Automatic transmission, bending and welding integrated device used for large span box beam main reinforcement

A technology of transmission device and welding device, which is applied in the field of welding, automatic transmission of large-span box girder main reinforcement, bending, bending of large-span box girder main reinforcement for expressway construction, and welding integrated device field, which can solve the problem of reducing production efficiency, no Problems such as bending machine and heavy labor load of workers, to achieve the effect of improving production efficiency, high bending efficiency and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

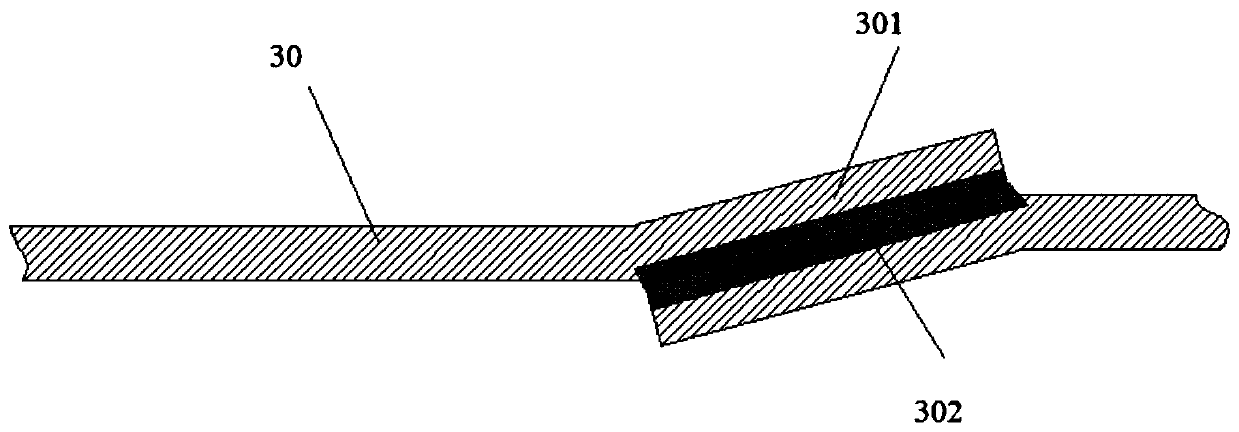

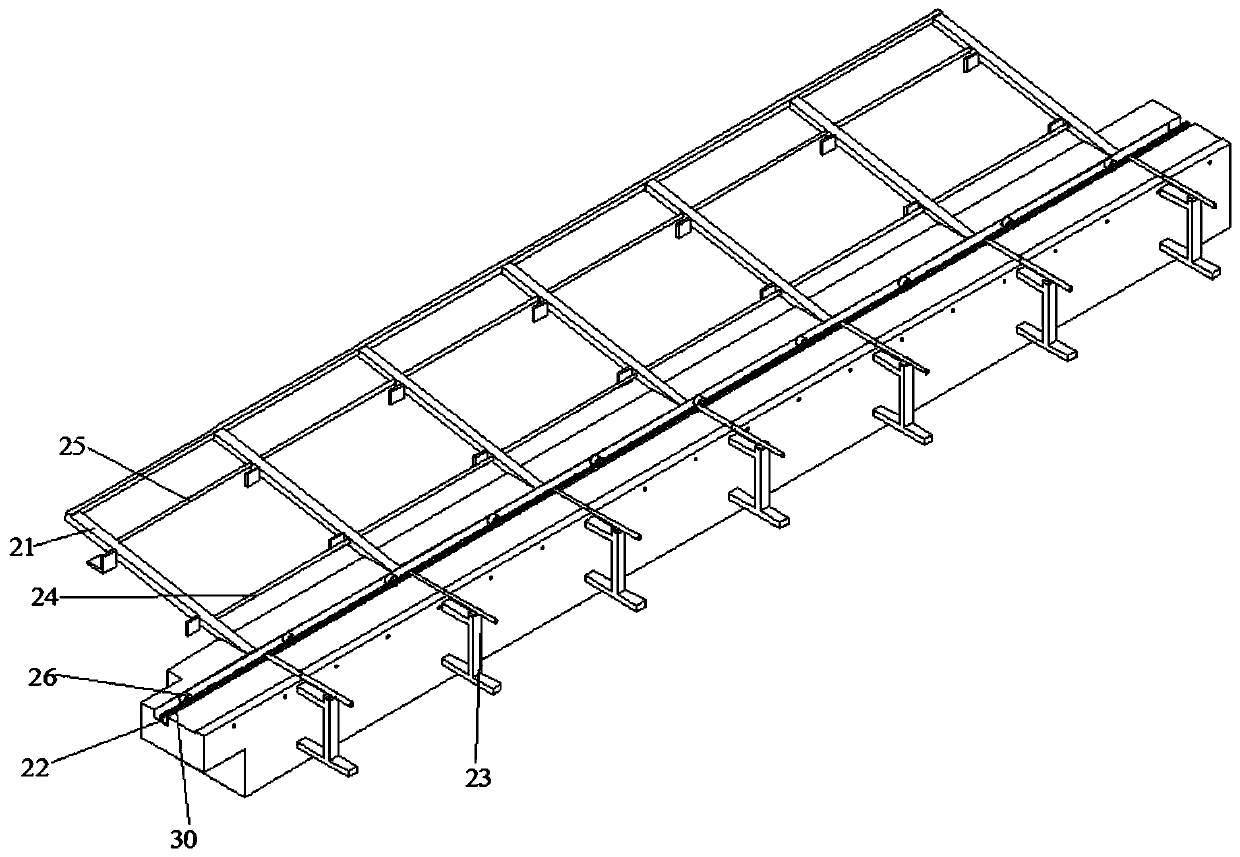

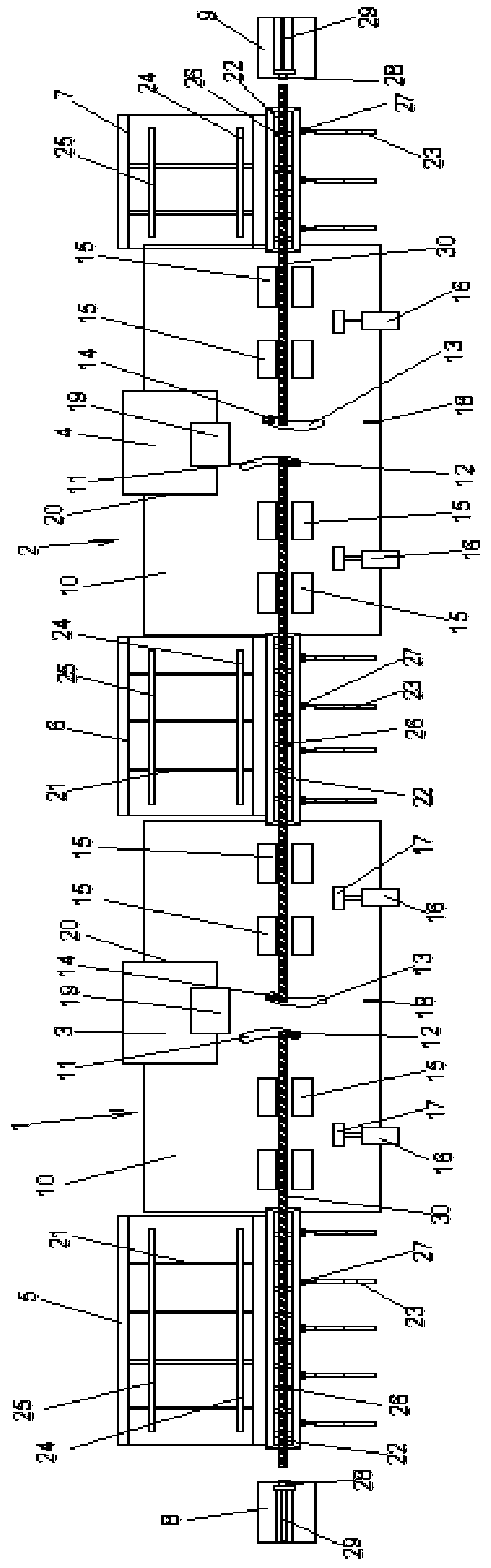

[0038] Such as Figure 1-Figure 5 As shown, an integrated automatic transmission, bending and welding device for the main reinforcement of a large-span box girder includes a bending platform, a welding device arranged on the bending platform, a transmission device and a rotating device;

[0039]The bending platform includes a first bending platform 1 and a second bending platform 2, and the welding device is respectively provided with a first welding device 3 and a second welding device 4 corresponding to the first bending platform 1 and the second bending platform 2; Described conveying device comprises first conveying device 5, second conveying device 6 and the 3rd conveying device 7; These described conveying devices are successively used in conveying the steel bar that length is 12 meters, 12 meters and 6 meters; Said first conveying device The device 5 is located on the left side of the first bending platform 1, the second transmission device 6 is located between the firs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com