Two dimension displacement measurement device which uses double frequency laser and diffraction grating

A dual-frequency laser and diffraction grating technology, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems that are not conducive to large range measurement in the Z direction, unfavorable interference signal quality, and narrowing of the interference area, so as to achieve enhanced Anti-interference ability, large Z-direction measurement range, and the effect of reducing the size of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

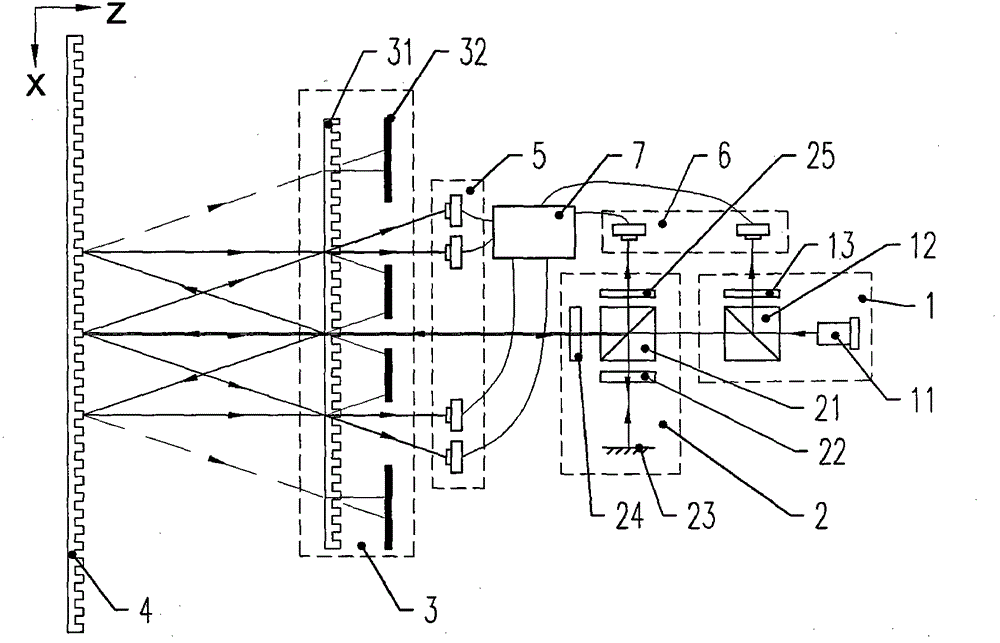

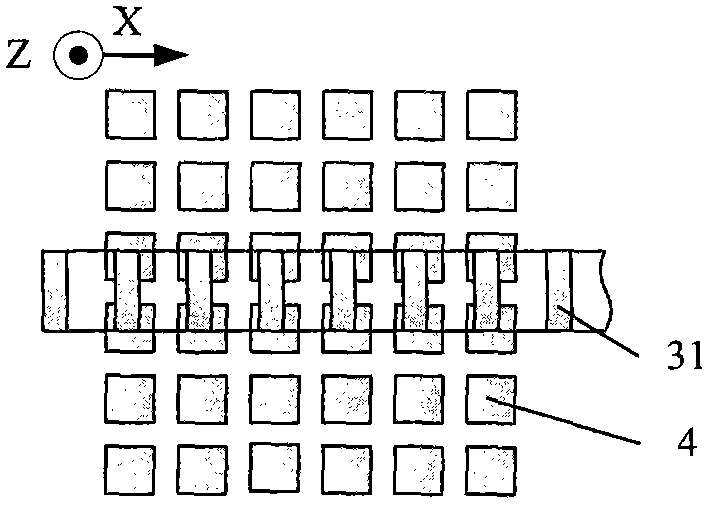

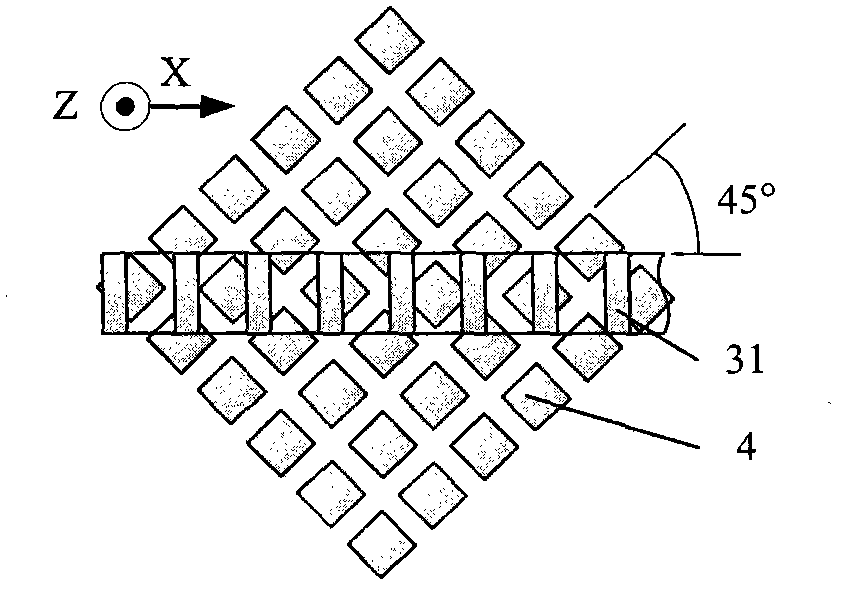

[0031] A two-dimensional displacement measurement device using a dual-frequency laser and a diffraction grating, including a scale grating 4 and a reading head, the reading head includes a dual-frequency laser light source 1, a Z-direction interference component 2, a scanning spectroscopic grating component 3, and an X-direction detection component 5 , Z-direction detection part 6, signal processing part 7; Dual-frequency laser source 1 includes dual-frequency laser 11, beam splitter 12, polarizer A13; Z-direction interference part 2 includes polarization beam-splitter prism 21, 1 / 4 wave plate A22, reflector Component 23, 1 / 4 wave plate B24, polarizer B25; Scanning spectroscopic grating component 3 comprises scanning spectroscopic grating 31, diaphragm 32; The spectroscopic grating 31 is a one-dimensional grating, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com