Combined dammam grating

A Damman grating and grating technology, which is applied in the field of combined Damman gratings, can solve the problems of a small number of Daman grating beam splitting and limited beam splitting angle, and achieve the effects of uniform light intensity and high diffraction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

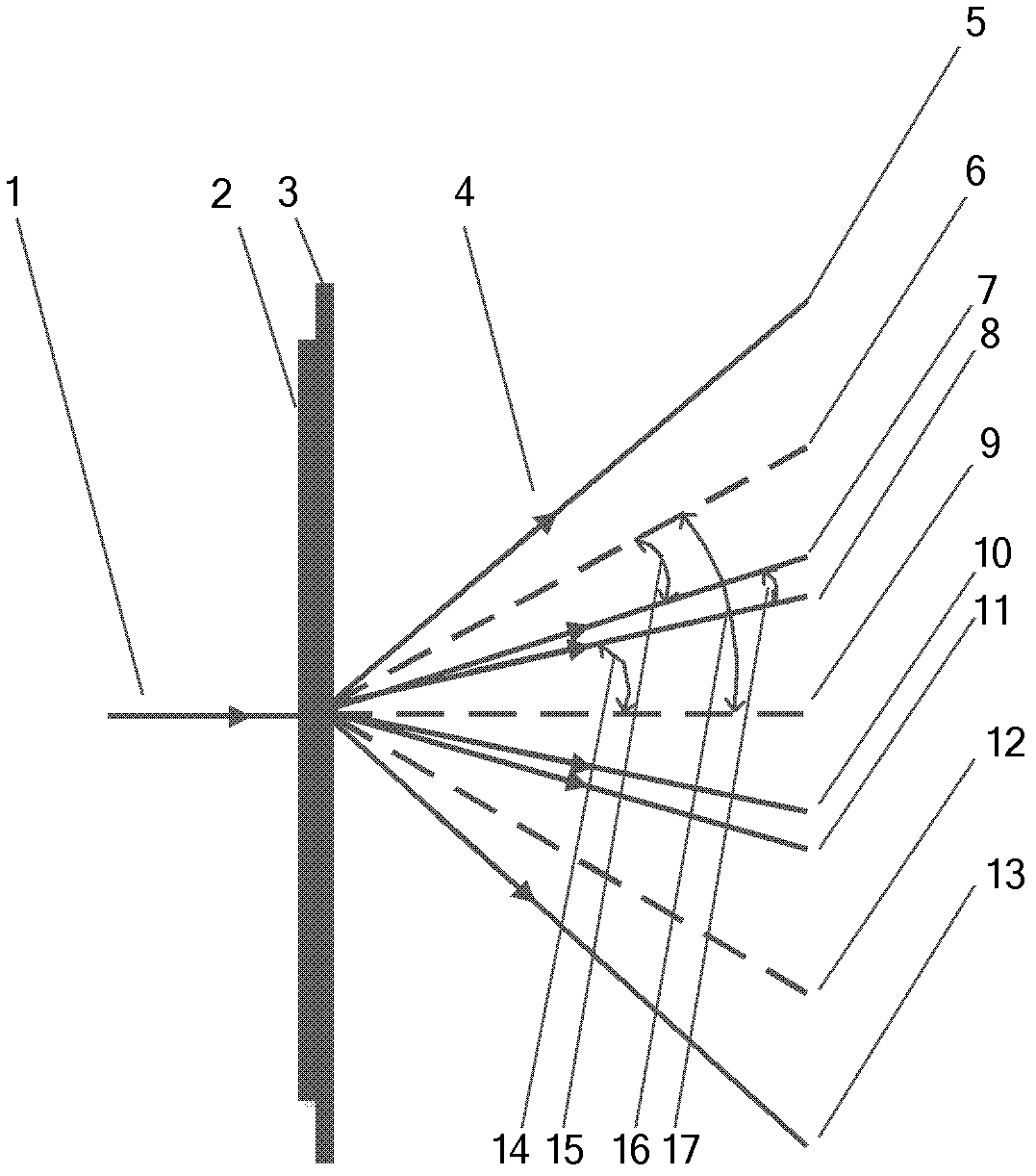

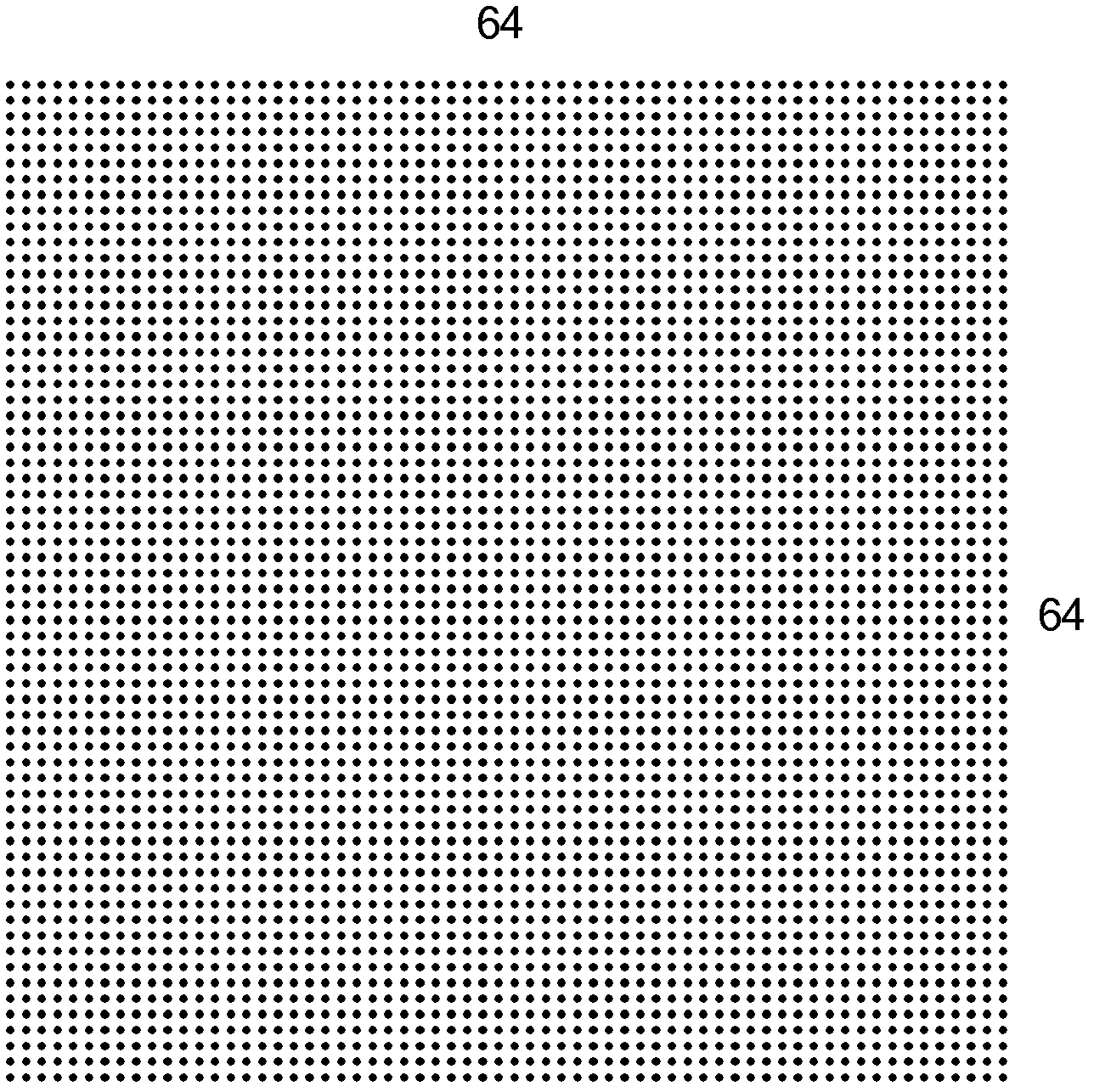

[0026] see figure 1 , figure 1 It is a schematic diagram showing that the combined Damman grating of the present invention is composed of Damman grating 2 and Damman grating 3 to realize a 192X 192 dot matrix. 1 in the figure is the laser beam with a wavelength of λ=532nm, and 2 is the period of realizing 3X3 beam splitting is d 2 = 3.9um odd-numbered Damman grating, the lattice effect is as follows figure 2 As shown, 3 is the period to realize 64X64 beam splitting is d 3 = 500um even-numbered grating, the dot matrix effect is as follows image 3 As shown, the Damman grating 2 and the Damman grating 3 constitute a combined Damman grating.

[0027] The laser beam 1 is vertically incident on the grating 2 and then diffracted by 3X3 laser beams with different incident directions on the 3, and the 3X3 laser beam is diffracted by the grating 3 to form a 192X192 lattice beam 4. The typical beams in the lattice beam 4 are: 5 is the +63-order light diffracted after the +1-order ...

Embodiment 2

[0030] Set the process condition as the minimum processable size is 500nm. Now it is hoped to realize 1X21 dot matrix beam splitting for 532nm wavelength laser with a beam splitting angle of 2 degrees. If a single Damman grating is used, the grating period is about 15.24um, and the minimum feature size is about 198nm, which cannot meet the process conditions. Under the set process conditions, the minimum grating period of the Damman grating is 38.46um, and its maximum beam splitting angle is only 0.79 degrees. Image 6 It is a schematic diagram of a single Damman grating achieving 1X21 beam splitting with a beam splitting angle of 0.79 degrees.

[0031] Therefore, the requirement of 1X21 beam splitting with a beam splitting angle of 2 degrees cannot be achieved by using a single Damman grating, and can only be realized by combining Damman gratings.

[0032] Now use two odd-numbered Damman gratings of 1X3 and 1X7 to realize 1X21 dot matrix beam splitting with a beam splitting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com