Patents

Literature

67 results about "Multiple diffraction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

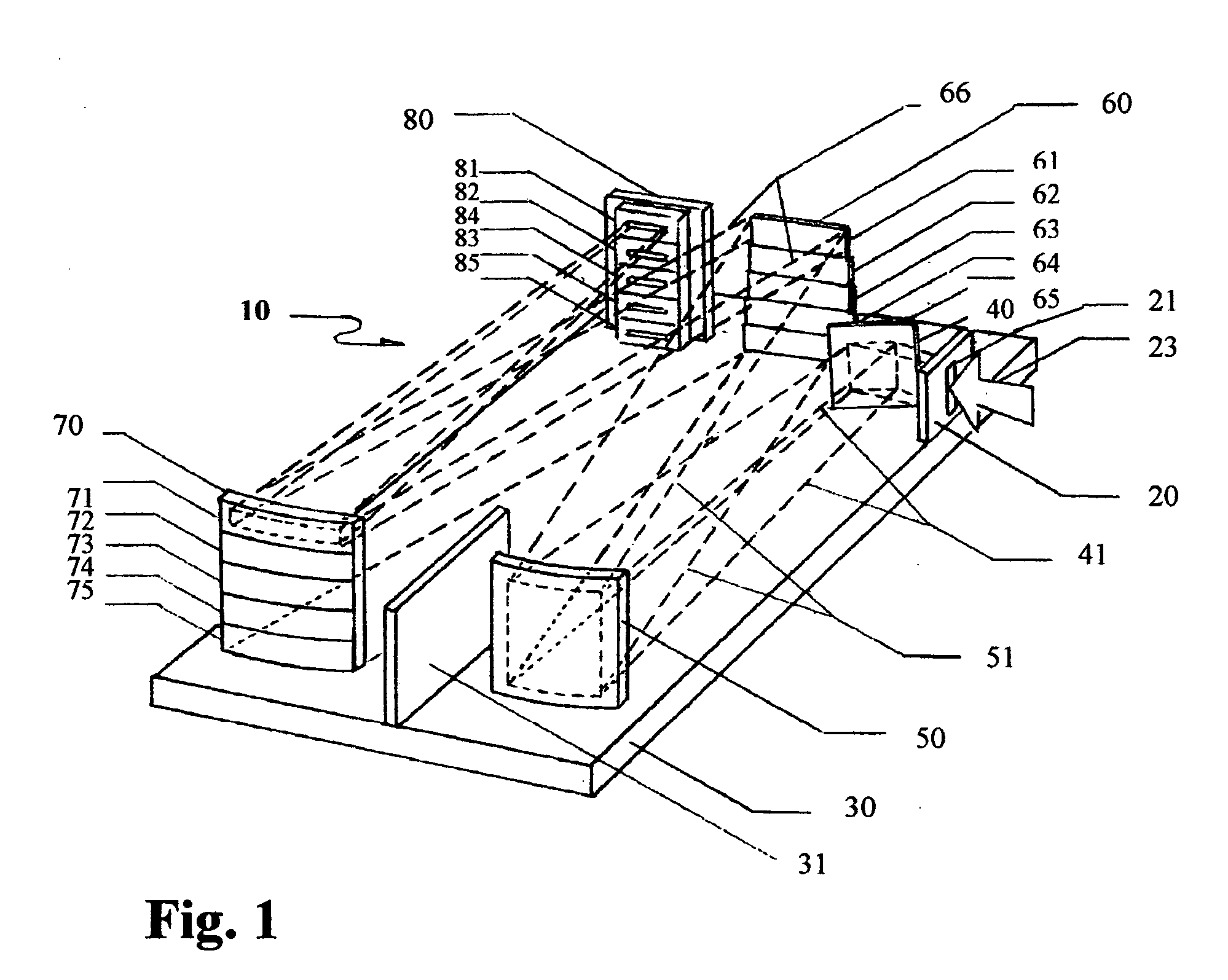

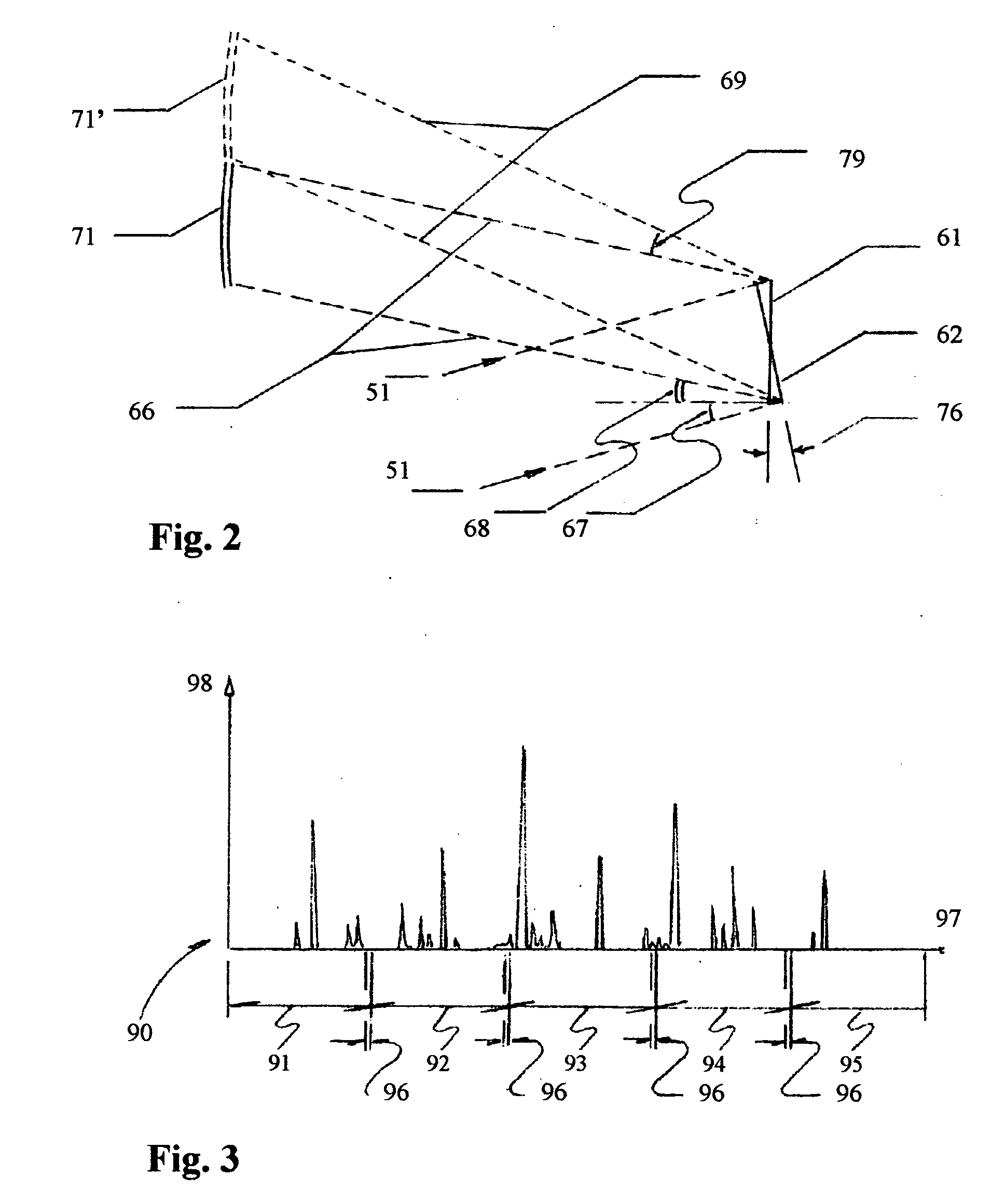

Apparatus and method for texture analysis on semiconductor wafers

InactiveUS6301330B1Rapid texture measurementQuick measurementX-ray spectral distribution measurementSemiconductor/solid-state device testing/measurementPhysicsMultiple diffraction

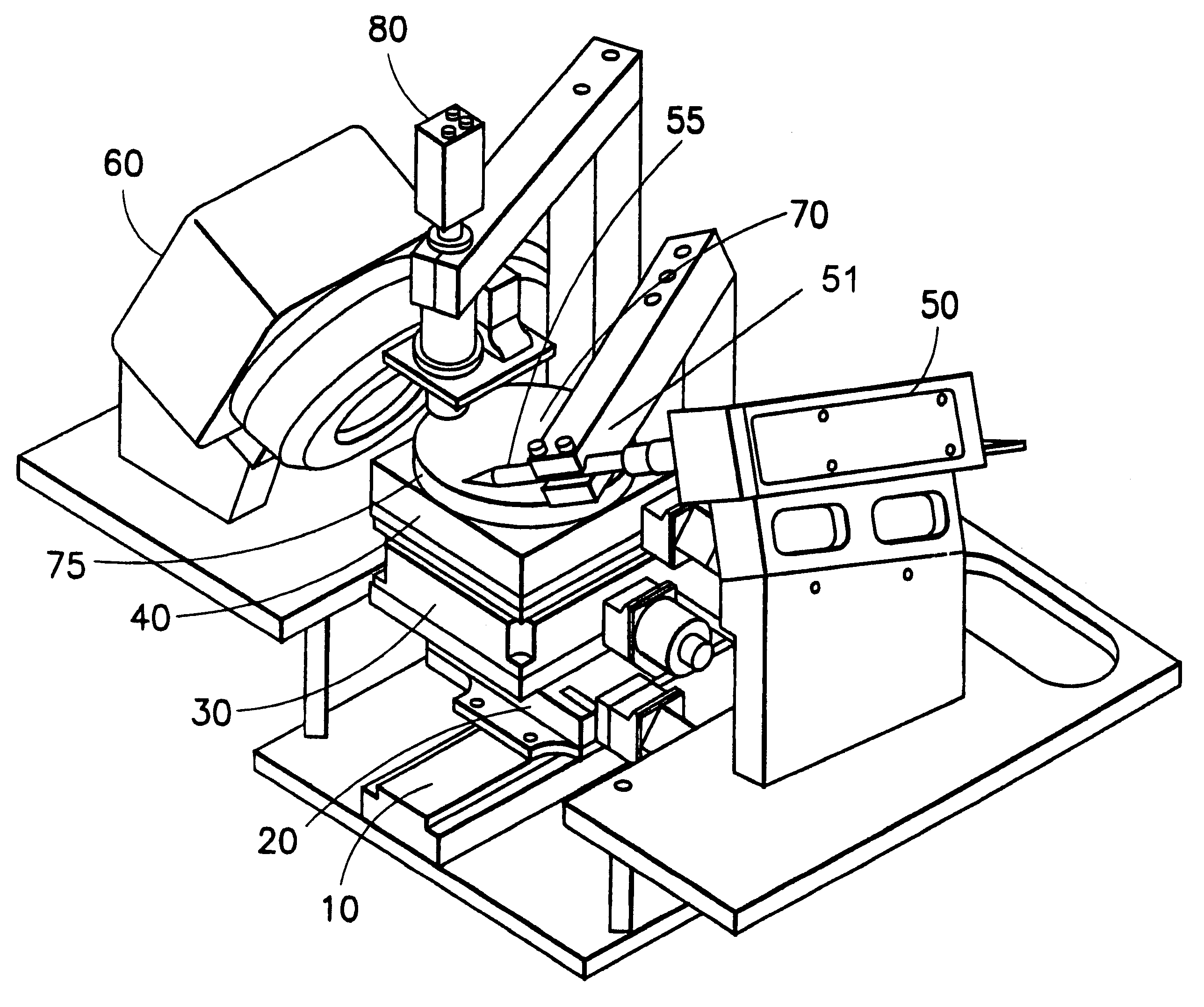

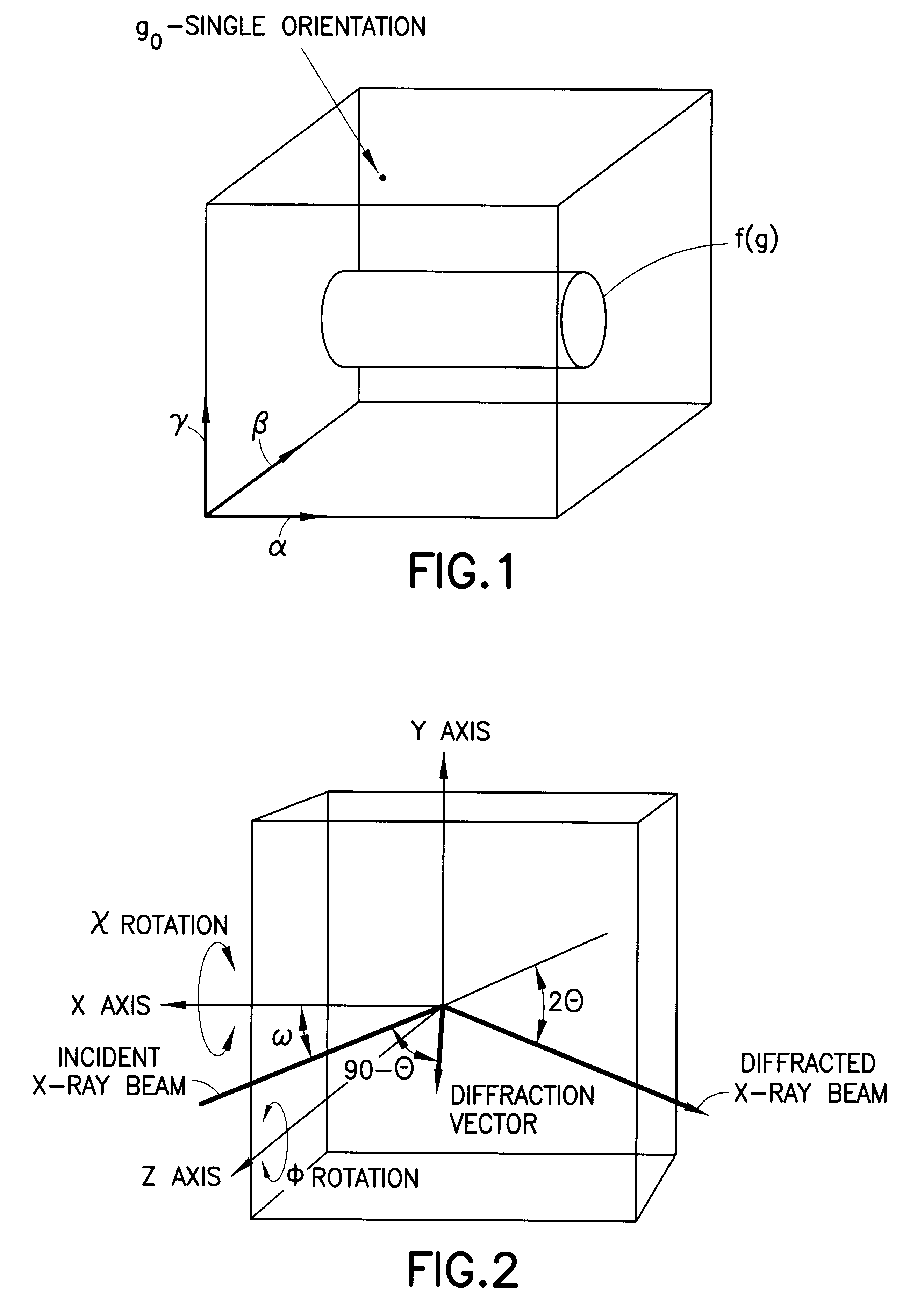

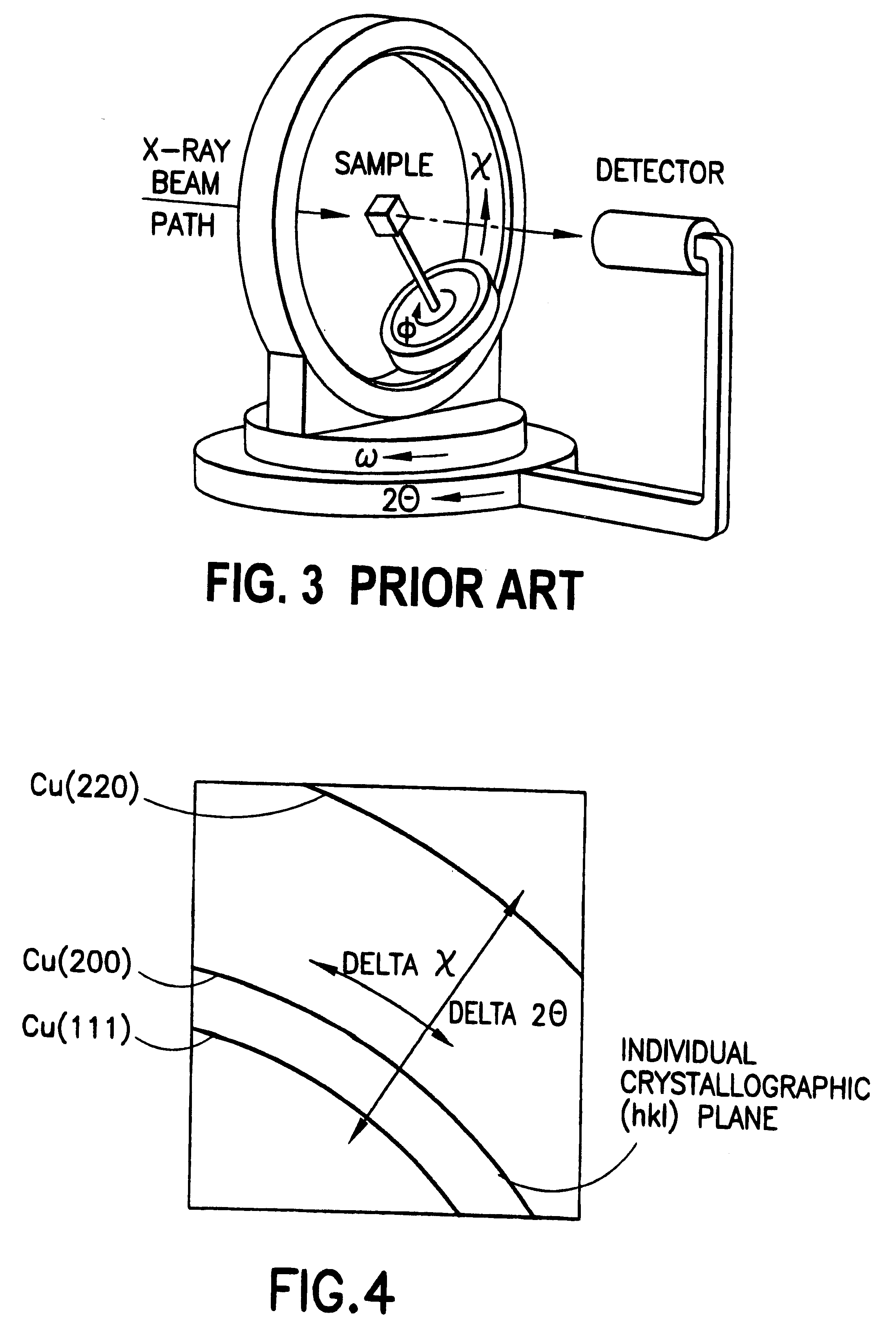

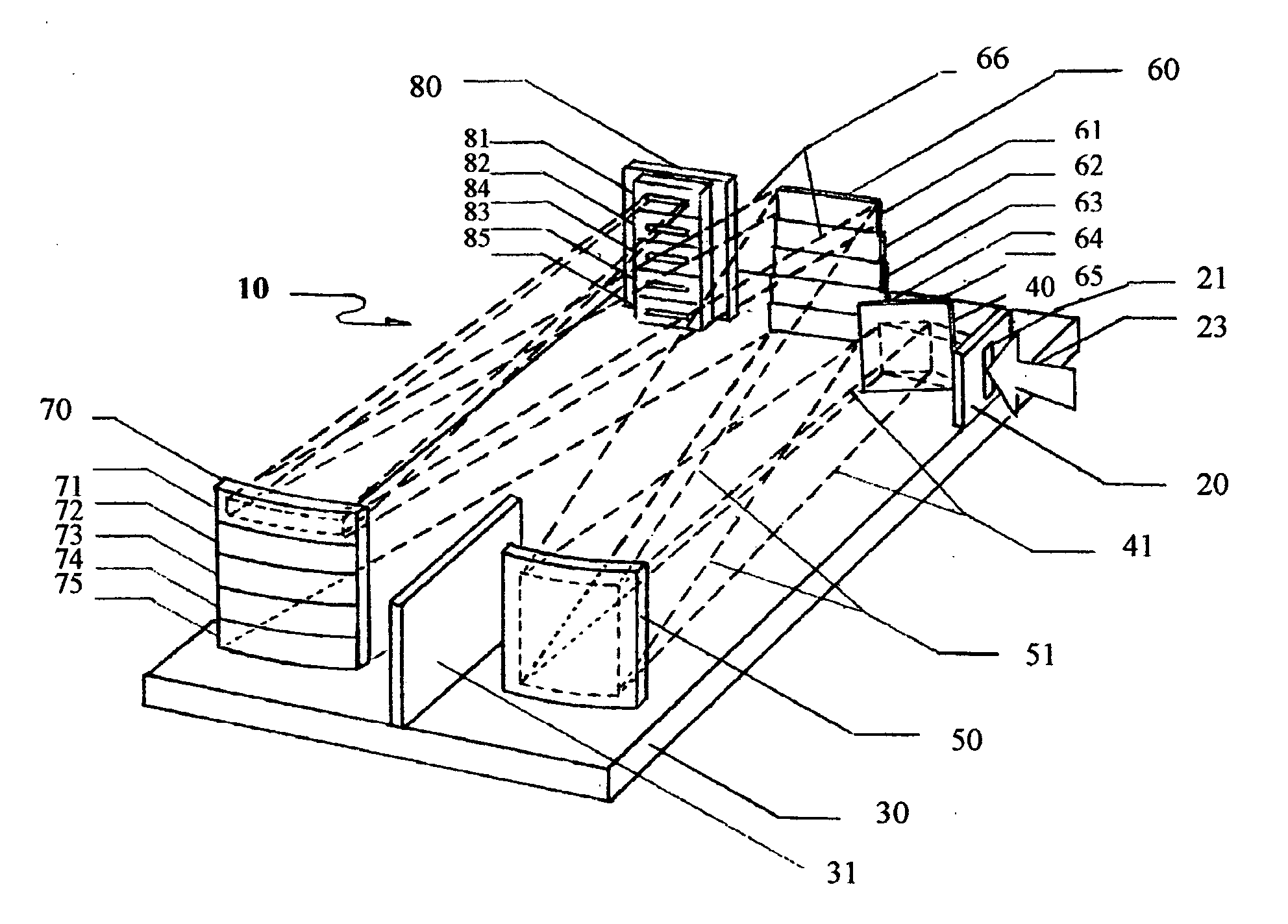

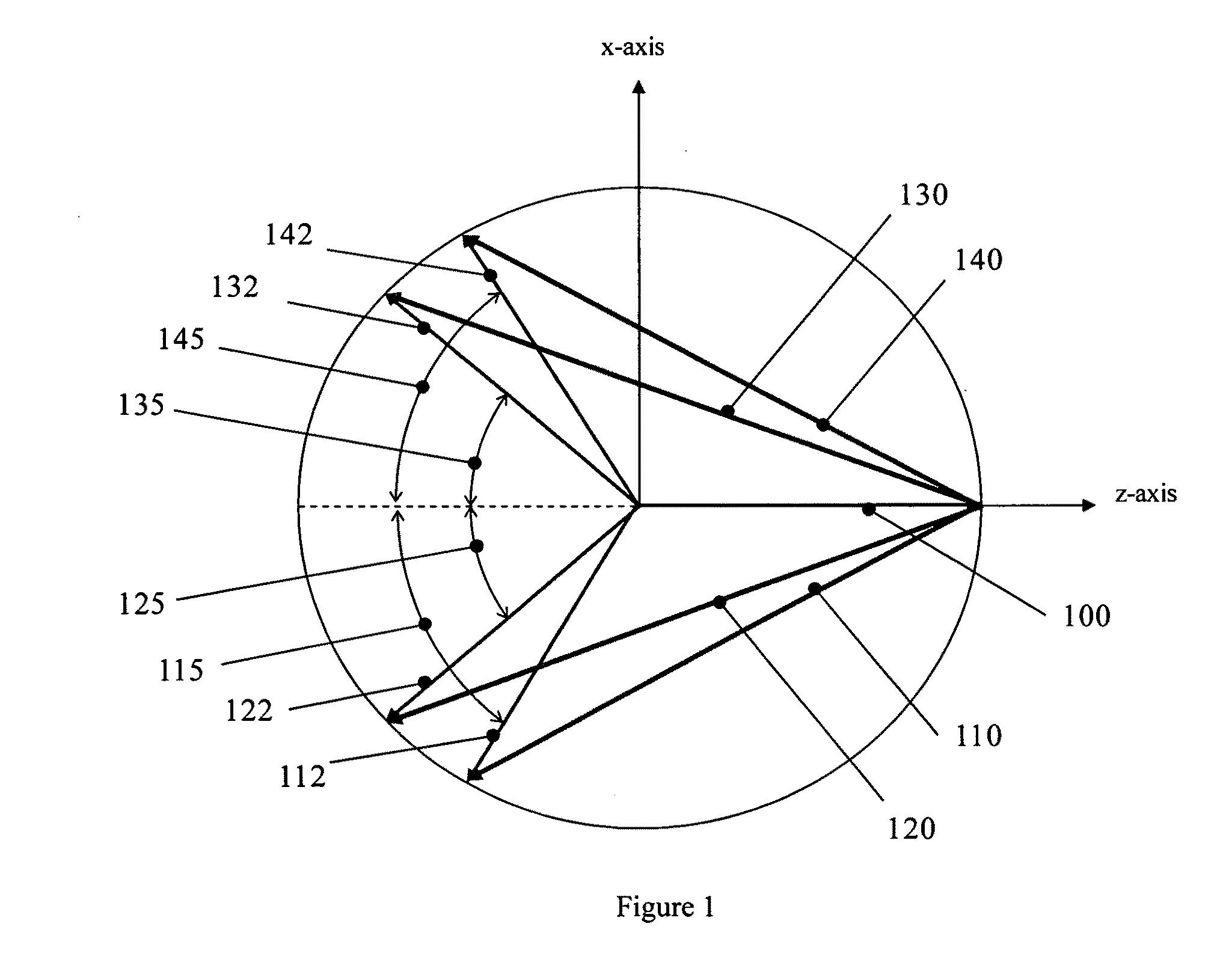

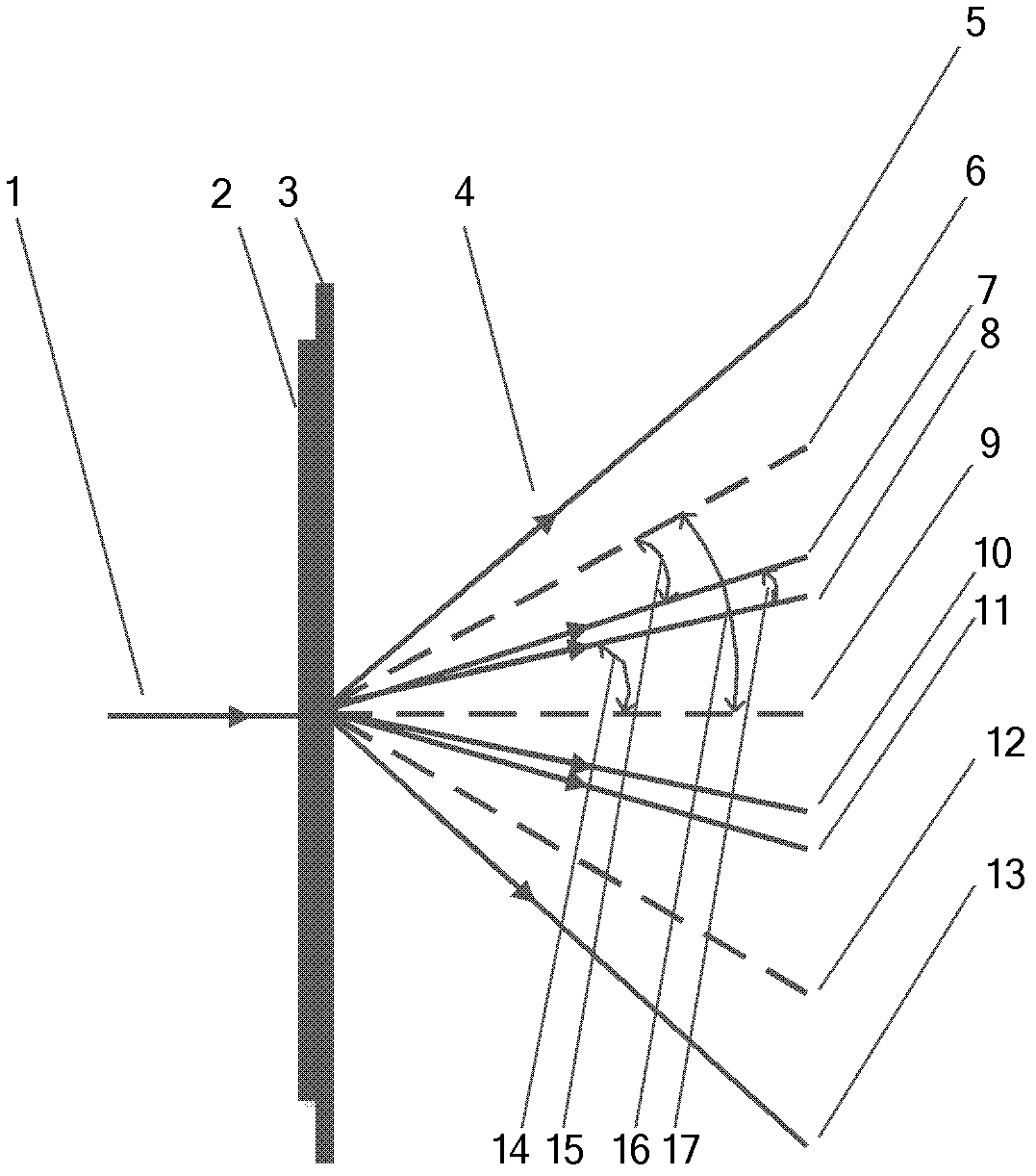

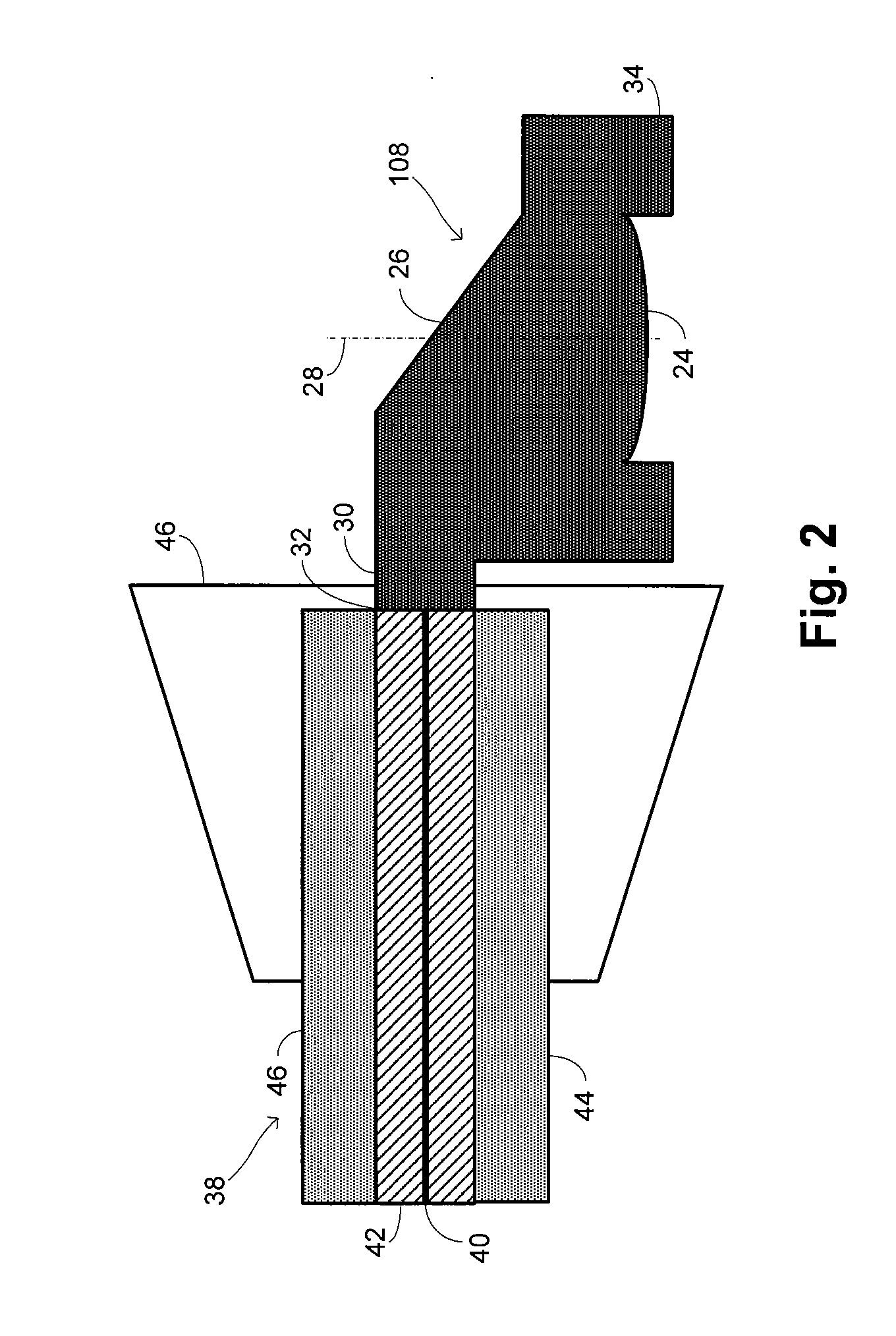

An apparatus and method for performing rapid, high-resolution polycrystalline crystallographic texture analysis, by calculating an Orientation Distribution Function (ODF) from partial pole figures obtained from x-ray diffraction measurements on large samples, e.g., 200 millimeter diameter wafers. The measurement apparatus includes a 2-D area x-ray detector and a collimated x-ray source arranged in a specific, fixed spatial relationship dependant on the properties of the sample to be measured, and also includes a particular wafer motion assembly. The wafer motion assembly includes three mutually orthogonal rectilinear translation stages, and a phi rotation stage mounted thereon, as an uppermost motion stage, with its range restricted to 180° of rotation. theta-2theta and χ motions are eliminated, and the close deployment of the x-ray source and area detector to the measuring spot on the wafer is such that the detector covers a sufficient range of 2theta and χ to capture multiple diffraction arcs in each frame. The invention employs a new and advantageous texture analysis protocol to determine ODF from the severely truncated pole figures thus obtained, through comparison of experimental ODF figures with calculated ones. The resulting system is fast, accurate, amenable to automation, and does not require highly skilled personnel to operate.

Owner:NOVA MEASURING INSTR LTD

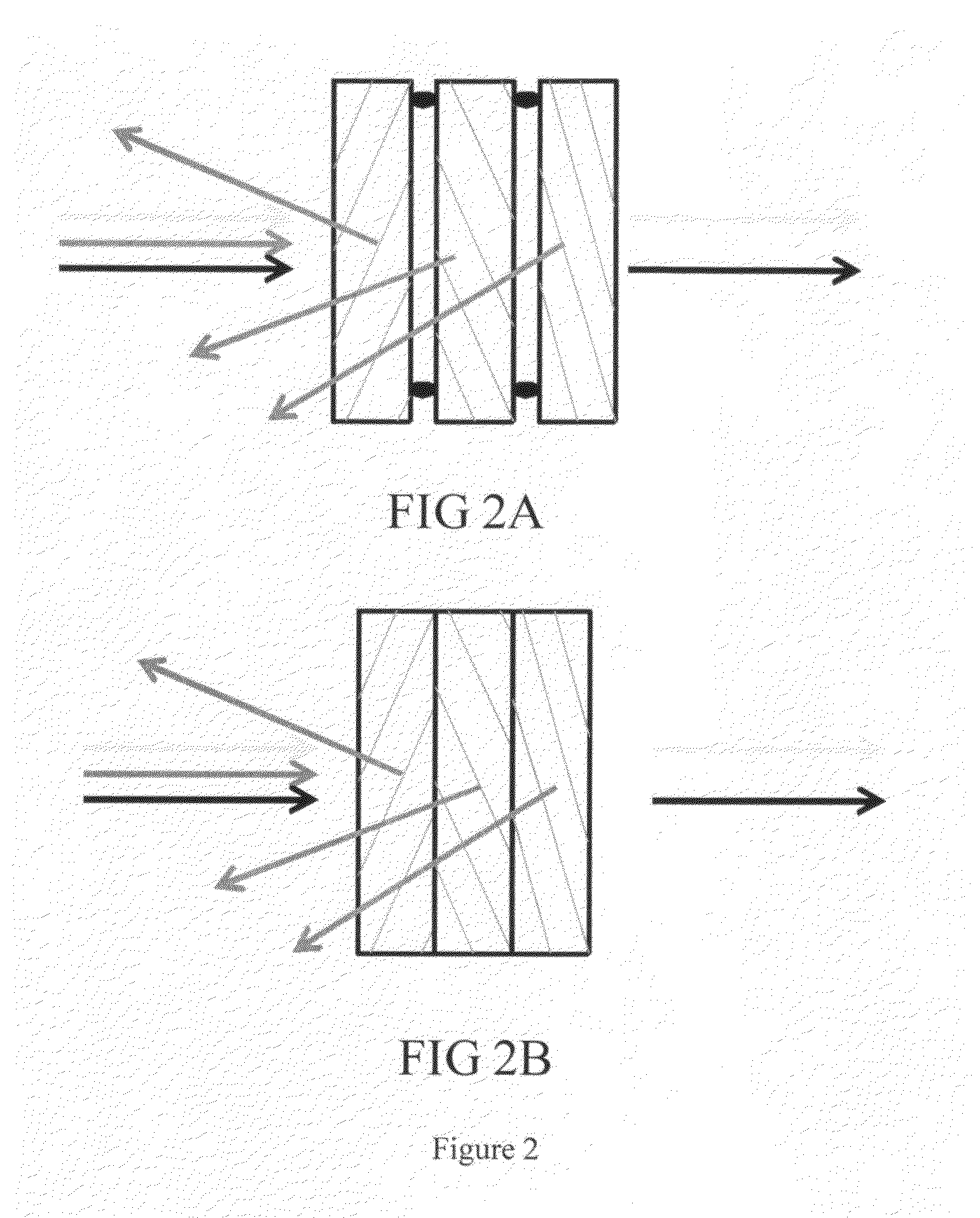

Full spectral range spectrometer

InactiveUS20070019194A1Eliminate shortcomingsHigh precision spectral analysisRadiation pyrometrySpectrum investigationDigital analysisLength wave

A spectrometer is designed capable of effectively covering the full desired spectral range using an array of multiple diffraction gratings arranged in gradually differentiated angles to diffract certain sub-range of photon wavelengths to the target detectors without relying on mechanically changing gratings or use of any moving parts. The optically subdivided spectral analysis results are then electronically integrated to accurately yield the desired full range spectral measurement at a speed compatible to the limit of optical and digital analyzers' speed of the measuring system without manual adjustment and / or mechanical movement delays.

Owner:CHEN LIANGYAO +2

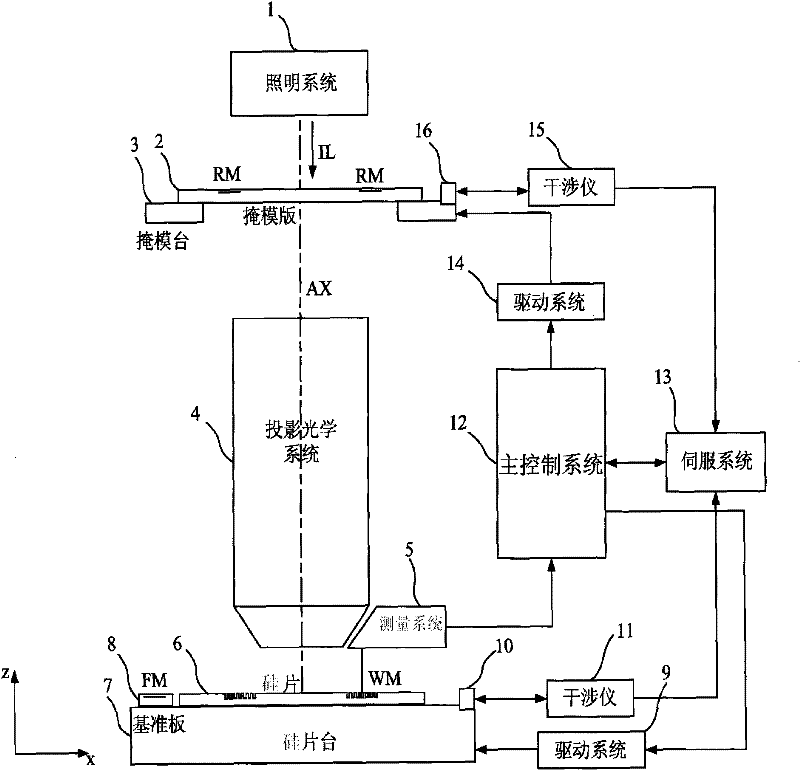

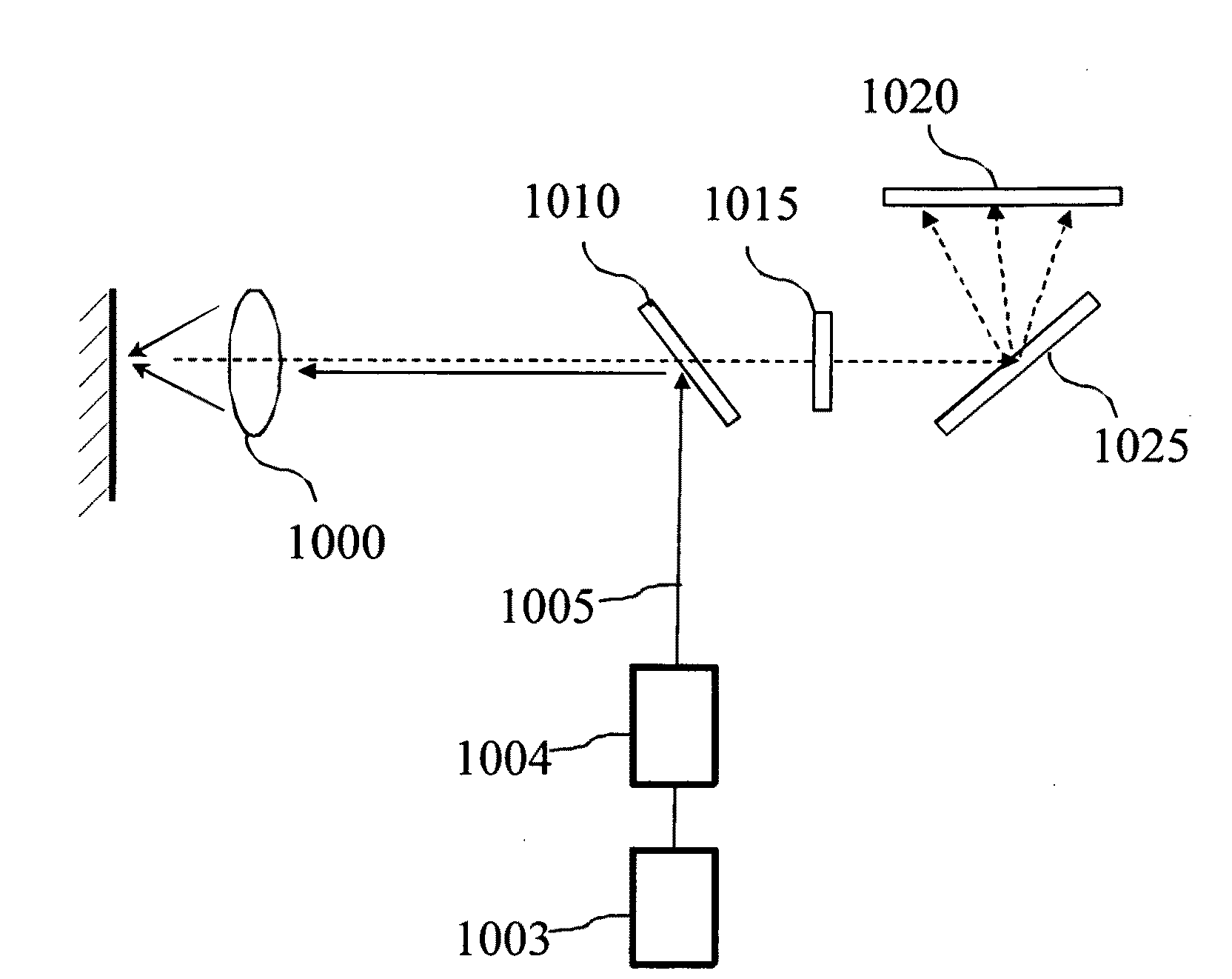

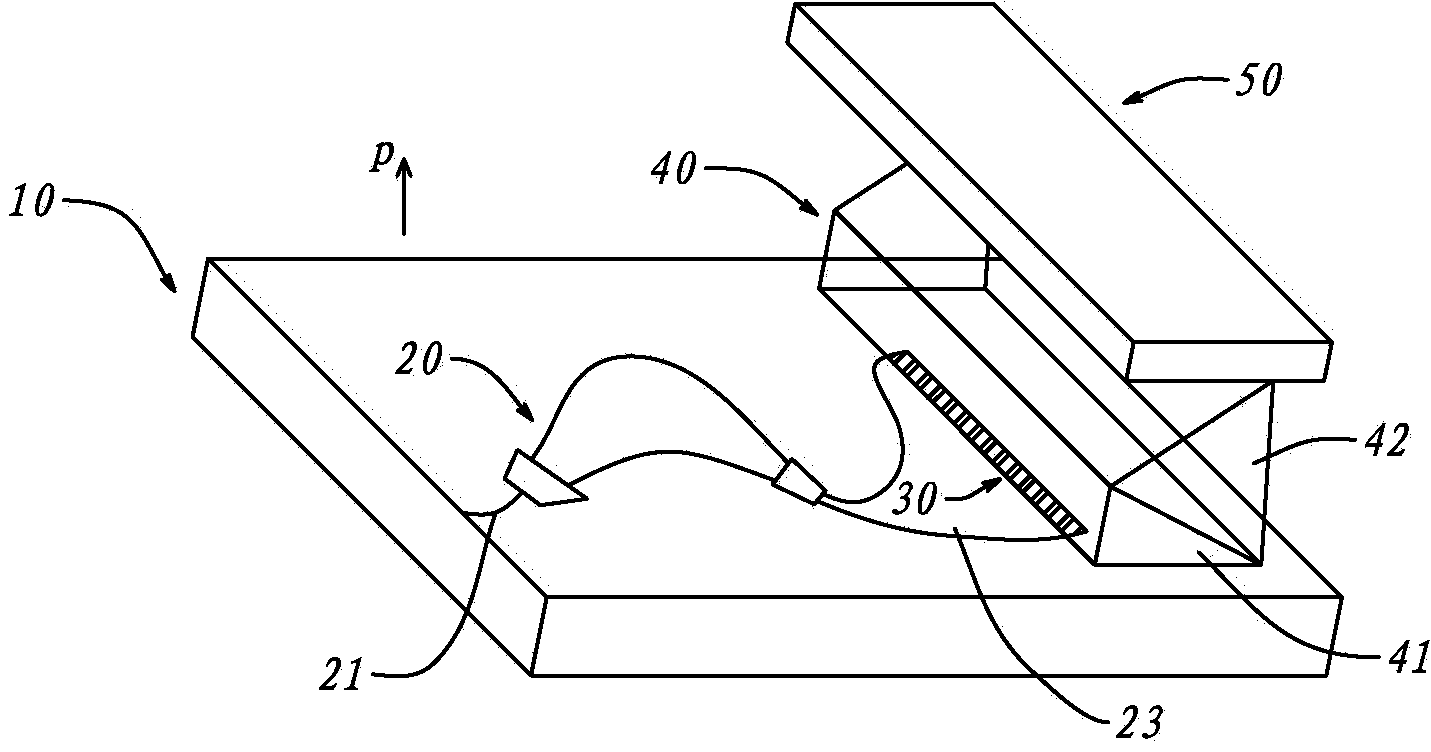

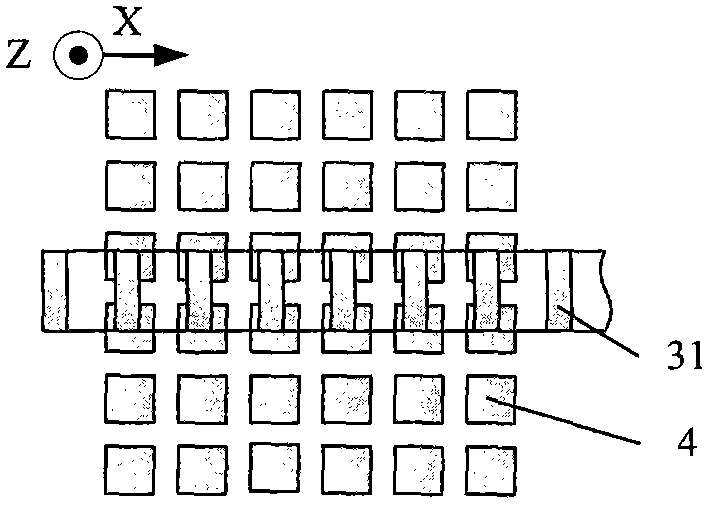

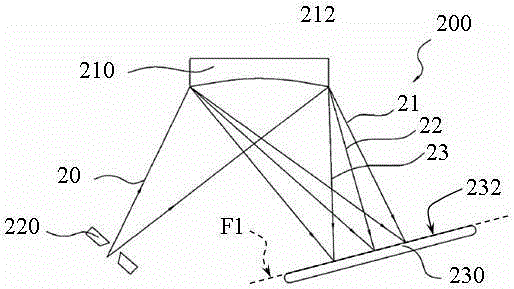

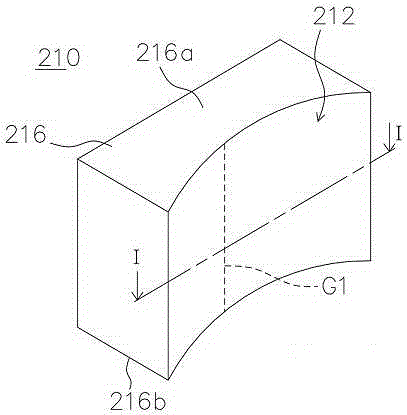

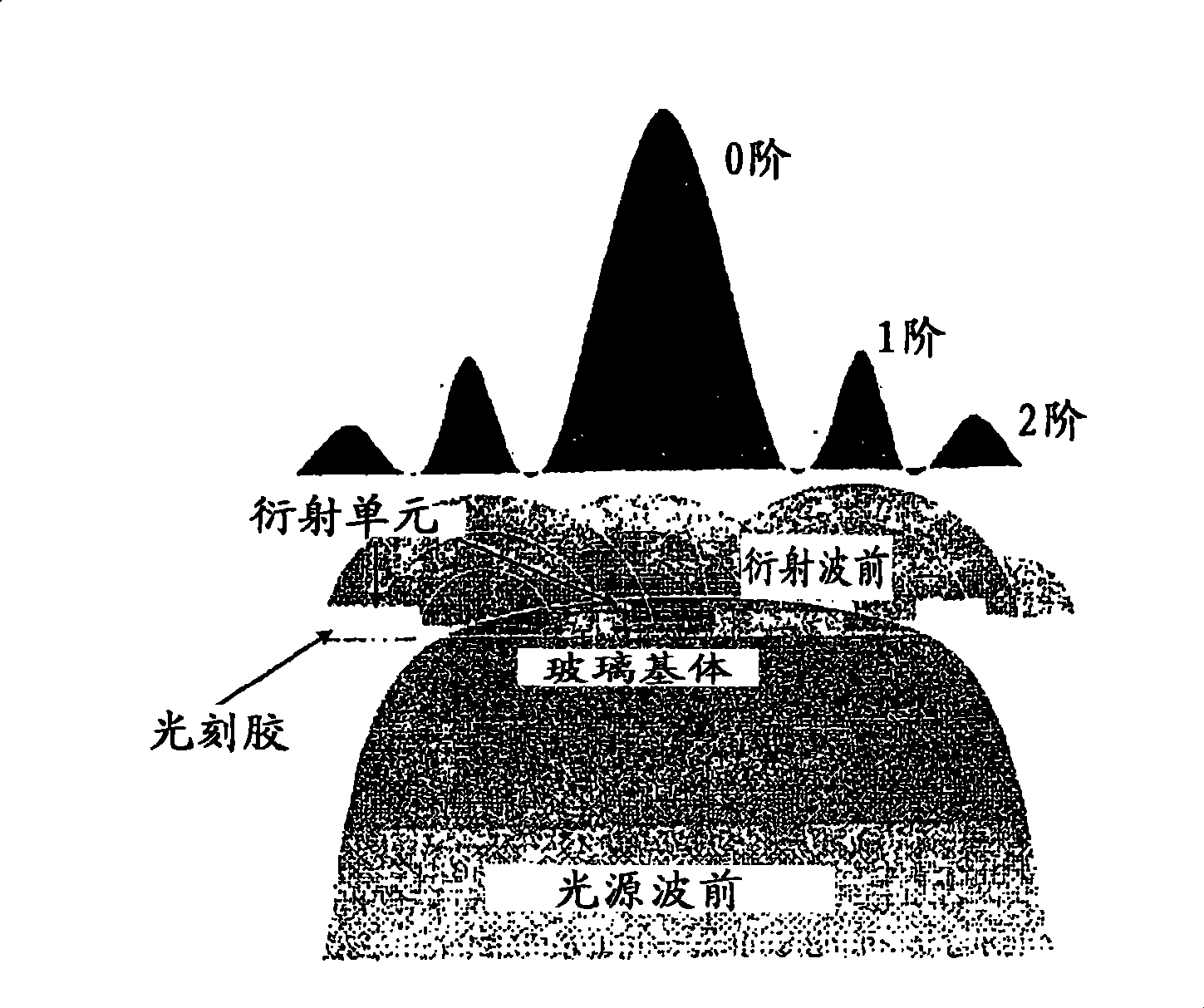

Measuring system and photoetching device using same

ActiveCN102540778AIncrease productivityReduce manufacturing costOptical measurementsPhotomechanical exposure apparatusGratingPhase difference

The invention discloses a measuring system which comprises a light source module, an illuminating module, an imaging module and a detecting module arranged in sequence along the light propagation direction, wherein the light source module is used for emitting a light beam; after the light beam enters the illuminating module, an illuminating beam is emitted to illuminate a mark on the surface of a substrate, then after the illuminating beam is reflected and diffracted by the mark, emergent light with multiple diffraction orders are formed; the detecting module comprises a detecting grating and a light intensity detector, the light with multiple diffraction orders becomes incident light to enter into the detecting grating after passing through the imaging module, the detecting grating carries out secondary diffraction on the incident light so as to form light beams with multiple diffraction orders to form interference patterns on the light intensity detector; wherein the light with multiple diffraction orders is subjected to phase modulation through moving the substrate or the detecting grating so as to obtain the information of phase difference of the light with multiple diffraction orders, and then according to the information of phase difference, the three-dimensional position information of the substrate is obtained, thereby realizing alignment, focusing and leveling measurement on the substrate.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

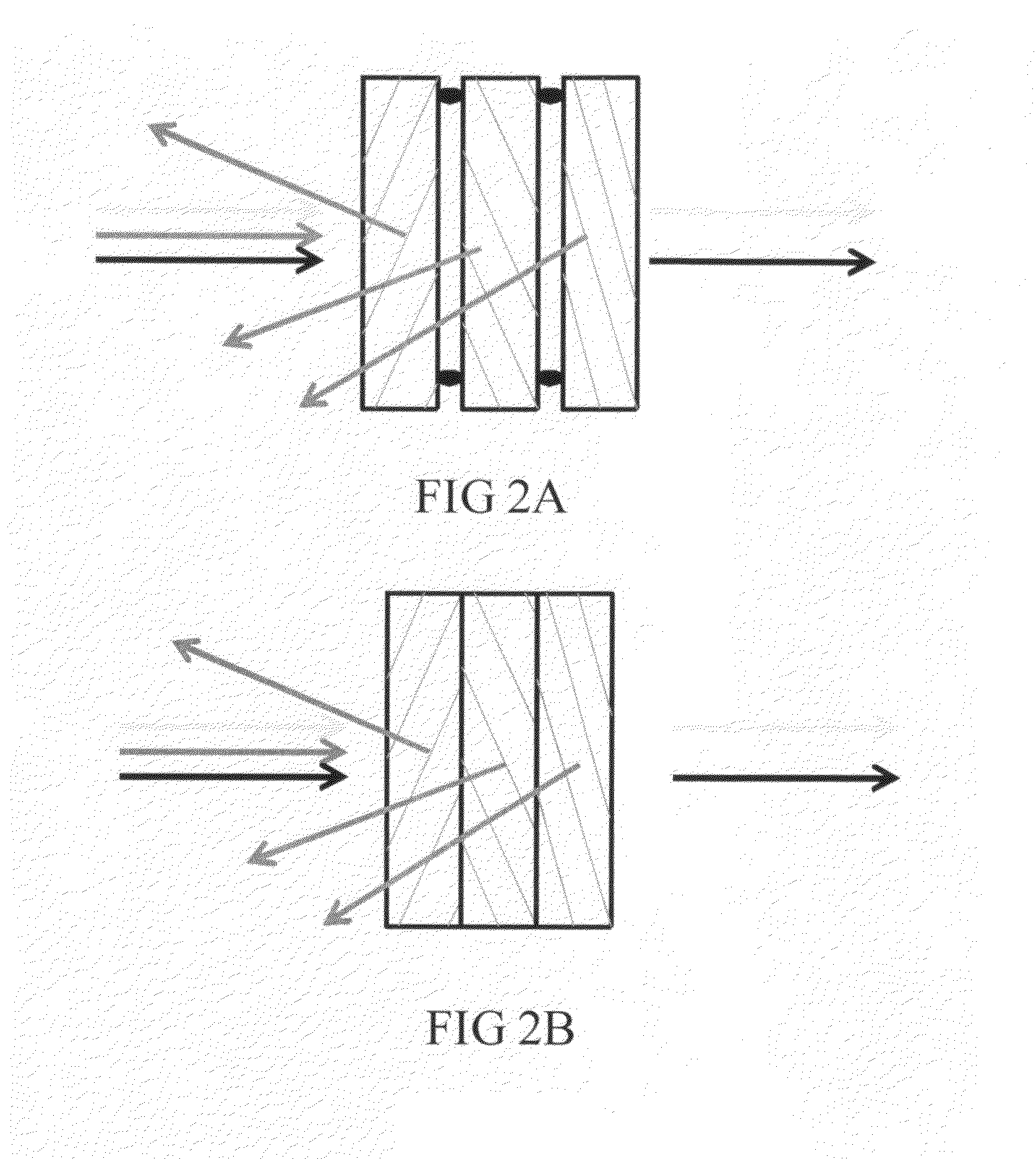

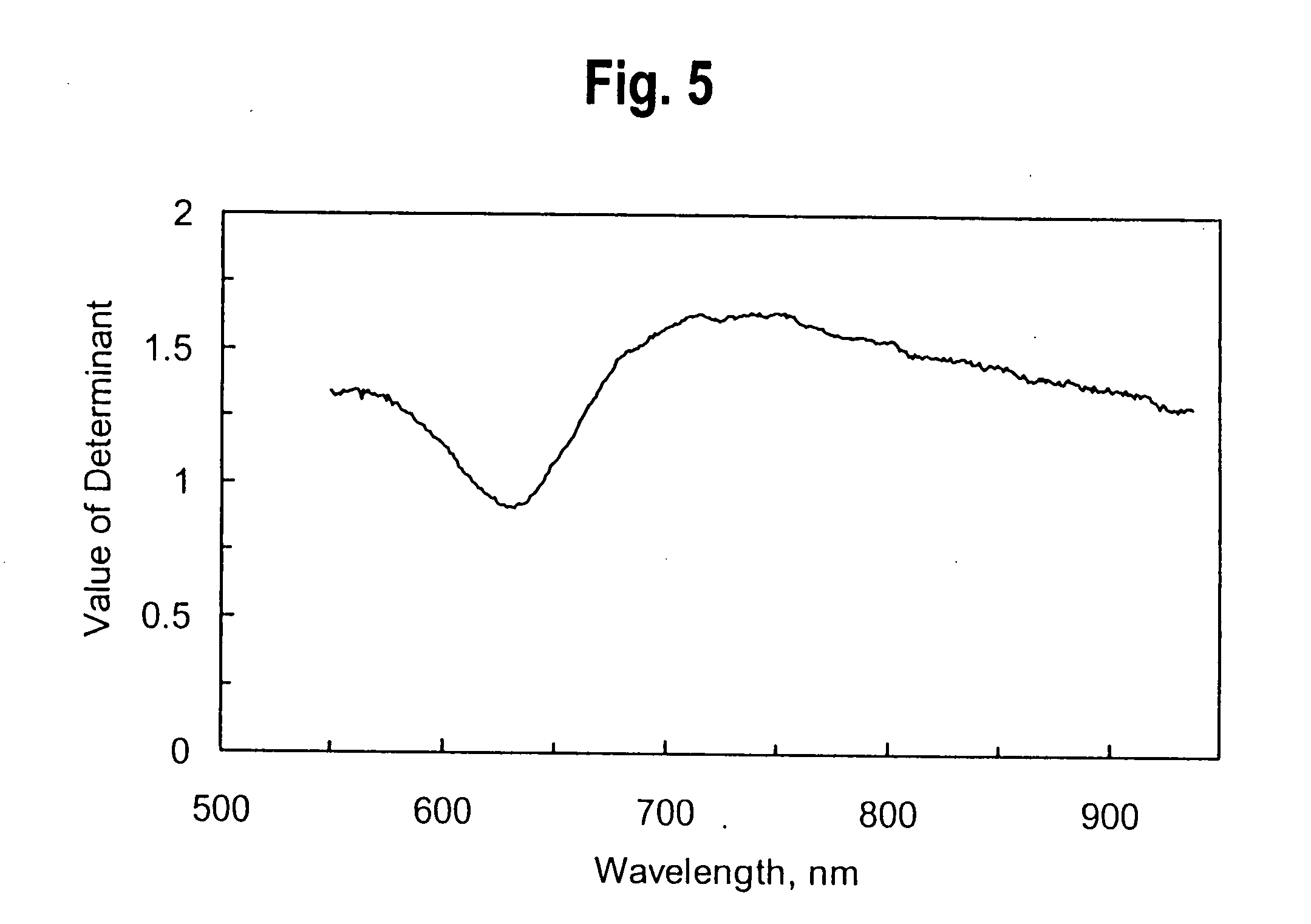

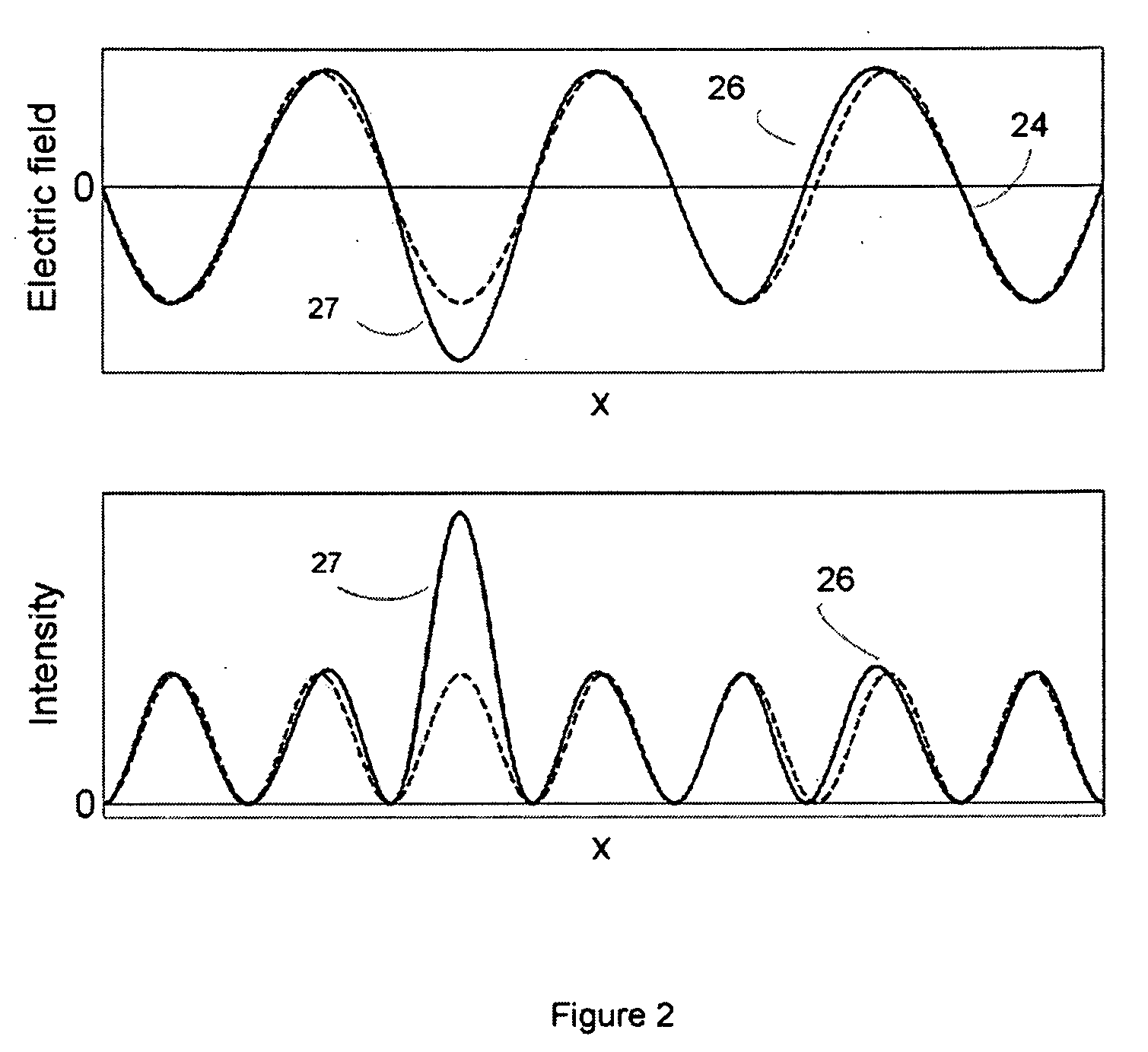

Method and apparatus using volume holographic wavelength blockers

ActiveUS20100027001A1Low costOvercome limitationsRadiation pyrometrySpectrometry/spectrophotometry/monochromatorsOptical densityLength wave

The invention disclosed here teaches methods to fabricate and utilize a non-dispersive holographic wavelength blocker. The invention enables the observation of the Raman signal near the excitation wavelength (˜9 cm−1) with the compactness of standard thin film / holographic notch filter. The novelty is contacting several individual volume holographic blocking notch filter (VHBF) to form one high optical density blocking filter without creating spurious multiple diffractions that degrade the filter performance. Such ultra-narrow-band VHBF can be used in existing compact Raman instruments and thus will help bring high-end research to a greater number of users at a lower cost.

Owner:COHERENT INC

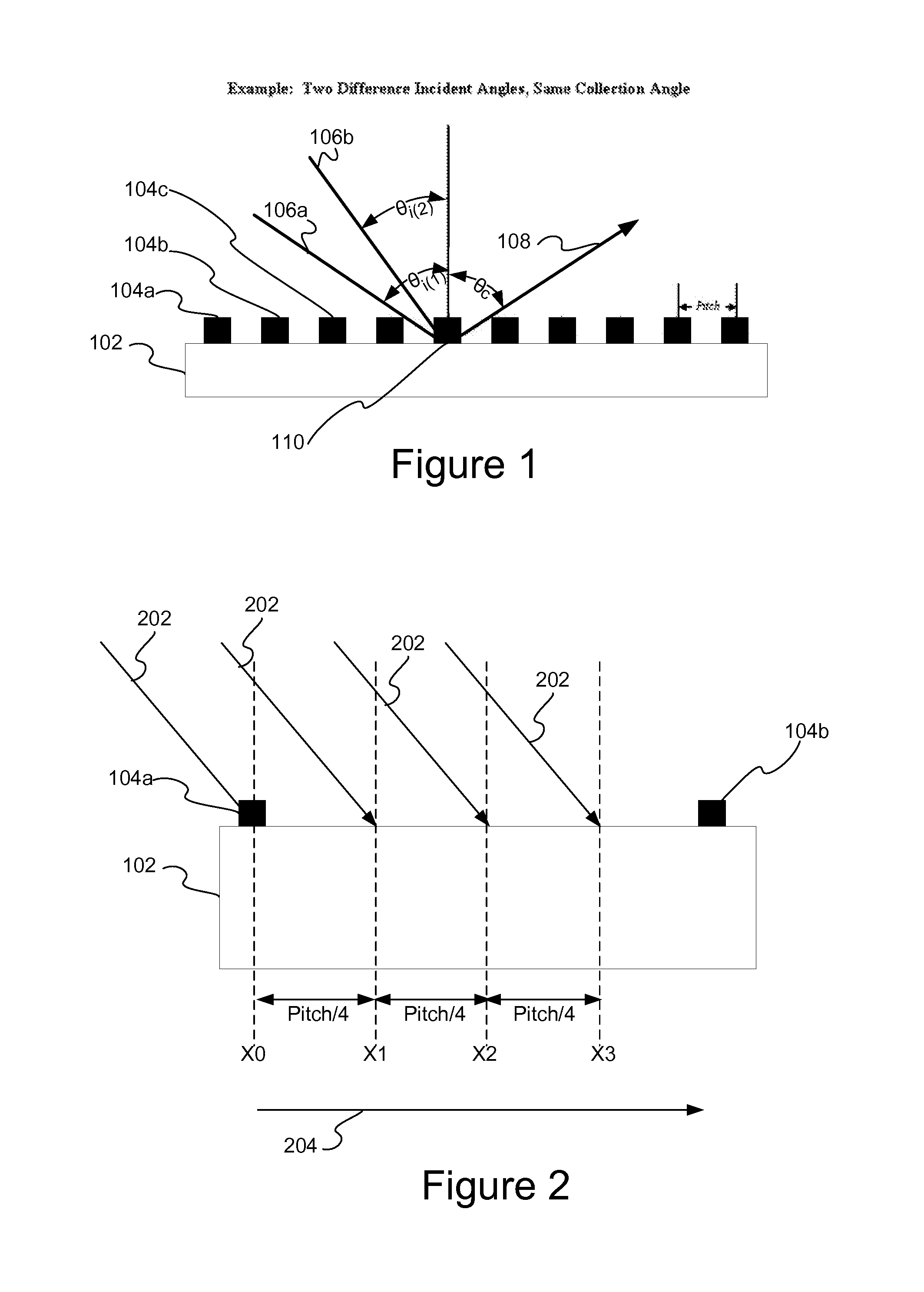

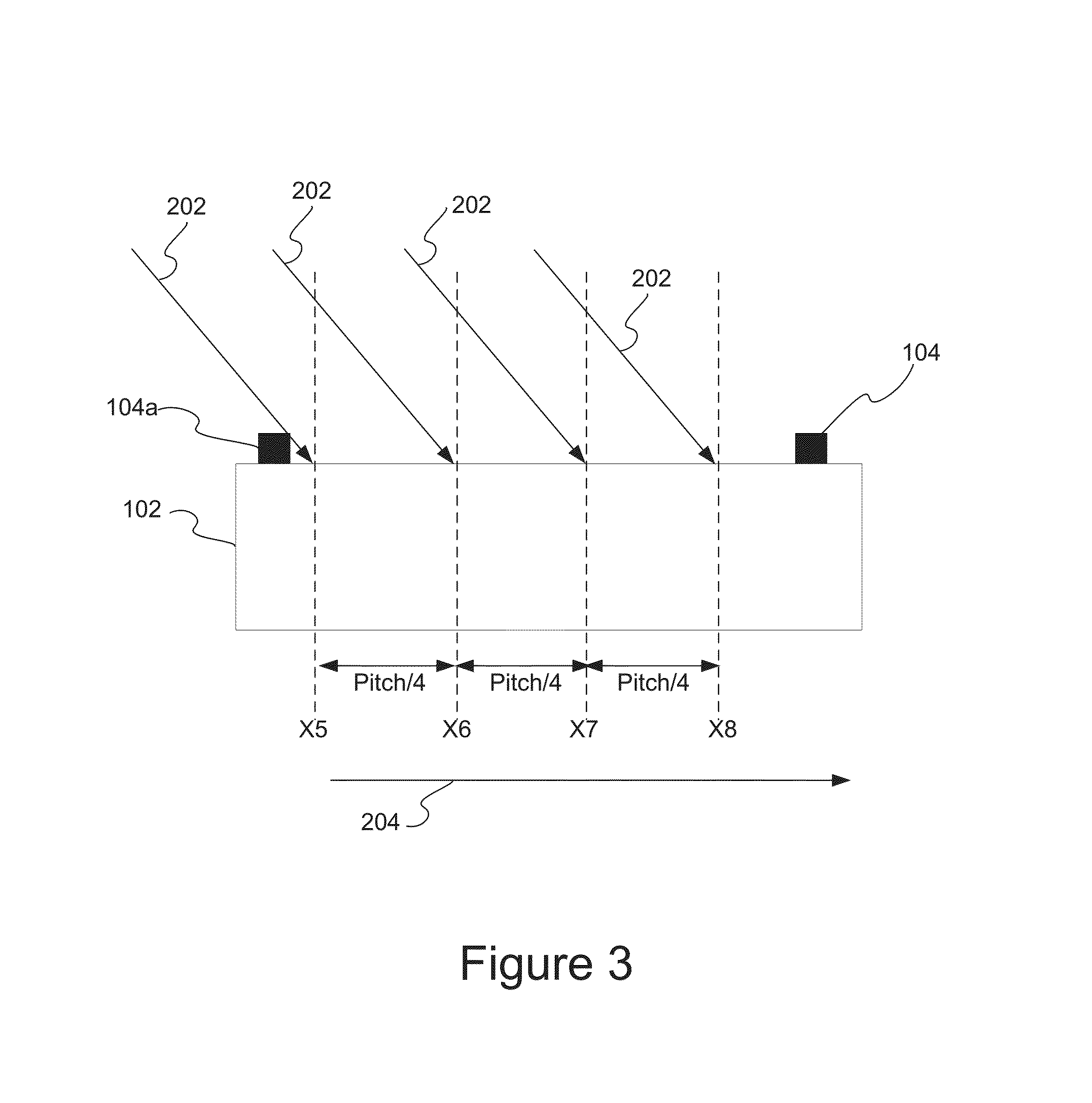

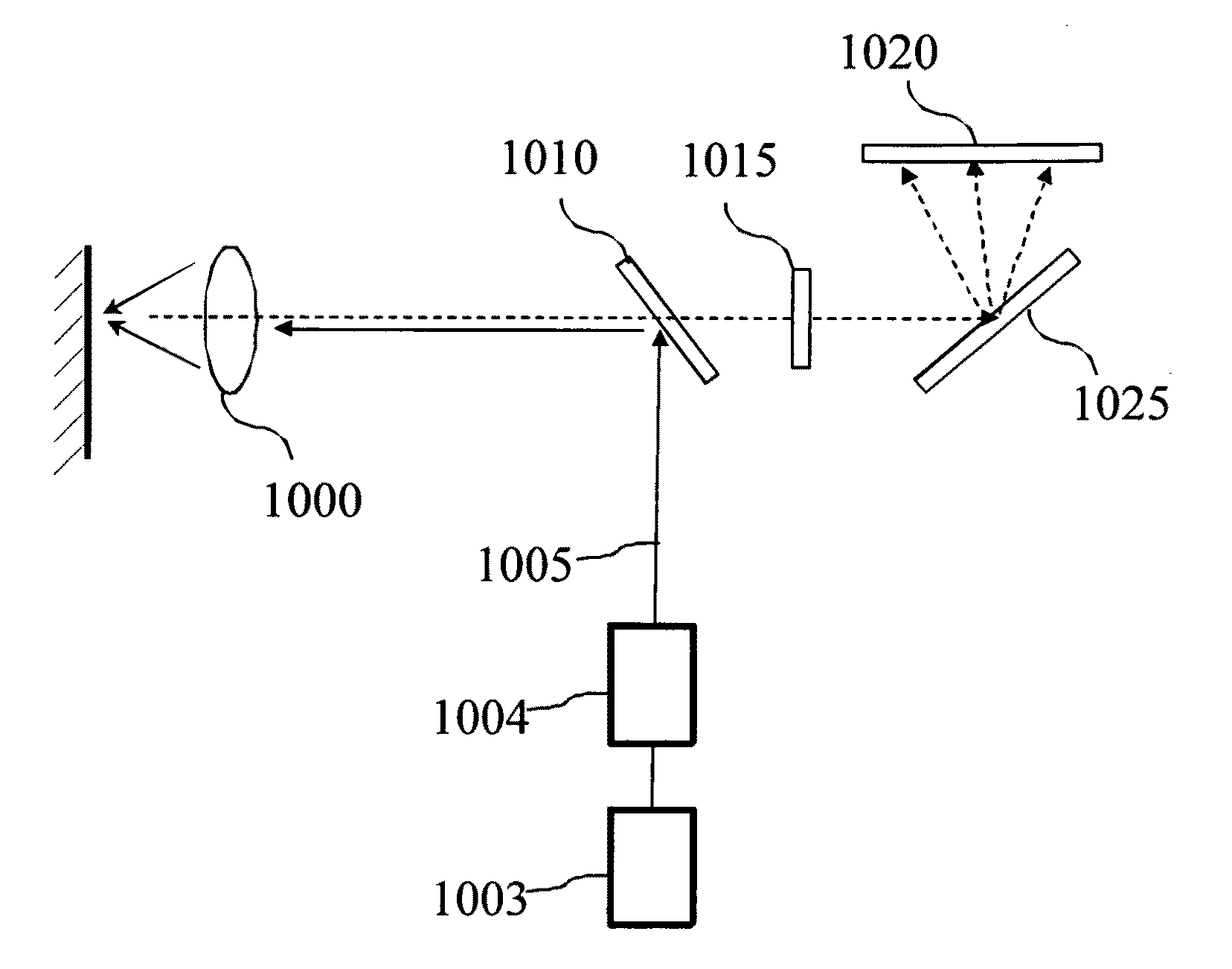

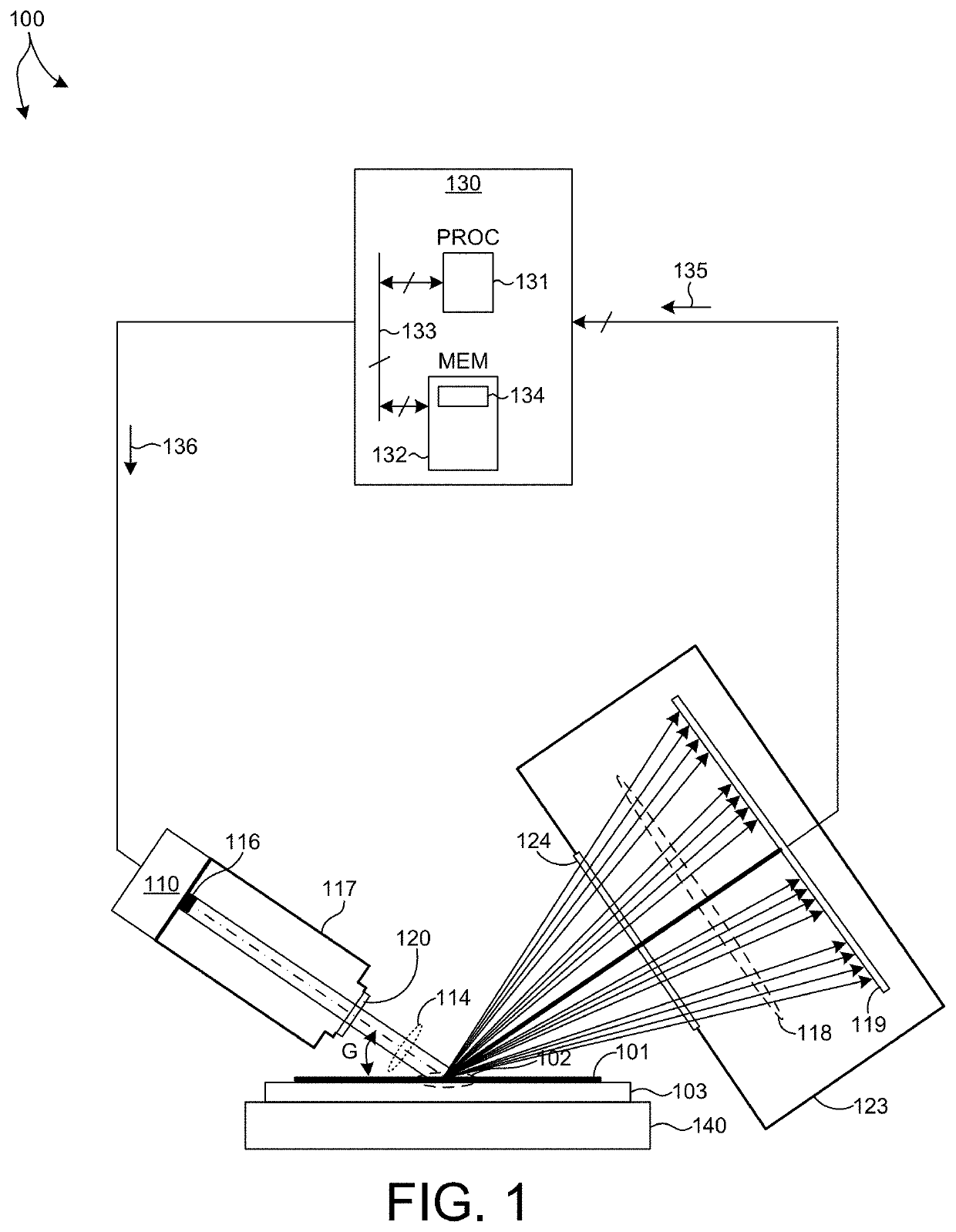

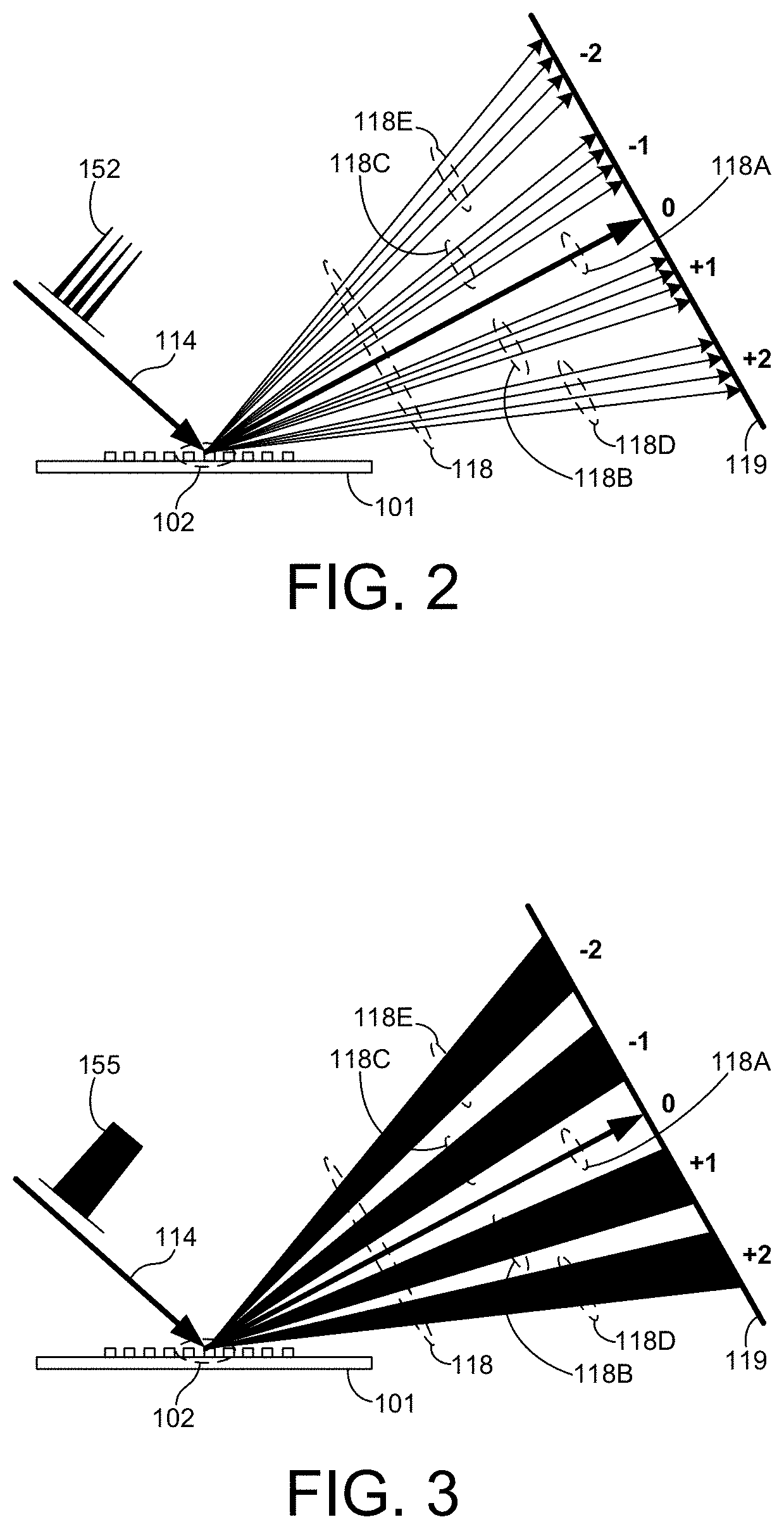

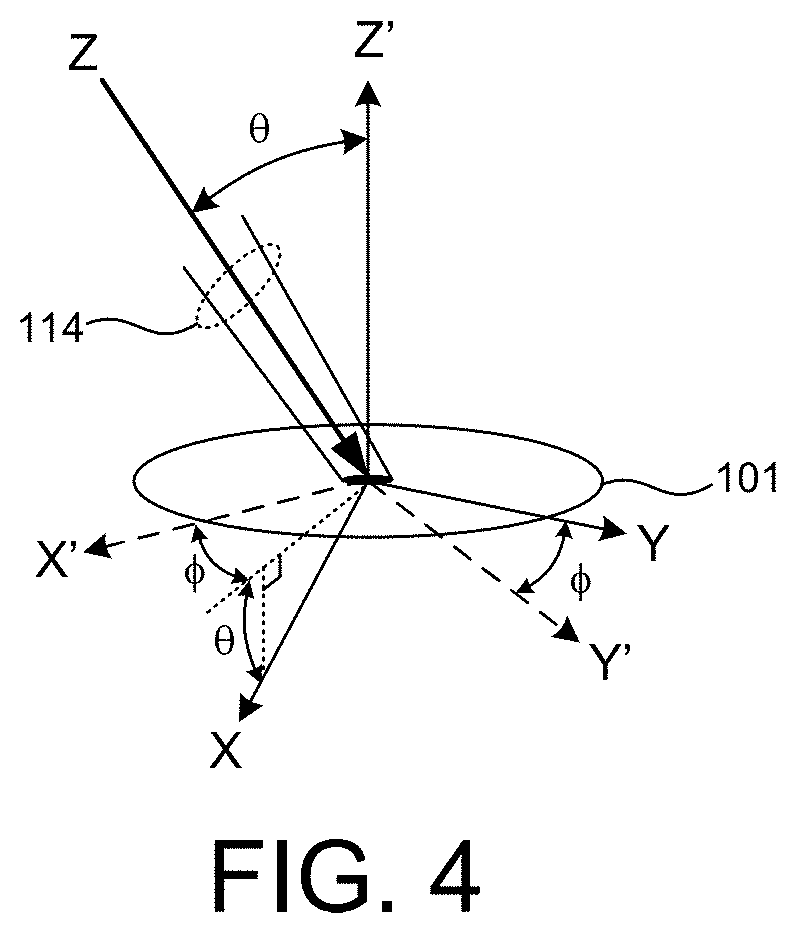

Optical metrology of periodic targets in presence of multiple diffraction orders

ActiveUS9243886B1Eliminate distractionsSemiconductor/solid-state device testing/measurementScattering properties measurementsDiffraction orderLight beam

One or more non-zero diffraction orders are selected, and these selected one or more zero or non-zero diffraction orders are selected for eliminating or obtaining corresponding zero or non-zero diffraction order terms or interference term from measurements from a periodic target using an optical metrology tool. The periodic target has a pitch, and the measurements contain a zero diffraction order and one or more non-zero diffraction order terms. Using the optical metrology tool, an incident beam is directed to positions on the target, and the measurements are obtained from the target in response to the incident beam. The measurements are processed to eliminate or obtain each zero or non-zero diffraction order term or interference term associated with each selected zero or non-zero diffraction order, resulting in a processed metrology signal. The positions are shifted from each other so as to cause the zero or non-zero diffraction order term or interference term corresponding to each selected zero or non-zero diffraction order to be eliminated or obtained.

Owner:KLA TENCOR TECH CORP

Diffraction device

PendingCN107479248AHigh refractive indexLow refractive indexNon-linear opticsLiquid-crystal displayOptical axis

The invention provides a diffraction device which comprises a first diffraction unit. The first diffraction unit comprises a first substrate, a first diffraction lens, a second substrate and a first liquid crystal layer, wherein a first polaroid is arranged on one side of the first substrate, and a first electrode is arranged on the other side of the first substrate; the first diffraction lens is arranged on the first electrode; the second substrate is opposite to the first substrate, and a second electrode is arranged on the side, opposite to the other side of the first substrate, of the second substrate; the first liquid crystal layer is arranged between the second electrode and the first diffraction lens, liquid crystals in the first liquid crystal layer can be in the state that the long axis direction of the liquid crystals is parallel to the axial direction of the optical axis of the first polaroid or the state that the long axis direction of the liquid crystals is perpendicular to the axial direction of the optical axis of the first polaroid. The diffraction device is provided with a plurality of diffraction units which can convert diffraction modes according to different external electric fields, and the working modes of the multiple diffraction units can be converted freely according to user's needs.

Owner:BOE TECH GRP CO LTD

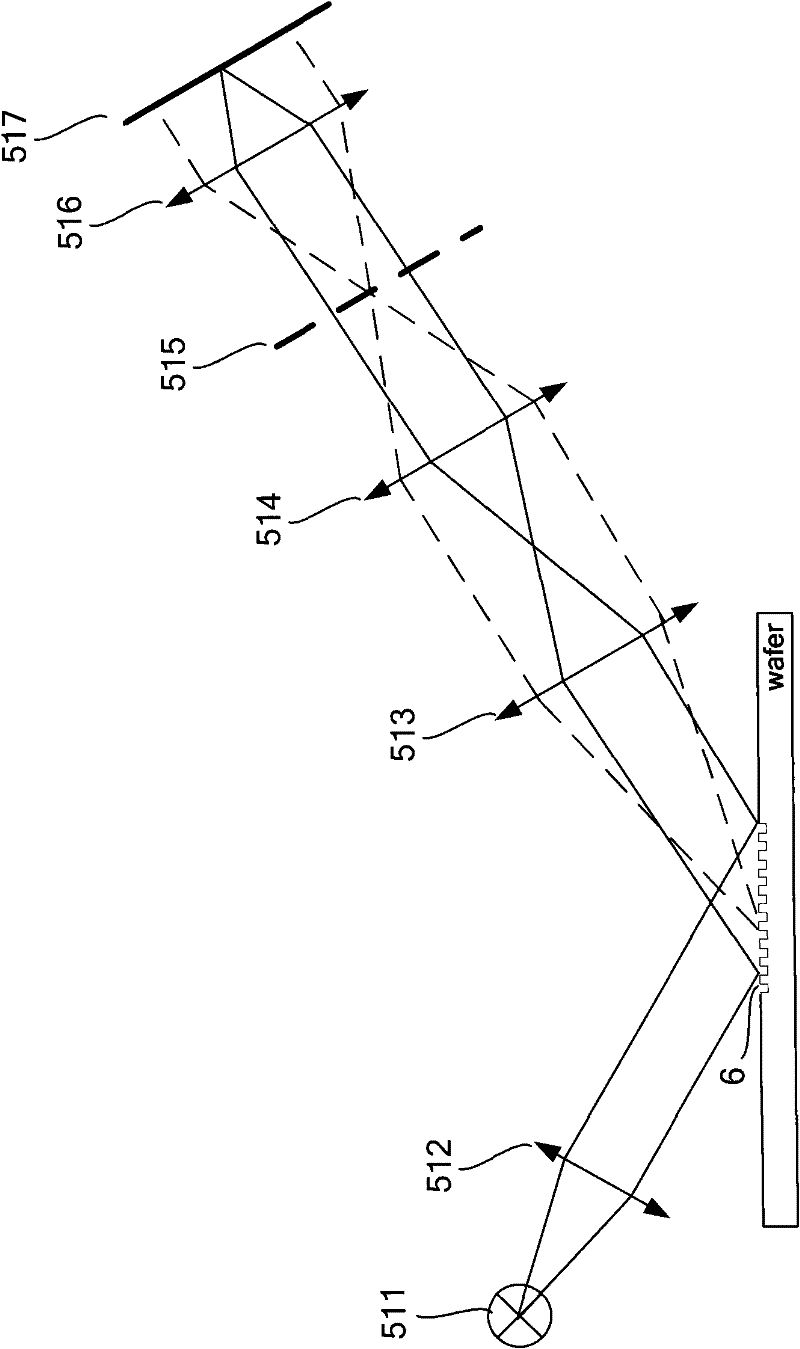

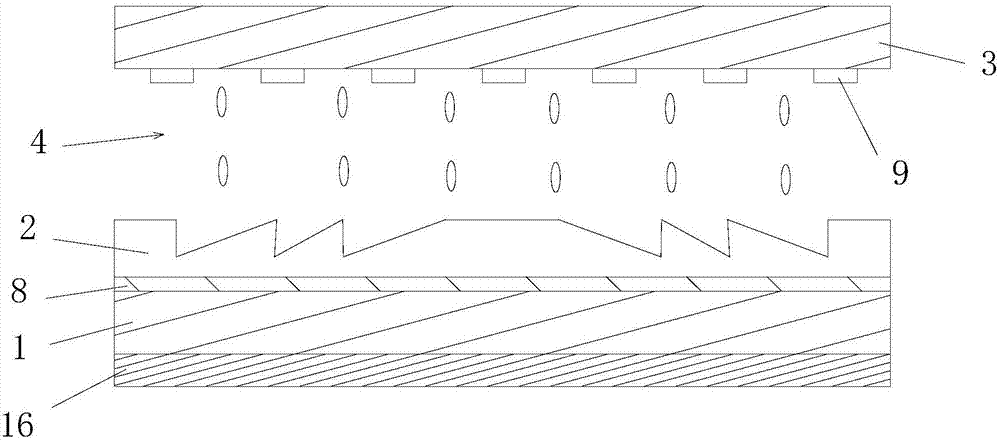

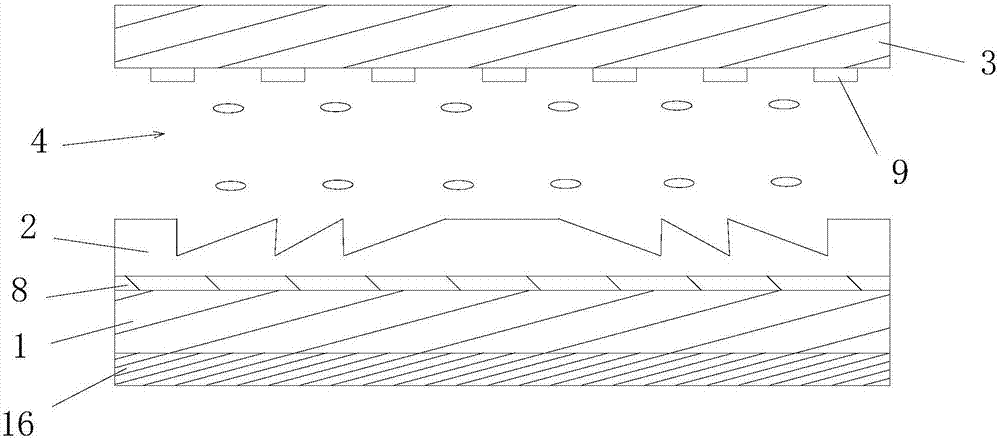

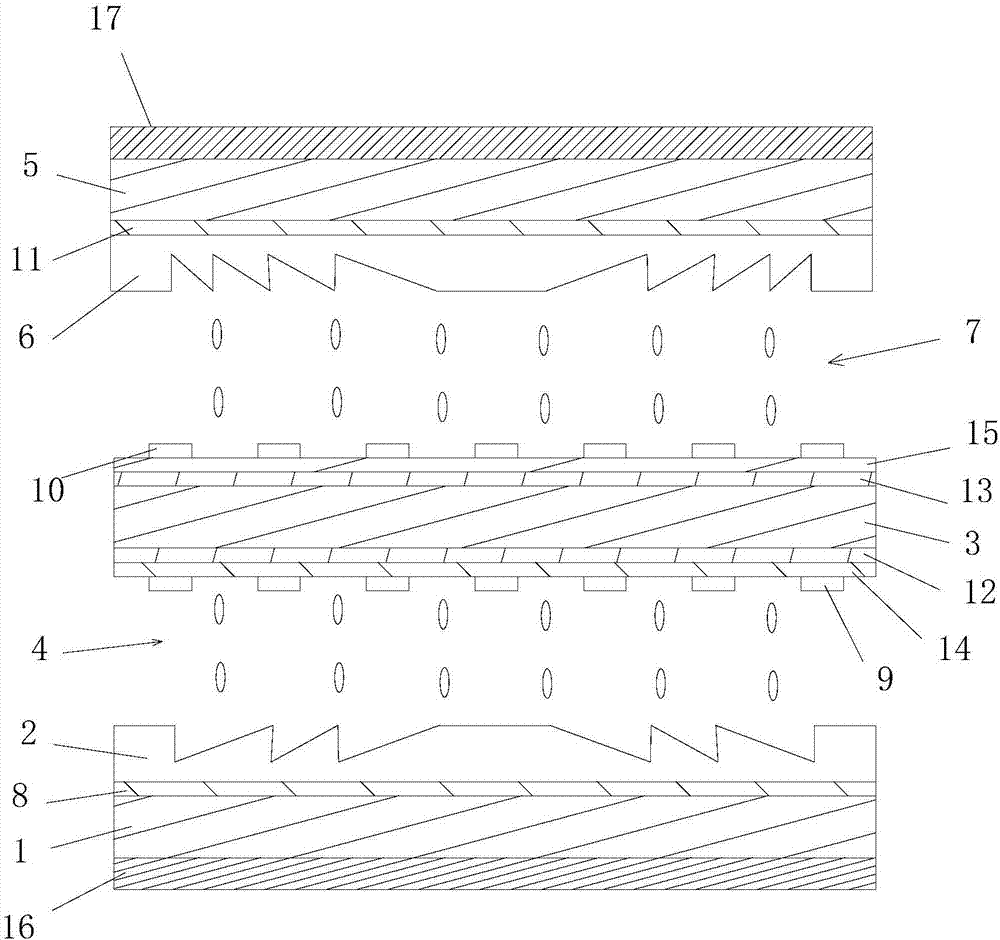

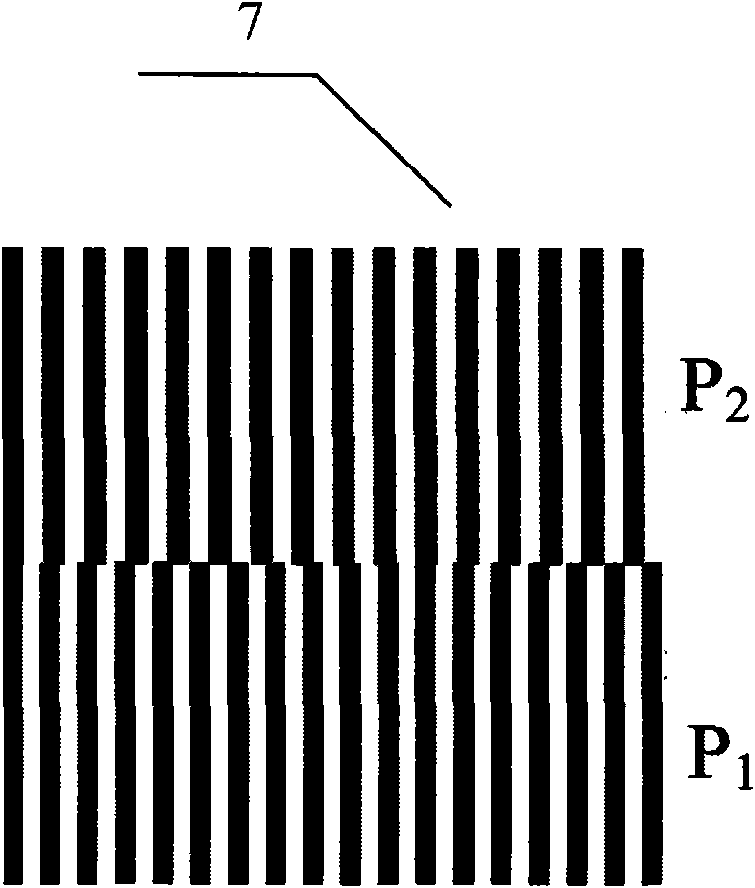

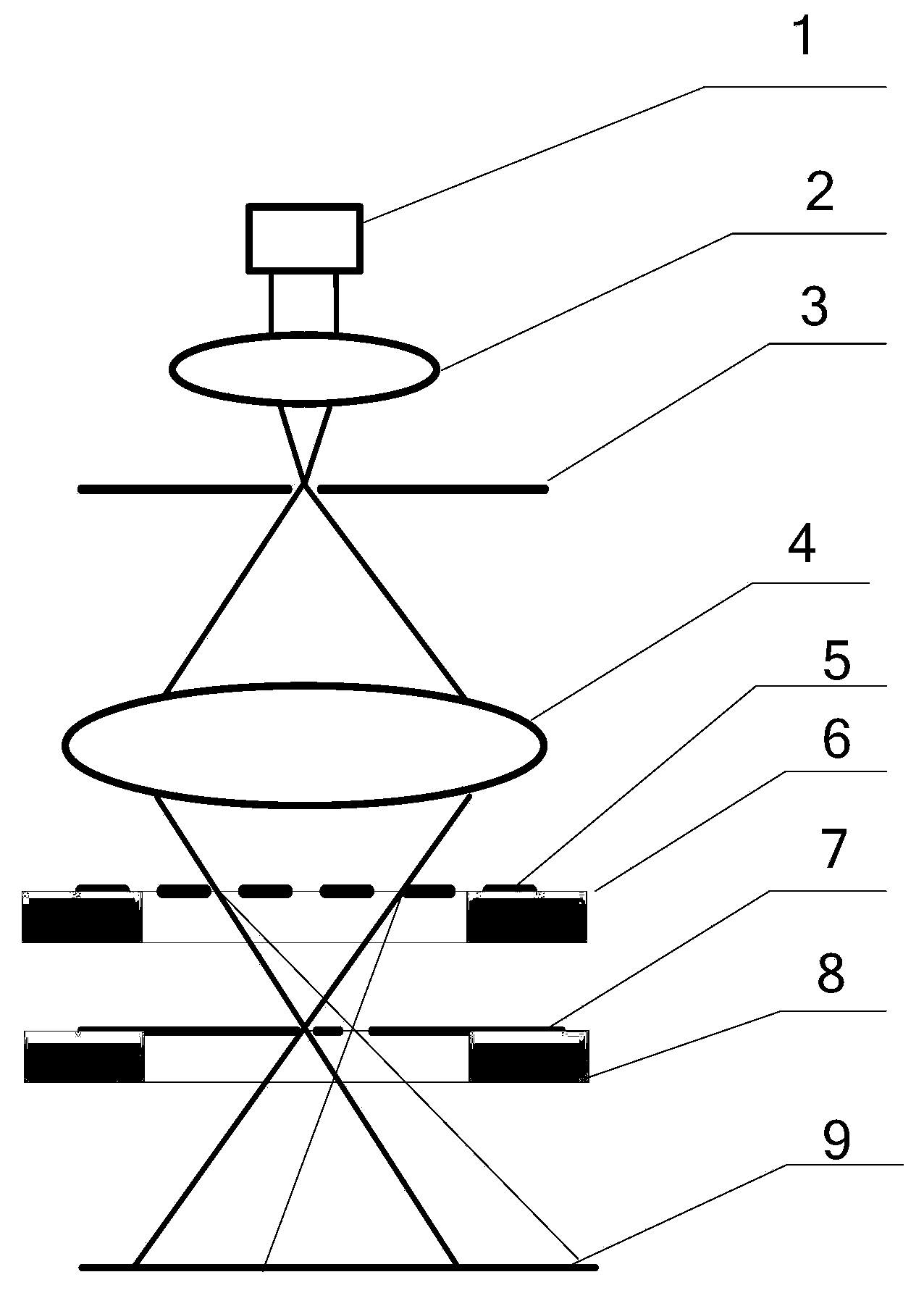

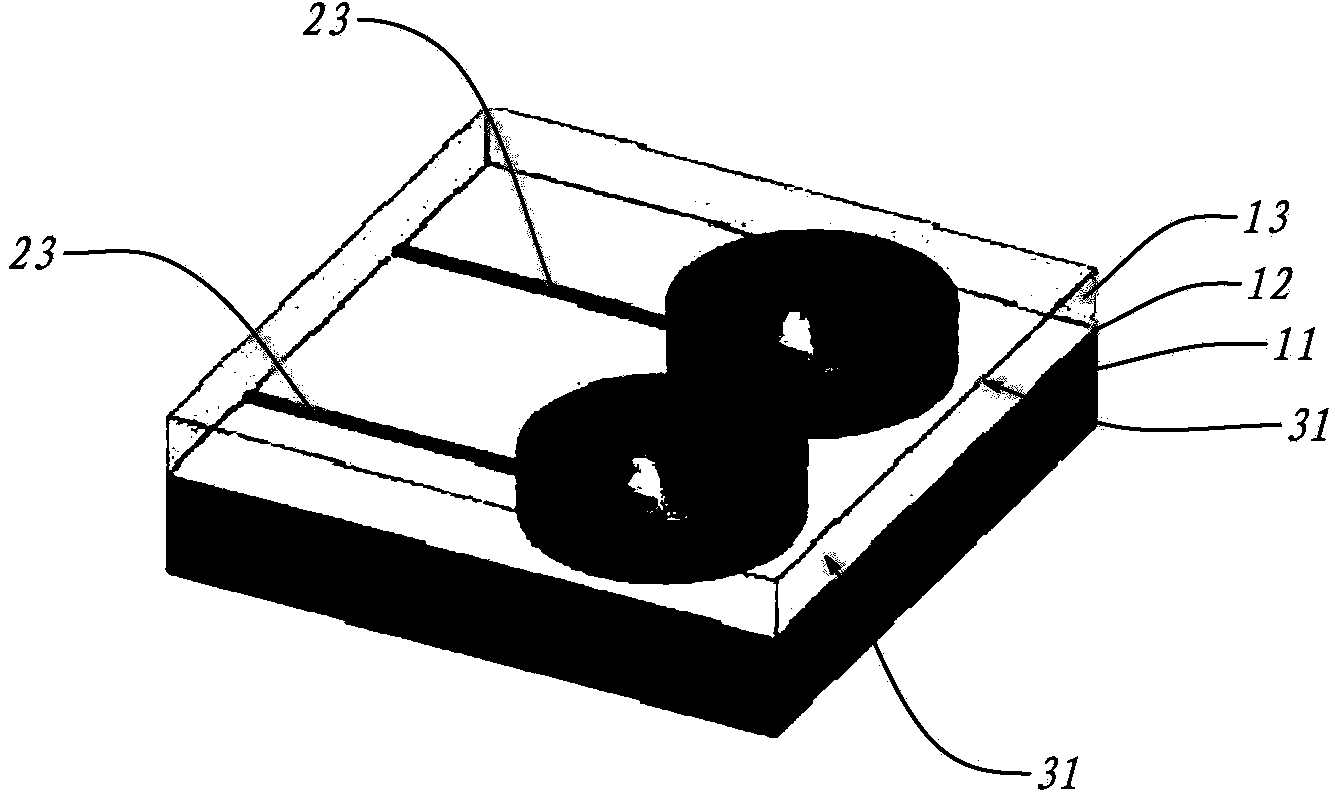

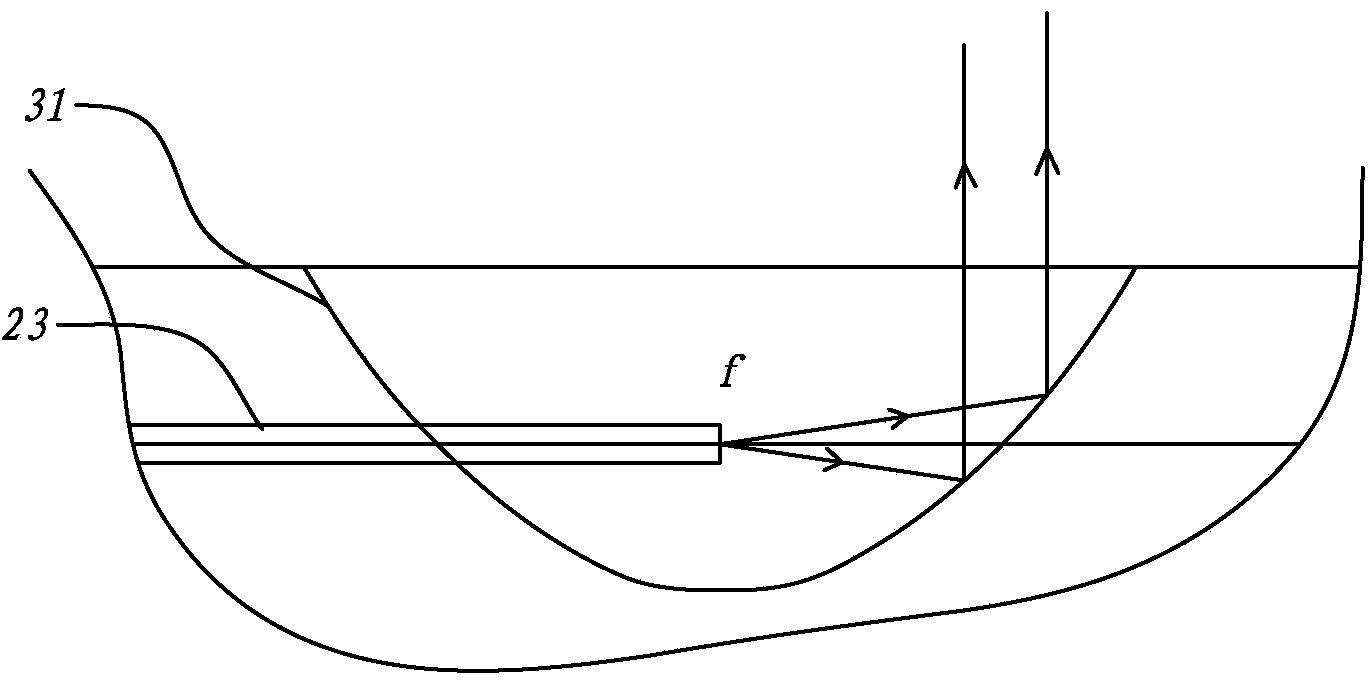

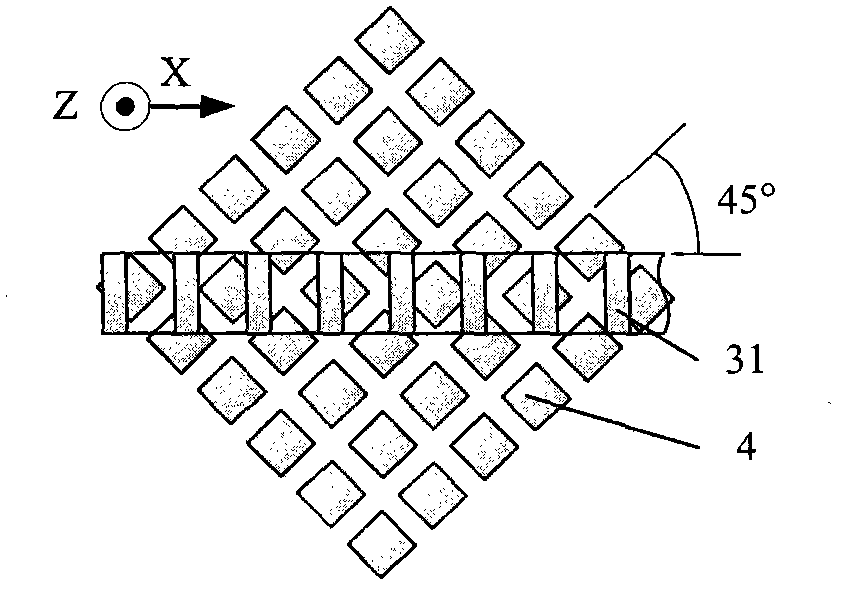

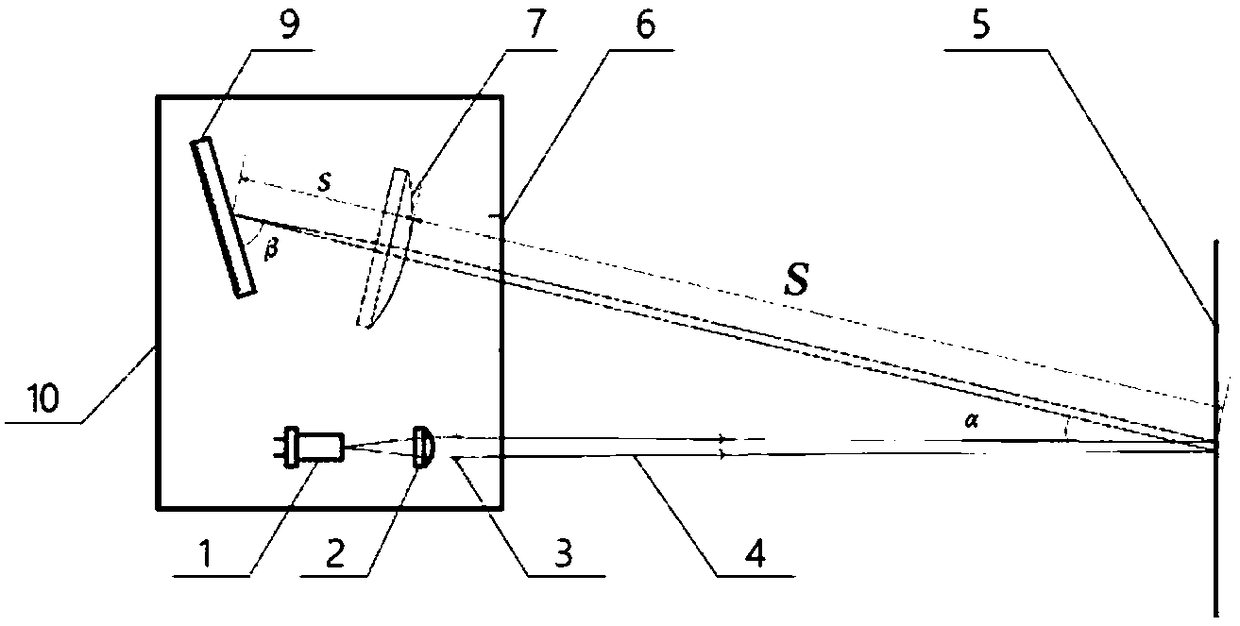

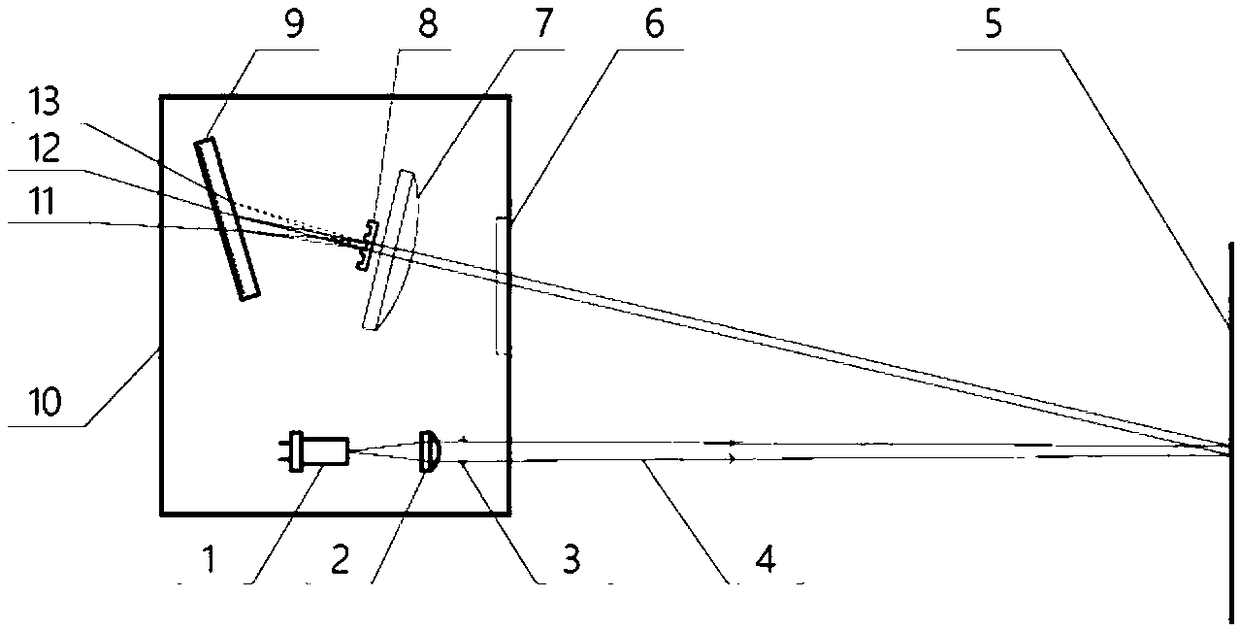

Nanometer-level automatic focusing system for projection lithography

InactiveCN102141738AAvoid the effects of out-of-focus amountHigh precisionPhotomechanical exposure apparatusMicrolithography exposure apparatusGratingPhase difference

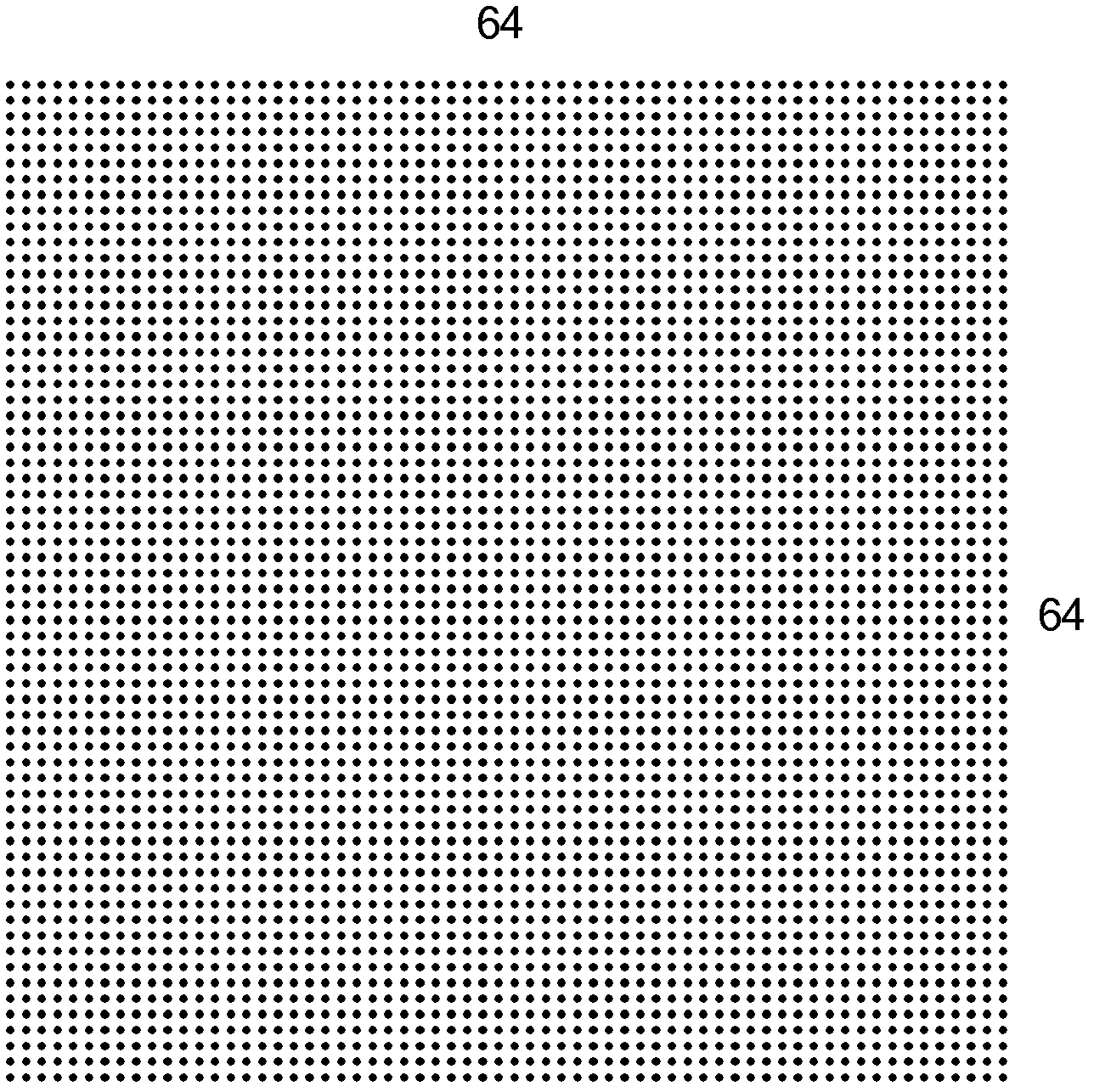

The invention relates to a nanometer-level automatic focusing system for projection lithography, comprising a light path, an image processing module and a circuit control module. The light path comprises a collimated light beam, two grating marks, four lenses, a silicon wafer stage and a CCD (Charge Coupled Device) image detector, wherein a collimated light beam vertically illuminates one grating mark, carries out glancing incidence imaging on the surface of the silicon wafer stage along the optic axes of the first lens and the second lens, is projected on the tested surface of the silicon wafer stage and undergoes mirror reflection; a grating image is reimaged on the focal plane of the fourth lens through the third lens and the fourth lens; and the image of one grating mark is superposed with the two grating marks by a fixed gap, undergoes multiple diffraction, forms amplified Moire interference fringes on the surface of the grating and then is imaged on the CCD image detector. The image processing module is used for processing images to extract a phase difference and further calculate a defocusing amount; and then, the circuit control module is used for judging the defocusing condition of the surface of the silicon wafer stage to further control the movement of the silicon wafer stage so that the surface of the silicon wafer stage reaches an optimal focal plane position.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

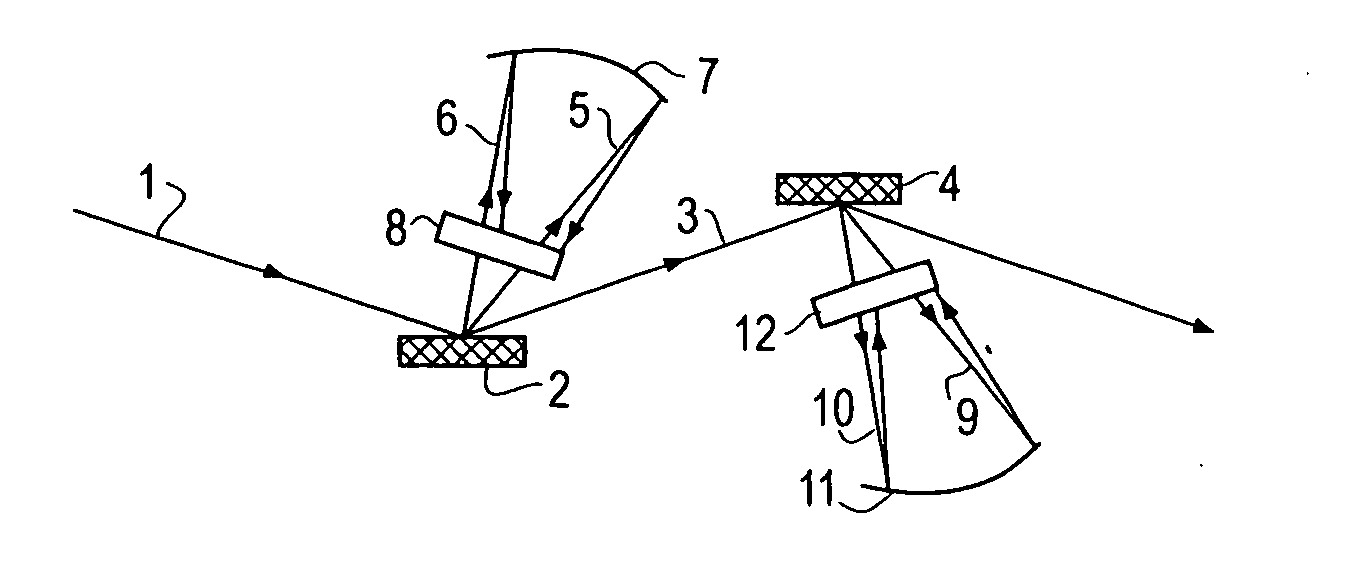

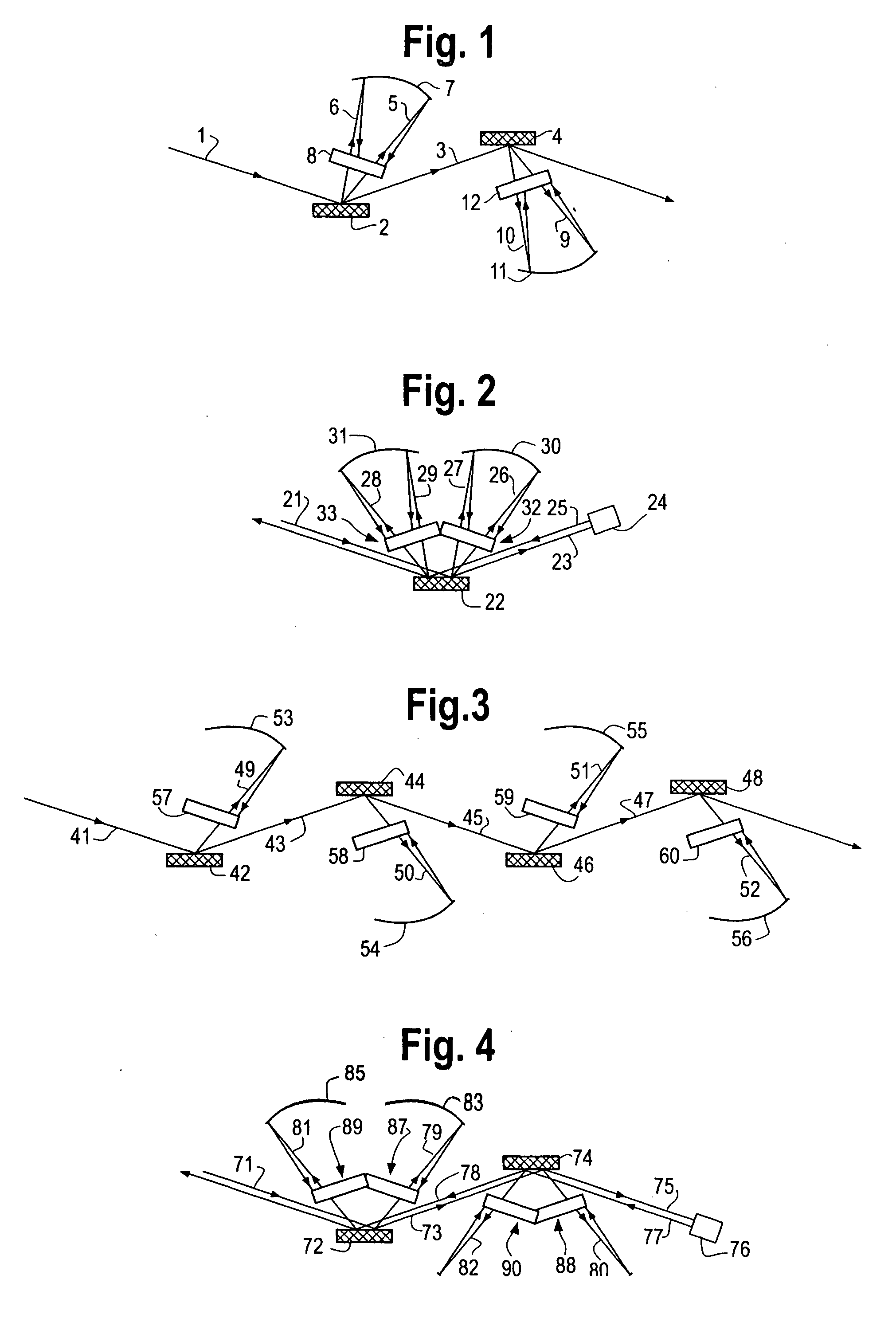

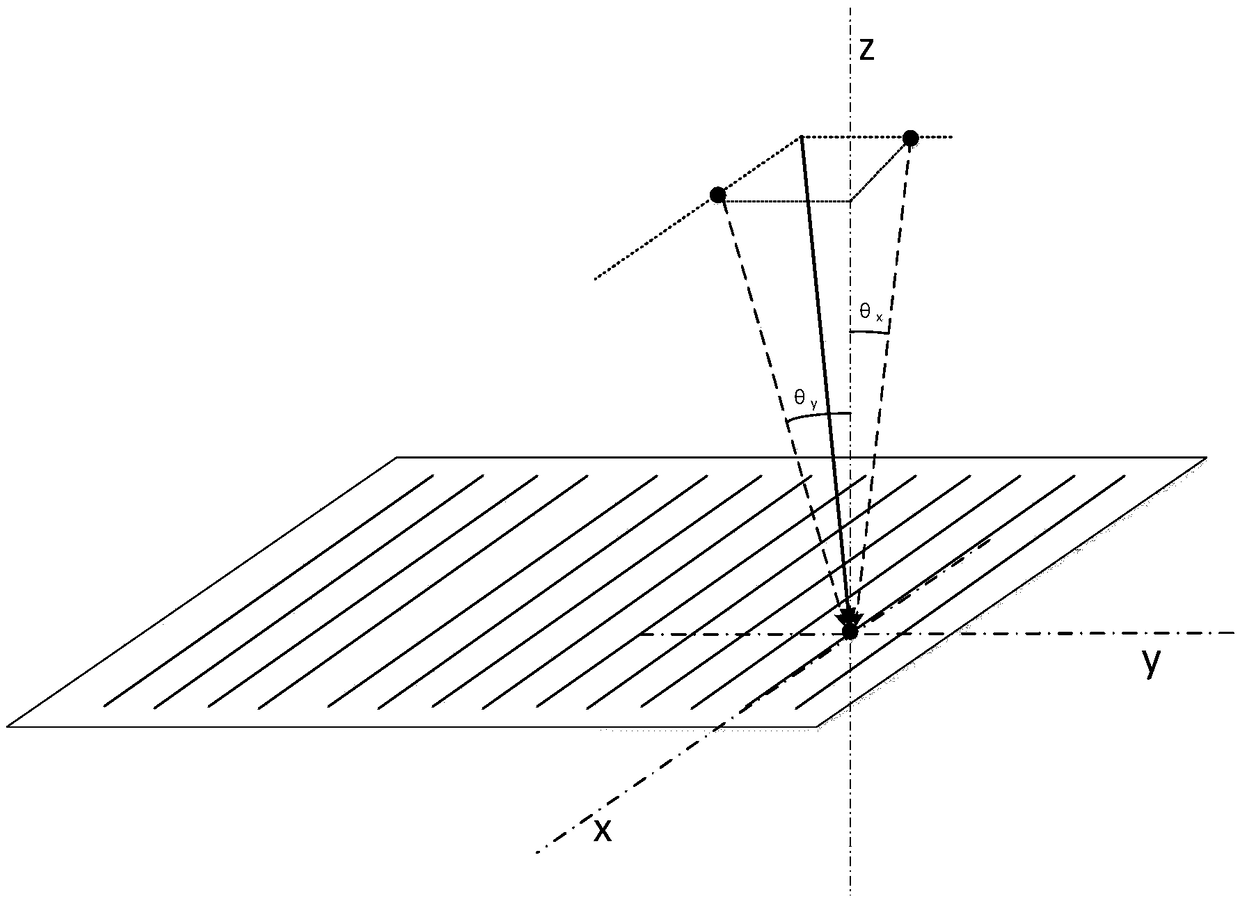

Photopolarimeters and spectrophotopolarimaters with multiple diffraction gratings

InactiveUS20050018189A1Broad spectral bandwidthHigh sensitivityRadiation pyrometryPolarisation spectroscopySpectral bandsLength wave

In a device for measuring the complete polarization state of light over a spectral bandwidth, an optical input signal (41) with wavelengths of light within a spectral band is incident on two or more diffraction gratings (42, 44, 46, 48), or incident from at least two directions on one or more diffraction gratings (72, 74), and the intensity is measured as a function of wavelength for at least four of the diffraction spectra produced by the grating(s). The polarization state of light is then calculated as a function of wavelength over the spectral bandwidth from the intensity measurements.

Owner:CONTAINERLESS RES

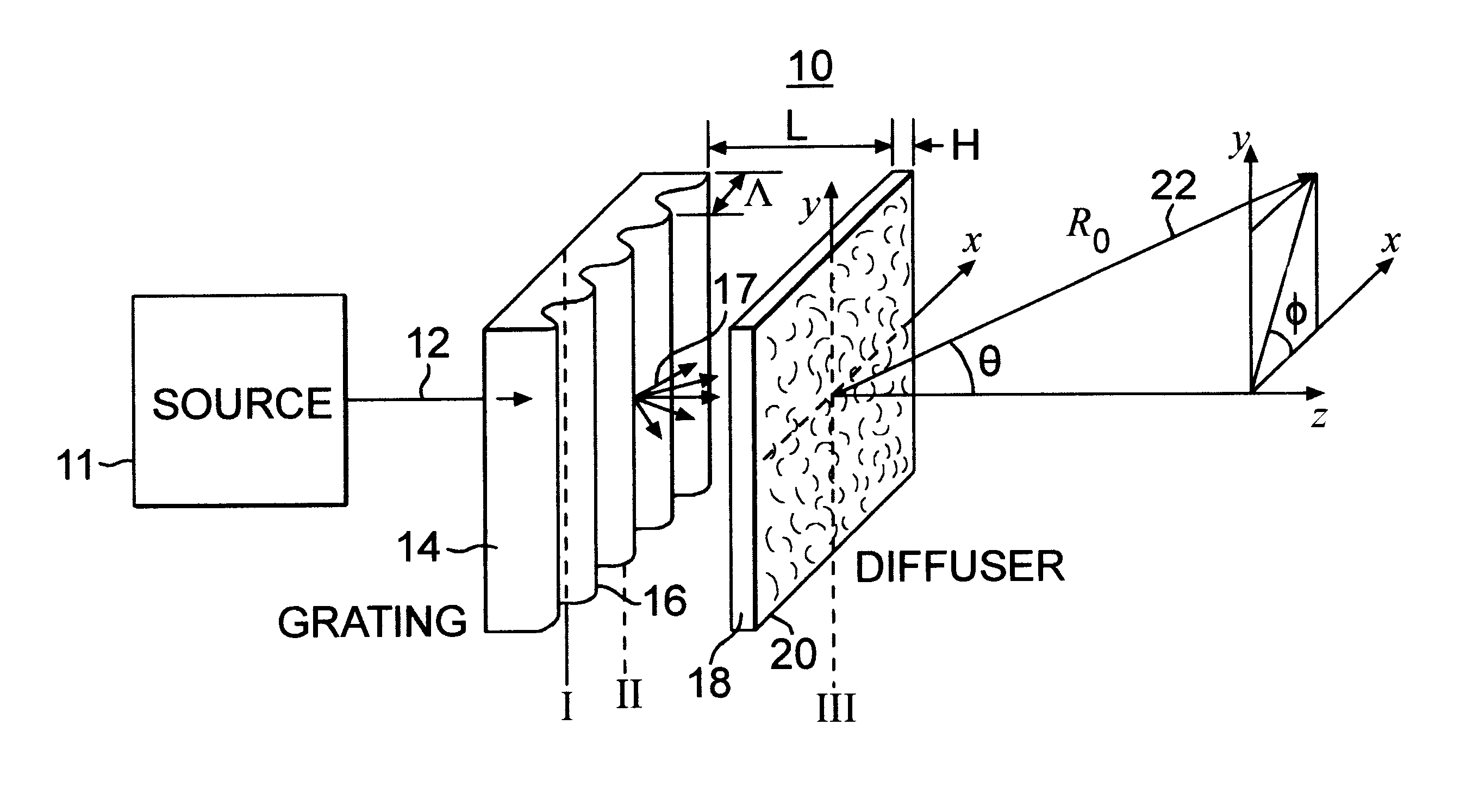

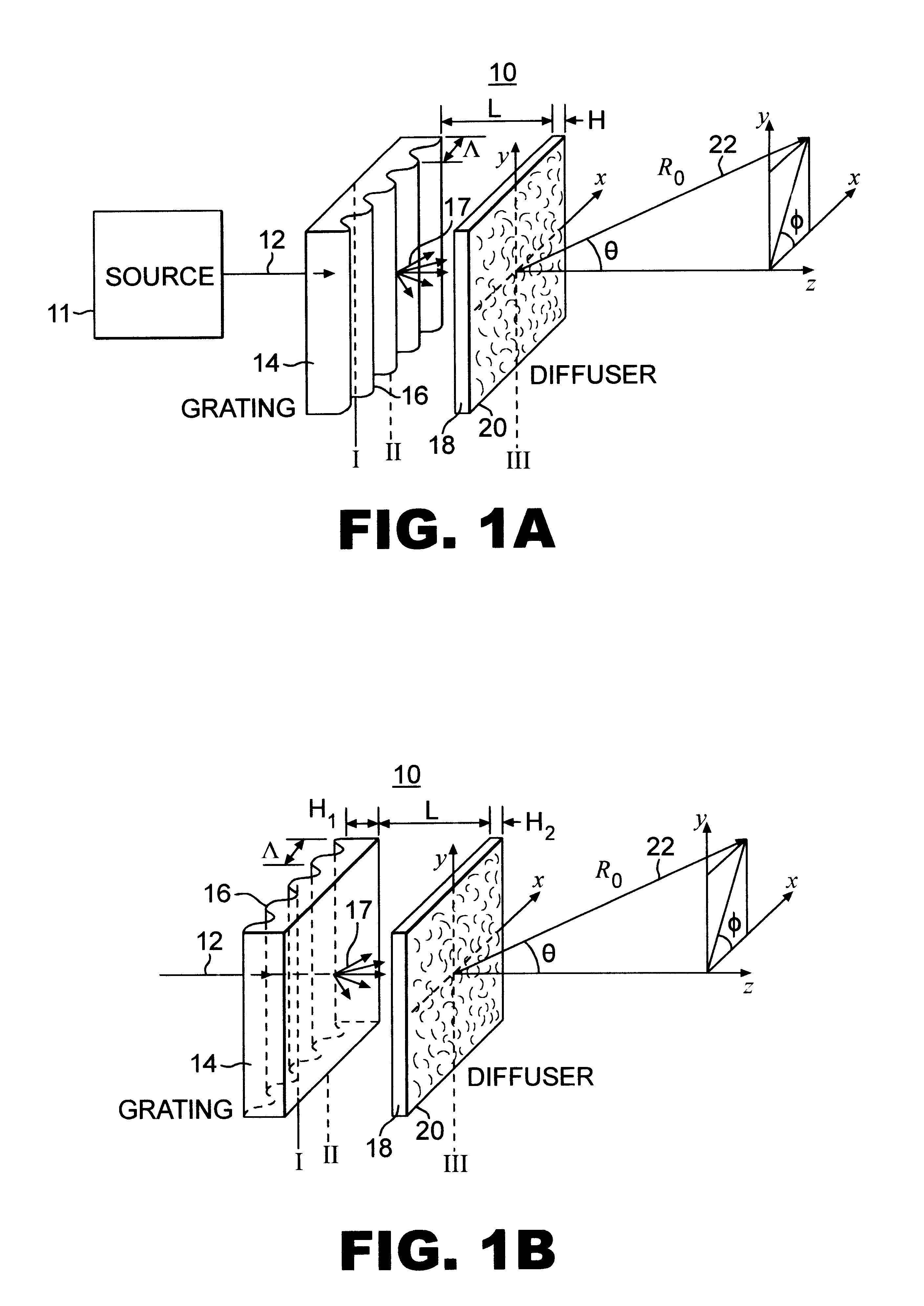

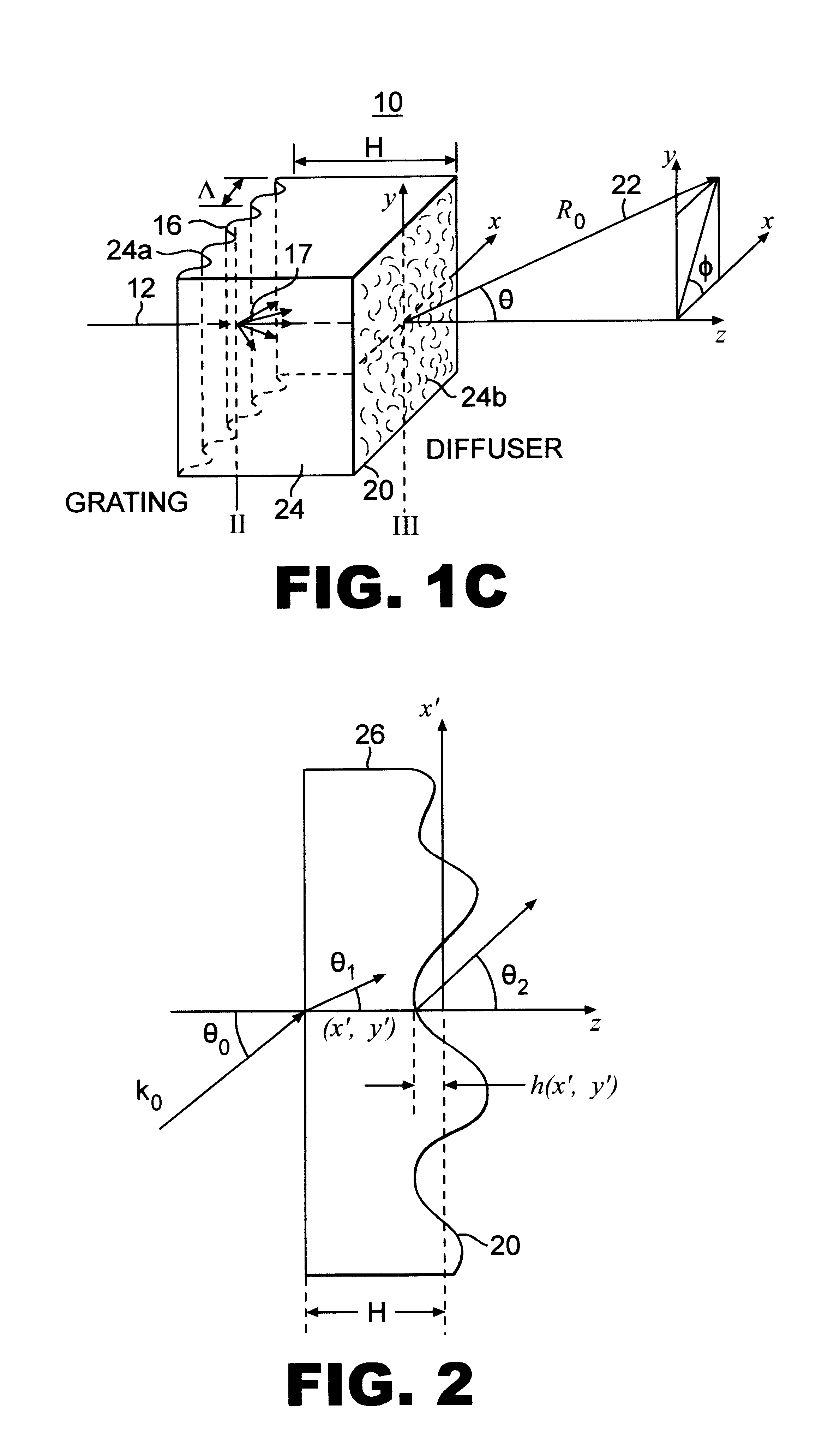

Optical system for diffusing light

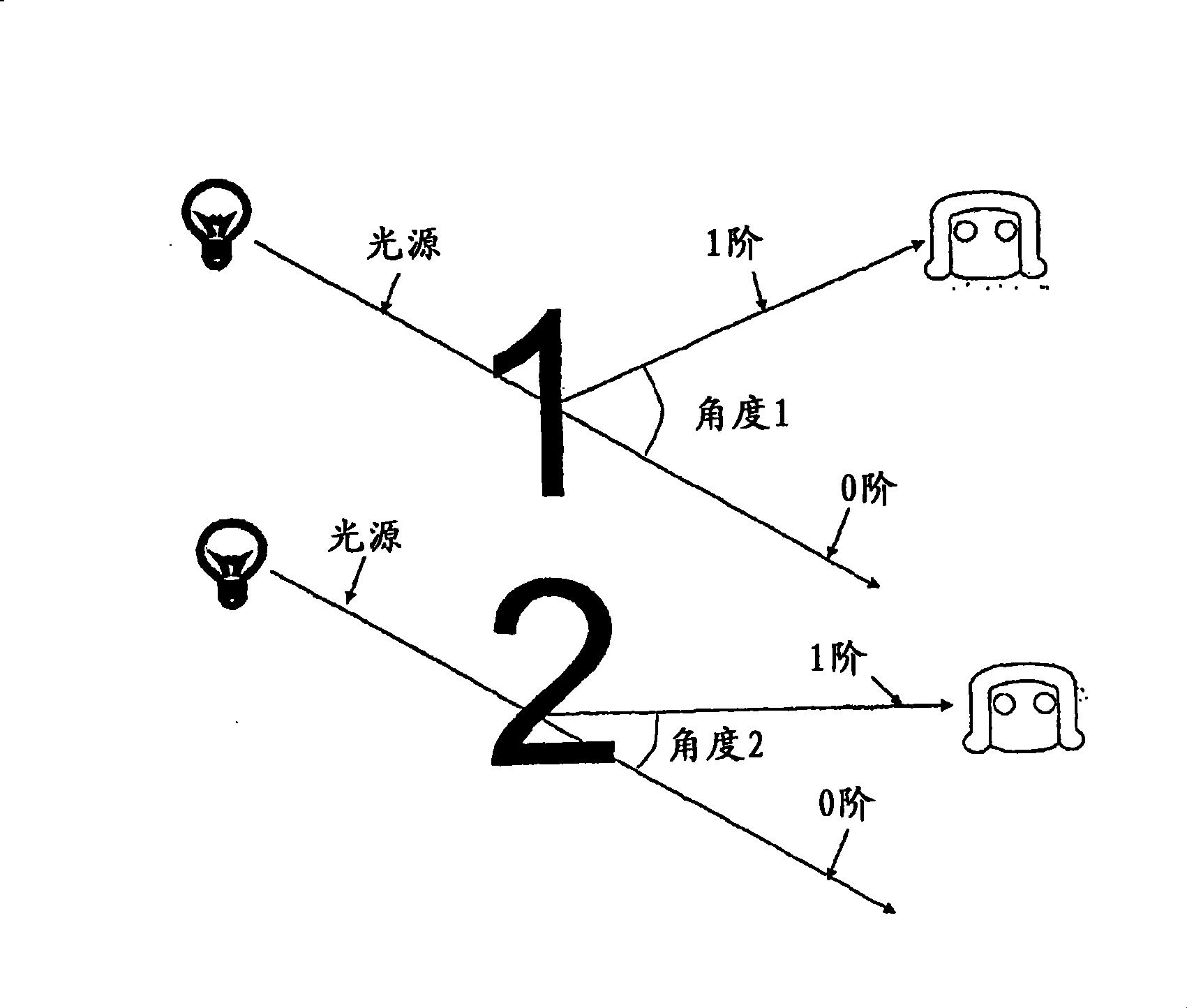

InactiveUS6583932B1Improve efficiencyEasy to replaceDiffusing elementsDiffraction gratingsDiffraction orderFull width at half maximum

An improved optical system is provided for diffusing light uniformly over a wide angle, including, a diffractive element for diffracting light received by the system in multiple diffraction orders, and a diffusing element which diffuses the diffracted light. The diffractive element provides diffracted light having an angular distribution of intensities over the diffraction orders which is correlated to the power spectrum of the diffusing element such that the system produces a predetermined intensity distribution of diffused light. The diffraction period of the diffractive element is selected such that the angular separation between the zeroeth and first diffraction orders is approximately one-half the angular extent of the full-width-at-half-maximum of the power spectrum of the diffusing element. The strengths of the diffraction orders are selected such that the combination of diffused light from each diffractive order provides uniformity in the intensity of the diffused light from the system.

Owner:UNIVERSITY OF ROCHESTER

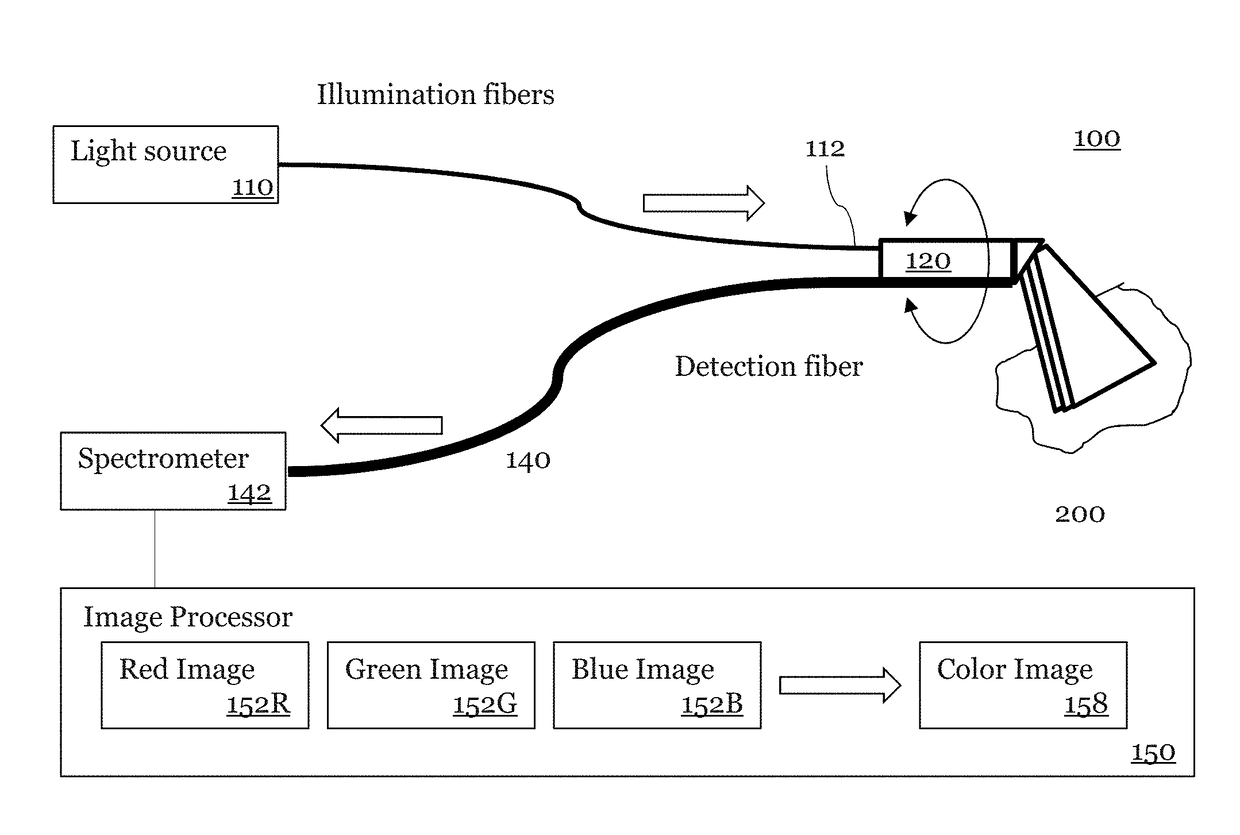

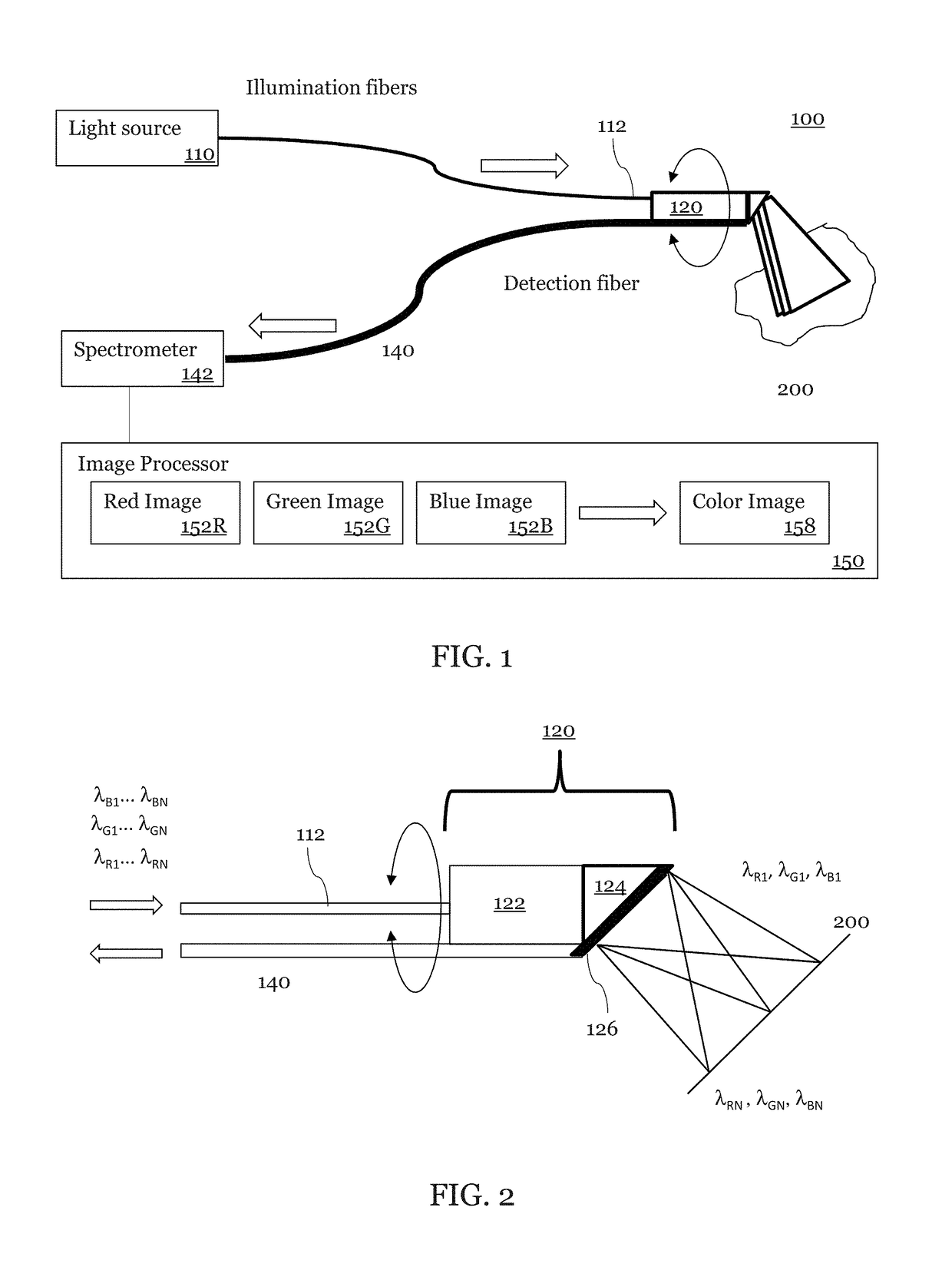

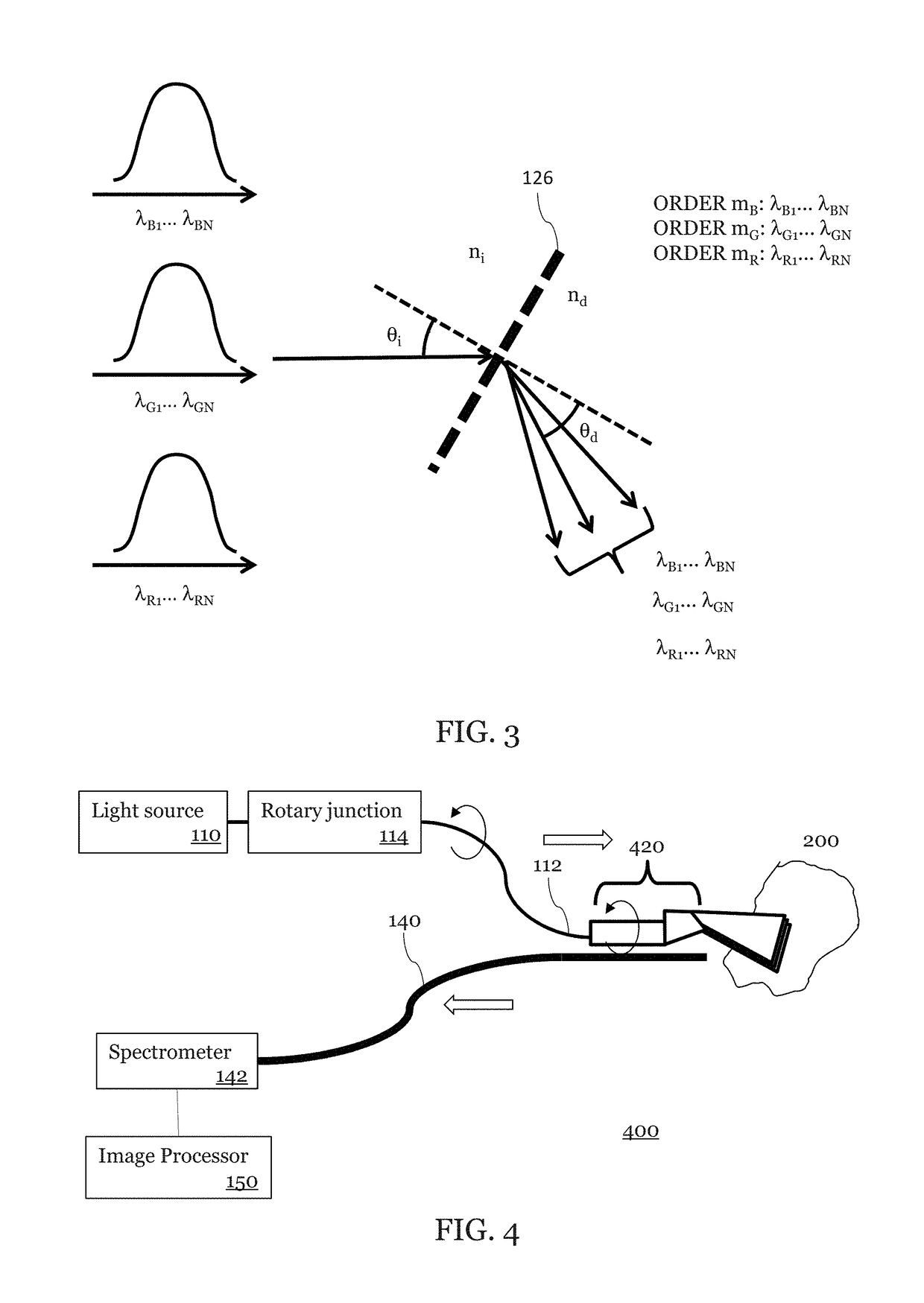

Spectrally Encoded Probe with Multiple Diffraction Orders

A spectrally encoded endoscopic probe. The probe has a light guiding component, a light focusing component, and a grating component. The probe is configured such that a set of light beams of multiple wavelengths are diffracted by the grating component in different orders at substantially the same angle. The set of light beams includes at least 3 light beams. Each light beam among the set of light beams is associated with a different wavelength.

Owner:THE GENERAL HOSPITAL CORP +1

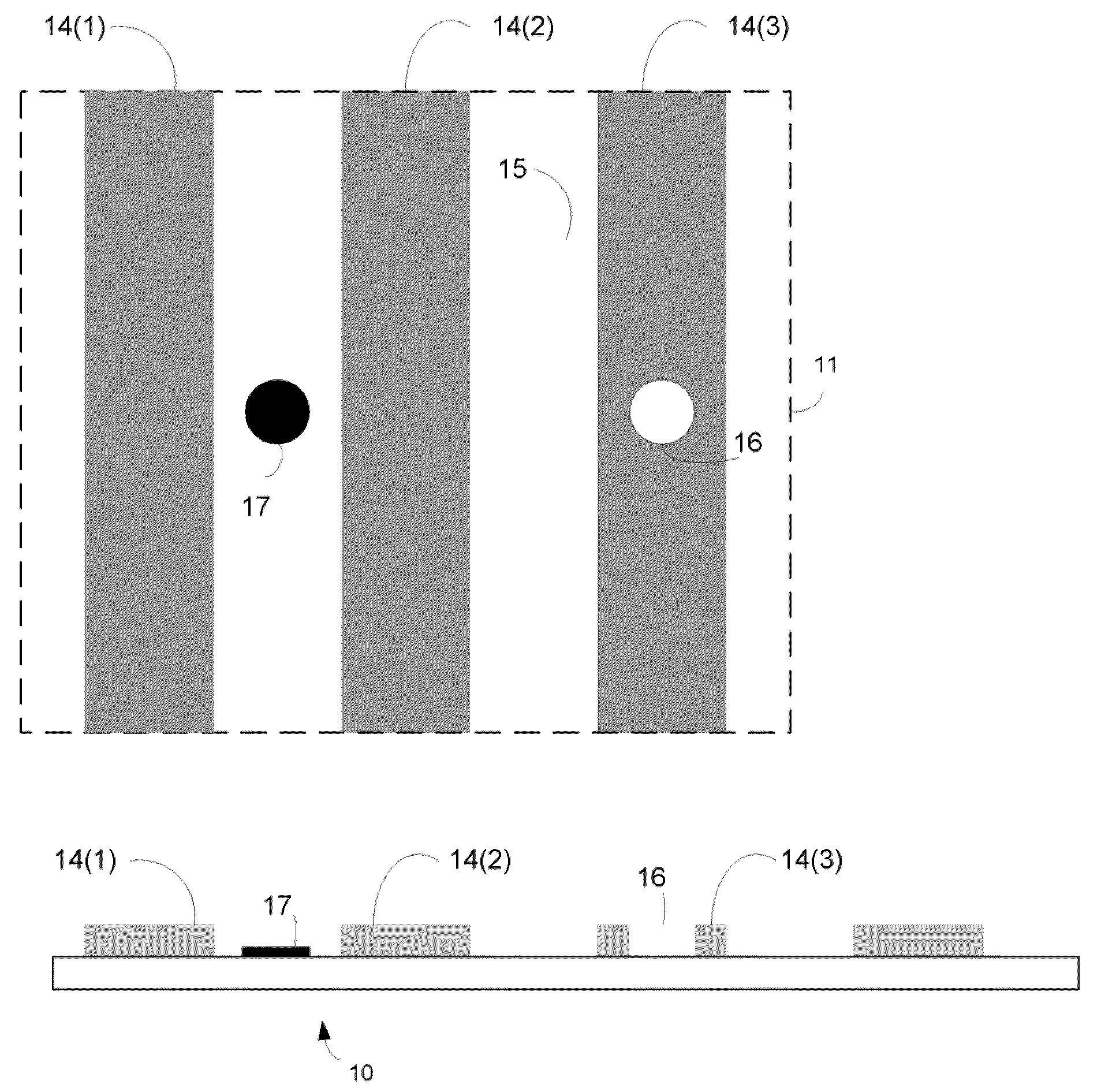

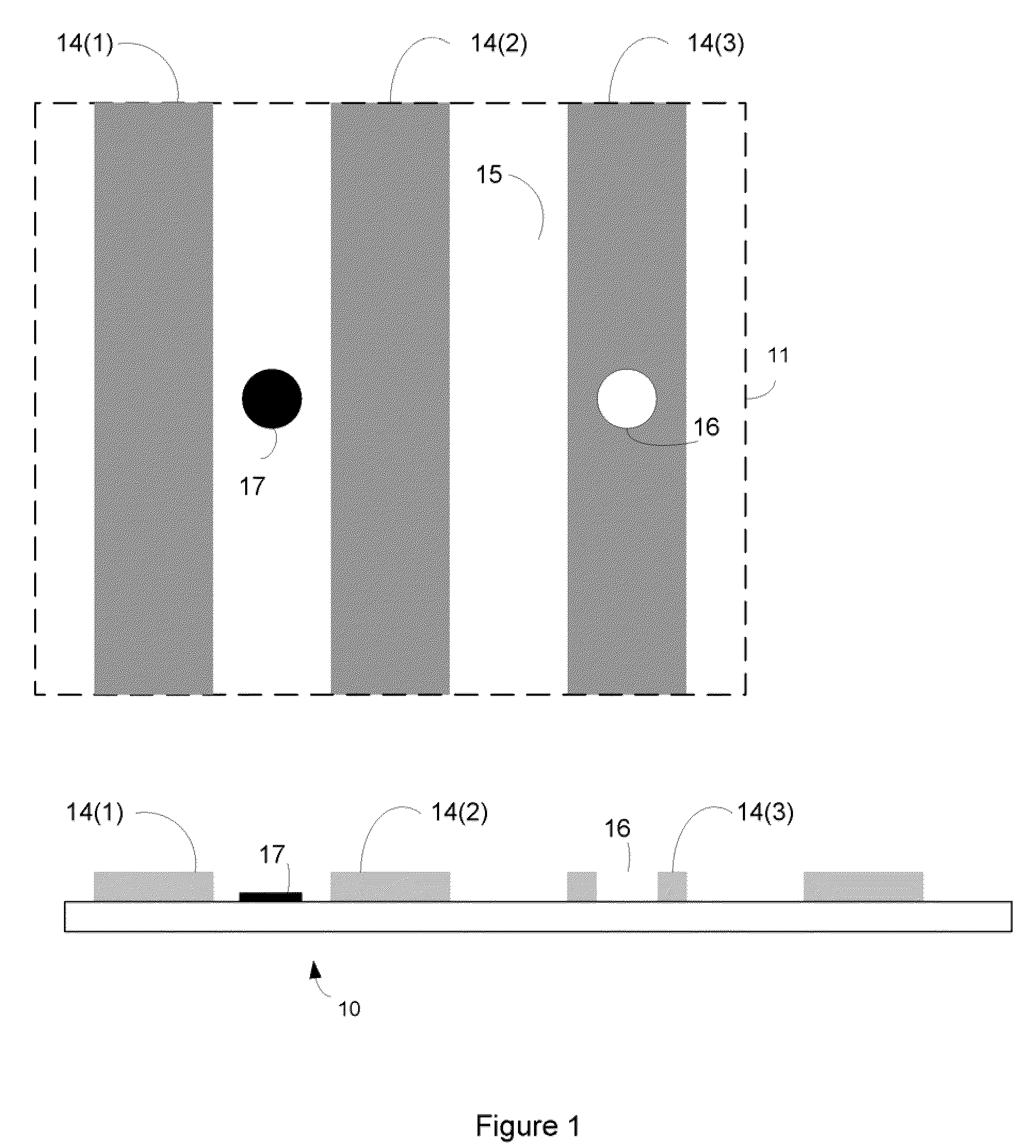

Method and system for evaluating an object that has a repetitive pattern

ActiveUS20090066942A1Semiconductor/solid-state device testing/measurementOptically investigating flaws/contaminationMultiple diffractionRadiation pattern

A method and system for evaluating an object that has a repetitive pattern. Illumination optics of an optical unit are adapted to scan a spot of radiation over a repetitive pattern that includes multiple regularly repeating structural elements that are optically distinguishable from their background, generating a diffraction pattern that includes multiple diffraction lobes. Collection optics are adapted to focus radiation from the repetitive pattern onto a detector. The focused radiation includes a single diffraction lobe while not including other diffraction lobes. A grey field detector generates detection signals, responsive to the focused collected radiation. The optical unit is adapted to maintain, at a detection surface of the grew field detector, a radiation pattern that includes a first radiation pattern component resulting from the repetitive pattern and a second radiation pattern component resulting from a defect; wherein the first radiation pattern component is stronger than the second radiation component.

Owner:APPL MATERIALS ISRAEL LTD

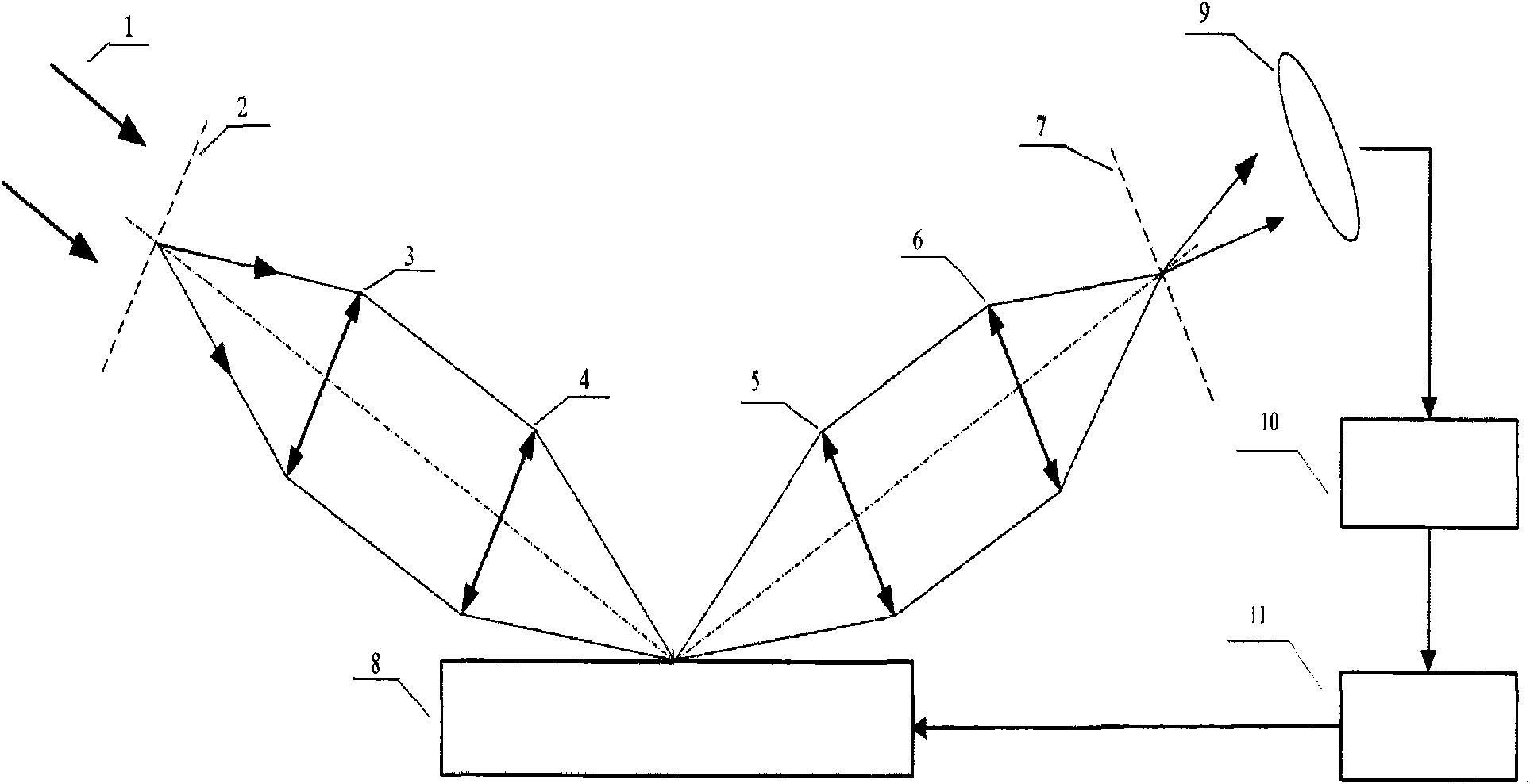

Grating shear wave aberration detection interferometer and detection method thereof

ActiveCN104165755AEliminate tilt errorsImprove detection accuracyTesting optical propertiesPath lengthGrating

The invention provides a grating shear wave aberration detection interferometer. The grating shear wave aberration detection interferometer comprises a light source, a focus lens, a filtering pinhole, a two-dimensional grating, a grating displacement platform, a diaphragm plate, a diaphragm alignment displacement platform and a two-dimensional photoelectric sensor. According to the grating shear wave aberration detection interferometer, the wave aberration of an optical system to be detected is detected; when the optical system to be detected is illuminated by the light source, the wavefront of the optical system to be detected generates an interference pattern through grating separation and shear, wavefront reconstruction is conducted on differential information generated by multiple diffraction levels in different directions through shear and interference, so that a system error correlative is obtained, and then the relevant parameters, namely, the distance between every two adjacent focusing points of different levels of diffraction light and the inclination angle of a detector, of main system error terms influencing the wave aberration detection precision of the grating shear interferometer are obtained; in this way, geometric path-length errors and detector inclination errors existing in wave aberration detection are eliminated, and the precision of wavefront reconstruction and the accuracy of wave aberration detection are improved. By the adoption of the grating shear wave aberration detection interferometer, wave aberration detection of the optical system to be detected is conducted, system errors existing during detection are eliminated, and the detection precision is improved.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Micro hybrid light splitting device

ActiveCN103528679AExpand the scope ofHigh resolutionRadiation pyrometrySpectrum investigationGratingLight spot

The invention discloses a micro hybrid light splitting device, which is characterized by comprising a substrate, wherein the substrate is provided with an arrayed waveguide grating, a reflecting mirror array, a prism assembly and a photoelectric detector array, wherein the arrayed waveguide grating is provided with an input optical fiber and n output waveguides; the reflecting mirror array is positioned on the substrate, and is provided with n reflecting mirror bodies which correspond to the output waveguides respectively; the prism assembly is arranged in the emitting area of the reflecting mirror array, and is used for splitting n strands of light rays from the reflecting mirror array into m strands respectively, and outputting; the photoelectric detector array is arranged at the back stage of the prism assembly. In the scheme, the prism assembly is taken as a back stage element of the arrayed waveguide grating working at multiple diffraction orders, so that light signals of multiple diffraction orders output by the output waveguides of the arrayed waveguide grating can be further dispersed longitudinally to form a light spot array on a focal plane where the photoelectric detector array is positioned, and the light signals are converted into digital signals through the photoelectric detector array. The device can be used for realizing light splitting in a wide wavelength range at a high wavelength resolution in a small volume.

Owner:XIAMEN UNIV

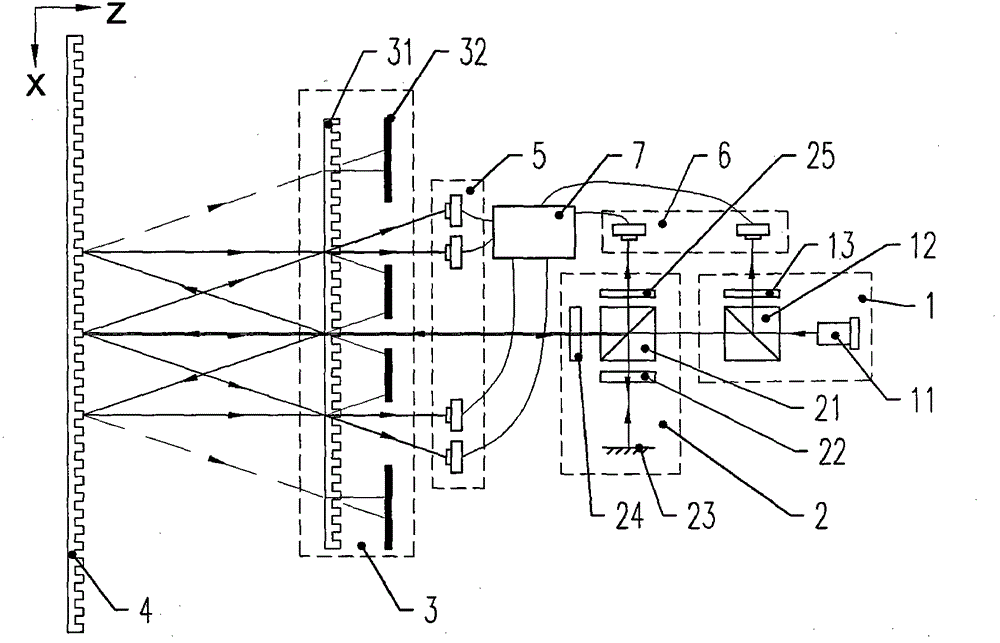

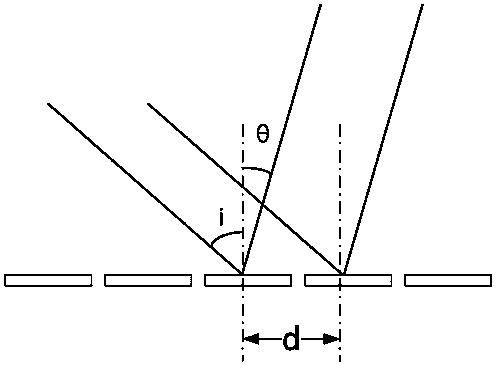

Two dimension displacement measurement device which uses double frequency laser and diffraction grating

The invention discloses a two dimension displacement measurement device which uses a double frequency laser and a diffraction grating, and relates to an ultra precise displacement measurement technology and an optical grating displacement measurement system. The two dimension displacement measurement device which uses the double frequency laser and the diffraction grating is composed of a scale grating and a reading head, wherein the reading head comprises a double frequency laser light source, a Z direction interference component, a scan light splitting grating component, an X direction detection component, a Z direction detection component and a signal processing component. The two dimension displacement measurement device which uses the double frequency laser and the diffraction grating is based on a Michelson interferometer theory, a multiple diffraction grating interference theory and an optics beat frequency theory, can achieve simultaneous measurement for X direction displacement and Z direction displacement, has the advantages of being compact in structure, strong in interference resisting ability, and low in demand for backward zero order diffraction intensity of the scale grating, decoupling the X direction measurement and the Z direction measurement and the like, can achieve nanometer level or even higher lelvel measurement resolution, and can be used in displacement measurement multiple in freedom degree and high in accuracy.

Owner:HARBIN INST OF TECH

Method and apparatus using volume holographic wavelength blockers

ActiveUS7986407B2Low costRadiation pyrometrySpectrometry/spectrophotometry/monochromatorsLength waveOptical density

The invention disclosed here teaches methods to fabricate and utilize a non-dispersive holographic wavelength blocker. The invention enables the observation of the Raman signal near the excitation wavelength (˜9 cm−1) with the compactness of standard thin film / holographic notch filter. The novelty is contacting several individual volume holographic blocking notch filter (VHBF) to form one high optical density blocking filter without creating spurious multiple diffractions that degrade the filter performance. Such ultra-narrow-band VHBF can be used in existing compact Raman instruments and thus will help bring high-end research to a greater number of users at a lower cost.

Owner:COHERENT INC

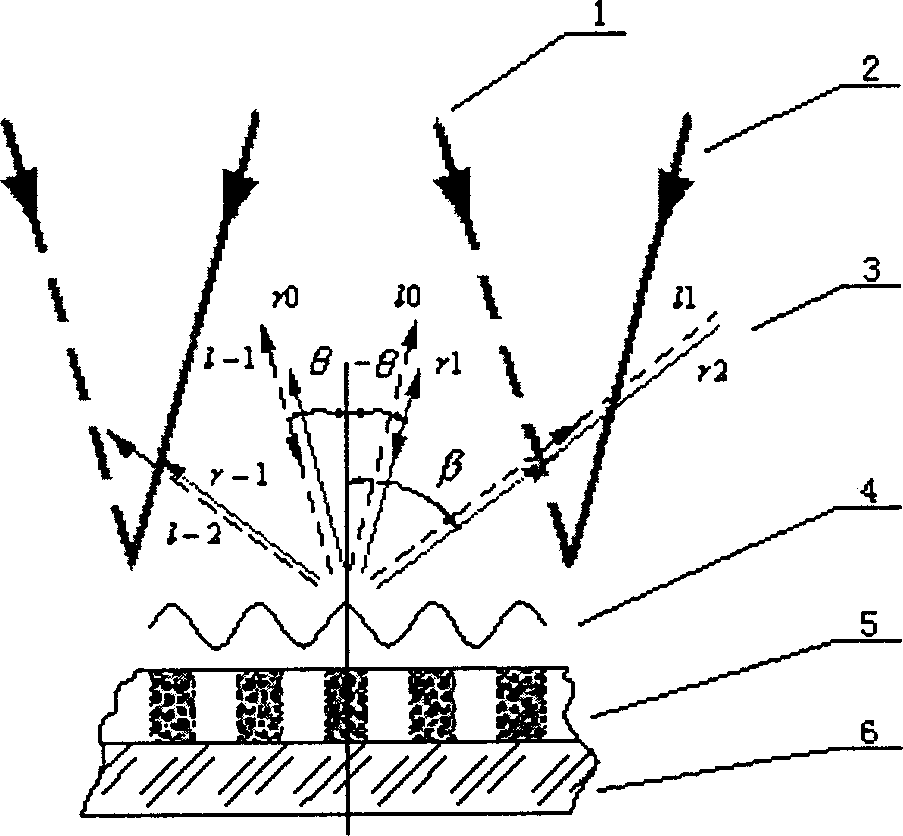

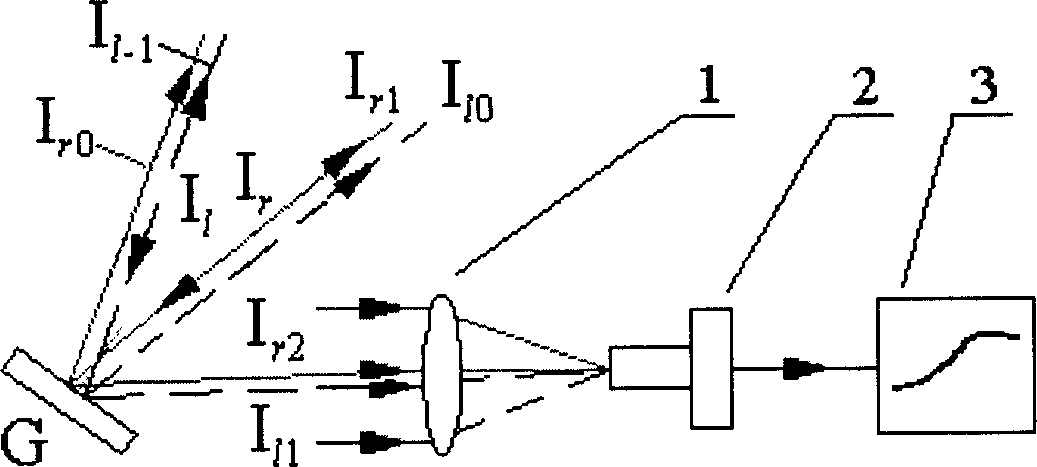

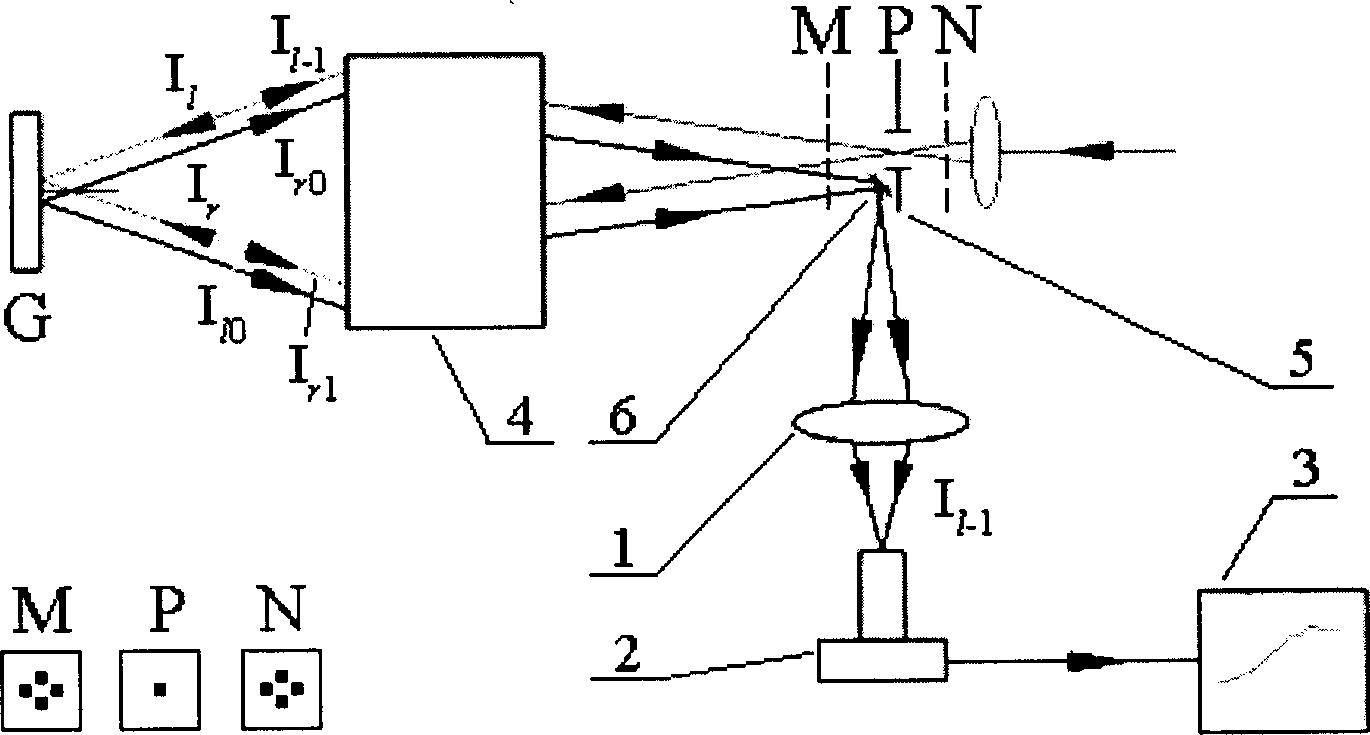

Optical method for real time latent image self-moritoring in holographic raster mfg

The invention refers to a real-time latent-image self-monitoring method in the course of making a holographic grating. It uses arbitrary interference recording light beam of the light intensity acting on the grating as the real-time sub-image self-monotiring incident light beam, and when the ratio of the wavelength of the incident light beam and the period of the grating lambda / d<2 / 3, the gratinghas multiple diffraction levels, it real-time self-monitors the light beam outside the system collimated and photoelectricly multiplied in the transmission direction of self-diffractions Ir2 and Ir1 of arbitrary level sub-image, or real-timely self-monitors the autocollimating level returning according to the original route filtered, collimated and photoelectricaly multiplied.

Owner:TSINGHUA UNIV

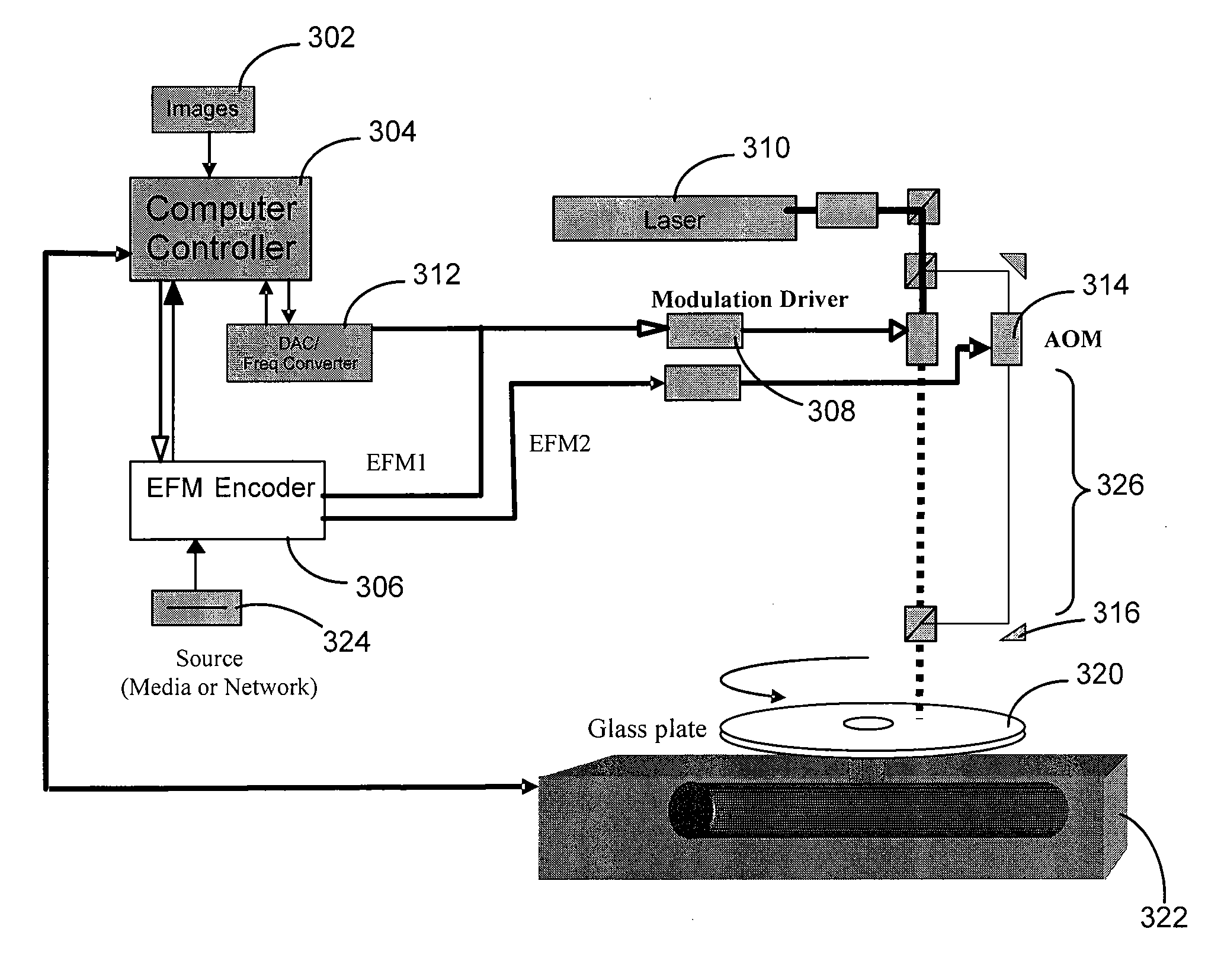

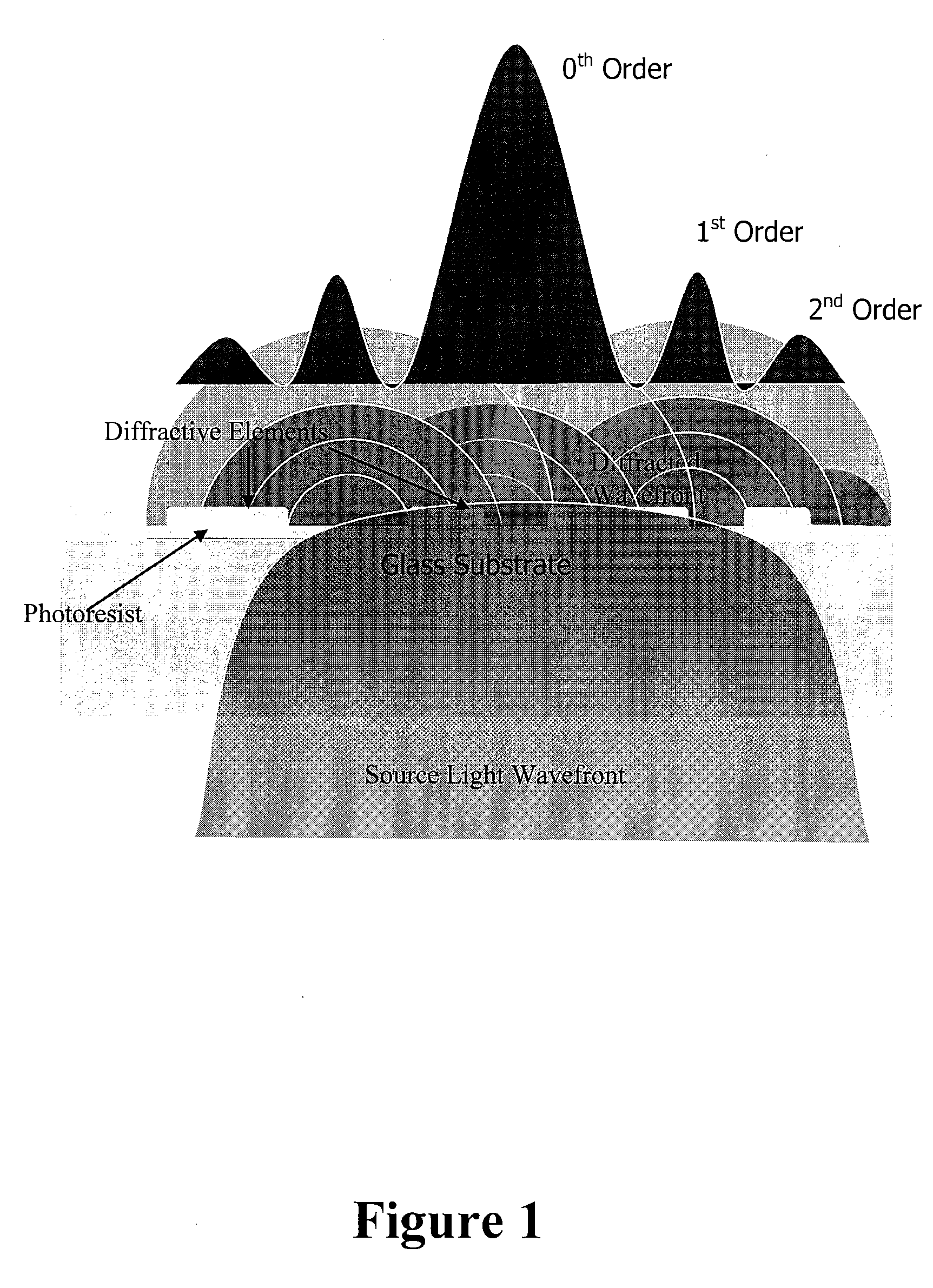

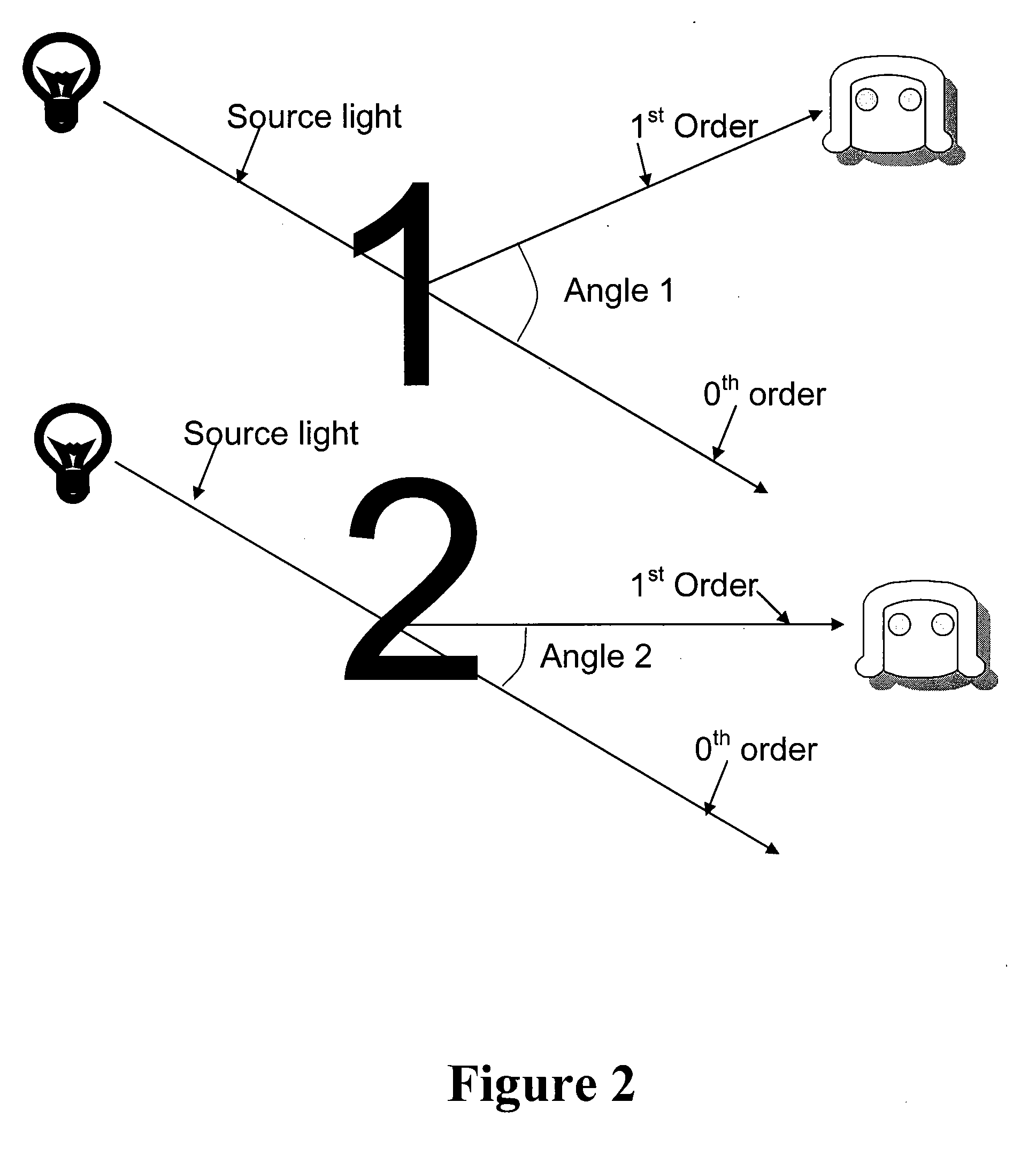

Method and System for Producing Multiple Images in a Single Image Plane Using Diffraction

The present invention is directed to methods for creating pseudo-holographic images viewable under different selected angles on optical storage devices and other photosensitive surfaces. The present invention also discloses novel optical storage devices with super-imposed pseudo-holographic images. Generally, a photosensitive surface is exposed with multiple diffraction patterns creating super-imposed pseudo-holographic images. These diffraction patterns create super-imposed images on the photosensitive surfaces, which can be read by either a human or a computer.

Owner:NANO IP HLDG LLC

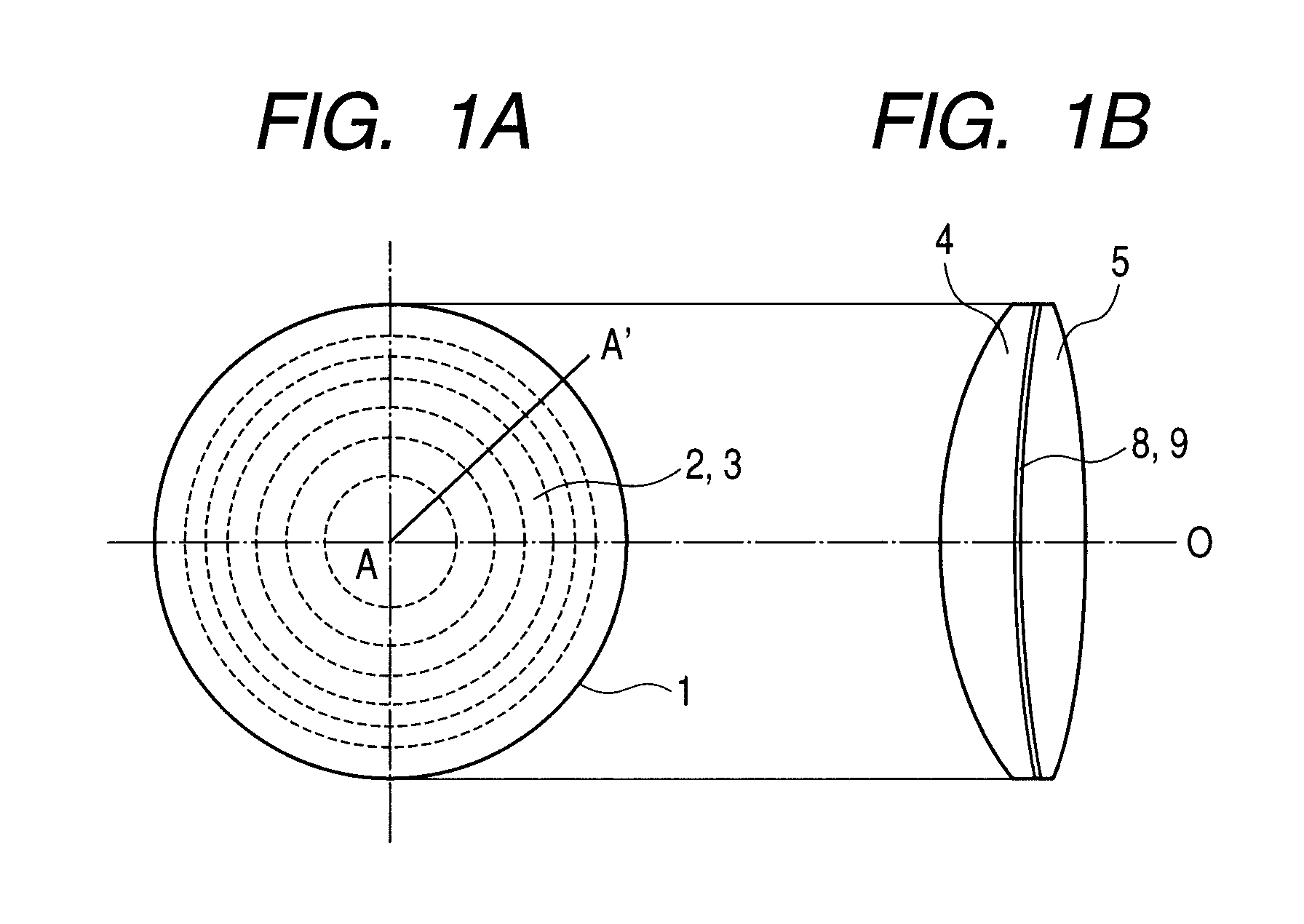

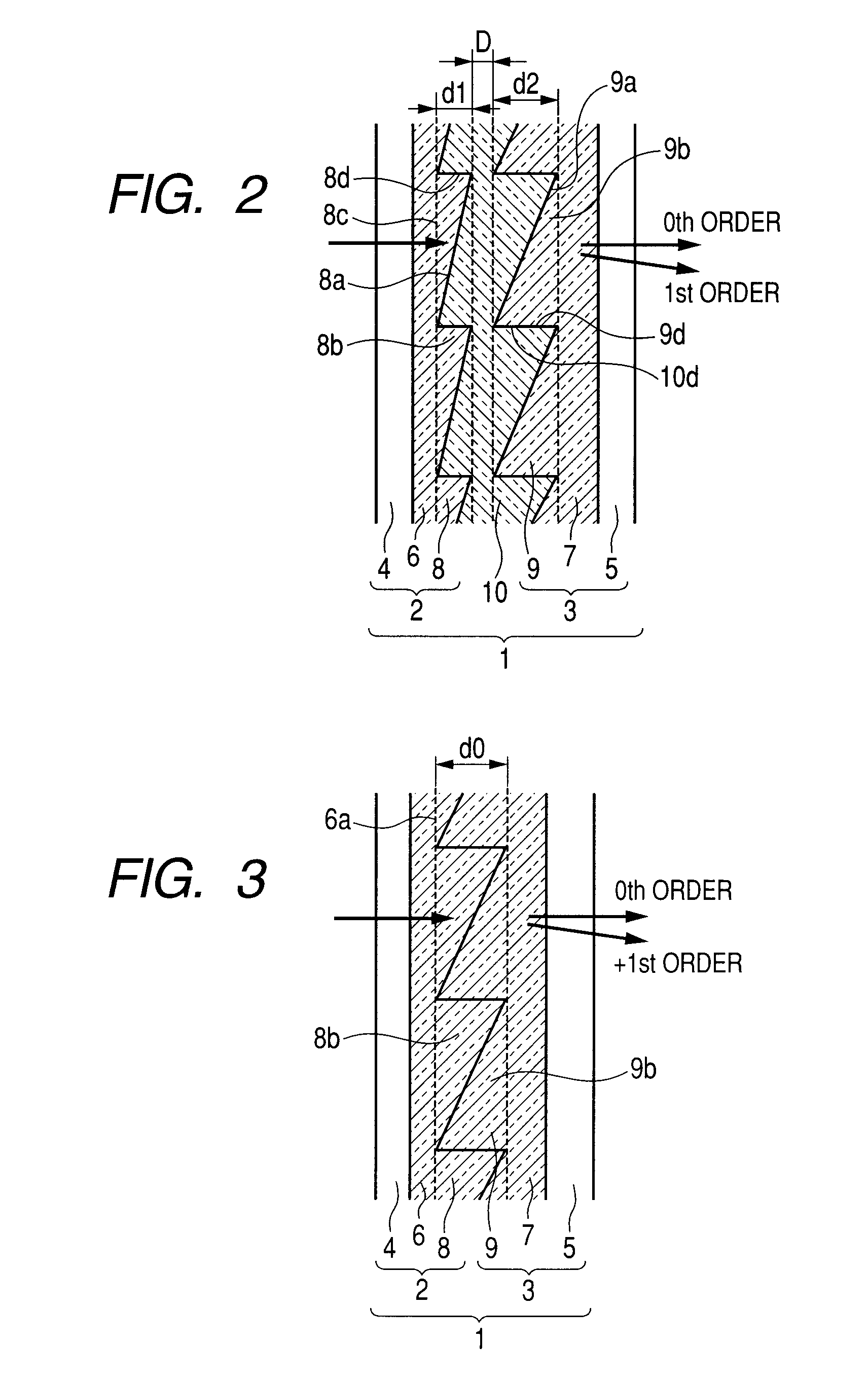

Diffractive optical element, optical system including the same, and image pickup apparatus

InactiveUS20110122305A1Television system detailsTelevision system scanning detailsMaterial typeRefractive index

A diffractive optical element includes multiple diffraction gratings laminated and made of at least three material types, wherein the multiple diffraction gratings include: a first combination part including two diffraction gratings of materials different from each other in which grating side surfaces of grating parts contact with each other or are disposed close to each other in a grating pitch direction; and a second combination part including two diffraction gratings of materials different from each other in which at least one material is different from the materials of the first combination part; and when N1Aw and N1Bw denote refractive indices of the first combination part at a wavelength (w), ν1A and ν1B denote Abbe numbers, N2Ad and N2Bd denote refractive indices of the second combination part on a d-line, ν2A and ν2B denote Abbe numbers, the wavelength (w) is 370<w<730 (nm). The followings are satisfied:N1Aw−N1Bw=0;16<(ν1A−ν1B)<75;0.03<|N2Ad−N2Bd|<0.5; and16<(ν2A−ν2B)<75.

Owner:CANON KK

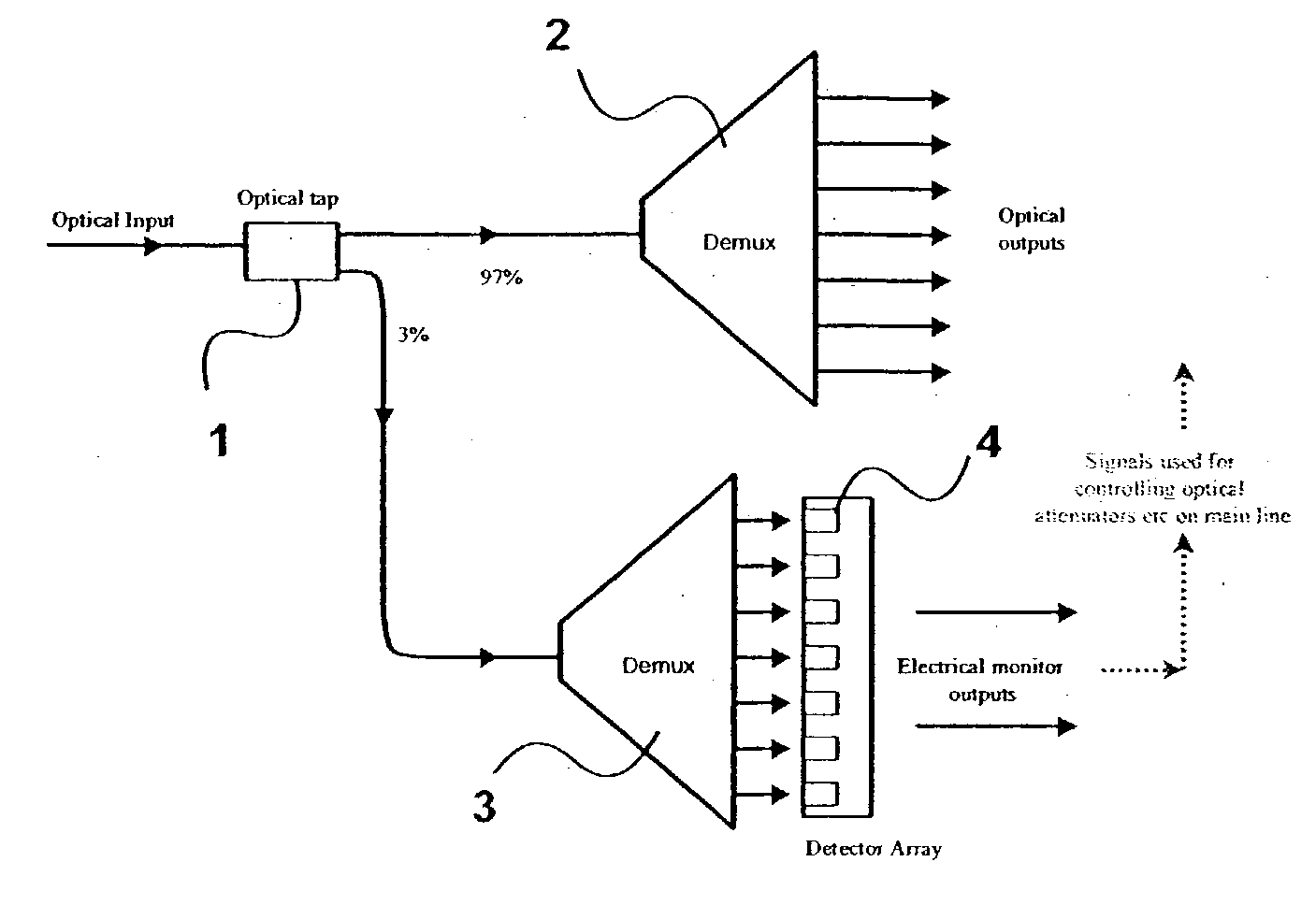

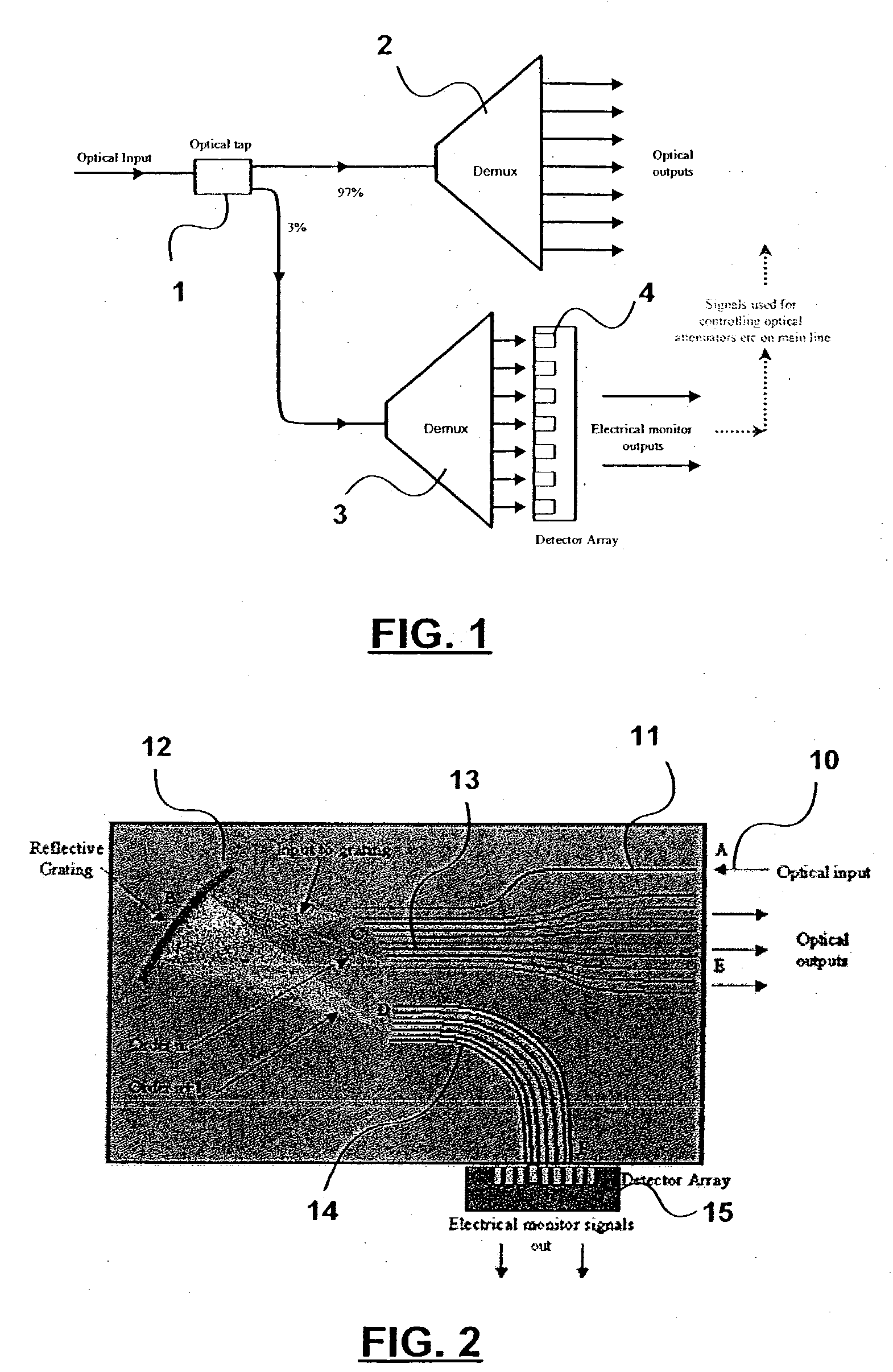

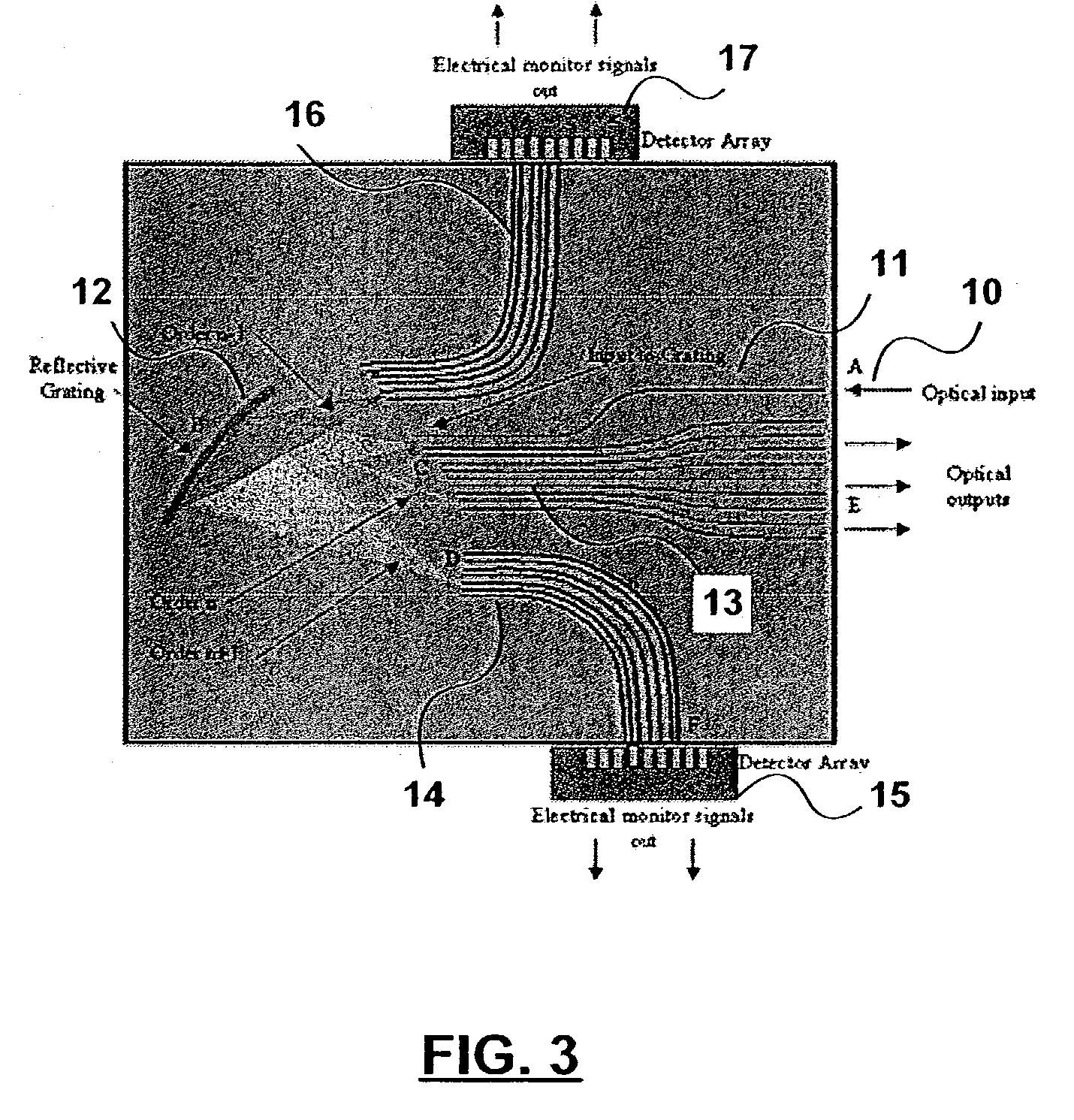

Device for integrating demultiplexing and optical channel monitoring

A method for integrating power monitoring capabilities with passive demultiplexing operations, utilizing the high-order diffraction from an optical diffraction grating. The technique helps avoid insertion loss and polarization dependent loss penalties, and device size penalties, typically incurred with optical taps and multiple diffraction gratings. The technique can also be modified slightly to provide information on channel wavelength and optical signal-to-noise-ratio, as well as channel power.

Owner:ENABLENCE +1

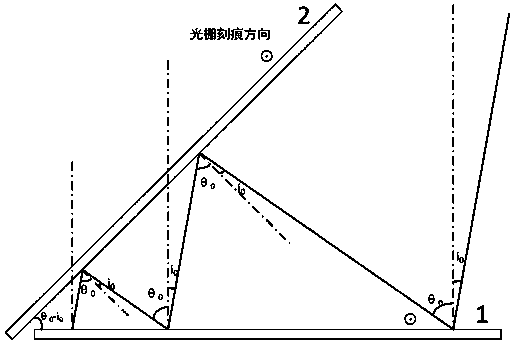

Blazed grating based beam deflection angle amplifying unit

The invention discloses a blazed grating based beam deflection angle amplifying unit. The blazed grating based beam deflection angle amplifying unit includes beam deflection angle amplifying subunits;each beam deflection angle amplifying subunit includes two blazed gratings; if an incident angle of a beam incident on the blazed grating is i0, the diffraction angle of the diffracted light containing the main energy of the beam is Theta 0; an included angle between the two blazed gratings is Theta0-i0, so that the incident beam can be diffracted back and forth between the two blazed gratings for multiple times, and the incident angle and the diffraction angle of the incident light are identical in the two blazed gratings. The incident angle i0 and the diffraction angle Theta0 are adjusted,so that the deflection amount of the diffracted light is larger than the deflection amount of the incident light when the incident light is deflected, and multiple diffraction amplifications of the deflection amount of the incident light can be realized. The method can achieve multiple diffraction amplifications of the deflection amount of the incident light.

Owner:HUAZHONG UNIV OF SCI & TECH

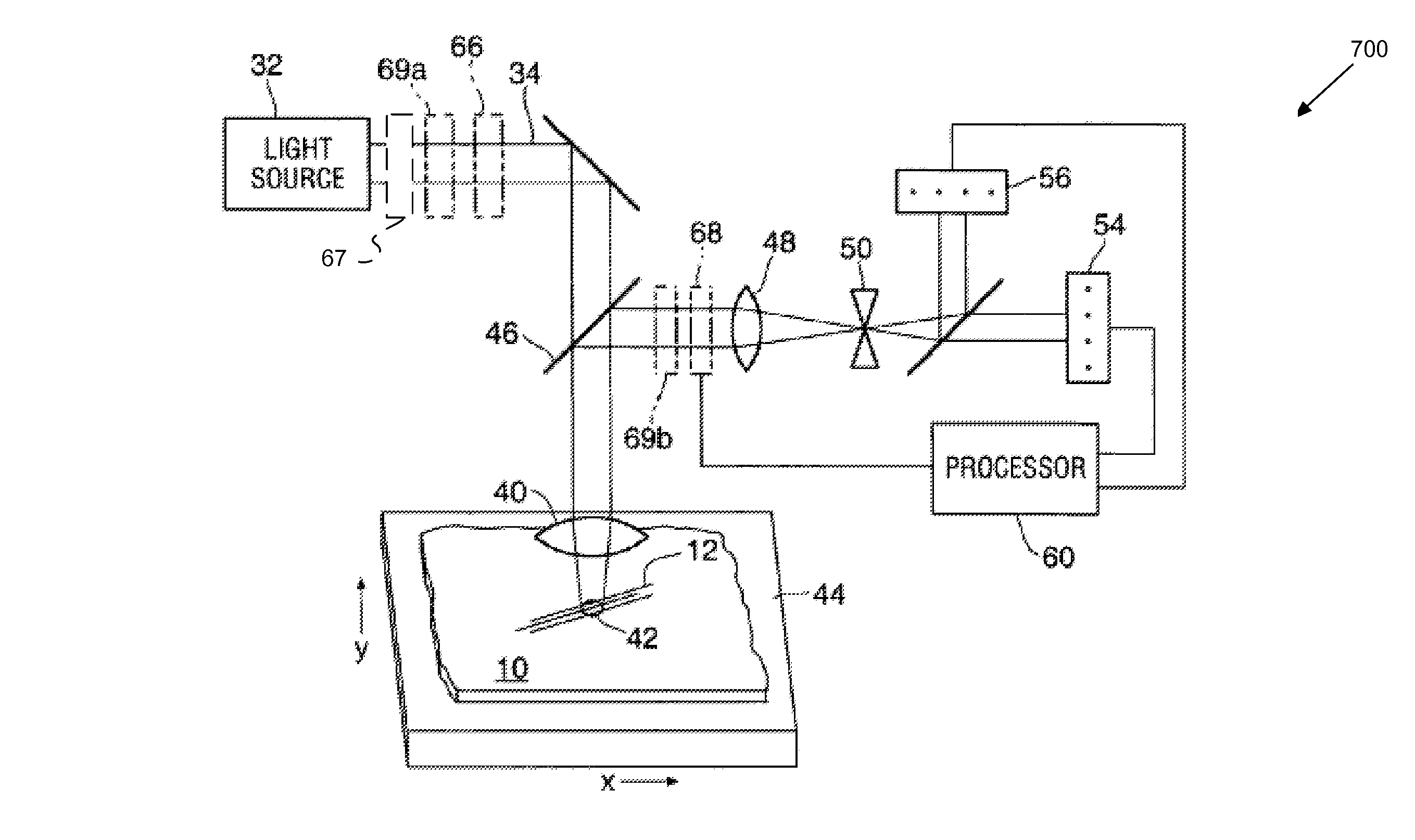

Methods And Systems For Semiconductor Metrology Based On Wavelength Resolved Soft X-Ray Reflectometry

ActiveUS20210063329A1High throughput measurementHigh measurement accuracySemiconductor/solid-state device testing/measurementMaterial analysis using radiation diffractionDiffraction orderAngle of incidence

Methods and systems for measuring structural and material characteristics of semiconductor structures based on wavelength resolved, soft x-ray reflectometry (WR-SXR) at multiple diffraction orders are presented. WR-SXR measurements are simultaneous, high throughput measurements over multiple diffraction orders with broad spectral width. The availability of wavelength resolved signal information at each of the multiple diffraction orders improves measurement accuracy and throughput. Each non-zero diffraction order includes multiple measurement points, each different measurement point associated with a different wavelength. In some embodiments, WR-SXR measurements are performed with x-ray radiation energy in a range of 10-5,000 electron volts at grazing angles of incidence in a range of 1-45 degrees. In some embodiments, the illumination beam is controlled to have relatively high divergence in one direction and relatively low divergence in a second direction, orthogonal to the first direction. In some embodiments, multiple detectors are employed, each detecting different diffraction orders.

Owner:KLA TENCOR TECH CORP

Integrated diffraction grating type high stability laser displacement sensor

The invention discloses an integrated diffraction grating type high stability laser displacement sensor. The sensor includes a sensor body, wherein the sensor body includes a collimation module of a laser diode, a diffraction grating, a diaphragm, a filter, an imaging lens and a CMOS linear image sensor, the laser diode collimation module of the laser displacement sensor emits a collimation beam,the beam is diffusely reflected by a surface of a detected object, passes through the diaphragm and the imaging lens and is then split into multiple diffraction spots by the special transmission typediffraction grating, displacement of the detected object is reversed through utilizing each diffraction spot, solved multiple displacement data are subjected to averaging or median value processing, and the actual displacement of the detected object can be obtained. Compared with a conventional laser triangle range finding sensor, the displacement of the detected object is solved through utilizingthe information of the multiple diffraction spots in the case of measuring the displacement once, influence of environmental factors such as noise is reduced, and the stability of the measured data is effectively improved.

Owner:XI AN JIAOTONG UNIV

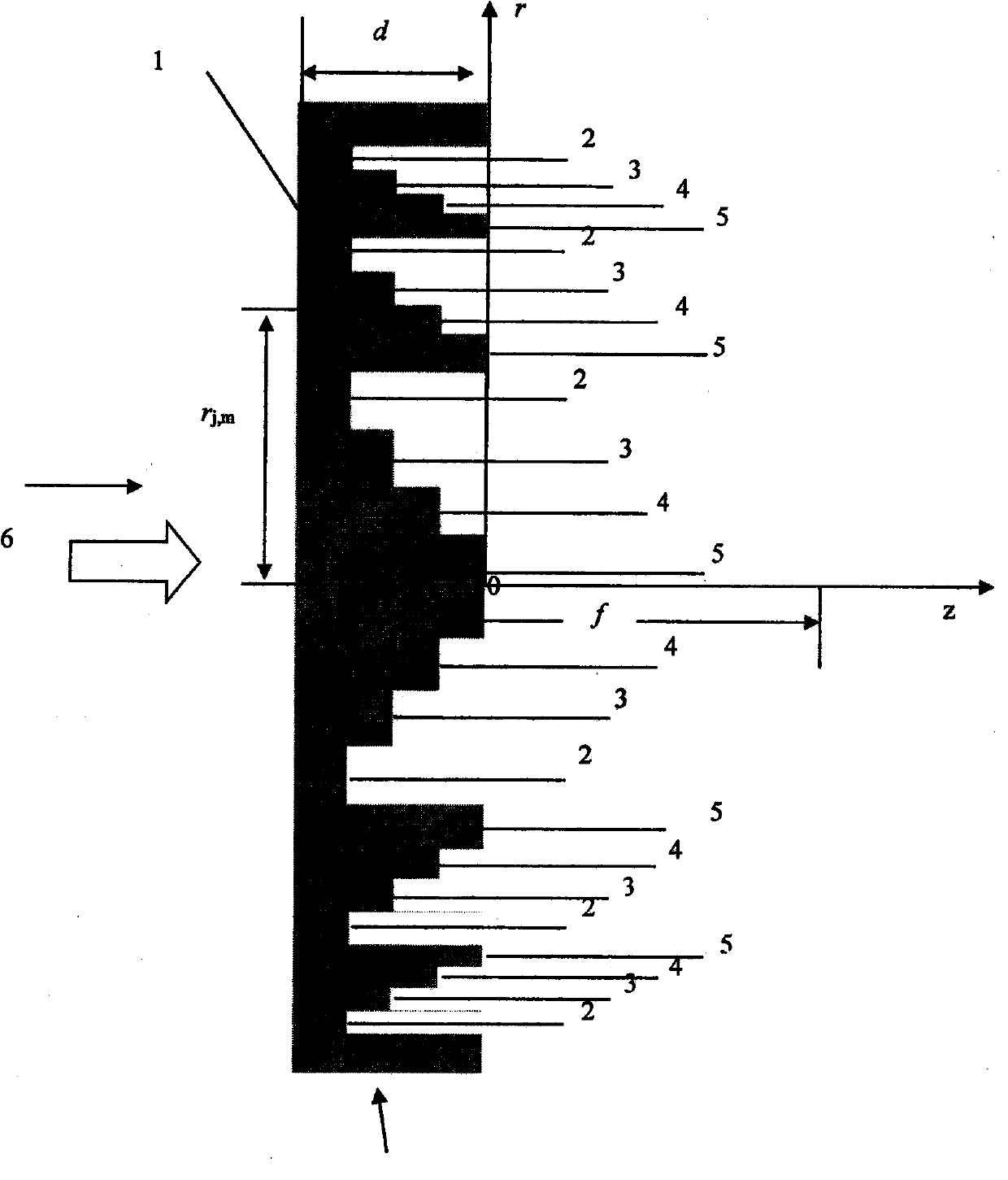

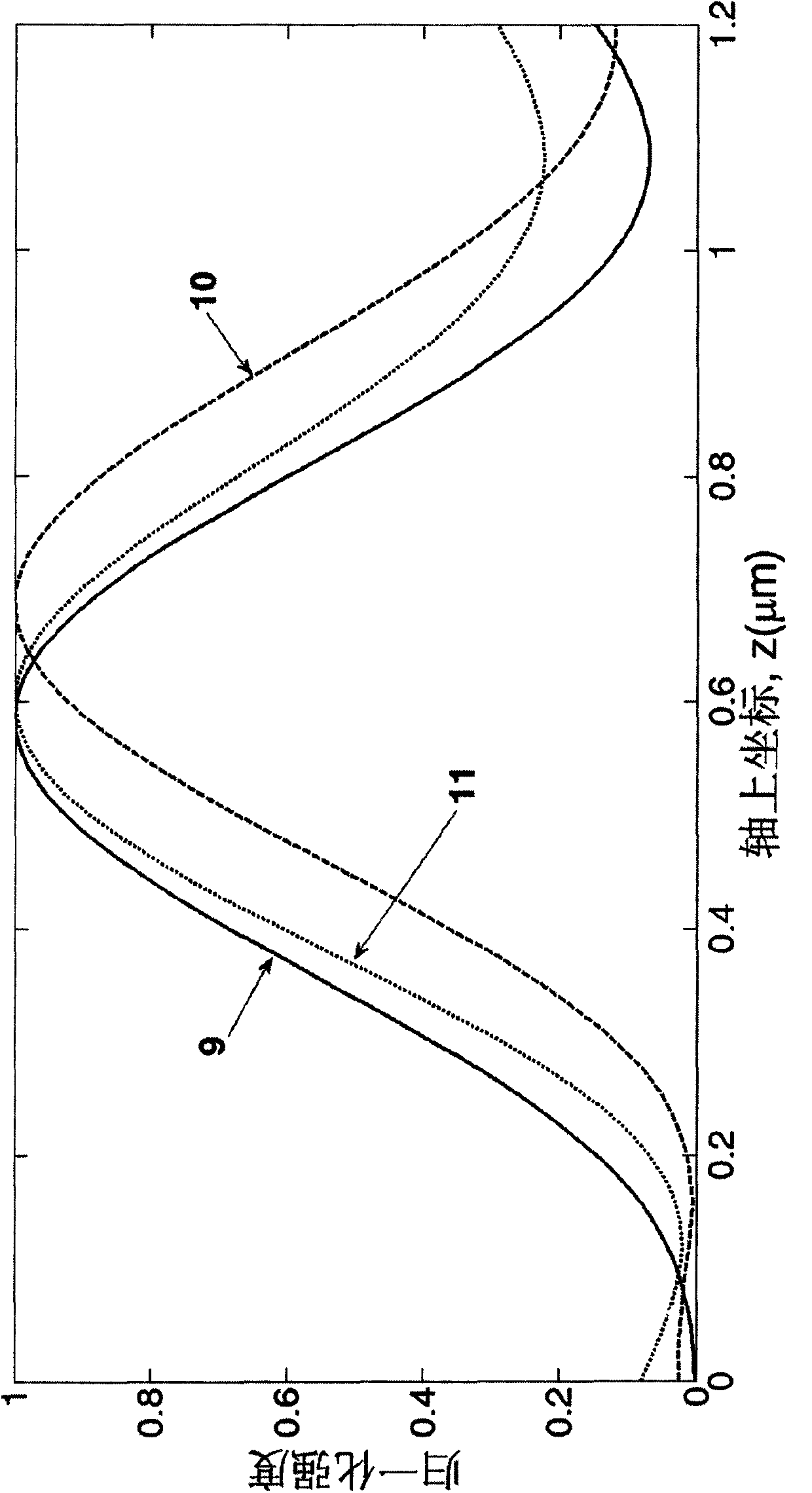

Design method of high-numerical-aperture short-focal-length step phase position type thick FZP

The invention relates to a design method of a high-numerical-aperture short-focal-length step phase position type thick FZP. The step phase position type FZP is equivalent to multiple diffraction screens based on a multi-screen diffraction theory, the diffraction effect in a step phase position type FZP body is considered, a diffraction field of the whole FZP is formed by superposing diffraction fields of multiple equivalent diffraction fields, a vector diffraction theoretical formula is formed, the step phase position type FZP can be designed and diffraction field distribution can be analyzed according to a vector diffraction theory. By adopting the design method, a computing result can be basically consistent to a time domain finite difference simulated result, and the high-numerical-aperture short-focal-length step phase position type thick FZP can be simply and effectively designed.

Owner:WENZHOU UNIVERSITY

Single exposure wavefront reconstruction and phase imaging device and method based on dynamic modulation

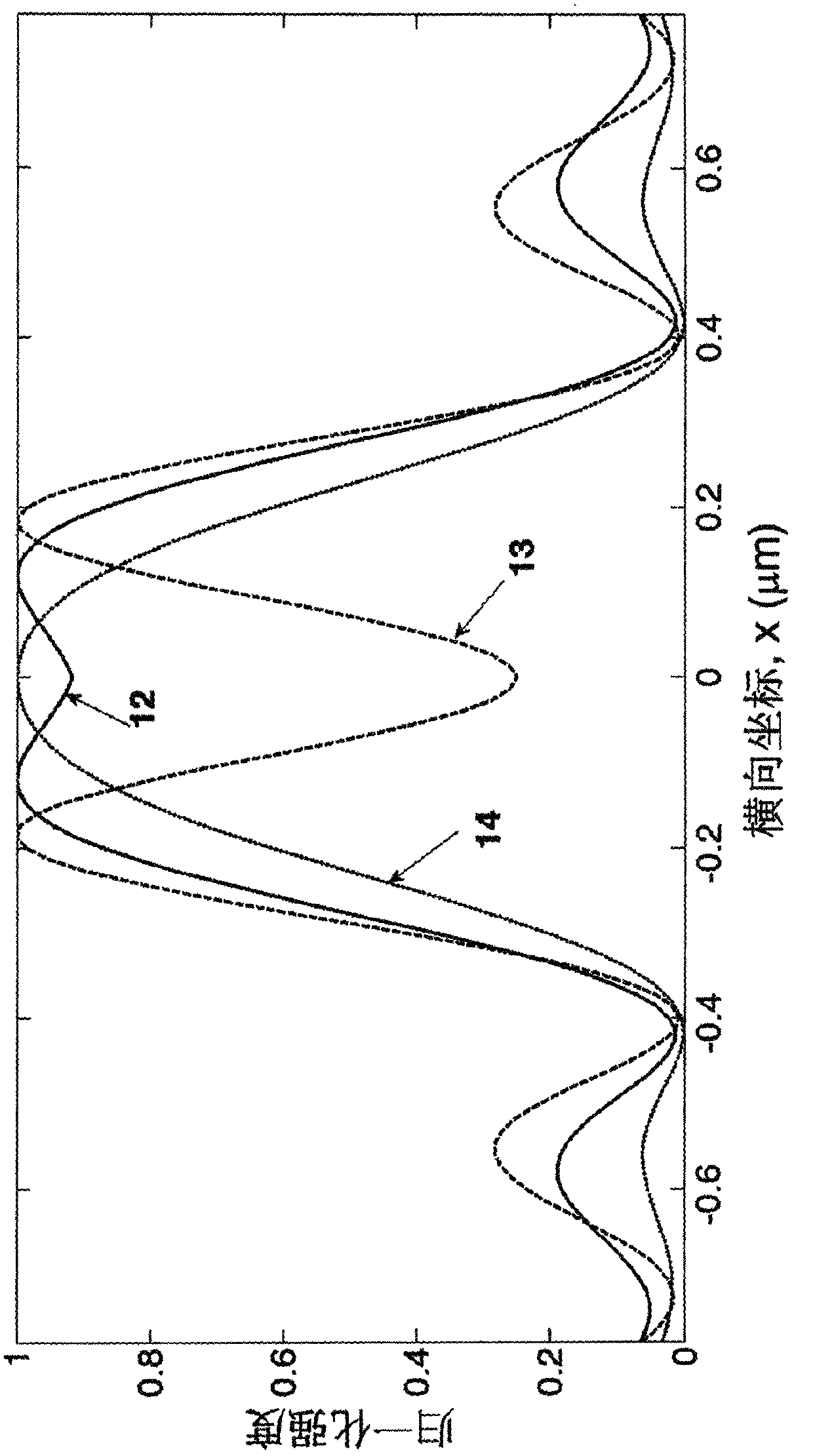

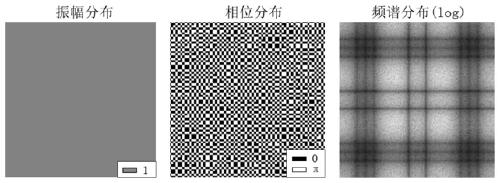

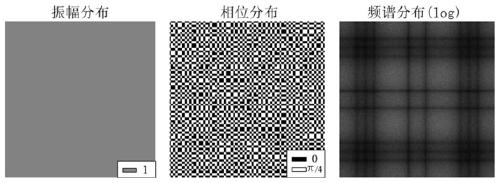

ActiveCN111474188ASimple structureFast convergenceMaterial analysis using wave/particle radiationWavefrontFrequency spectrum

The invention discloses a single exposure wavefront reconstruction and phase imaging device and method based on dynamic modulation. After a to-be-measured light beam passes through the specially designed wavefront modulator, diffraction light spots of the wavefront modulator have divisibility. Meanwhile, the frequency spectrum of the wavefront modulator also has divisibility, equivalently, multiple diffraction light spots are obtained after a light beam to be measured passes through multiple different wavefront modulators, complex amplitude distribution of the wavefront to be measured can be obtained through rapid reconstruction by means of a matching iterative algorithm, and finally wavefront reconstruction and phase imaging under single exposure are achieved.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

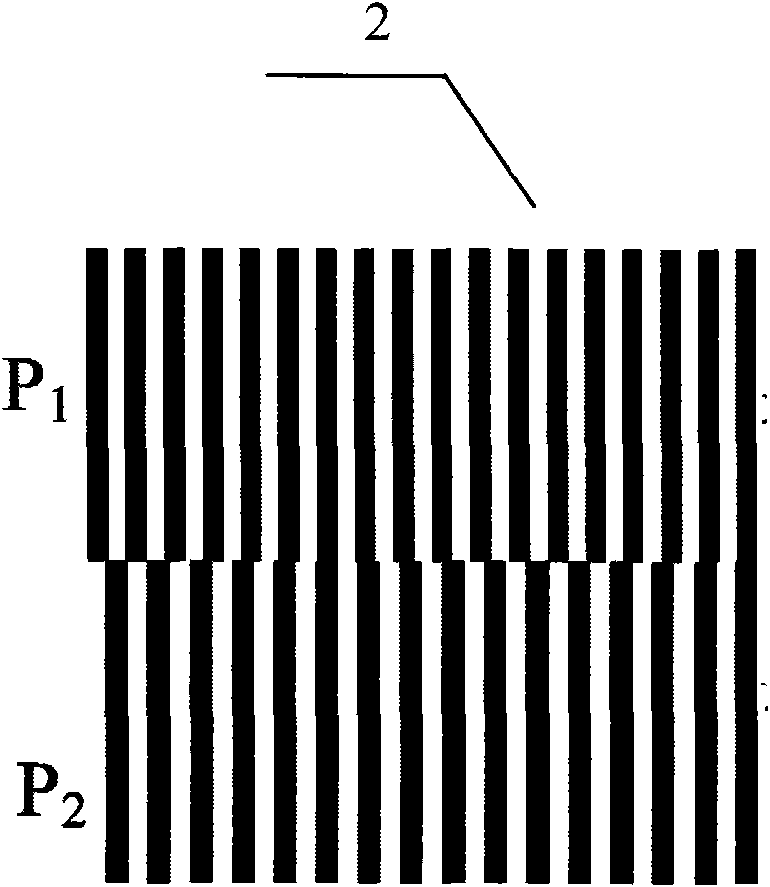

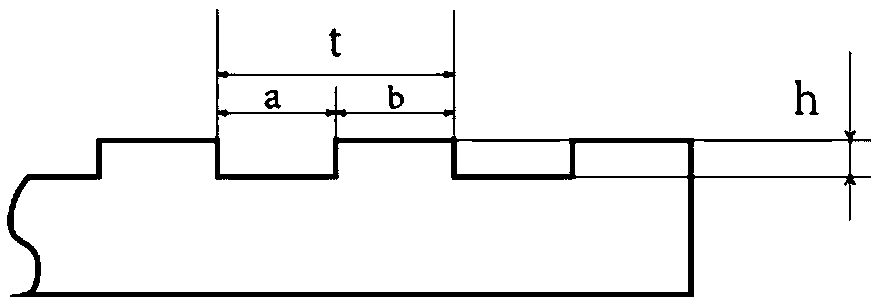

Combined dammam grating

ActiveCN102566056AUniform light intensityHigh diffraction efficiencyDiffraction gratingsMultiple diffractionLasing wavelength

A combined dammam grating is made by combination of N dammam gratings which meet grating period matching conditions. The grating is obliged to meet the period matching conditions. If the nth dammam grating is an even grating, the dn is required to meet the grating period strict matching condition that 2 sin - 1 (mn lambada / dn) + sin - 1 (2 lambada / dn) = sin - 1 (lambada / dn - 1); if the nth dammam grating is an odd grating, the dn is required to meet the grating period strict matching condition that 2 sin - 1 (mn lambada / dn) + sin - 1 (lambada / dn) = sin - 1 (lambada / dn - 1); and the dn is the period of the nth dammam grating, mn is order of edge diffraction of the nth dammam grating, n is a positive integer and belongs to N, and lambada is incident laser wavelength. By means of the combined dammam grating, beam splitting quantity and beam splitting angle which a single dammam grating can not achieve under same processing conditions can be achieved in terms of incident light multiple diffractions. The combined dammam grating has the advantages that the usage is convenient, cost is low, light spot and light intensity are uniform, and the like. Application range of dammam gratings can be greatly extended, and the combined dammam grating is expected to be widely applied in fields of precision measurement, machine vision, aerospace and the like.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Spectrograph, monochromator, diffraction grating and manufacturing method thereof, and female die manufacturing method

ActiveCN106482832AReduce in quantityReduce volumeSpectrum generation using diffraction elementsDiffraction gratingsMonochromatorSpectrograph

The invention discloses a diffraction grating which comprises a substrate and multiple diffraction structures. The diffraction structures are connected with one another and formed on the substrate. The diffraction structures, which are columnar, are arranged along a concave cylindrical surface. The axis of each diffraction structure extends along the generatrix of the concave cylindrical surface. Each diffraction structure is sectioned along a direction perpendicular to the axis thereof to get a section profile. The vertexes of the connected diffraction structures in the section profile form a reference curve, which is provided with multiple first inflection points. The diffraction structures are used for separating an optical signal into multiple spectral components, and the diffraction structures focus the spectral components in a focal plane.

Owner:OTO PHOTONICS

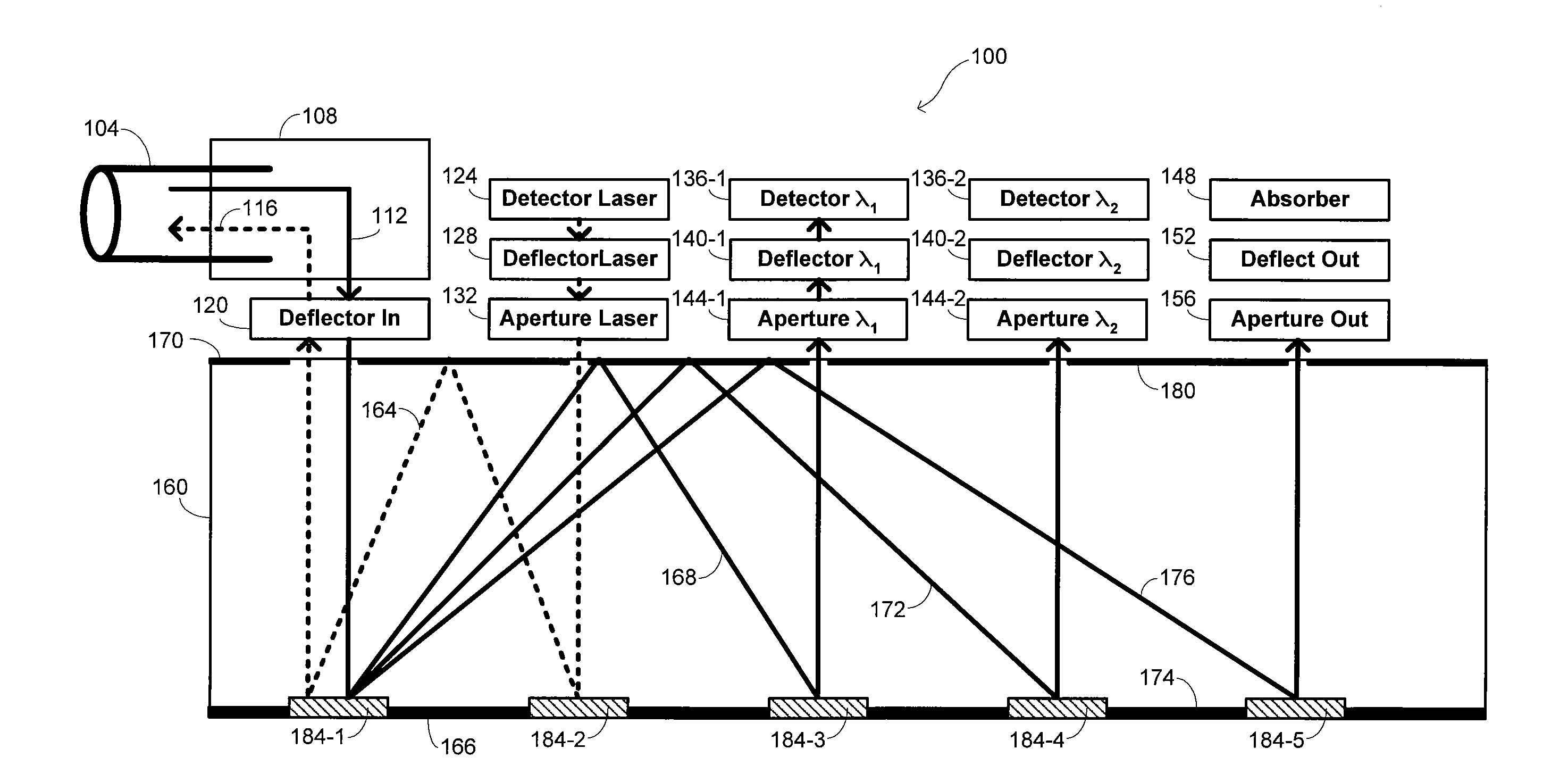

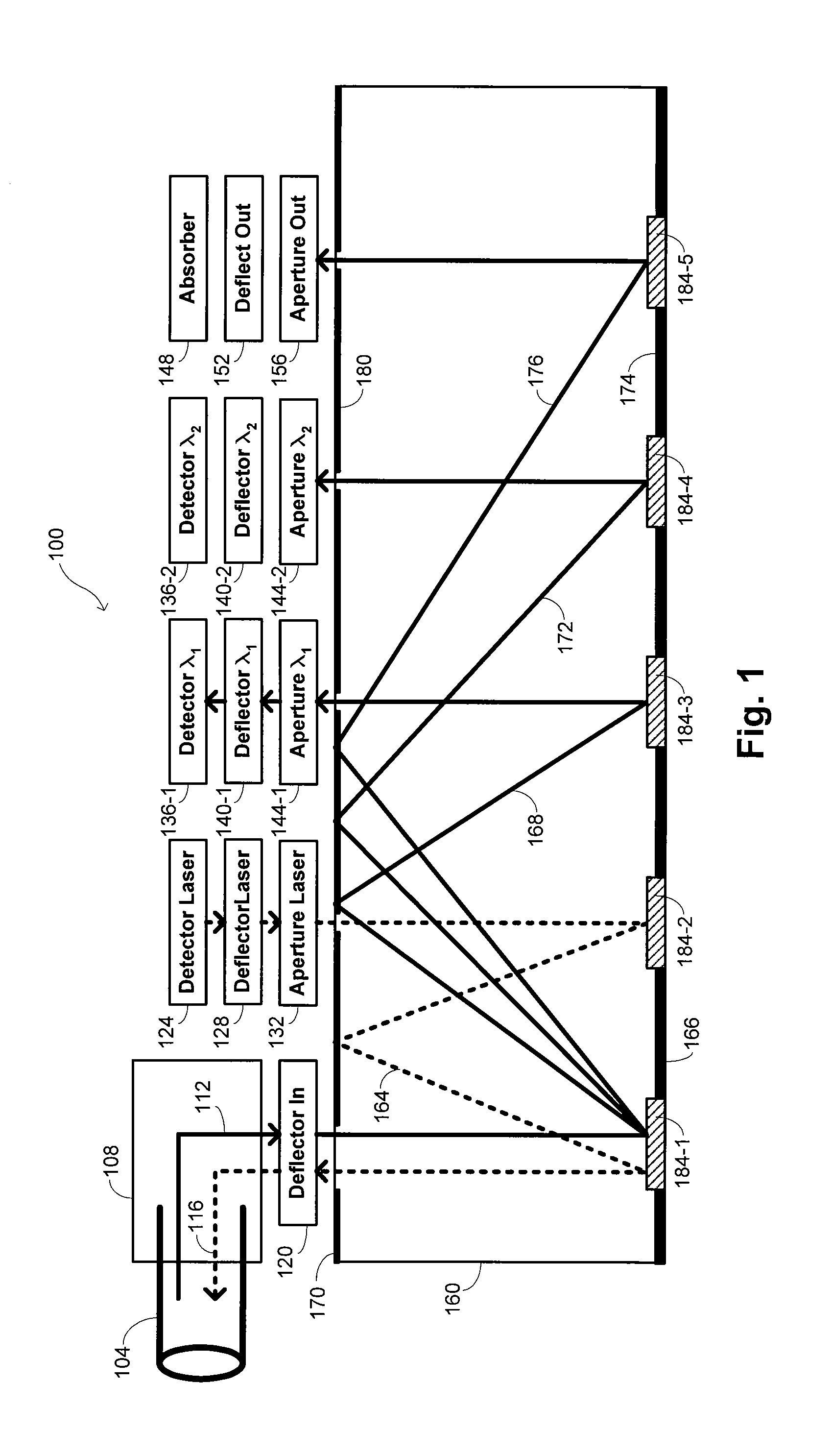

Optical assemblies and methods for fabrication of optical assemblies

InactiveUS20080124084A1Effectively manages wavelength isolation and stray radiationImprove accuracyWavelength-division multiplex systemsDiffraction gratingsMultiple diffractionSilicon

An optical assembly is formed with a silicon substrate having a first surface and a second surface confronting the first surface. A reflective coating is formed over the first surface. Multiple diffraction gratings are formed integrally within the second surface of the silicon substrate. An optical absorber is formed over the second surface between the diffraction gratings.

Owner:APPLIED MATERIALS INC

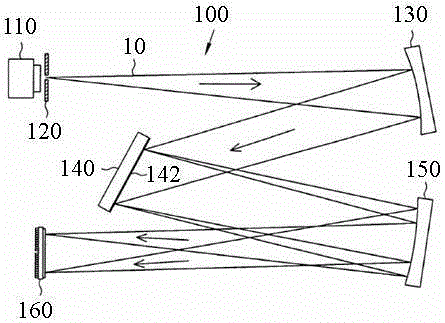

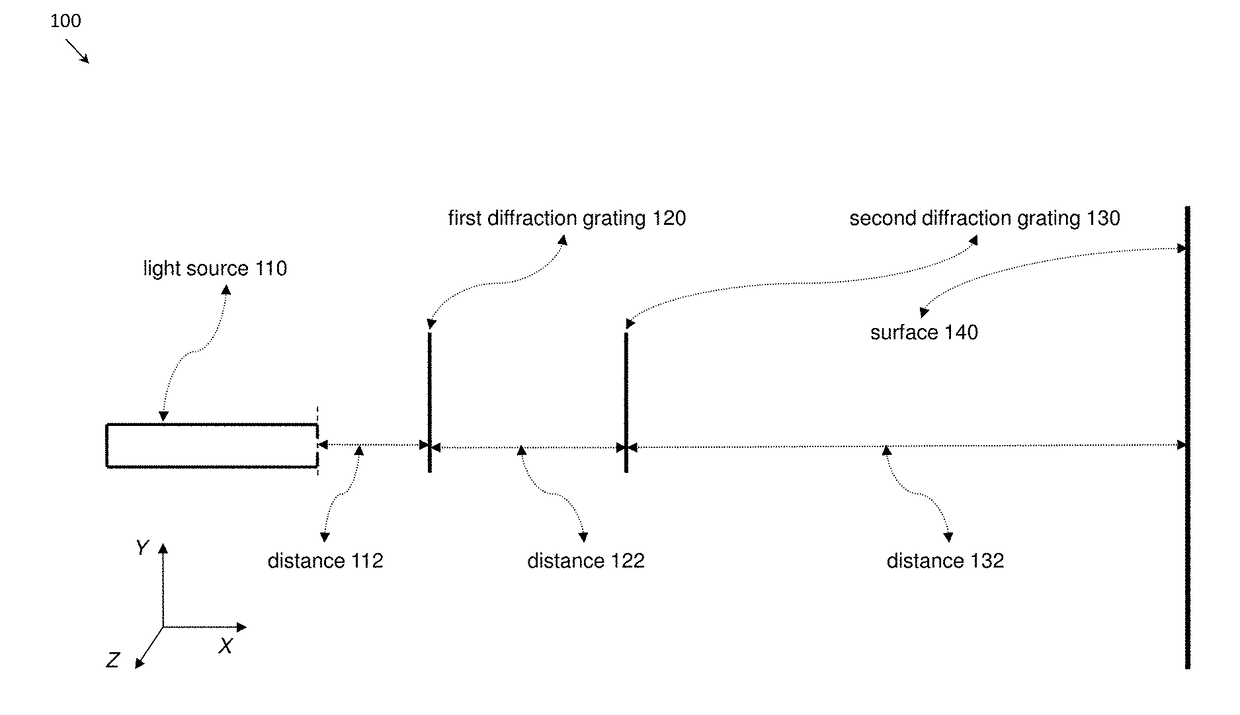

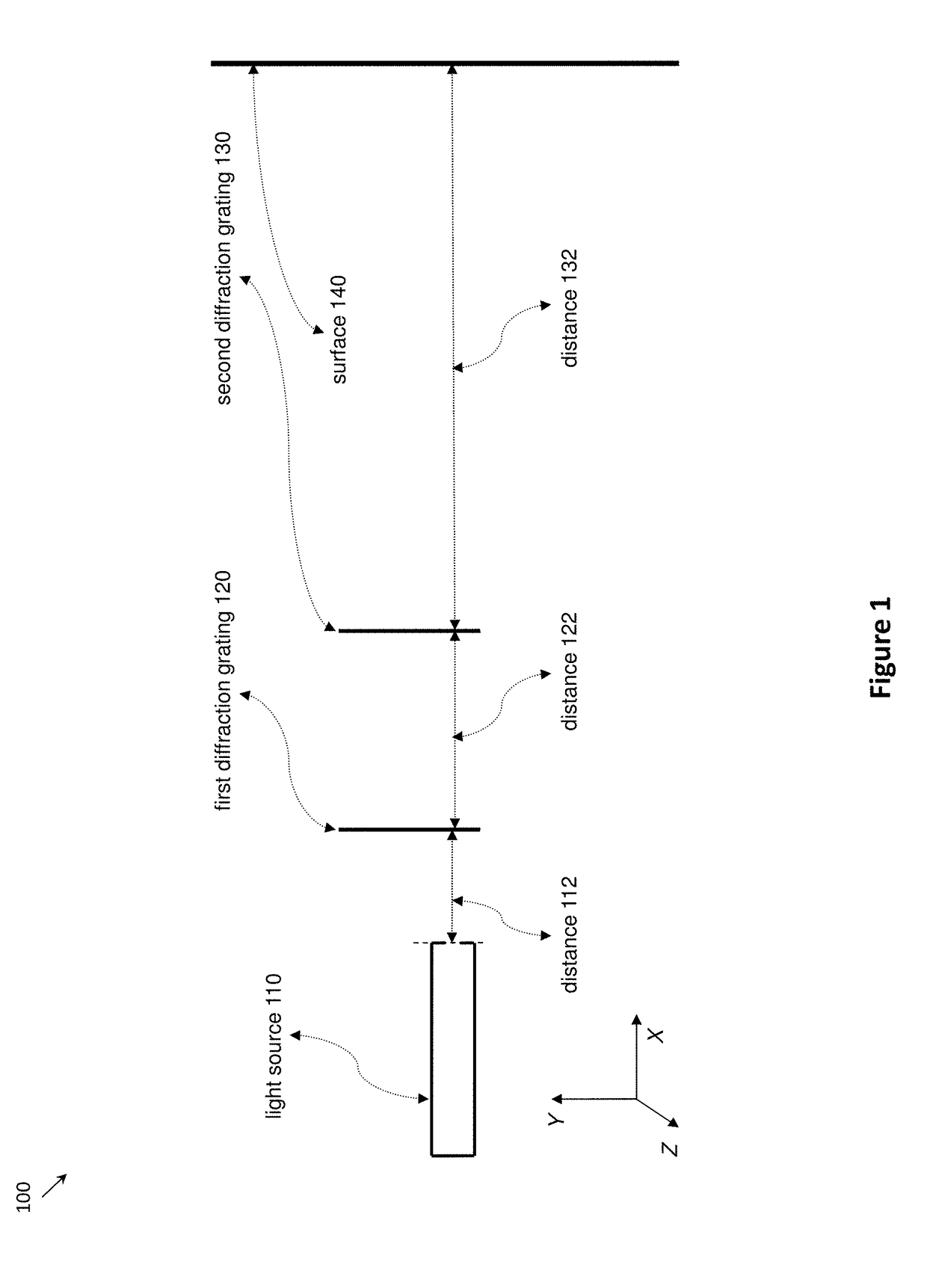

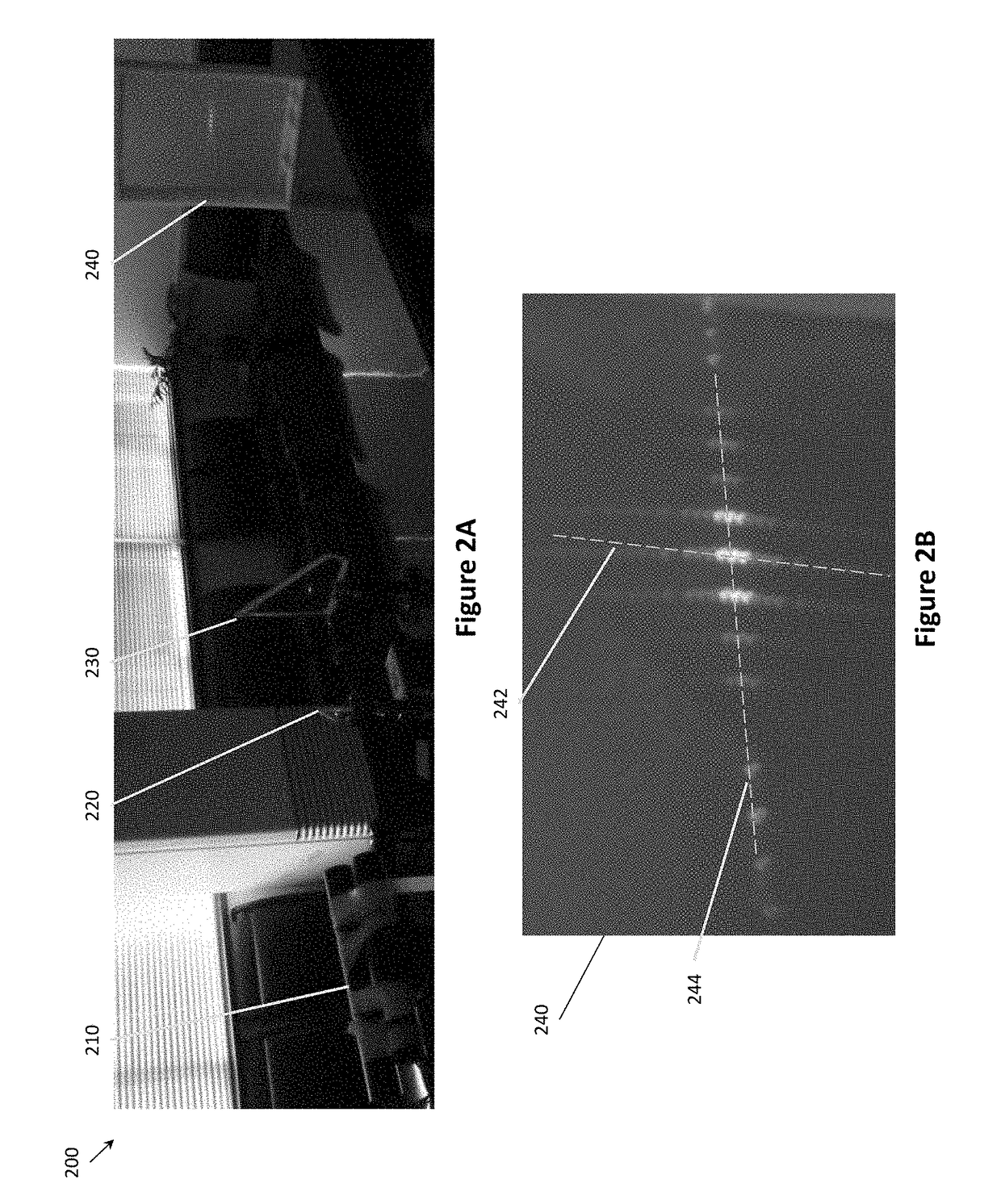

Spectrum-generation system based on multiple-diffraction optical phasometry

An optical guide has at least two diffraction gratings in serial in front of a light source in order to diffract a light beam from the light source twice. The first diffraction grating could split the light beam into several parallel light beams along a first axis, and the second diffraction grating could split the light beams into several points of light along a second axis, and so on and so forth. By rotating the diffraction gratings relative to one another and by adjusting the distance between the diffraction gratings, a user of the optical guide could adjust the angle of the axis points and adjust a relative distance of the points of light relative to one another. These light beams could provide convenient guides for users in a variety of applications.

Owner:ZHEJIANG UNIV

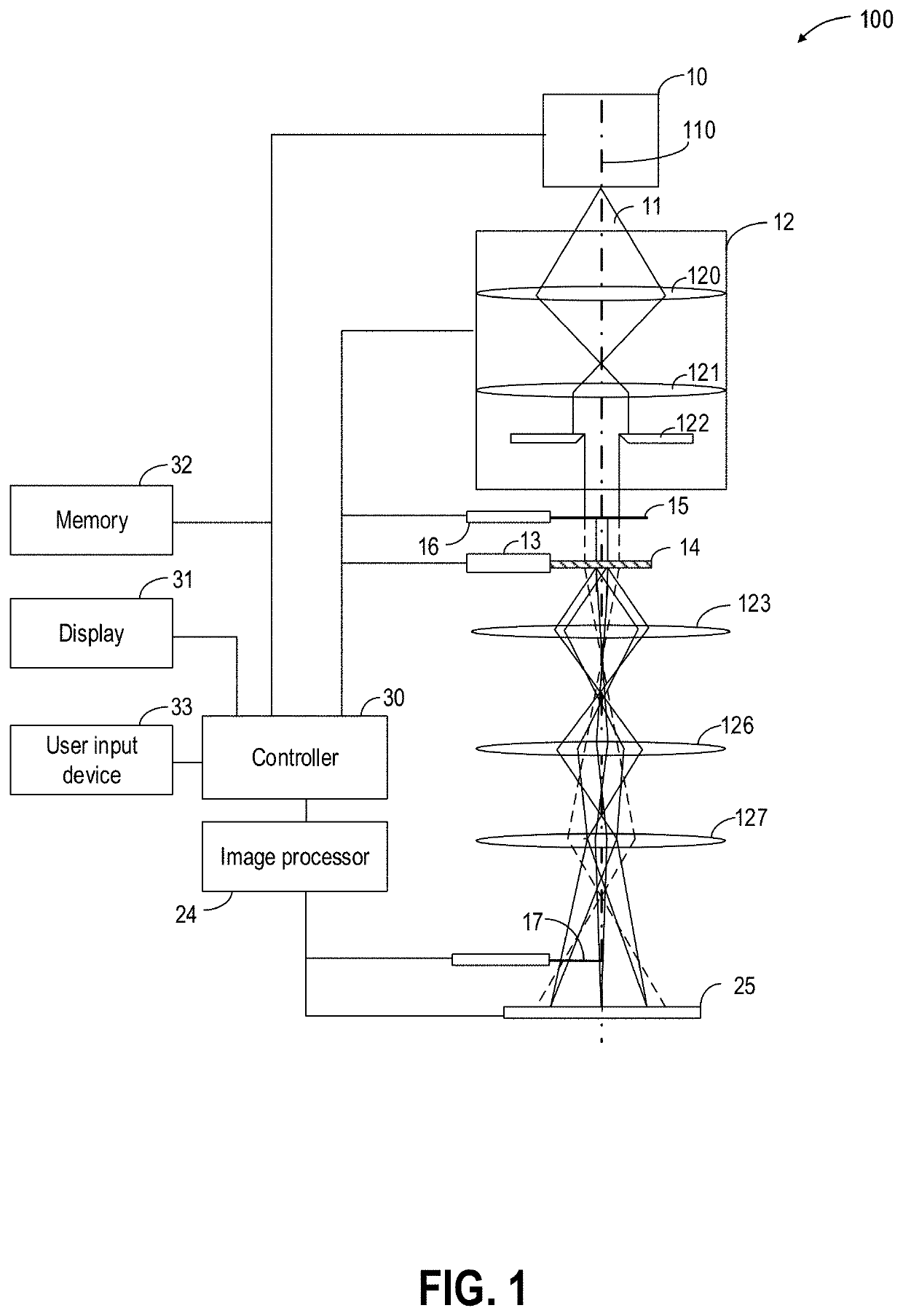

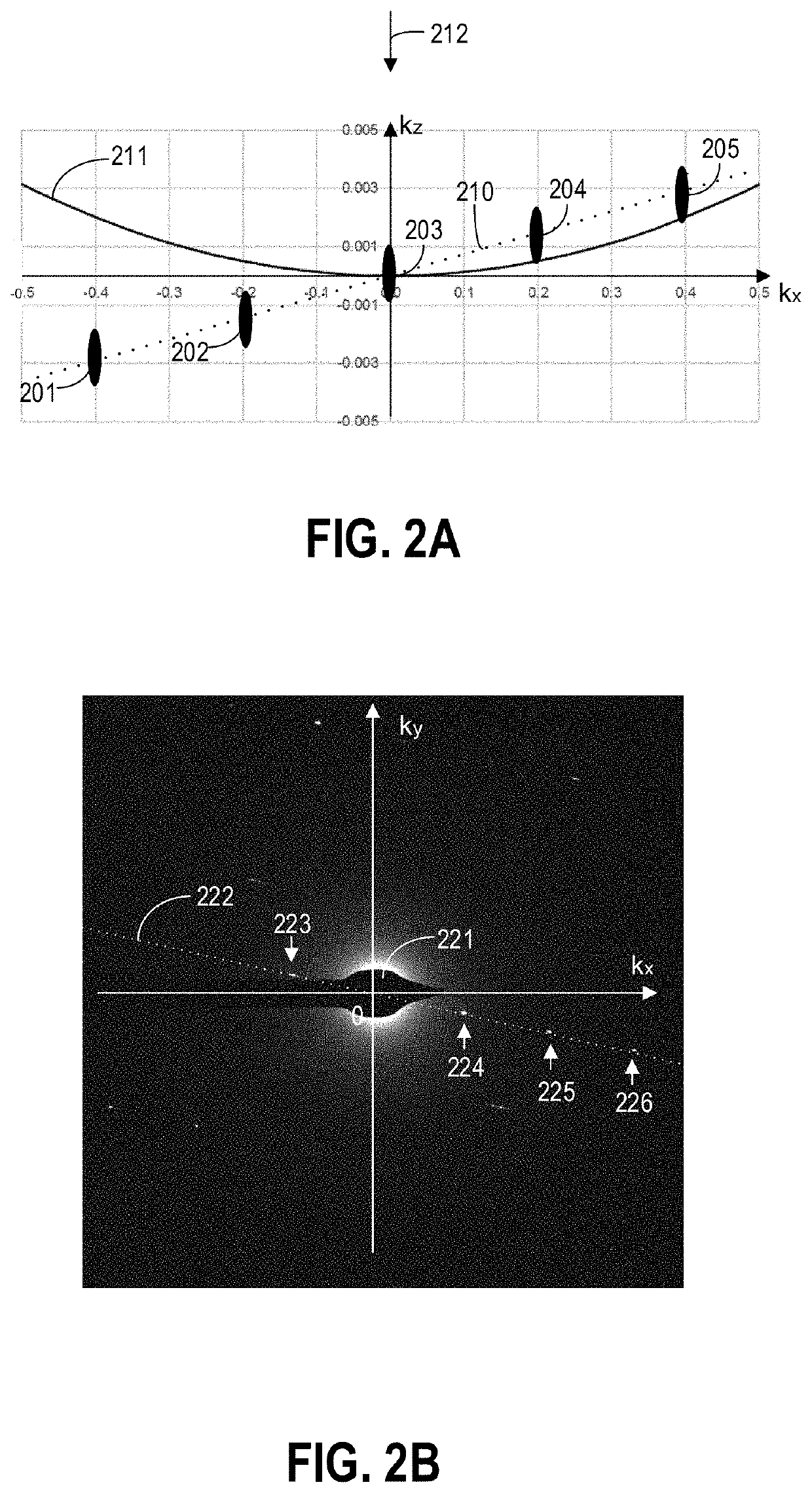

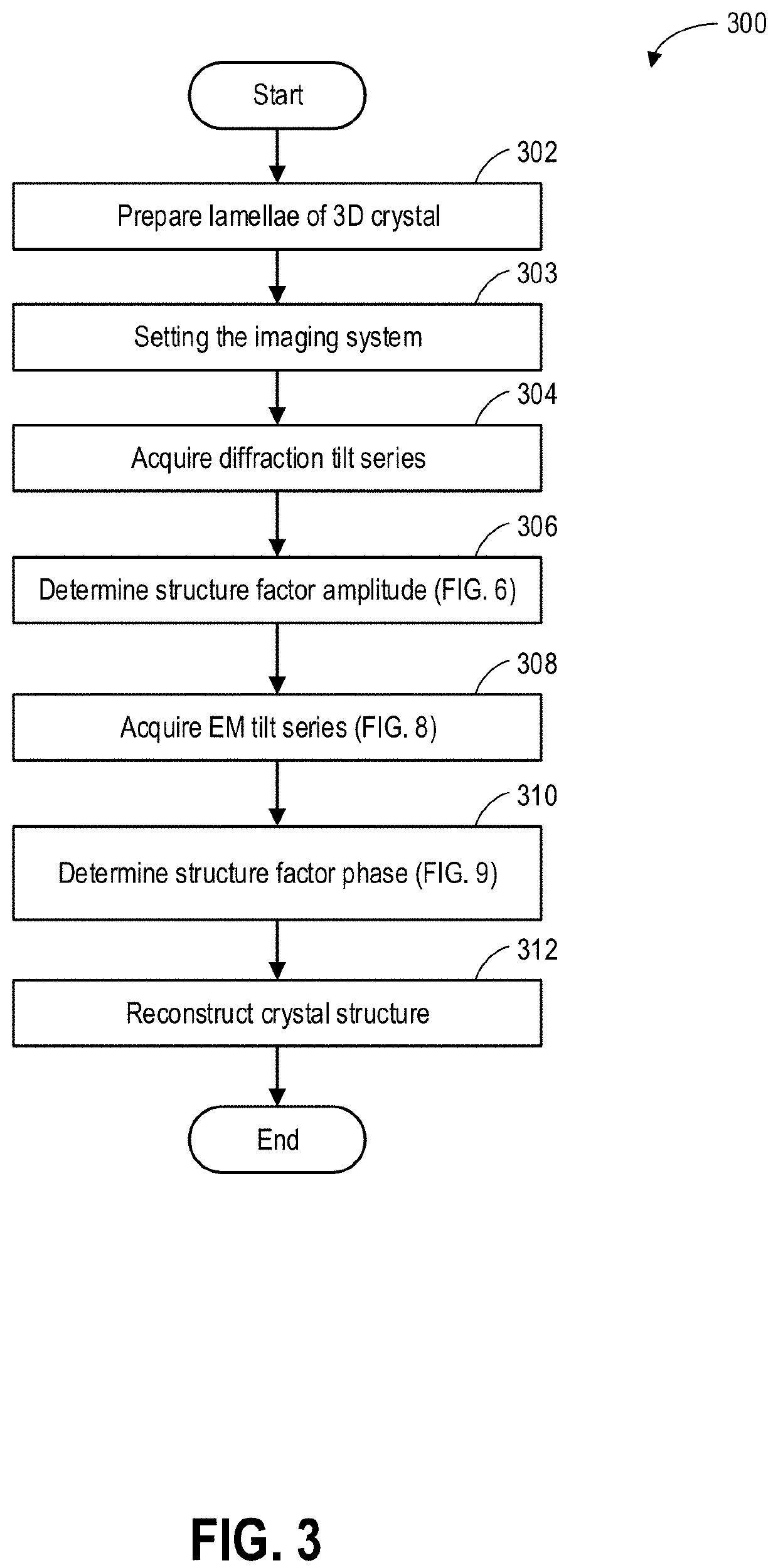

Method and system for determining molecular structure

ActiveUS20200400594A1Material analysis by transmitting radiationMaterial analysis using radiation diffractionElectron microscopeParticle physics

Molecular structure may be determined based on structure factors solved from the diffraction pattern and the electron microscopy image of the sample. In particular, the amplitudes of the structure factors may be determined based on intensities of diffraction peaks in the multiple diffraction patterns. The phases of the structure factors may be determined based on electron microscopy images and the intensities of the diffraction peaks.

Owner:FEI CO

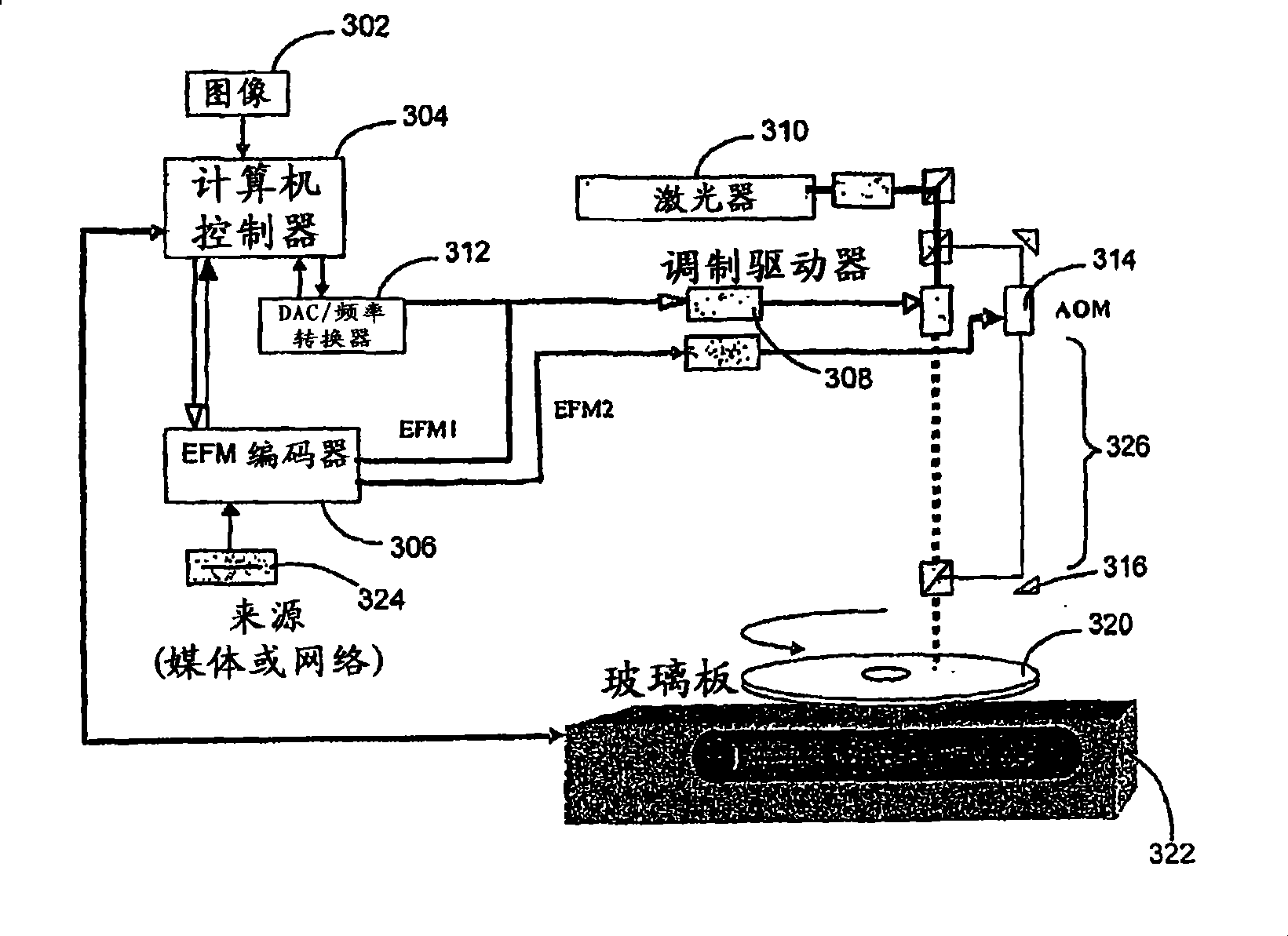

Method and system for producing multiple images in a single image plane using diffraction

The present invention is directed to methods for creating pseudo-holographic images viewable under different selected angles on optical storage devices and other photosensitive surfaces. The present invention also discloses novel optical storage devices with super-imposed pseudo-holographic images. Generally, a photosensitive surface is exposed with multiple diffraction patterns creating super-imposed pseudo-holographic images. These diffraction patterns create super-imposed images on the photosensitive surfaces, which can be read by either a human or a computer.

Owner:布鲁斯哈

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com