Laser cleaning device for inductor pins

A technology for laser cleaning and pins, which is applied in the direction of cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems of inapplicability, residual paint layer on the side of pins, high defect rate, etc., so as to improve processing efficiency and reduce unit cost , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

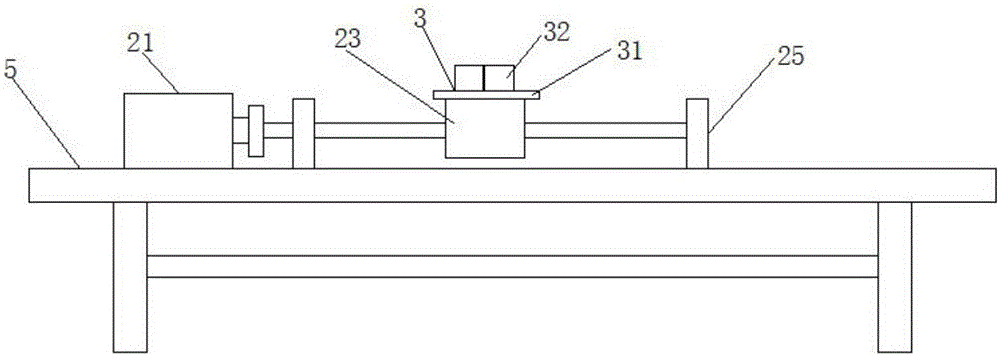

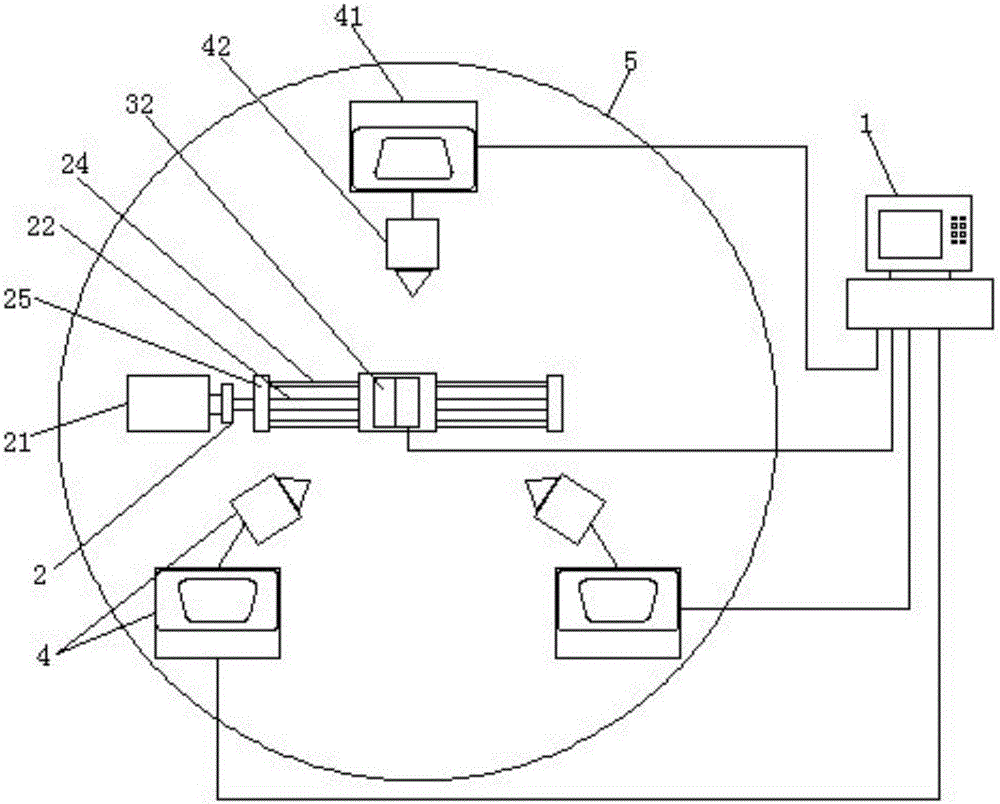

[0017] Example: such as Figures 1 to 2 As shown, the inductance pin laser cleaning equipment of the present invention includes an industrial computer 1, a telescopic transmission mechanism 2, a clamp tray mechanism 3, 3 laser generator assemblies 4 and a workbench 5, and the above-mentioned telescopic transmission mechanism 2 is installed on the workbench 5 , and connect the above-mentioned industrial computer 1 through the line, the above-mentioned clamp tray mechanism 3 is fixed on the telescopic transmission mechanism 2, and connect the above-mentioned industrial computer 1 through the line, and the three above-mentioned laser generator assemblies 4 are all installed on the workbench 1;

[0018] Above-mentioned laser generator assembly 4 comprises laser generator 41 and the laser vibrating mirror 42 that is connected with laser generator 41, and above-mentioned laser generator 41 connects above-mentioned industrial computer 1 by line, and the laser vibrating mirror 42 of 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com