Method for rapidly detecting out-of-control pixel points of display screen

A detection method and display screen technology, applied in the direction of testing optical properties, etc., can solve the problems of reducing production efficiency and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

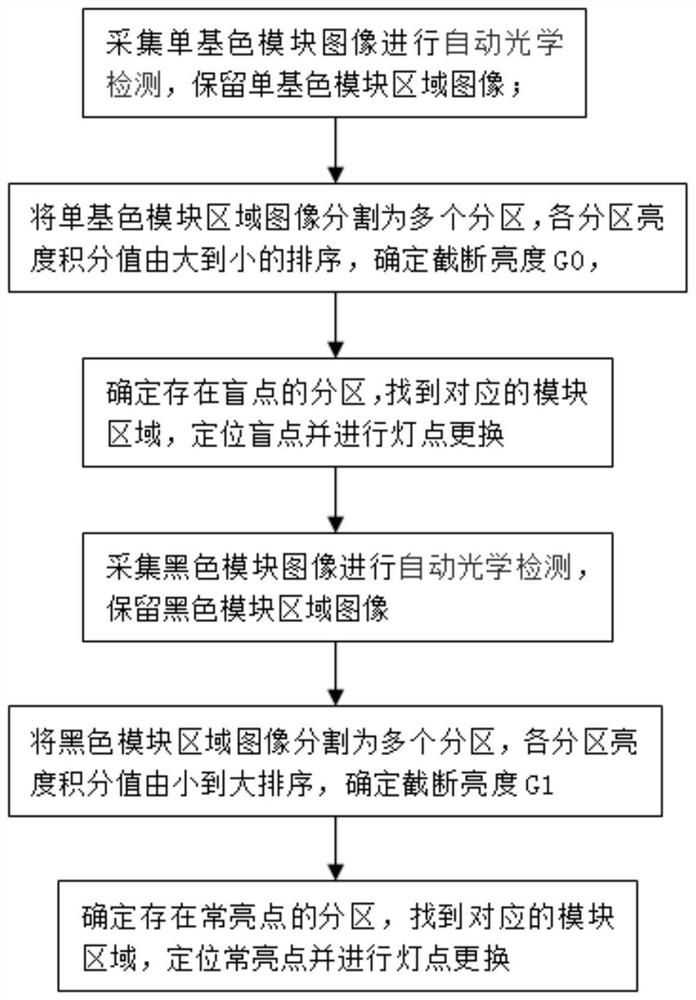

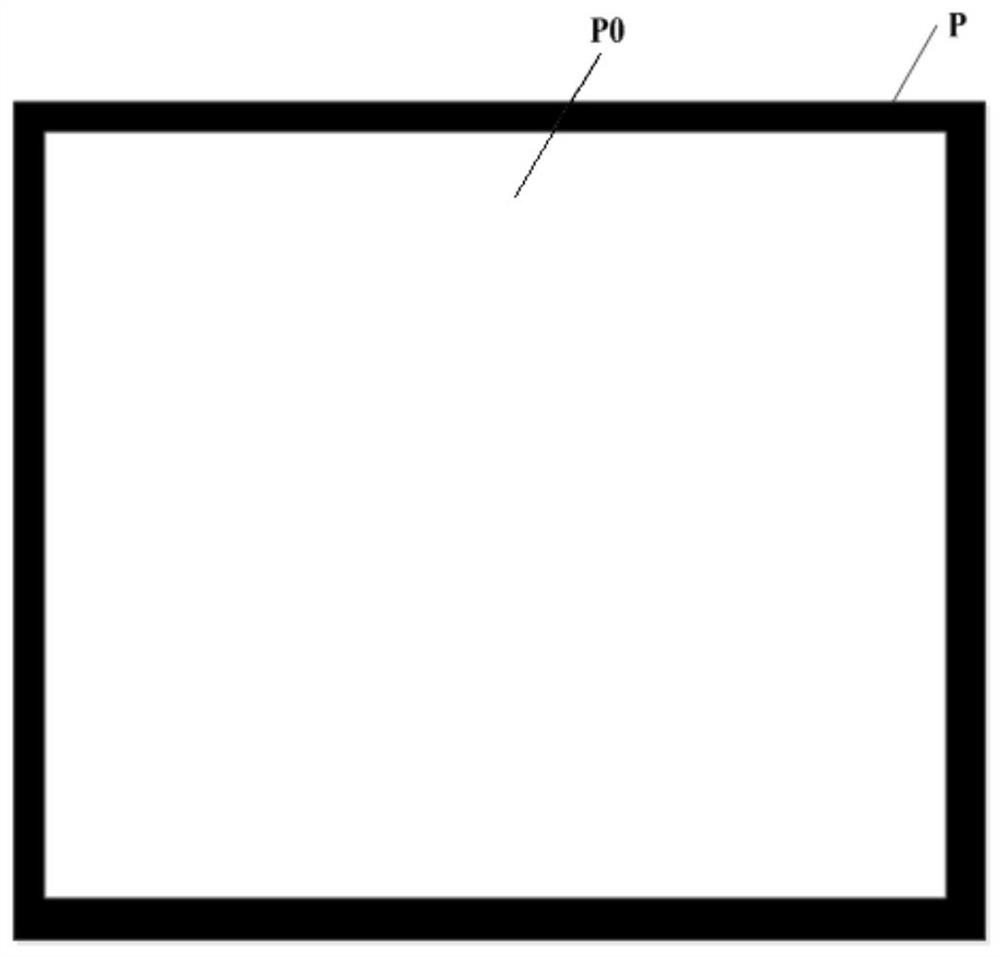

Method used

Image

Examples

Embodiment 1

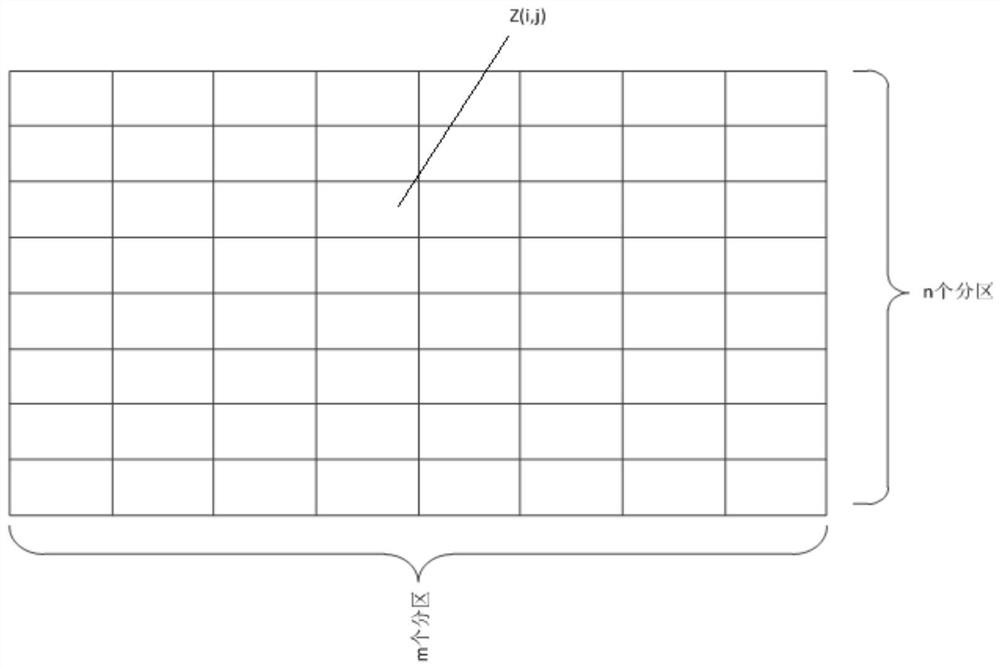

[0038] For P1.27 dot pitch LED display products, the module specification is 120×90 dots, the horizontal resolution is 120 dots, and the vertical resolution is 90 dots. Horizontal partition m=24, vertical partition n=18. Such a block image has 24*18=432 partitions. There are 5×5=25 light points in the module area corresponding to each partition. According to the detection method of constant bright spots and blind spots of the present invention, the row and column values of the partitions to which the out-of-control points belong are given, and the position of the out-of-control points can be quickly judged manually in the module area corresponding to the partition (5×5 light spots) and the lamp points can be replaced. .

Embodiment 2

[0040] P1.25 dot pitch LED display product, the module specification is 96×96 light points, the horizontal resolution is 96 light points, and the vertical resolution is 96 light points. Horizontal partition m=16, vertical partition n=16. Such a block image has 16*16=256 partitions. There are 6×6=36 light points in the module area corresponding to each partition. According to the method for detecting constant bright spots and blind spots of the present invention, the row and column values of the subregion to which the out-of-control point belongs are given, and the position of the out-of-control point can be quickly judged manually in the module area (6×6 light spots) corresponding to the subregion and the light point can be replaced. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com