Nanometer-level automatic focusing system for projection lithography

An automatic focusing and projecting light technology, which is applied in microlithography exposure equipment, optics, photography, etc., can solve the problems of lower measurement efficiency, low degree of automation, and increased calculation amount, and achieve simple operation and automation High, high production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

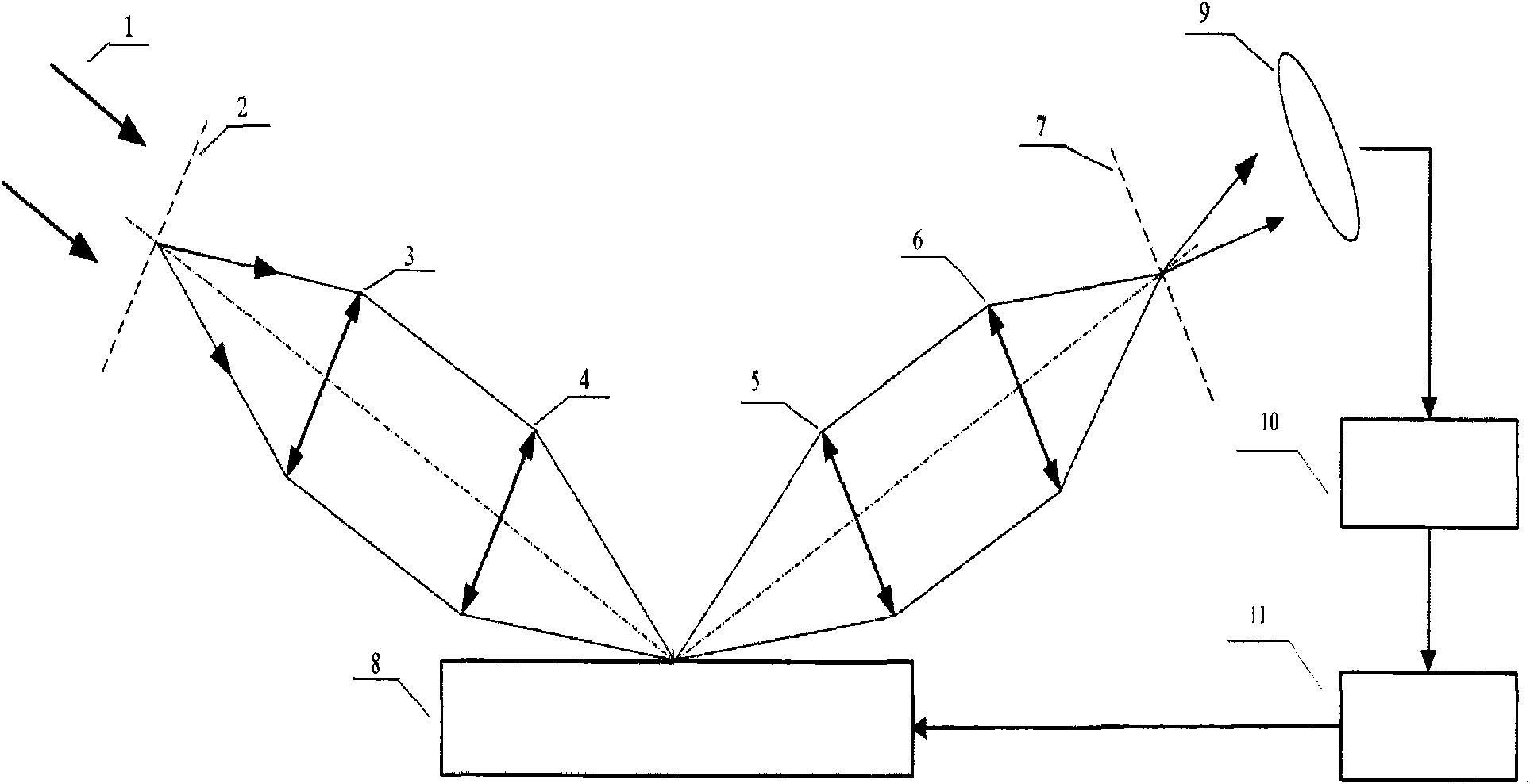

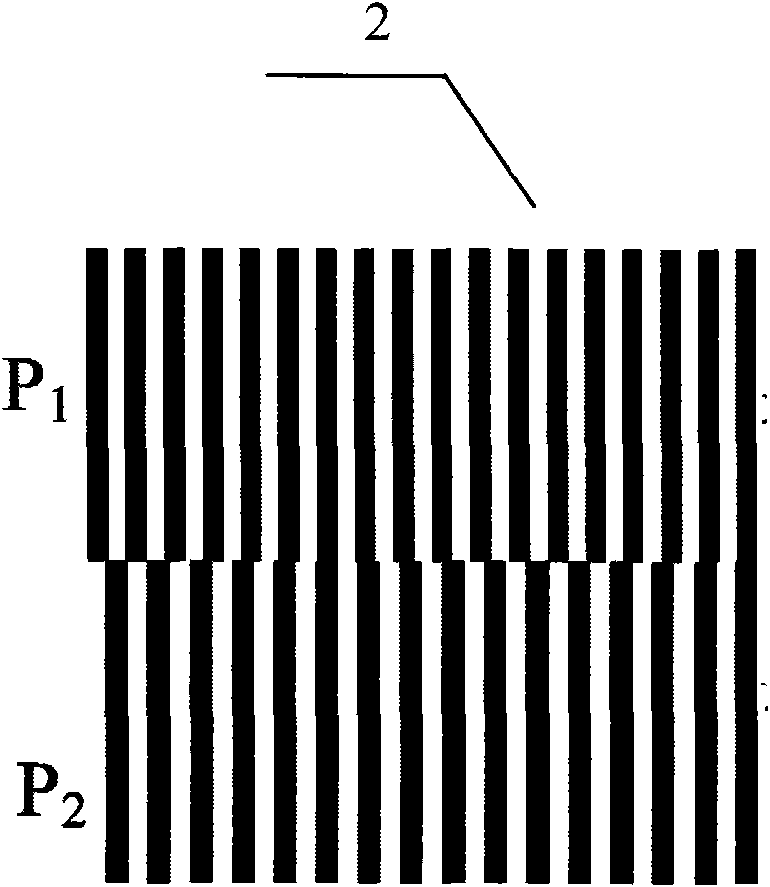

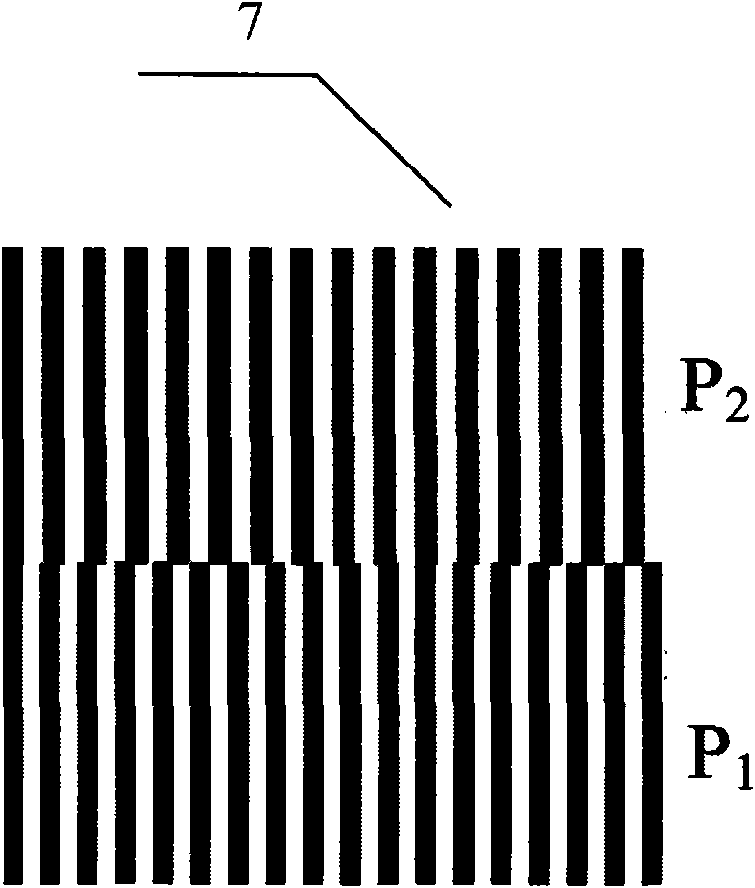

[0028] The present invention is used in projection lithography nanoscale automatic focusing system is composed of optical path A, image processing module 10 and circuit control module 11, wherein: as figure 1 As shown, the optical path A includes a collimated laser beam 1, a first grating mark 2, a first lens 3, a second lens 4, a third lens 5, a fourth lens 6, a second grating mark 7, a wafer stage 8 and a CCD Image detector 9; collimated laser beam 1 (in this embodiment, the wavelength of incident light is 633nm) vertically illuminates the first grating mark 2 located on the front focal plane of the first lens 3, and along the first lens 3 and the second lens 4 The optical axis of the formed first 4f system constitutes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com