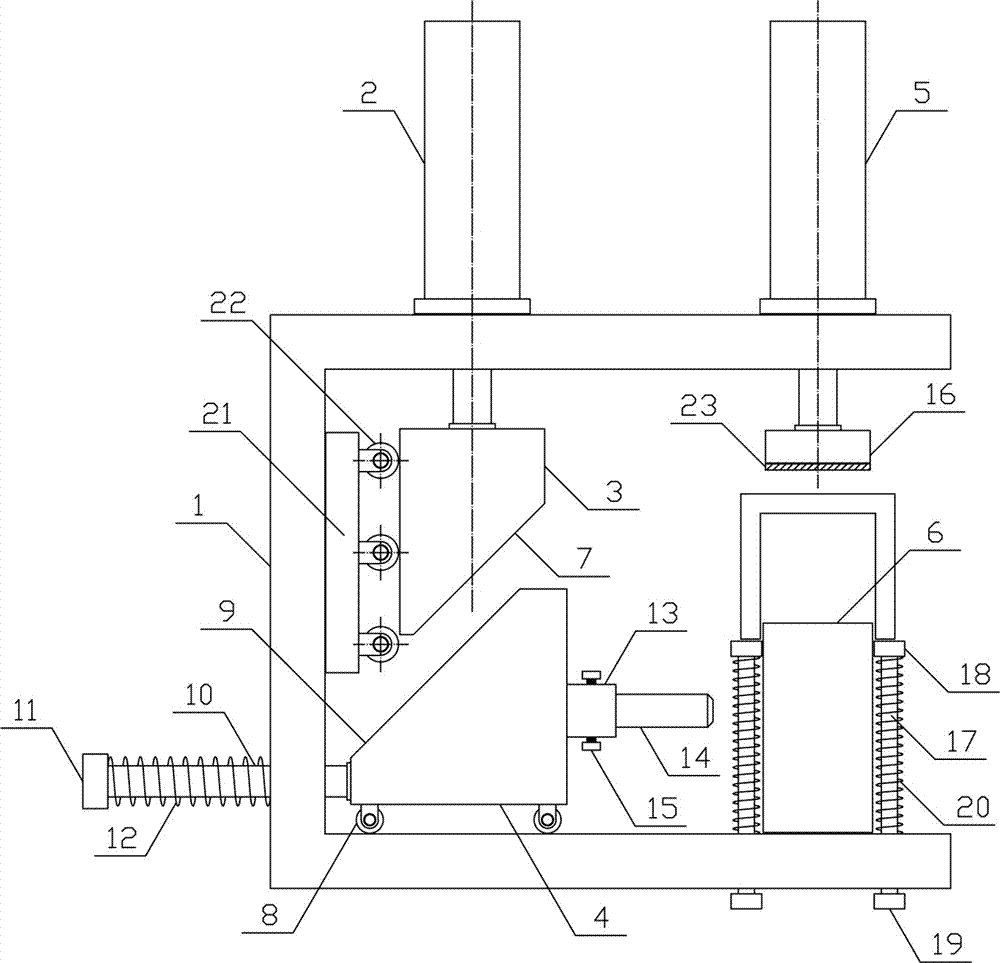

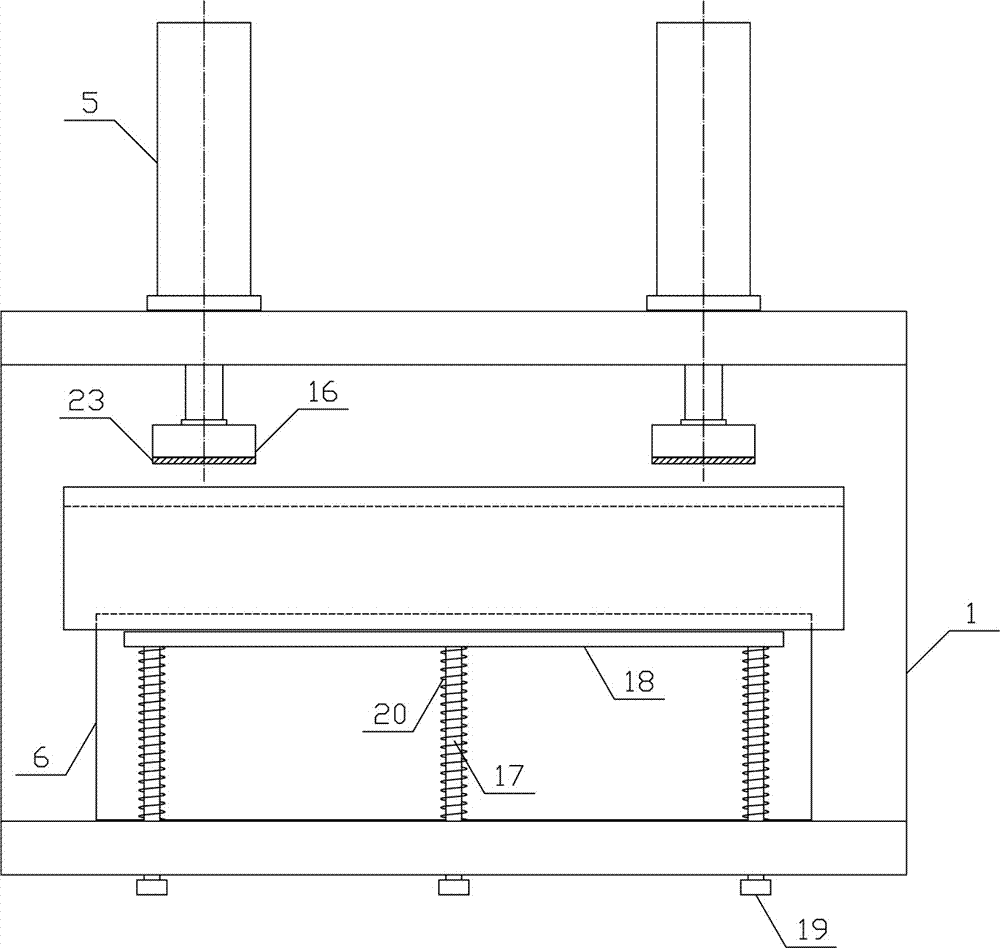

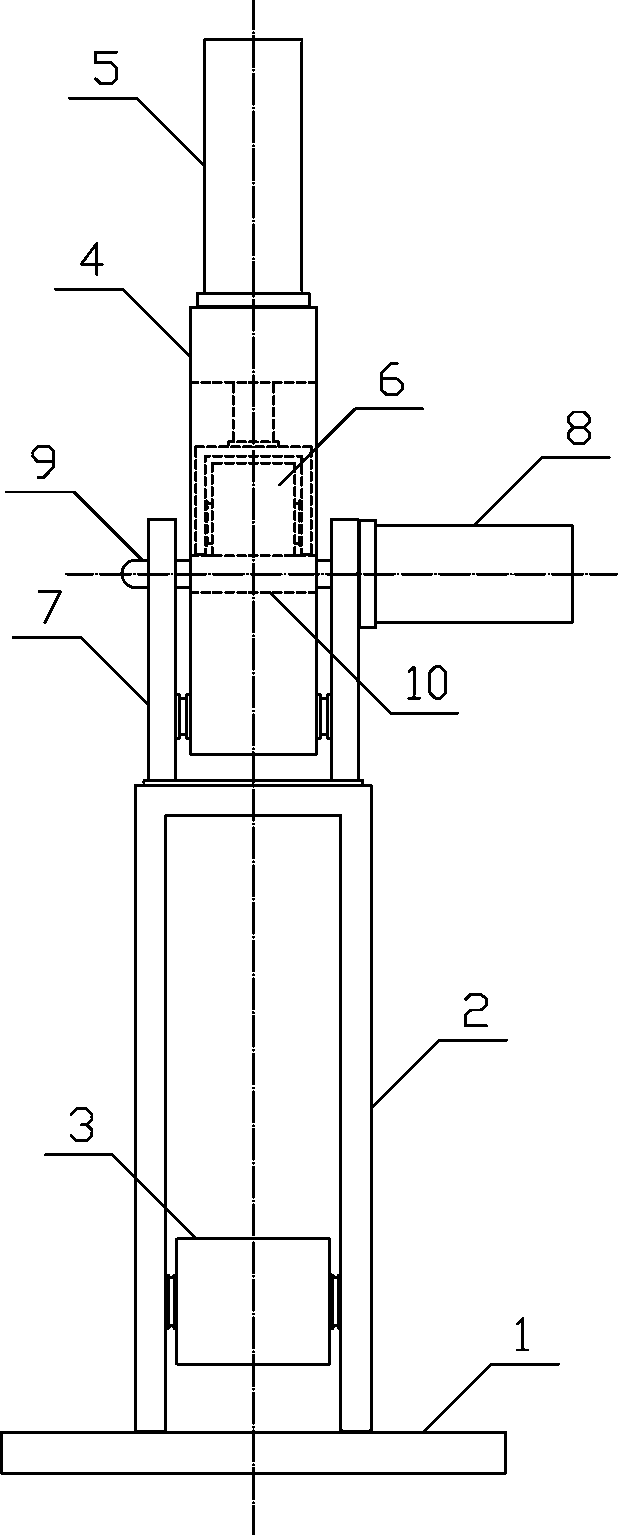

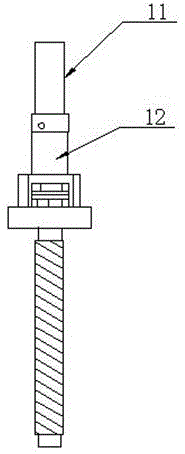

Special servo radial riveting machine

InactiveCN105618658AMeet production and processing needsAdjustable riveting strokeThree phase asynchronous motorControl theory

The invention discloses a special servo radial riveting machine, and relates to the technical field of production of vehicle parts. An electric module is arranged at the upper end of a riveting module; a positioning module is arranged at the bottom of the riveting module; a servo motor is connected with a speed reducing machine; the lower end of the motor is connected with a riveting body through a connecting plate; the upper end and the lower end of a lead screw are respectively connected with a lead screw upper connecting plate and a lead screw lower connecting plate; the lower part of the lead screw is fixed with a connecting plate; a travel detecting plate is arranged on one side of the connecting plate; slide rail lateral connecting plates are arranged on two sides of the connecting plate; multiple slide rails are arranged on the slide rail lateral connecting plates; the lead screw is connected with the speed reducing machine of the electric module; and a riveting baseplate is arranged on the baseplate, and is connected with a riveting workpiece. The special servo radial riveting machine combines the servo motor, detecting equipment and a three-phase asynchronous motor, can adjust the riveting travel, can limit the riveting force, satisfies traditional vehicle part production demands, and improves the production efficiency.

Owner:HEFEI QINYI ELECTROMECHANICAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com