Spectrograph, monochromator, diffraction grating and manufacturing method thereof, and female die manufacturing method

A technology of diffraction grating and manufacturing method, which is applied in the direction of diffraction grating, spectrum generation by using diffraction elements, spectrum generation, etc., can solve the problems of multi-optical components and spectrometer 100 with complicated structure and reduced volume, so as to simplify structure and assembly, and promote Effects of size reduction and reduction in the number of optical components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

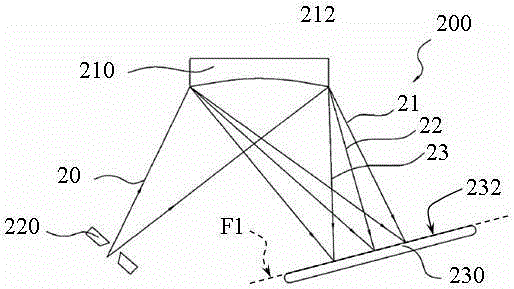

[0061] Figure 2A It is a schematic diagram of the optical path of a spectrometer according to an embodiment of the present invention. see Figure 2A , the spectrometer 200 includes a diffraction grating 210 , an input unit 220 and an optical sensor 230 . The input part 220 can receive the optical signal 20 , and the wavelength range of the optical signal 20 can be between infrared light (Infrared, IR) and ultraviolet light (Ultraviolet, UV). The input part 220 can be a slit, such as Figure 2A shown. However, the input part 220 can also be the end of an optical fiber, or be made of an optical fiber. For example, the input unit 220 may be made of a fiber core. In addition, the input part 220 may also be an assembly including an optical fiber and a slit.

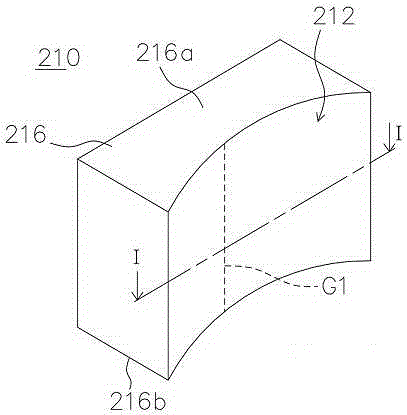

[0062] The diffraction grating 210 has a diffraction surface 212 capable of separating the optical signal 20 into a plurality of spectral components 21 , 22 and 23 , wherein the spectral components 21 , 22 and 23 have d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com