Micro hybrid light splitting device

A spectroscopic device and miniature technology, applied in the direction of measuring devices, spectrometry/spectrophotometry/monochromator, analytical materials, etc., to achieve the effect of wide volume, high spectroscopic, high wavelength resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

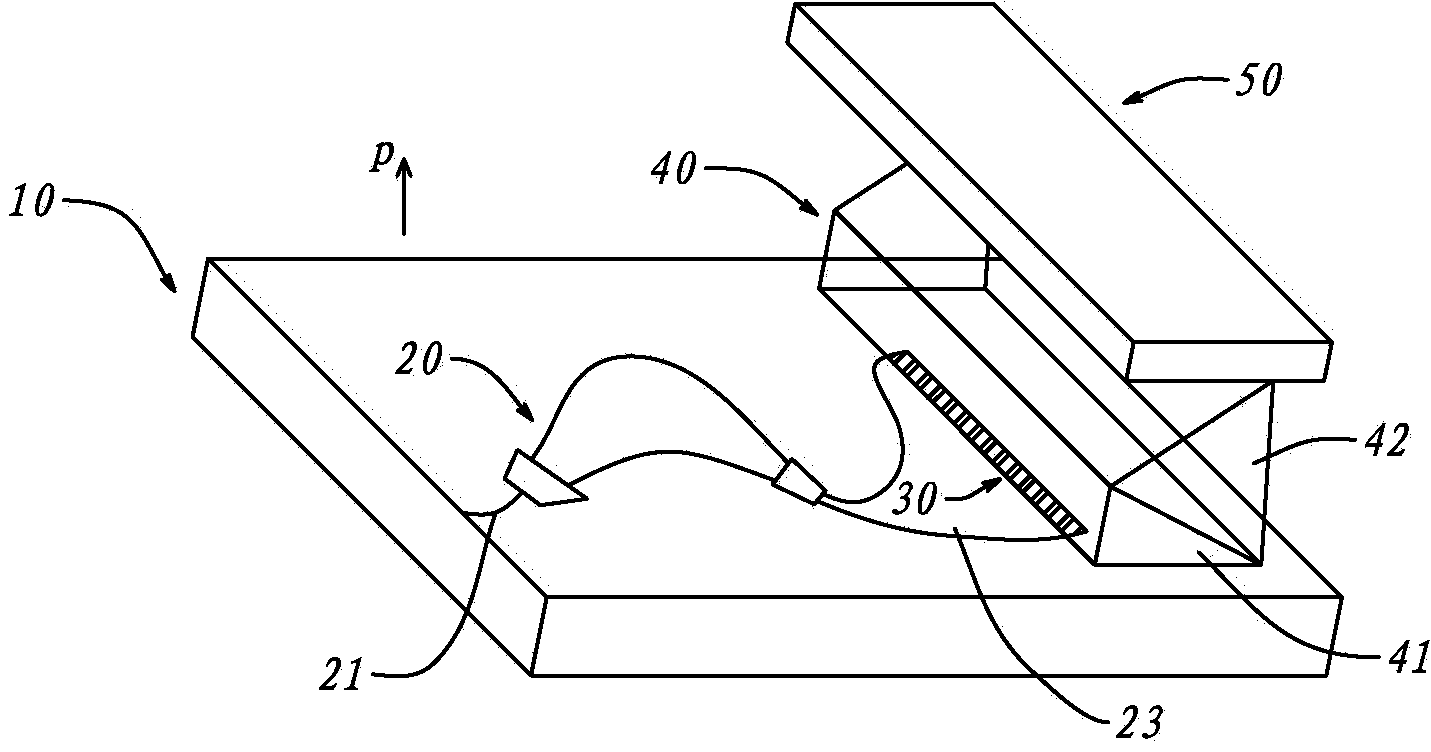

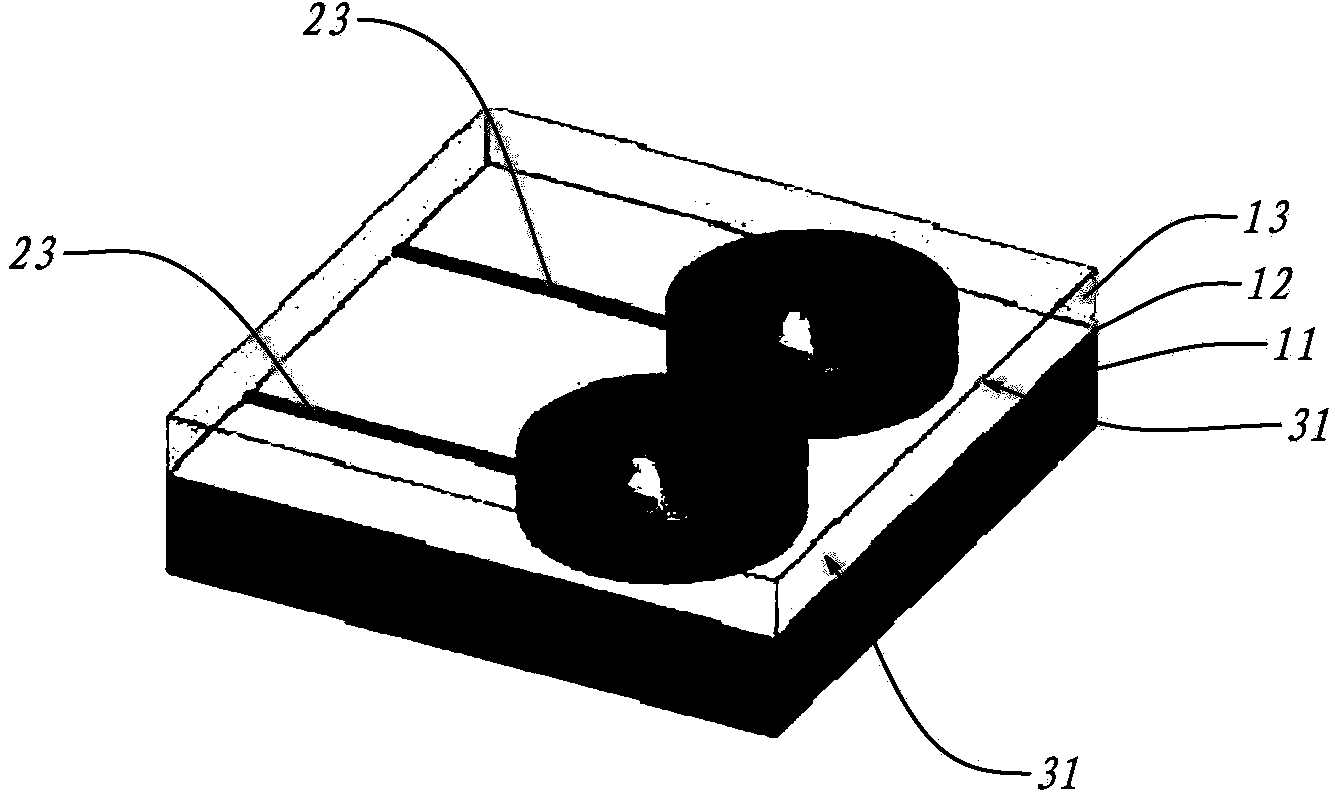

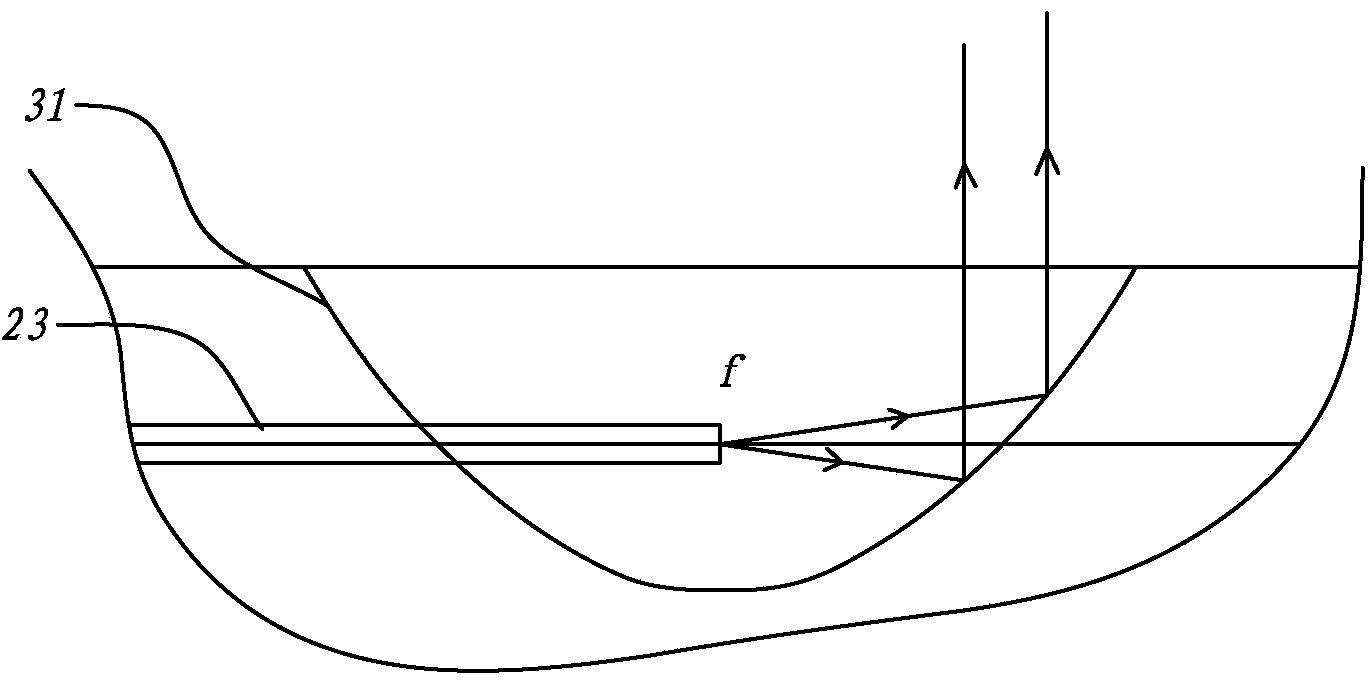

[0035] Such as Figure 1 to Figure 6 Shown, a series of schematic diagrams of Embodiment 1 of the present invention, wherein, figure 1 , figure 2 with image 3 Shows its main structure and its enlarged perspective view; Figure 4 with Figure 5 then shows the output spectrum of the output waveguide 23, Image 6 The spot projection obtained by the final spectroscopic is shown.

[0036] This embodiment is a micro-hybrid spectroscopic device, which includes a substrate 10 with an arrayed waveguide grating 20 on the substrate 10, and the arrayed waveguide grating has an input optical fiber and 40 output waveguides 23.

[0037] There is a mirror array 30 on the substrate 10 , and the mirror array 30 has 40 mirror bodies 31 , each mirror body 31 corresponds to the output waveguide 23 one by one. The exit area of reflector array 30 has a prism assembly 40, and this prism assembly 40 rear stage has a photodetector array 50, and photodetector array 50 has photoelectric probe; ...

Embodiment 2

[0050] Such as Figure 7 Shown is a schematic diagram of Embodiment 2 of the present invention.

[0051] The substrate 10, arrayed waveguide grating 20, optical glue 41, and prism 42 of this embodiment are similar to those of the first embodiment, the difference is that there is another plane reflection device 60, which is arranged on the light-emitting surface of the prism 42, and the The light emitted from the light emitting surface of the prism 42 is reflected and then projected to the photodetector array 50 . This structure further improves the final light splitting effect and makes the light spots obtained on the photodetector array 50 more independent. This embodiment enables a more compact installation. The whole device is connected with the input optical fiber through the installable universal optical fiber connector, and it can be docked with the external probe without cumbersome optical alignment, realizing a compact and modular solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com