Measuring analytical system and measuring analytical method for distinguishing diffraction image of particles automatically

An image measurement and analysis system technology, applied in the field of diffraction image measurement and analysis systems, can solve complex and time-consuming processes, biological particles such as cell interference effects, time-consuming and other problems, and achieve the effect of low measurement cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

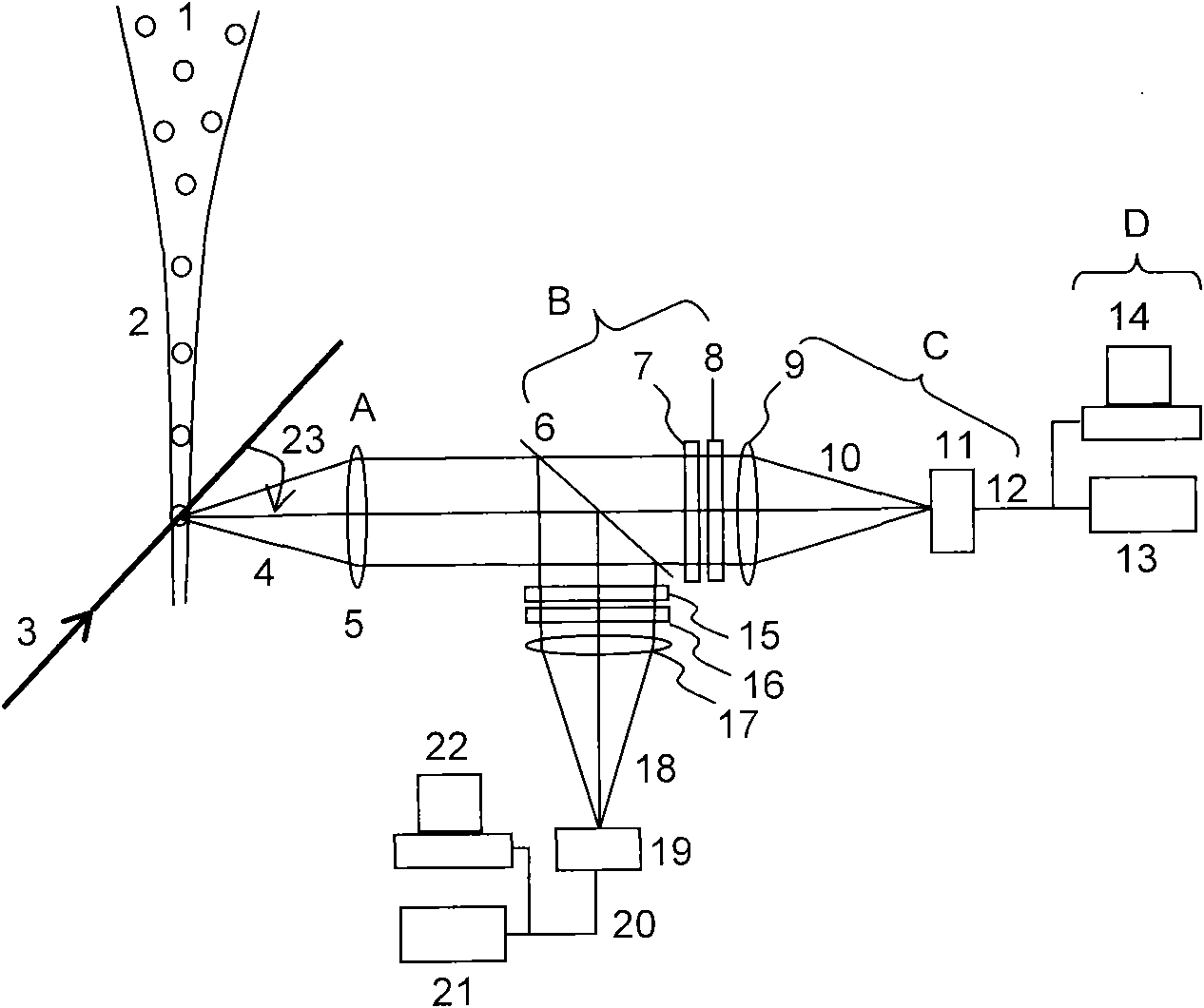

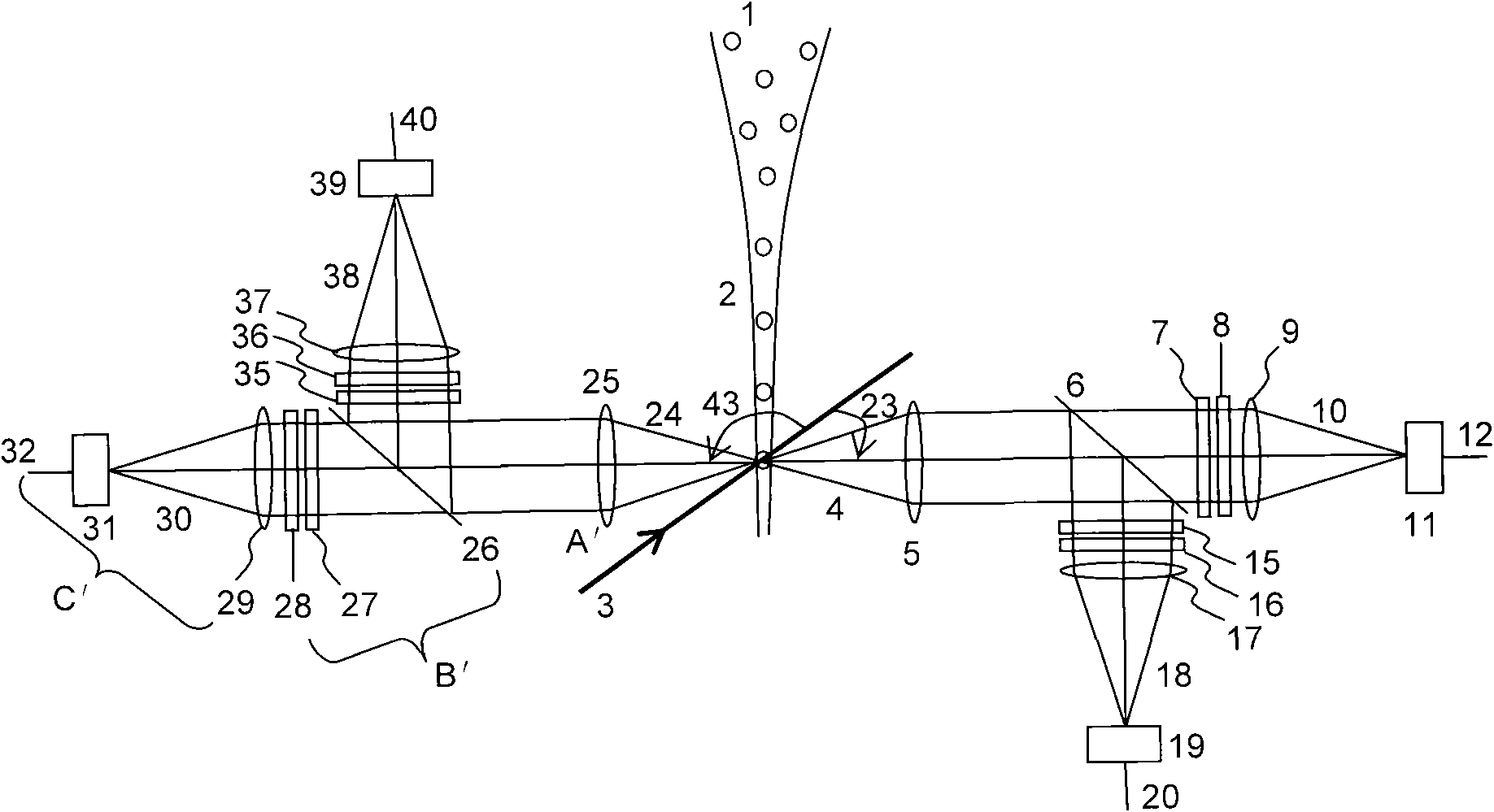

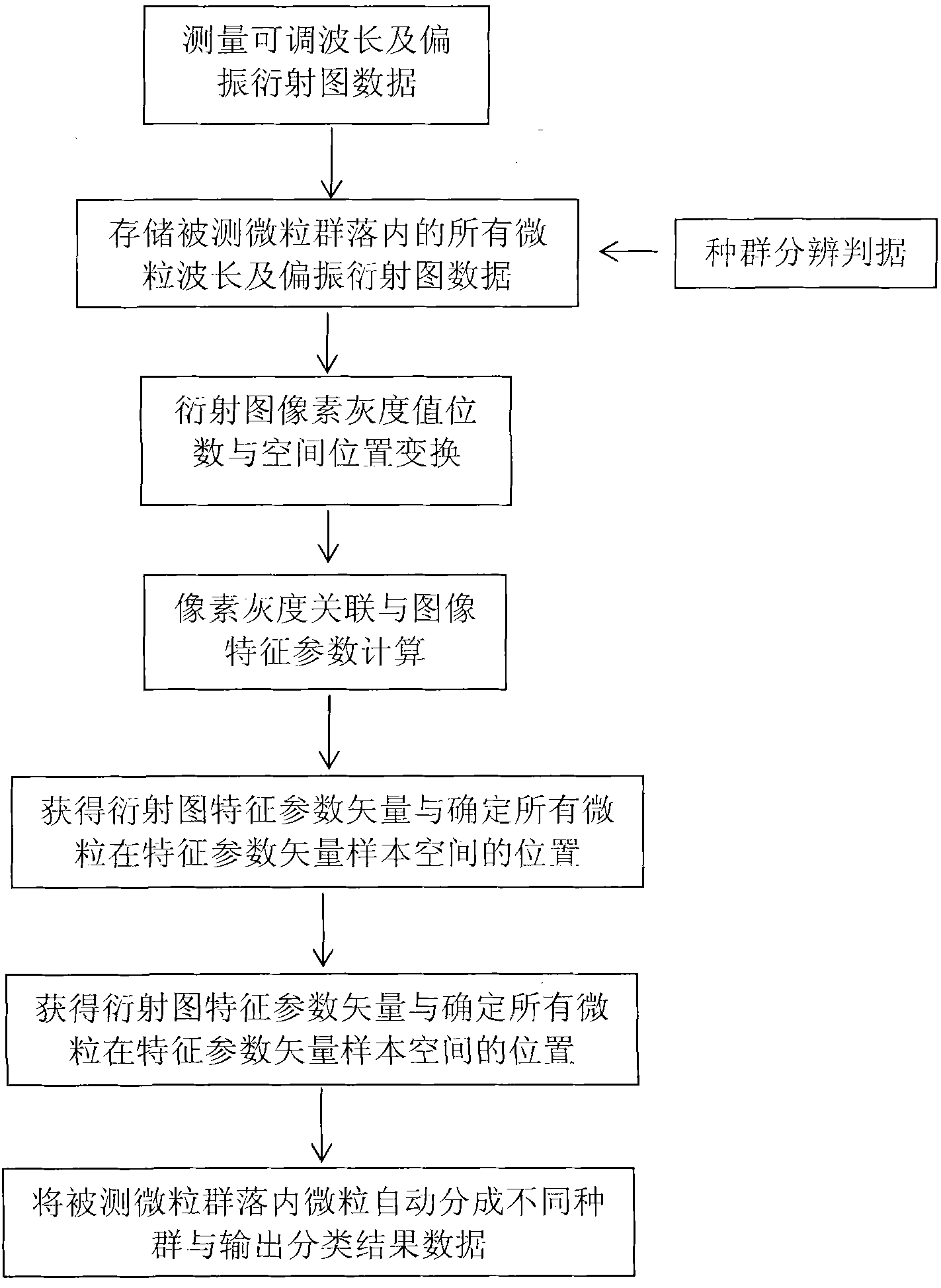

[0066] The diffraction image measurement and analysis system and method for automatically identifying particles of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0067] An implementation method of the diffraction image measurement and analysis system and method for automatically distinguishing particles described in the present invention uses an adjustable imaging system to measure diffraction images of different wavelengths and polarizations, and then quickly analyzes the pixel gray of multiple diffraction image data through computer software. The degree correlation parameters are extracted, and the image pattern statistical parameter vectors are extracted, and the communities containing a large number of particles are quickly classified according to these parameter vectors and population discrimination criteria. The present invention can also be implemented by computer software for rapid population clas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com