Patents

Literature

37results about How to "No decolorization required" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing edible camellia oleosa seed oil

InactiveCN103113979AEasy to processHigh yieldFatty-oils/fats refiningFatty-oils/fats productionAdditive ingredientEdible oil

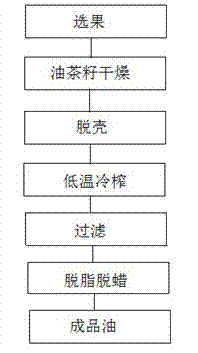

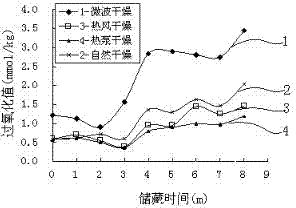

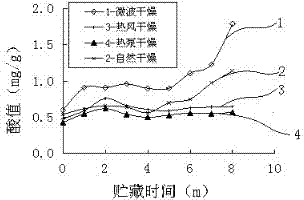

The invention relates to the technical field of edible oil production and discloses a method for producing an edible camellia oleosa seed oil and the edible camellia oleosa seed oil. The method for producing the edible camellia oleosa seed oil provided by the invention comprises the steps of fruit selection, camellia oleosa seed drying, unshelling, low-temperature cold pressing, filtering, and degreasing and dewaxing, and abandons the complicated refining processes including degumming, deacidification, decoloration, deodorization and the like. The key process of the method for producing the edible camellia oleosa seed oil is optimized and improved creatively so that the integrated production process of the edible camellia oleosa seed oil which is obviously different from the prior art is obtained; the process is greatly simplified and the losses of the nutritional ingredients in the camellia oleosa seed oil and the finished product oil are also avoided; as a result, the nutritional and functional ingredients such as flavonoids, polyphenols, sterol and carotenoid in the camellia oleosa seed oil are guaranteed to an utmost extent; and the first-grade edible camellia oleosa seed oil is obtained simply and feasibly.

Owner:SOUTH CHINA AGRI UNIV

Protein powder preparation method through hydrolyzing egg white using protease

InactiveCN101422204ASimple processEasy to operateMicroorganism based processesFermentationAlkaline proteaseNeutral protease

The invention provides a method for preparing a protein powder by utilizing proteinase to hydrolyze albumen. The method is as follows: the albumen of fresh poultry eggs is taken as raw material and stirred to obtain a protein liquid; the liquid is added with ferment for fermentation and desugarization, added with water to be diluted, and heated to be denatured; hydrolysis through alkaline protease, neutral protease and flavor enzyme is carried out and then the mixture is heated to passivate protease and dried, thus obtaining the protein powder. The method has the advantages of simple technique, convenient operation, high efficiency, low cost, high nitrogen utilization ratio, needing no debitterizing, decolorizing or desalination treatment and having significant application prospect.

Owner:ZHEJIANG UNIV

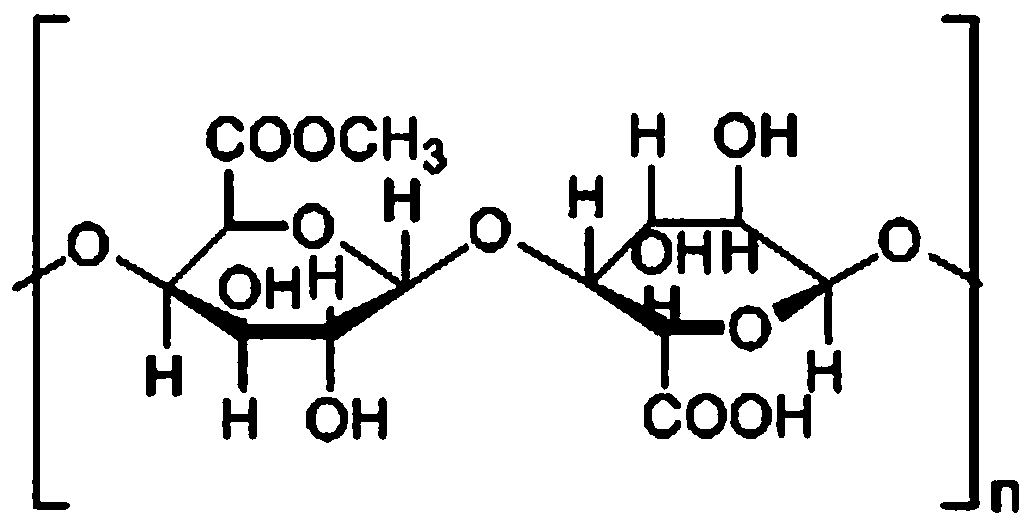

Method for preparing pectin by using waste sisal dregs

The invention discloses a method for preparing pectin by using waste sisal dregs. By utilizing the waste sisal dregs as raw materials, the method for preparing the pectin comprises the steps of pretreatment of the raw materials, enzyme inactivation, water rinsing, microwave assisted acid water extraction, extracting solution treatment and concentration, alcohol precipitation, filtration and drying. Compared with the prior art, the method has the advantages of: 1, high pectin yield, low impurity content, simple process, low energy consumption and easy large batch production of the pectin; 2, short extraction time and high yield by using the microwave for assisting in the extraction during the decomposition of the acid water; low energy consumption, low impurity content and easy industrialization by using the membrane separation technology for filtrate concentration; and light color of the obtained product and no need of color removal by using the freeze drying technology for the drying process. The pectin obtained by the method is low methoxyl pectin and has the advantages of good solubility and easy formation of gel.

Owner:GUANGXI UNIV

Method for extracting camellia oil through subcritical fluid extraction technology

InactiveCN102071098AHigh extraction rateReduce extraction timeFatty-oils/fats productionAlkaneSolvent

The invention provides a method for extracting camellia oil through subcritical fluid extraction technology, which comprises the steps of: putting weighed camellia seed raw materials into an extraction kettle; and introducing CO2 or an odorless and nontoxic alkane solvent for extraction, wherein the extraction conditions are that: the temperature is 5 to 50DEG C, the pressure is 0.1 to 45Mpa, the extraction time is 10 to 240min, and the flow is 30 to 60L / h. Through the method, the one-time extraction rate is about 98 percent, the extraction time can be shortened by about 30 percent, harmful solvent residual does not exist, the extraction refinement can be realized through one-time treatment, the high temperature process is avoided, high-quality camellia oil can be obtained, and subsequent treatment such as deodorization and decoloration are not needed; and the method is convenient, safe and environment-friendly to operate, and the cost is reduced by about 10 percent compared with that of the traditional high-grade camellia oil processing method.

Owner:曹庸

Compound stevioside substitute and preparation method thereof

The invention discloses a compound stevioside substitute and a preparation method thereof, relating to a natural sweetener and providing a compound stevioside substitute with natural and pure sweet taste and low cost and a preparation method thereof. The compound stevioside substitute comprises a stevia extract, a complexing agent, a pH regulating agent, a natural malt extract, the natural sweetener and natural edible essence in percent by weight of 100: (20 to 100): (1 to 3): (1 to 3): (0.1 to 0.6): (0.01 to 0.03). After dry leaves of stevia are extracted by using water, extract liquid is decolored, smell removed and then filtered; the complexing agent and the pH regulating agent are added according to a proportion to react; the natural malt extract, the natural sweetener and the natural edible essence are added and uniformly stirred, and dried by spray by a spray drying method for preparing a powdery product. The obtained novel compound stevioside product still is a natural high-magnification sweetener and the sweetness of the compound stevioside sweetener is 60 to 80 times of cane sugar. The compound stevioside substitute can replace 70% of the cane sugar in practical application.

Owner:DAMIN FOODSTUFF ZHANGZHOU CO LTD

Preparation method of walnut oil

InactiveCN106665890AImprove qualityGood colorFatty-oils/fats refiningFatty-oils/fats productionWaxOil separation

The invention discloses a preparation method of walnut oil. The preparation method of the walnut oil comprises the following steps: carrying out careful selecting, carrying out washing, carrying out sterilization, carrying out peeling, carrying out pressing, and carrying out ultrasonic extraction. According to the preparation method of the walnut oil, the preparation is carried out at 45 DEG C, and the walnut kernel peel is removed before pressing by using alkaline liquor, so that the qualities and the color of the walnut oil are improved; and ultrasonic extraction is adopted so as to increase yield rate, reduce oil content rate of the oil cakes, balance protein in the walnut oil and the oil cakes so as to ensure protein stability in the oil cakes, and improve wax-oil separation effect. The preparation method of the walnut oil is simple in processes; and the walnut oil which is clear, transparent and bright in color, free of impurities, rich in nutrition and high in oil yield can be prepared without the step of carrying out decoloring by adopting the preparation method.

Owner:迪庆香格里拉舒达有机食品有限公司

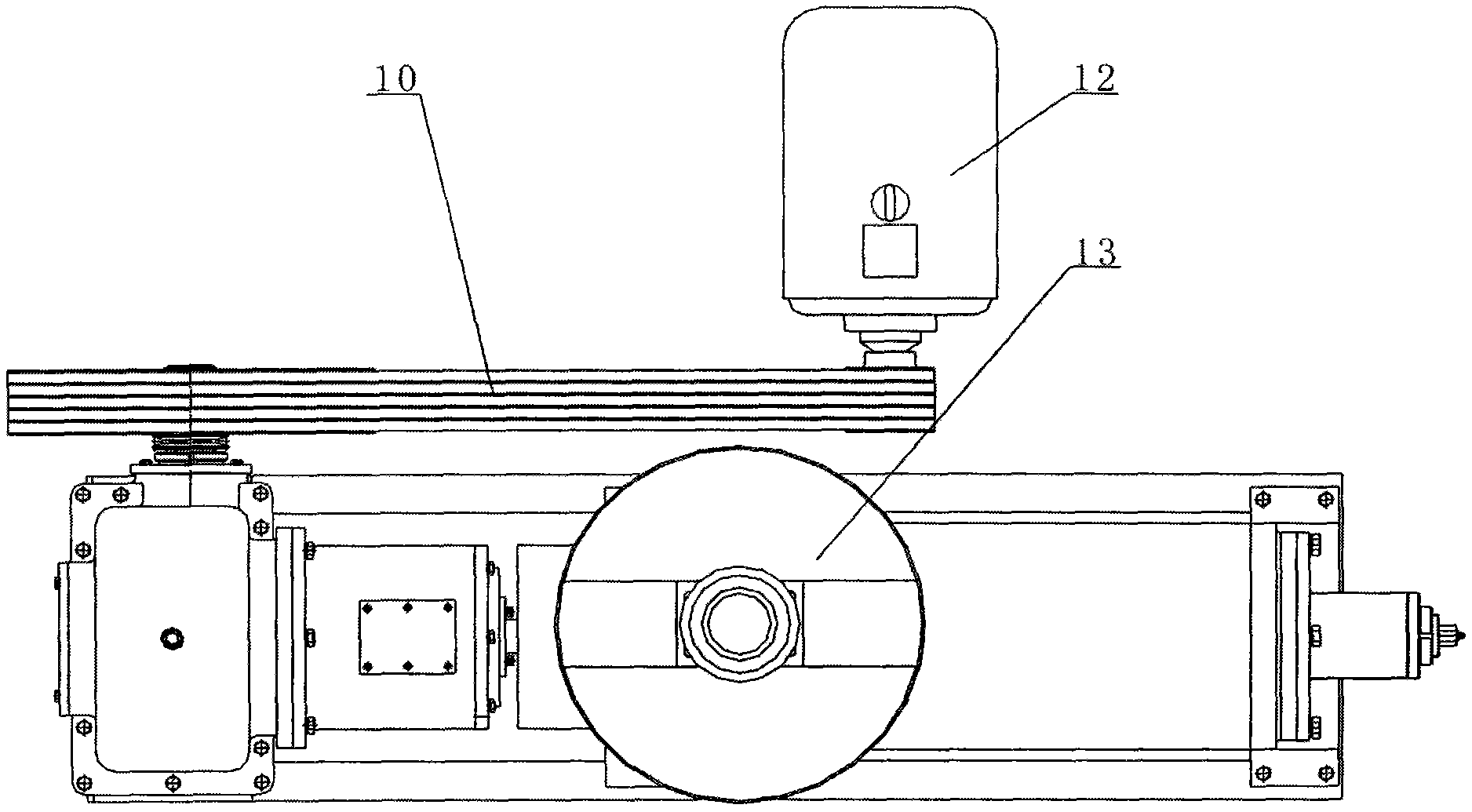

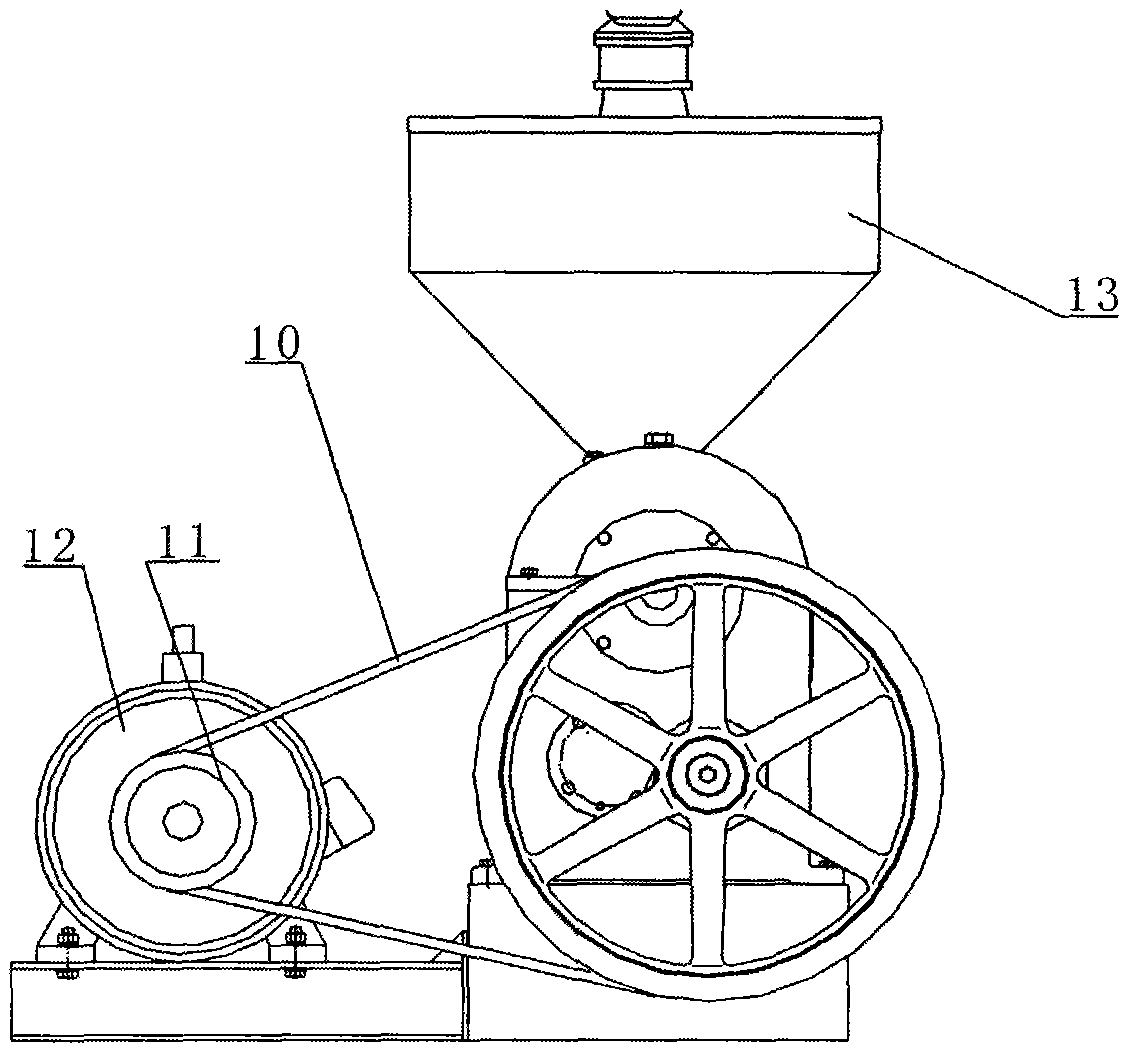

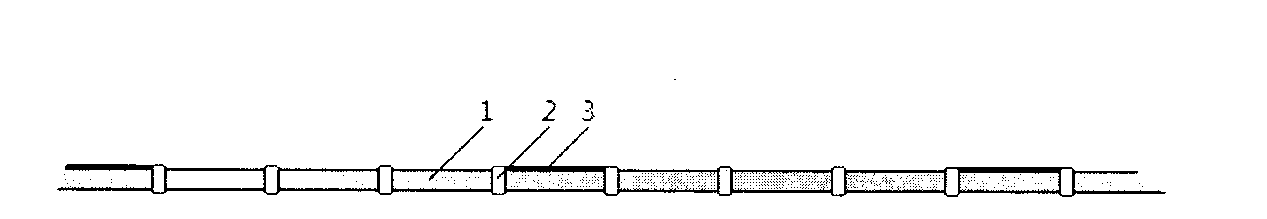

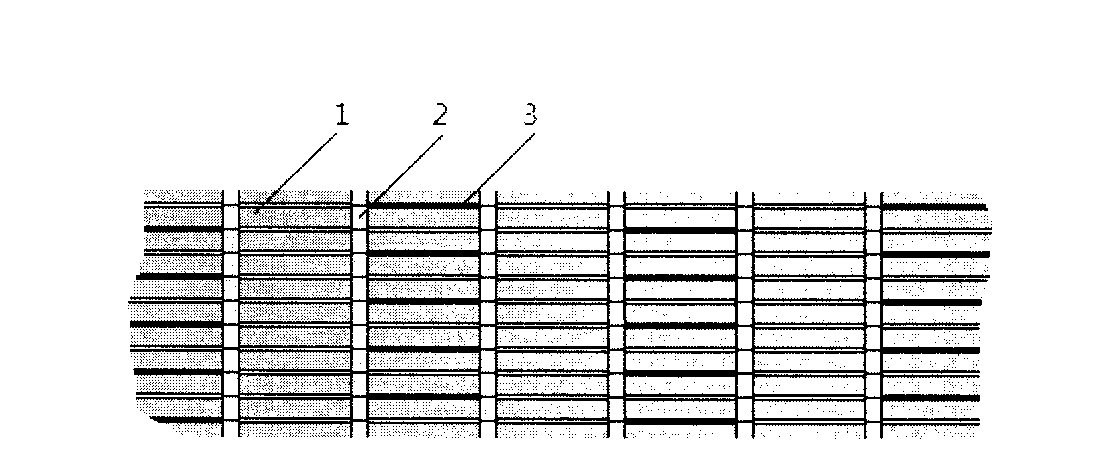

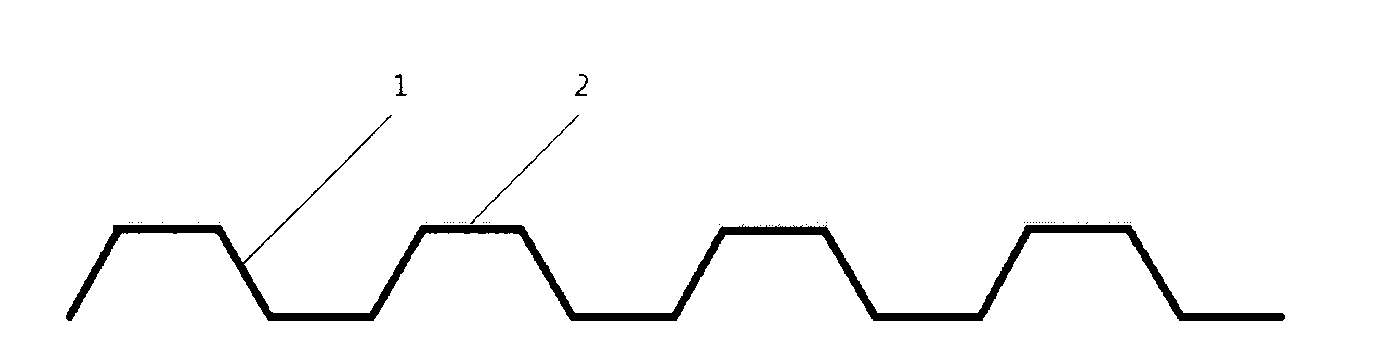

Pressing ring type double-screw spiral oil press

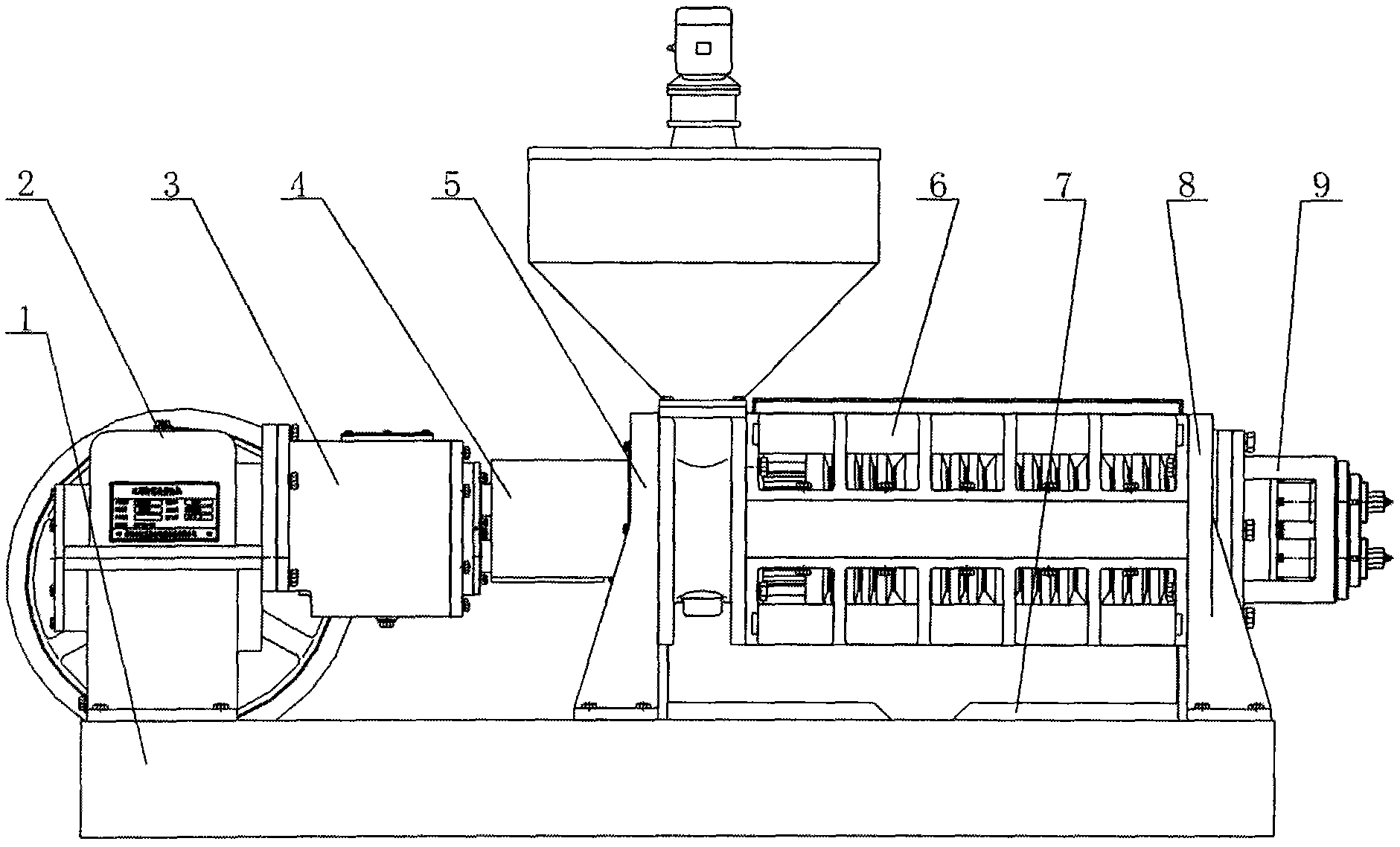

InactiveCN103895249AIncrease pressureImprove oil output efficiencyToothed gearingsPressesEngineeringRing type

The invention discloses a pressing ring type double-screw spiral oil press comprising a base, a motor mounted on the base, a transmission mechanism, a left support and a right support. The motor is connected to the transmission mechanism through a conveying belt. A pressing cage mechanism is mounted between the left support and the right support, an oil collecting plate is mounted below the pressing cage mechanism, and the tail of the pressing cage mechanism is provided with an oil cake regulating mechanism. A three-way feeding hole communicated with the pressing cage mechanism is formed in the left support, and the left support is provided with a feeding mechanism communicated with the three-way feeding hole. The pressing ring type double-screw spiral oil press is characterized in that the transmission mechanism is connected to a power distribution mechanism which is connected to the pressing cage mechanism; the pressing chamber of the pressing cage mechanism comprises a plurality of pressing rings mounted in a pressing cage; the end face of one side of the pressing ring is provided with a plurality of oil discharging grooves. The pressing ring type double-screw spiral oil press has the advantages that structure is simple, parts are few, equipment manufacturing cost is low, operation and maintenance can be performed simple and conveniently, and cold pressing and hot pressing can be performed both.

Owner:苟安富 +1

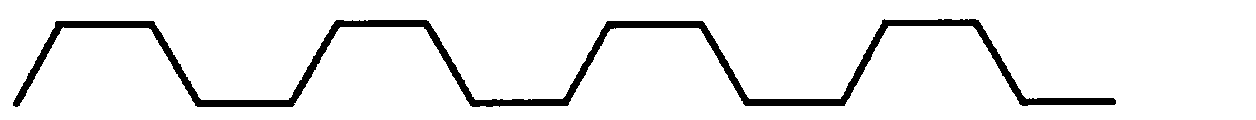

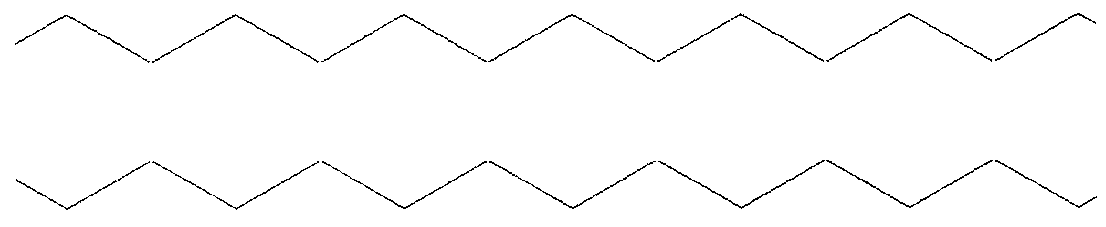

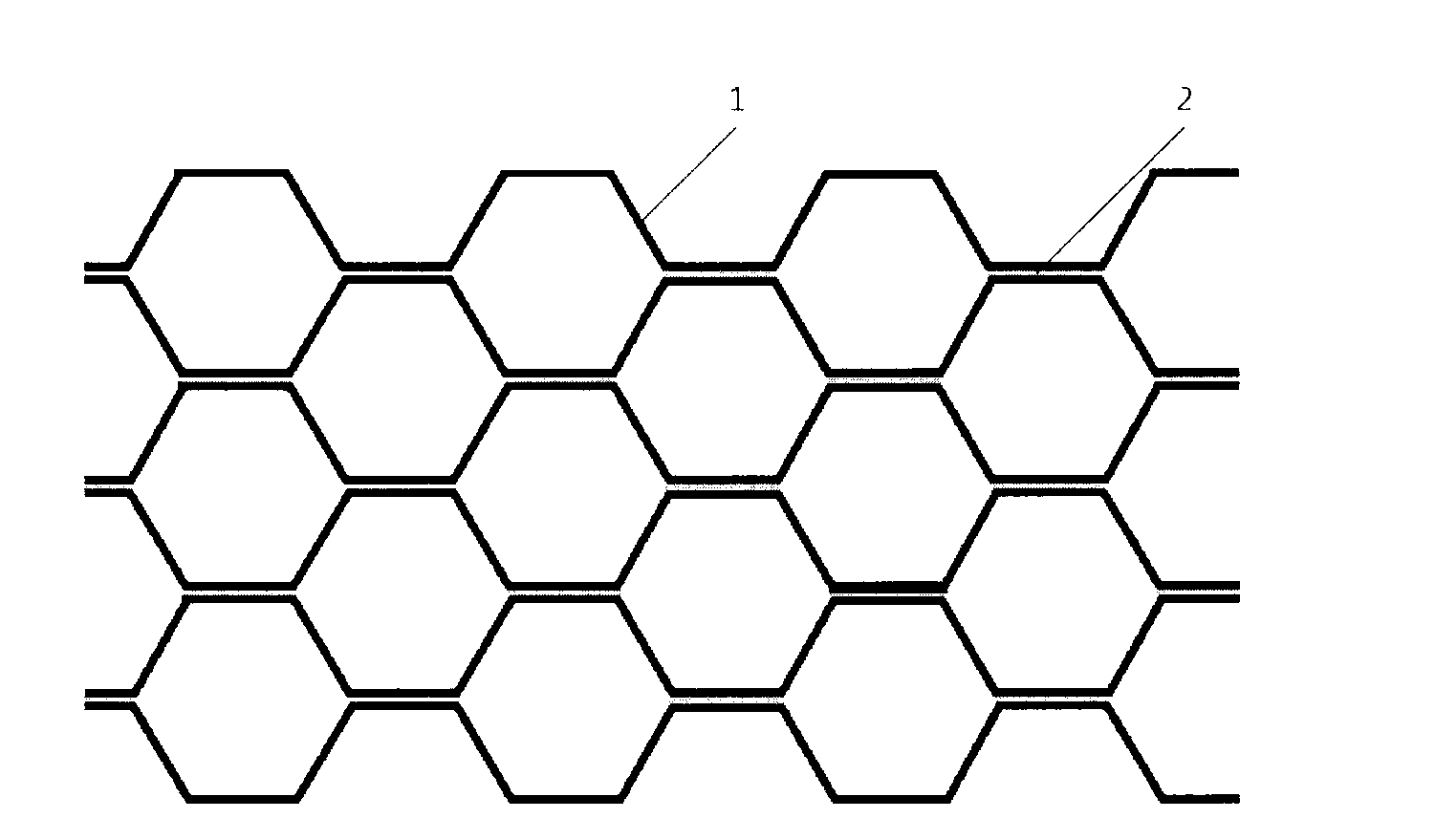

Method for manufacturing honeycomb core filled with fibrofelt by using textile wastes

InactiveCN103182801ANo decolorization requiredPrecise structureLamination ancillary operationsLaminationFiberFilling materials

The invention discloses a method for manufacturing a honeycomb core filled with fibrofelt by using textile wastes, which is characterized by comprising the following steps: (1) manufacturing of flat-head waved fiberboards and honeycomb-shaped fibrofelt strips by using textile wastes, that is, recovering textile wastes into reprocessing fibers, wherein the thermoplastic textile wastes are well mixed with common textile wastes in proportion; preparing fiber nets, performing hot pressing of the prepared fiber nets respectively, preparing flat-head waved fiberboards and broken-line waved fibrofelt, cutting the fibrofelt to obtain honeycomb-shaped fibrofelt strips; (2) bonding and cutting of the fiberboards and fibrofelt, that is, coating adhesive tapes on peaks and troughs of the fiberboards prepared in step (1), pasting the fibrofelt strips obtained in step (1) on the troughs of the fiberboards, bonding the fiberboards on the fibrofelt strips, repeating the bonding in the above manner to obtain a honeycomb core complex; cutting the complex at the cross section to obtain the honeycomb core filled with fibrofelt. The method can make use of hard textile wastes, and the honeycomb core and the filling material have accurate structures, and improved heat insulation and sound insulation performance.

Owner:JIANGNAN UNIV

Method for extracting pectin from green sunflower plates by salt

The invention belongs to the technical field of pectin extraction, and provides a method for extracting pectin from green sunflower plates by salt. The green sunflower plates are used as raw materials, enzyme deactivation is performed in a water bath kettle in constant temperature, filtering is conducted, and an enzyme-deactivated solution is removed; distilled water is added to sediment, ammoniumoxalate or sodium citrate is added for extraction, filtering is performed, filtrate is subjected to decompression and rotary distillation, and concentrated sunflower plate extract is obtained after concentration, the concentrated solution is precipitated by ethanol, still stands and then is filtered to obtain pectin, the pectin is washed once or twice with anhydrous ethanol for dehydration, thenpasses through a 60-mesh sieve, naturally dried or dried at 40 degree or below, and crushed to obtain pectin powder. The method for extracting the pectin has high pectin extraction rate, the product is attractive without decolorization treatment, the material-liquid ratio is small, and the use amount of solvents and salt is significantly reduced, the utilization ratio of the sunflower plate is effectively improved, waste utilization is achieved, and the added value of the sunflower industry is increased.

Owner:ZHONGBEI UNIV

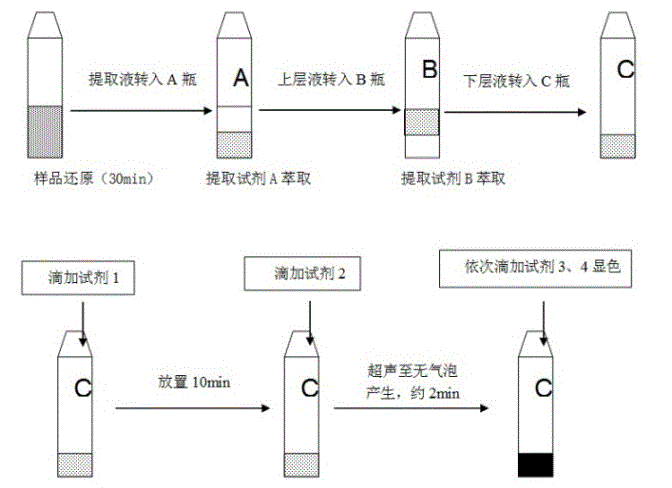

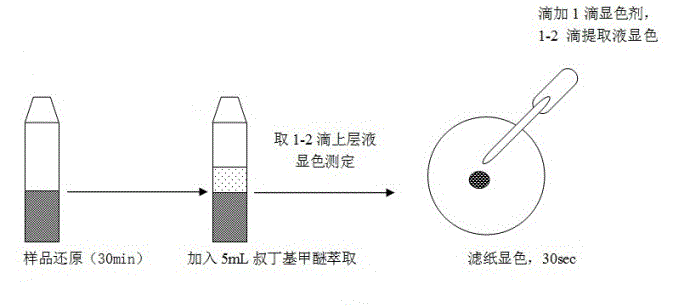

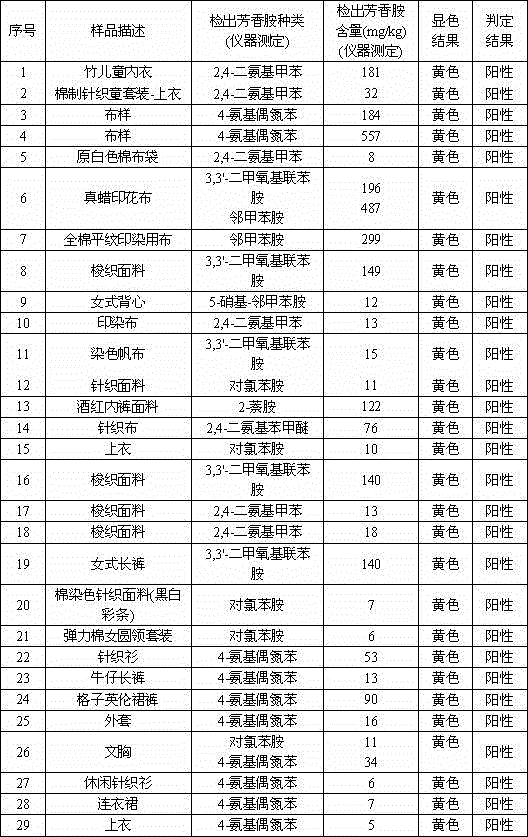

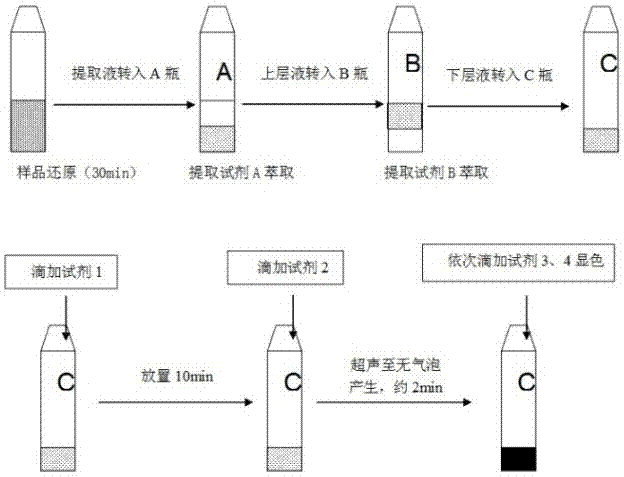

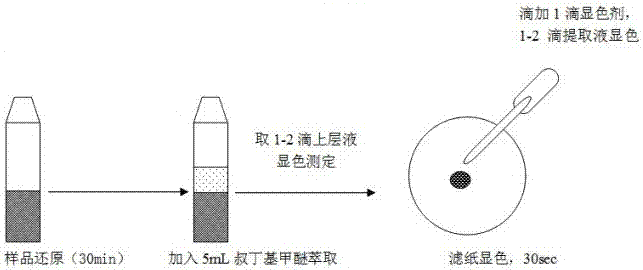

One-step color-development screening method for banned azo-dye in dyeing textiles

ActiveCN104897665AQuick screeningSimple screening methodMaterial analysis by observing effect on chemical indicatorEtherColor changes

The invention discloses a one-step color-development screening method for banned azo-dye in dyeing textiles. The one-step color-development screening method comprises the following steps: (1) reducing a sample; (2) color-development, to be specific, at the same position of filter paper, dripping a drop of a color-developing agent, and then dripping 1-2 drops of tert-butyl methyl ether extracting solution for color development, wherein the color-developing agent is an ethanol solution comprising paradimethylaminobenzaldehyde with the mass-volume ratio of 0.1-10% and hydrochloric acid with the volume ratio of 10-25%; (3) screening and determination, to be specific, judging results according to the fact that whether obvious color change occurs or not after dripping the sample solution on the color-developing agent, wherein if no obvious color change occurs after color development of the sample solution, the sample does not contain a substance to be detected or the concentration of the substance to be detected is lower than the detection limitation, and the result is negative; if obvious color change occurs after color development of the sample solution, the sample is likely to contain the banned azo-dye, the result is positive, and further confirmation is required to be carried out by a chromatographic apparatus. The one-step color-development screening method is simple and fast, the sample can be directly subjected to color-development to be determined after being reduced, and the whole color development process can be completed within 1 min.

Owner:INSPECTION & QUARANTINE TECH CENT SHANDONG ENTRY EXIT INSPECTION & QUARANTINE BUREAU

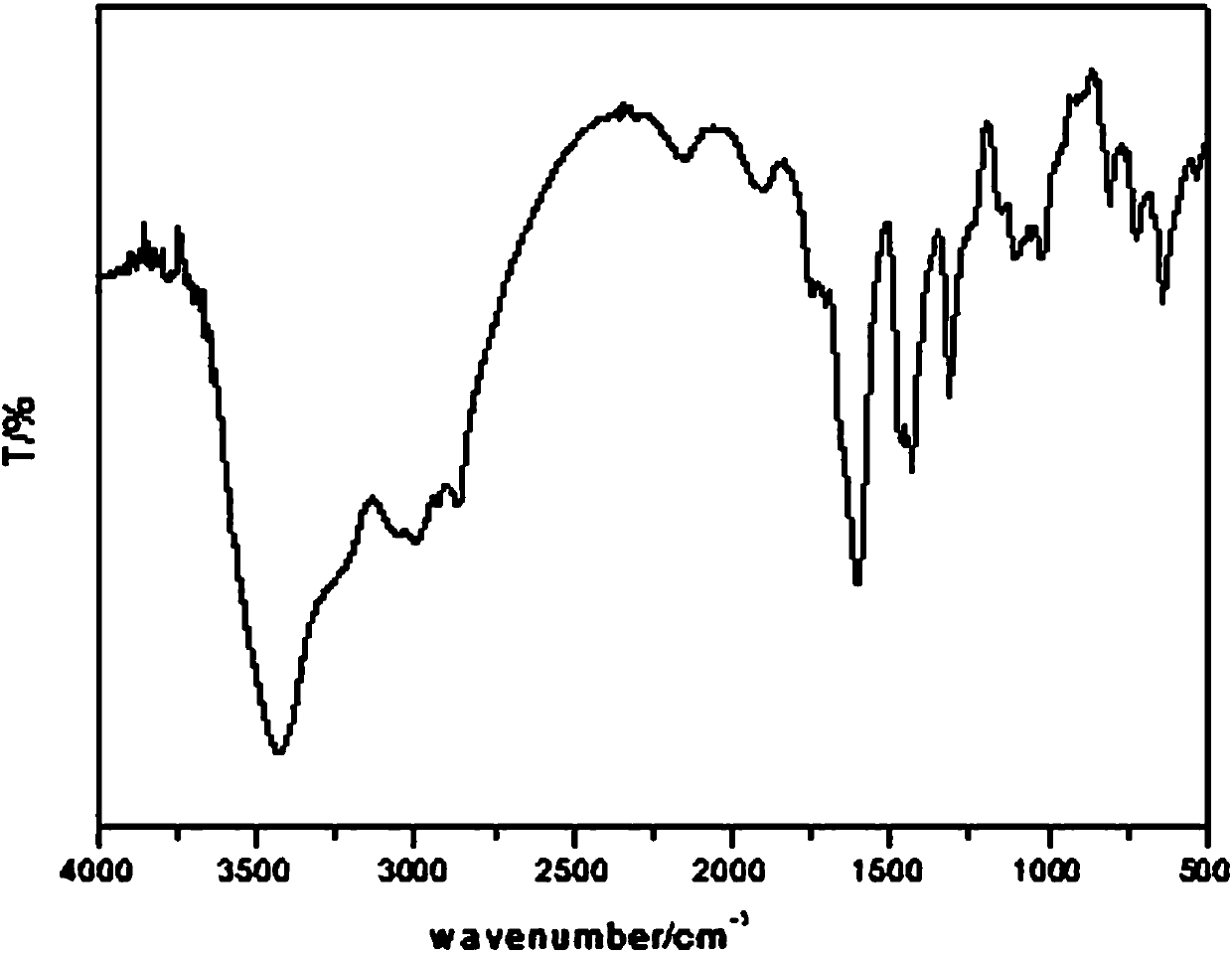

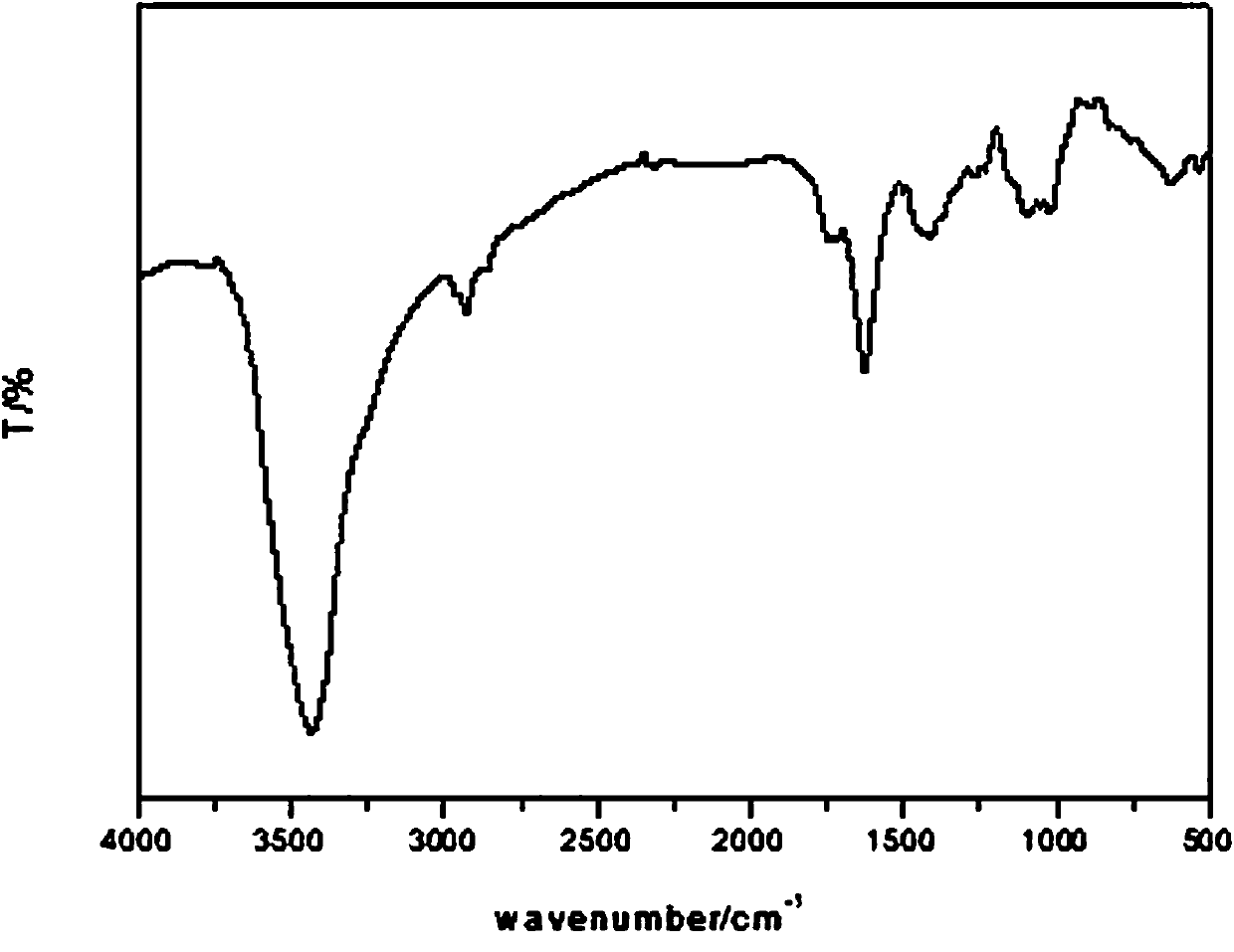

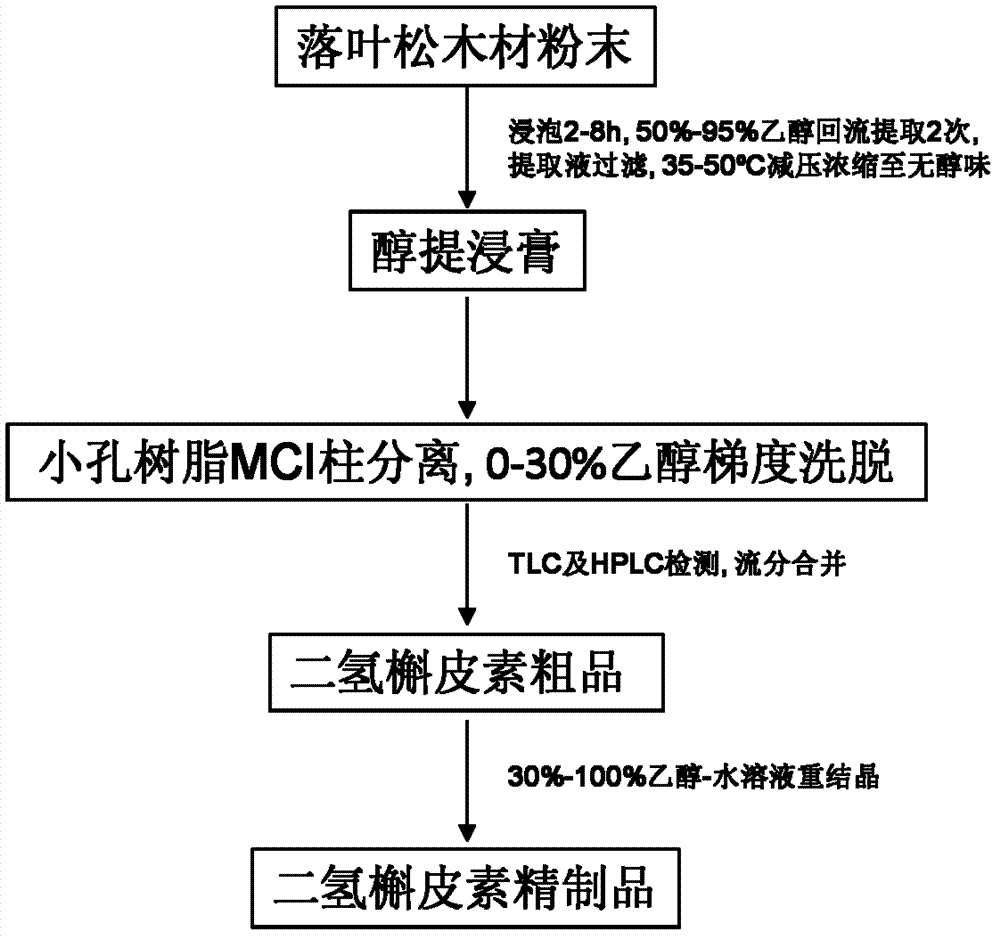

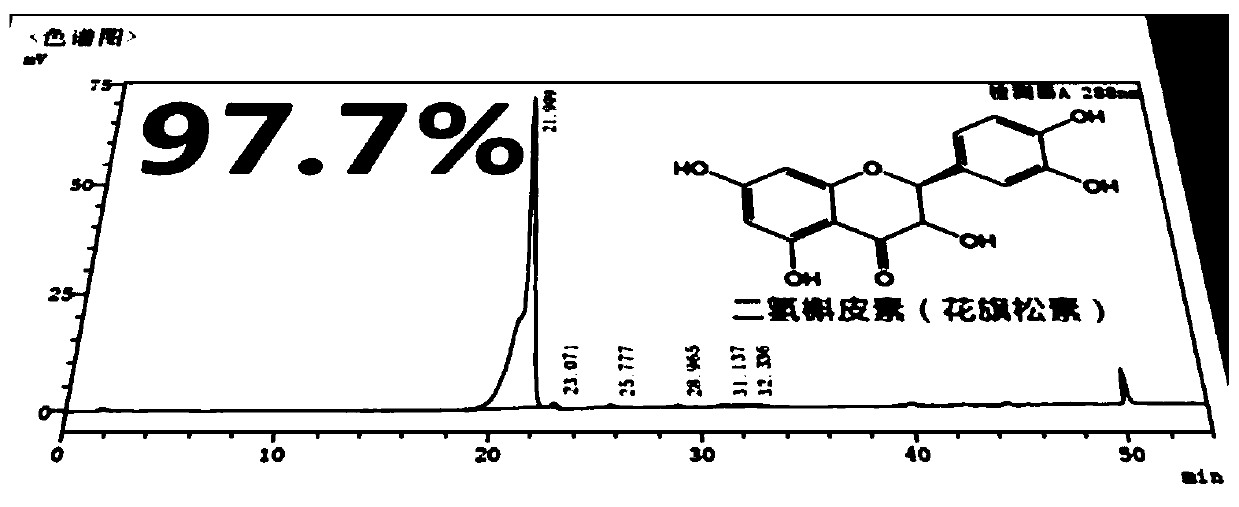

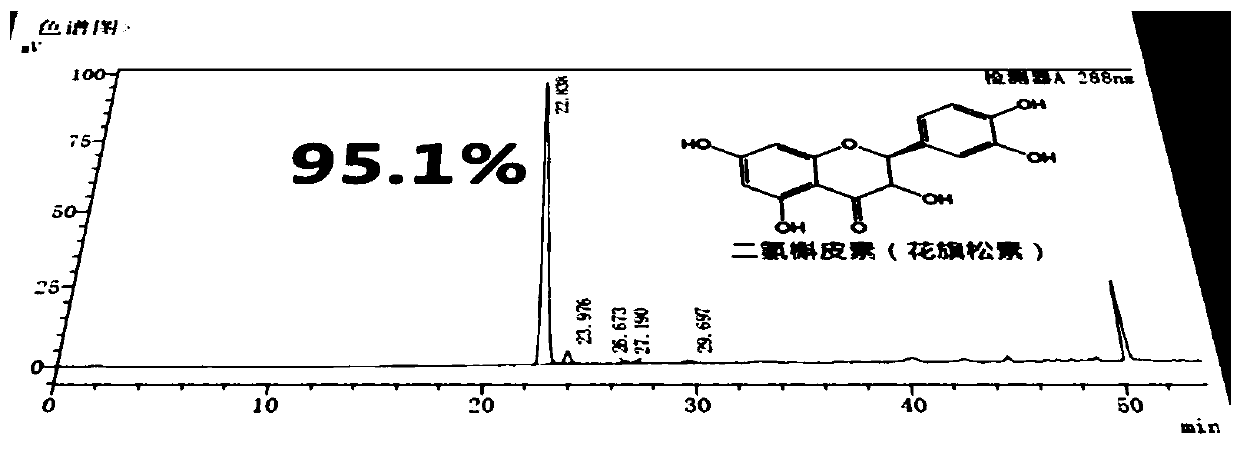

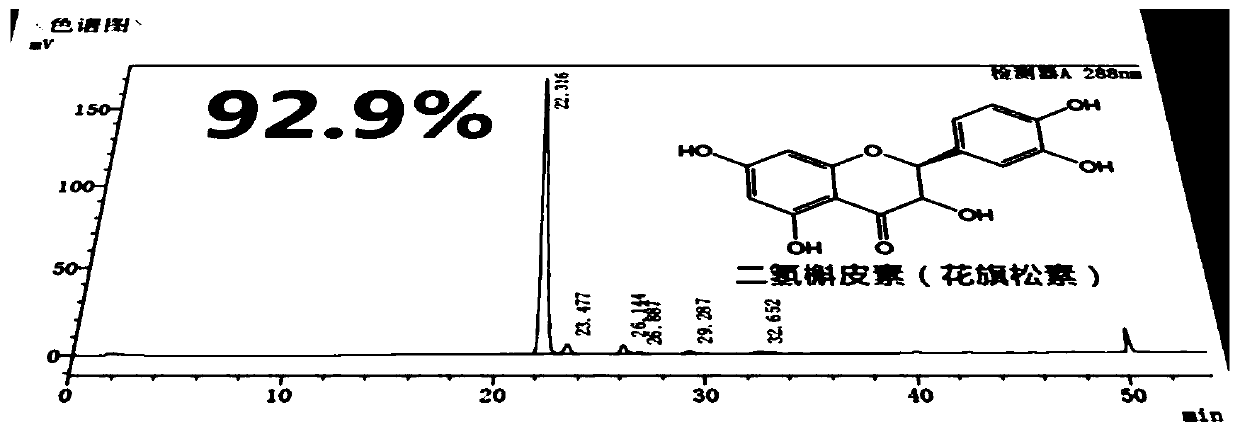

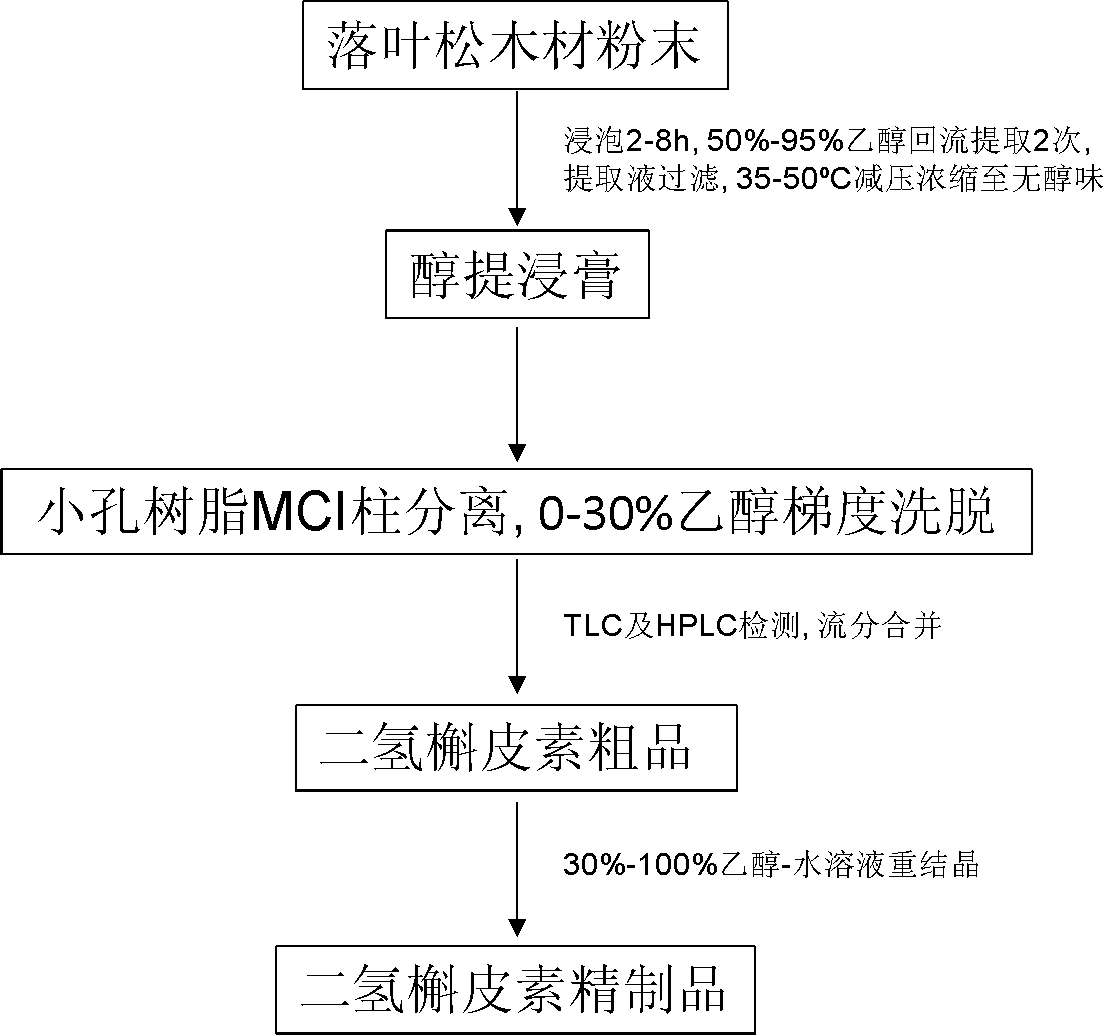

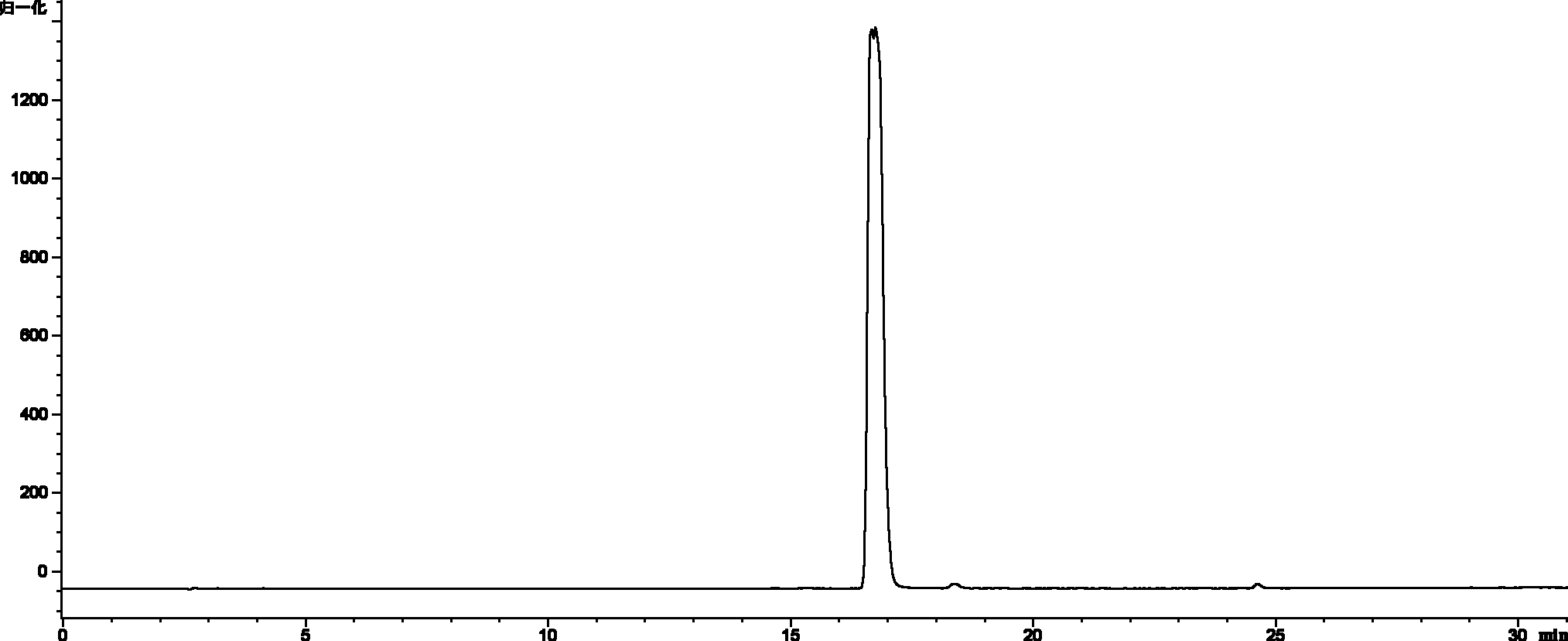

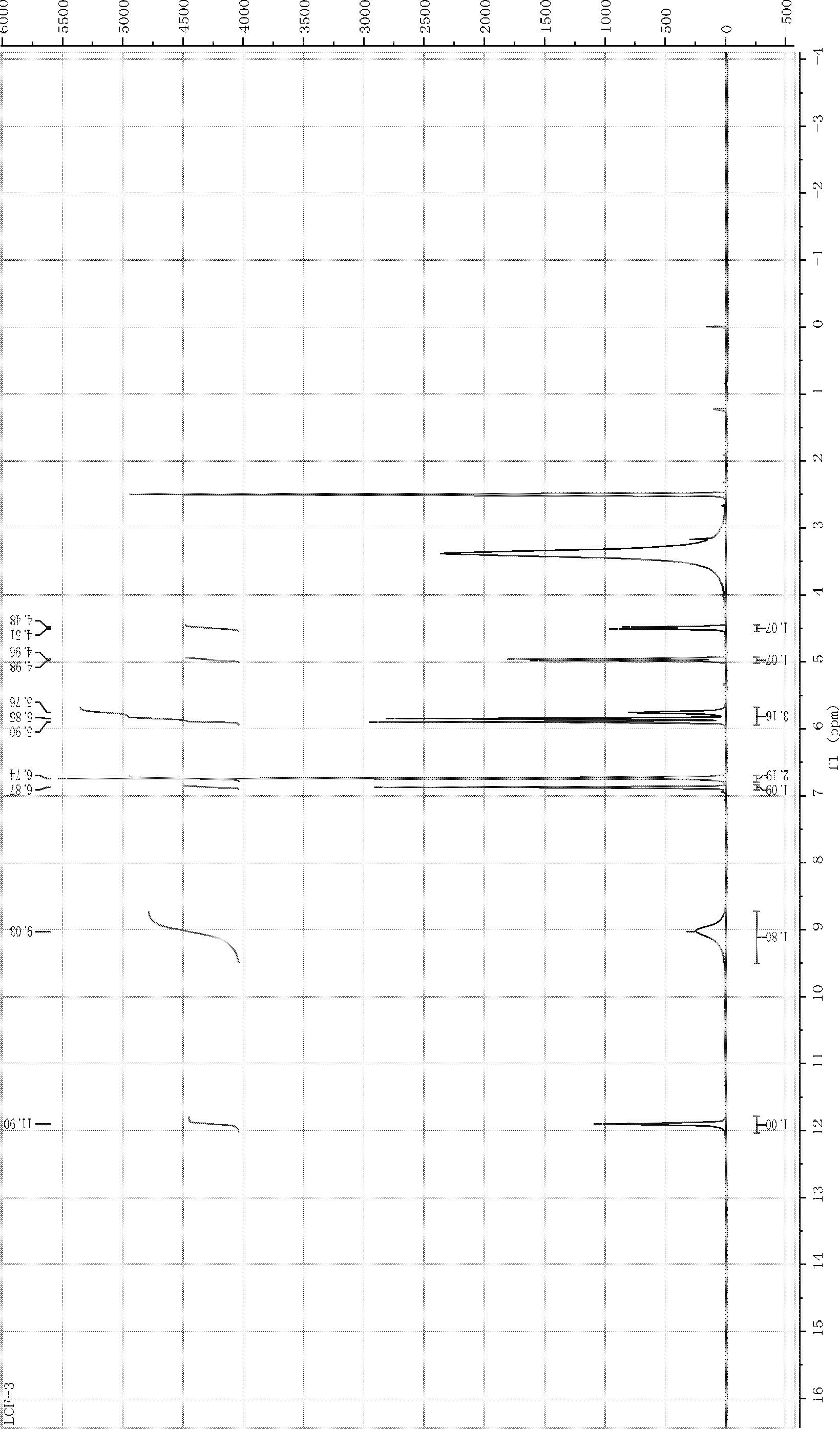

Method for refining dihydroquercetin from larch

The invention discloses a method for refining dihydroquercetin from larch by using micro-porous resin. The method comprises the following steps: (1) after crushing the raw material larch wood, adding ethanol water solution to extract, collecting extracting solution and concentrating to obtain extract; (2) performing liquid phase adsorption separation on the extract by using micro-porous resin MCI, performing gradient elution by taking the ethanol water solution with volume fraction of 0-30 percent as an eluant, collecting and combining elution components with volume fraction of 20-25 percent, concentrating and drying to obtain a dihydroquercetin rough product; and (3) recrystallizing the dihydroquercetin rough product to obtain refined dihydroquercetin. According to the method, environment-friendly solvents such as water and ethanol are adopted, are pollution-free and can be recycled; the used adsorbent micro-porous resin introduces less impurities and can be reused for times; the obtained product has purity of greater than 99 percent and has no toxic ingredient residues, and the pharmaceutical-grade raw material can be directly obtained. The method has the advantages of simple route, economy, environmental friendliness and high yield and is suitable for industrial production.

Owner:PEKING UNIV +1

Method for producing honeycomb core with textile waste material

InactiveCN103158323AWide range of usesIncrease dosageLamination ancillary operationsLaminationScrapHoneycomb

The present invention discloses a method for producing a honeycomb core with a textile waste material, which is characterized by including: 1) treatment of the textile waste material and production of fiber felt, including cutting up the textile waste material, tearing, fully mixing a thermoplasticity textile waste material with an ordinary textile waste material in proportion to produce re-processed fibers, performing net formation and hot melting reinforcement of the fibers to obtain a fiber felt; 2) production of a fiberboard and a honeycomb core blank, including preheating and molding the fiber felt obtained from the 1) step to obtain the fiberboard, coating a binder according to a certain rule on the fiberboard to form binder strips, bonding a plurality of layers of fiberboards to produce the honeycomb core blank; and 3) processing the honeycomb core, including cutting the honeycomb core blank obtained from the 2) step into the honeycomb core blank strips with an equal width, preheating the honeycomb core blank strips, and stretching at the cross-section by segments to make the honeycomb core blank strips expand, so as to obtain the honeycomb core with the textile waste material. The method can make use of rigid textile waste materials with large quality discrepancy, the different fibers in the textile waste material do not need to be distinguished, and the added value of the textile waste material is increased.

Owner:JIANGNAN UNIV

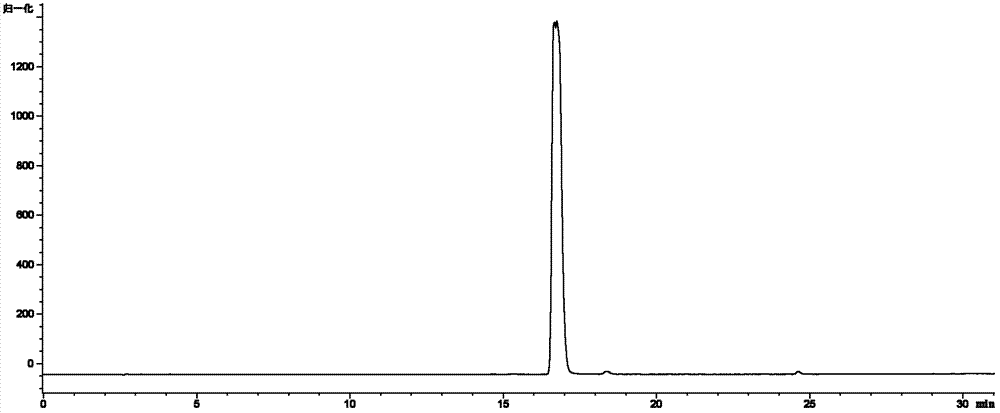

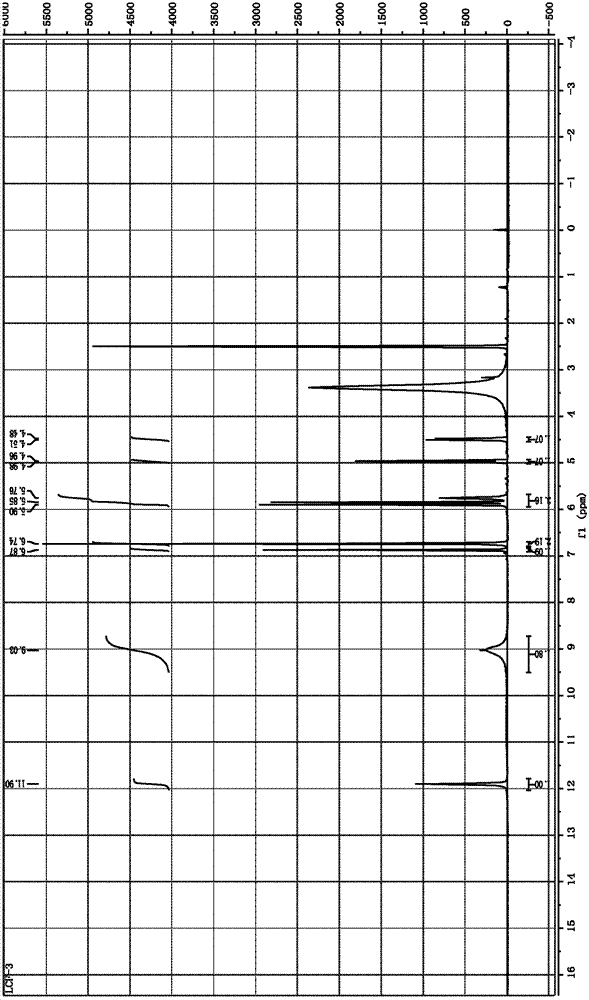

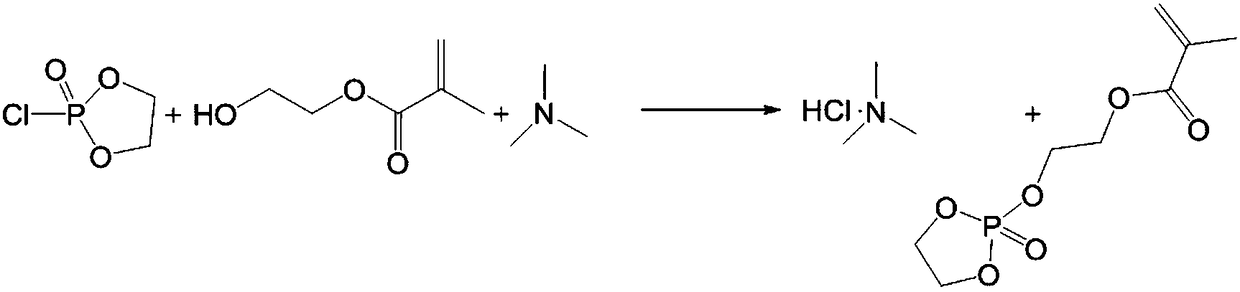

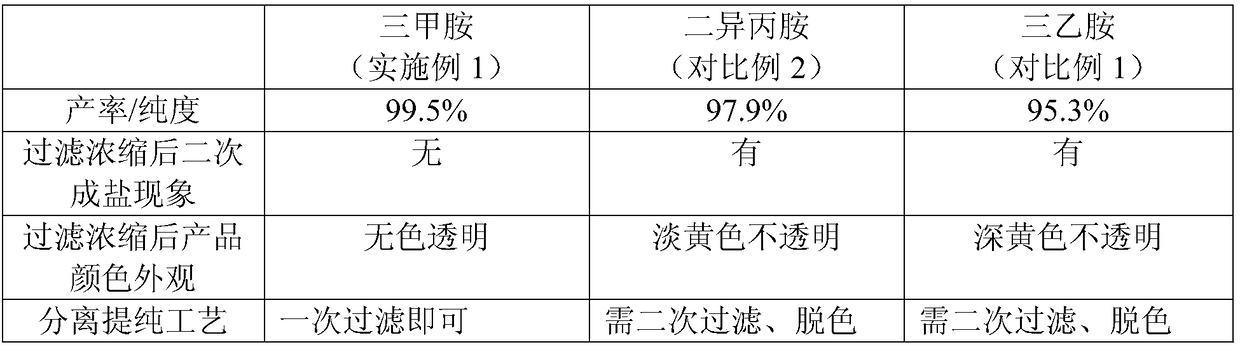

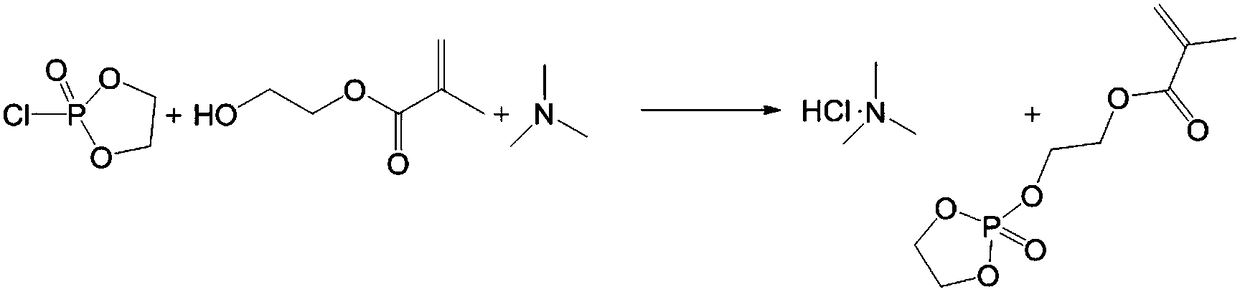

Method for preparing ethylene 2-(methacryloyloxy)ethyl phosphate

ActiveCN109438516AQuick responseHigh yieldGroup 5/15 element organic compounds(Hydroxyethyl)methacrylateEsterification reaction

The invention discloses a method for preparing ethylene 2-(methacryloyloxy)ethyl phosphate. Under the action of trimethylamine gas, hydroxyethyl methacrylate and 2-chloro-1,3,2-dioxaphospholane 2-oxide are subjected to esterification reaction. The method disclosed by the invention has the advantages of rapid reaction, high yield and high purity, simple technology and high repeatability; the technical difficulty that a synthetic product easily becomes yellow and forms salt for the second time is effectively solved, and industrialization is facilitated.

Owner:ANQING GOUYOU BIOMATERIALS TECH CO LTD

Method for manufacturing honeycomb core with filling material by using textile waste

InactiveCN103158325ANo decolorization requiredGood heat insulationLamination ancillary operationsLaminationFiberHoneycomb

The invention discloses a method for manufacturing a honeycomb core with a filling material by using textile waste. The method for manufacturing the honeycomb core with the filling material by using the textile waste is characterized by comprising the following steps: the first step is reverting the textile waste to reprocessing fibers, and preparing two kinds of fiber felts by using the obtained fibers, wherein the thermal properties of the two kinds of fiber felts are different, one of the fiber felt comprises thermoplastic fibers and the other fiber felt does not comprises thermoplastic fibers, and coating hot melting rubber bars on the fiber felt without the thermoplastic fibers at the intervals of three times of the length of the side of the honeycomb core, wherein the width of each hot melting rubber bar is equal to the length of the side of the honeycomb core; the second step is compositing the two kinds of fiber felts which are prepared in the first step, pre-heating, hot-pressing and cooling the composite body of the fiber felts to form semi-finished honeycomb core; and the third step is cutting the semi-finished honeycomb core prepared in the second step into a plurality of pieces of honeycomb core strips with required height, pre-heating the honeycomb core strips, drawing the honeycomb core strips along the sections of the honeycomb core strips, unfolding the honeycomb core strips, cooling the honeycomb core strips, and then obtaining the hexagonal honeycomb core. According to the method for manufacturing the honeycomb core with the filling material by using the textile waste, the mechanical property of the honeycomb core can be improved by using the poor-qualified rigid textile waste, cost is reduced, and heating insulation performance and sound insulation performance of the honeycomb core are improved.

Owner:JIANGNAN UNIV

Pretreatment ethanol extraction method of dihydroquercetin in larix gmelini wood powder

InactiveCN104710393AReduce energy consumptionThe method route is simpleOrganic chemistryPulp and paper industryLarix gmelini

The invention provides a pretreatment ethanol extraction method of dihydroquercetin in larix gmelini wood powder. The pretreatment ethanol extraction method comprises the following steps: with larix gmelini wood powder as a raw material, firstly pretreating the larix gmelini wood powder: leaching the larix gmelini wood powder with water, wherein the water leaching temperature is room temperature, the water leaching extraction time is 2-5 hours, and the material-water ratio is 1:5 to 1:10; then, filtering water, retaining the wet larix gmelini wood powder, adding an ethanol solution with an ethanol volume fraction of 10-95% for extracting to obtain an ethanol extracting solution, wherein the ethanol extraction method is a soaking extraction method, a reflux method or a leakage method; then concentrating and drying the ethanol extracting solution to obtain a dihydroquercetin crude product, and recrystallizing the dihydroquercetin crude product to obtain fine dihydroquercetin. The pretreatment ethanol extraction method has the main characteristics that the operation process can be directly used without drying, is economic, environmentally friendly, high in yield and suitable for industrial large-scale production, and all the solvents are recycled.

Owner:蔡兴福 +1

Environment-friendly food packaging paper

ActiveCN104032625AGood for healthNo decolorization requiredNon-fibrous pulp additionFlexible coversPullulanPapermaking

The invention belongs to the technical field of papermaking, and in particular relates to environment-friendly food packaging paper. The environment-friendly food packaging paper is prepared from the following raw materials in parts by weight: 100 parts of dried rice straw, 1-4 parts of pullulan, 1-4 parts of curdlan, 0.12-0.18 part of glucomannan and 40-50 parts of sterile water. The environment-friendly food packaging paper is prepared by crushing, pulping, steaming, paper film formation and drying, and has the characteristics of environment friendliness, nature, no toxicity, sanitation and the like.

Owner:ANQING TIANRUN PAPER PACKAGING

Chinese herbal medicine skin disinfectant wet wipe

InactiveCN104434667AGood sterilization effectGood hygroscopicityCosmetic preparationsToilet preparationsCarthamusDisinfectant

The invention provides a Chinese herbal medicine skin disinfectant wet wipe. The Chinese herbal medicine skin disinfectant wet wipe comprises a spunlace nonwoven base material, and a disinfectant loaded on the spunlace nonwoven base material, wherein the disinfectant is prepared by concentrating extracting solution of 15 parts of scutellarta root, 15 parts of cordate houttuynia, 15 parts of honeysuckle, 8 parts of garlic, 8 parts of aloe, 4 parts of lavandula angustifolia, and 6 parts of saffron, and then mixing the Chinese herbal medicine with 2 parts of hibitane, 2 parts of glycerin, and 7 parts of palmitic acid sucrose ester. The disinfectant wet wipe does not have pungent smell, is low in toxicity, can not cause skin irritation, and improves the sterilization and disinfection effects through the mating reaction between Chinese herbal medicine and the hibitane.

Owner:CHENGDU SHUNFA DISINFECTANT & WASHING TECH

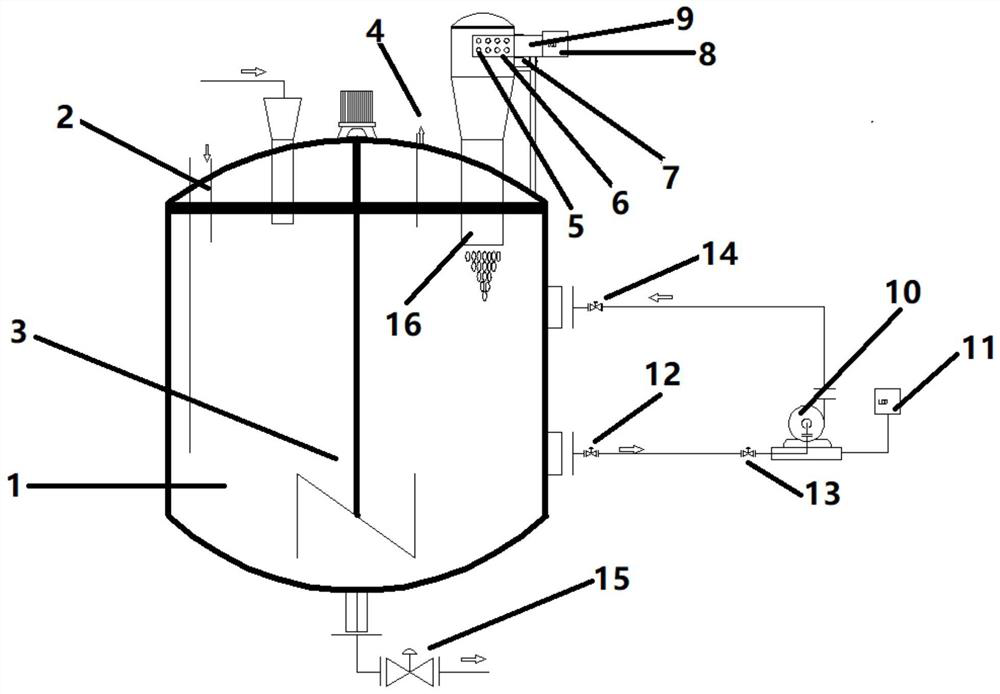

Synthesis method of phosphate

PendingCN112409403AGuaranteed stabilityProduct stabilityChemical/physical/physico-chemical stationary reactorsPhosphorus organic compoundsSolvent freePhosphorus pentoxide

The invention discloses a synthesis method of phosphate. The method comprises the following steps: (1) adding organic alcohol into a reaction kettle; (2) proportionally adding phosphorus pentoxide into a feeding box, and setting the rotating speed of the feeding box, wherein the adding time of phosphorus pentoxide is controlled to be 1-3 h, a circulating pump is started in the feeding process, thespeed of circulating liquid is controlled, a plurality of small holes are formed in the surface layer of the feeding box, phosphorus pentoxide overflows from the small holes through the rotation of abox body and enters the reaction kettle to react with organic alcohol; and (3) after addition of the phosphorus pentoxide is finished, raising the temperature of the reaction kettle to 70-90 DEG C, and continuing reacting for 5-7 hours to obtain a phosphate product. According to the invention, phosphate is prepared by adopting a solvent-free method; the adding amount and quality of phosphorus pentoxide are guaranteed by controlling the adding mode of phosphorus pentoxide and setting a material circulating device; heat generated by the reaction is discharged in time, so reaction stability is guaranteed, and the prepared phosphate product is stable and high in esterification rate; and the formed system is colorless and transparent, decoloration is not needed, and the product does not contain any decolorizing agent.

Owner:四川科宏达集团有限责任公司

Pretreatment steam extraction method for rosin, arabinogalactan and dihydroquercetin in larch wood powder

PendingCN110408324AAddressing Purity IssuesNo energy consumptionOrganic chemistryNatural resin purificationLarchFiltration

The invention relates to a pretreatment steam extraction method for rosin, arabinogalactan and dihydroquercetin in larch wood powder. The method comprises the following steps of S1, water immersion pretreatment, wherein the larch wood powder is subjected to water immersion treatment, filtration is conducted to obtain a filtrate containing arabinogalactan, and the moist larch wood powder is reserved; S2, steam extraction, wherein steam with the pressure of 0.2 MPa is added to the moist larch wood powder treated in the first step for steam extraction, and filtration is conducted to obtain an extraction solution; S3, concentration and drying of the extraction solution, wherein the extraction solution of the third step is concentrated and dried to obtain an extract containing rosin and dihydroquercetin; S4, recrystallization, wherein the extract containing the rosin and dihydroquercetin is recrystallized to obtain the refined rosin and dihydroquercetin separately. The method has the advantages that the material is directly used without being dried, the method is economical and environmentally friendly, many products are generated, the yield is high, solvents are not needed in all the processes, and the method is low in cost and suitable for industrial large-scale production.

Owner:吉林省五行泰和药业有限公司

Simple method for manufacturing honeycomb core by textile wastes

InactiveCN103182800AEasy to shapeSimple processLamination ancillary operationsLaminationScrapHoneycomb

The invention discloses a simple method for manufacturing a honeycomb core by textile wastes, which is characterized in that the method comprises the following steps of: (1) manufacturing of a fiber board spaced by fibrofelt by using textile wastes, that is, firstly cutting and opening textile wastes to recover the textile wastes into reprocessing fibers, wherein thermoplastic textile wastes is well mixed with common textile wastes in proportion; preparing a fiber net by using the obtained reprocessing fibers; preheating the prepared fiber net, molding with a mold with grooves, cooling to obtain the fiber board spaced by fibrofelt; (2) processing of a honeycomb core blank, that is, coating adhesive tapes on the fiber board spaced by fibrofelt manufactured in step (1), bonding together layer by layer to obtain the honeycomb core blank; (3) processing of the honeycomb core: cutting the honeycomb core blank obtained in step (2) into honeycomb core blank strips with a required height, stretching at the cross sections, expending the honeycomb core blank strips to obtain the honeycomb core. The method can make use of hard textile wastes, and the honeycomb core is easy to mold, accurate in structure, and simple in process.

Owner:JIANGNAN UNIV

Method for producing edible grade EDTA disodium

InactiveCN1561822AAppropriate proportionHigh temperature in the early stage of reactionFood preparationAcetic acidChloroacetic acids

A method for producing edible EDTA-2Na includes neutralizing reaction between chloroacetic acid and sodium carbonate, condensing reaction on ethyldiamine, using acid to regulate acidity to obtain EDTA, and reaction on sodium hydroxide to obtain EDTA-2Na.

Owner:广州市微生物研究所

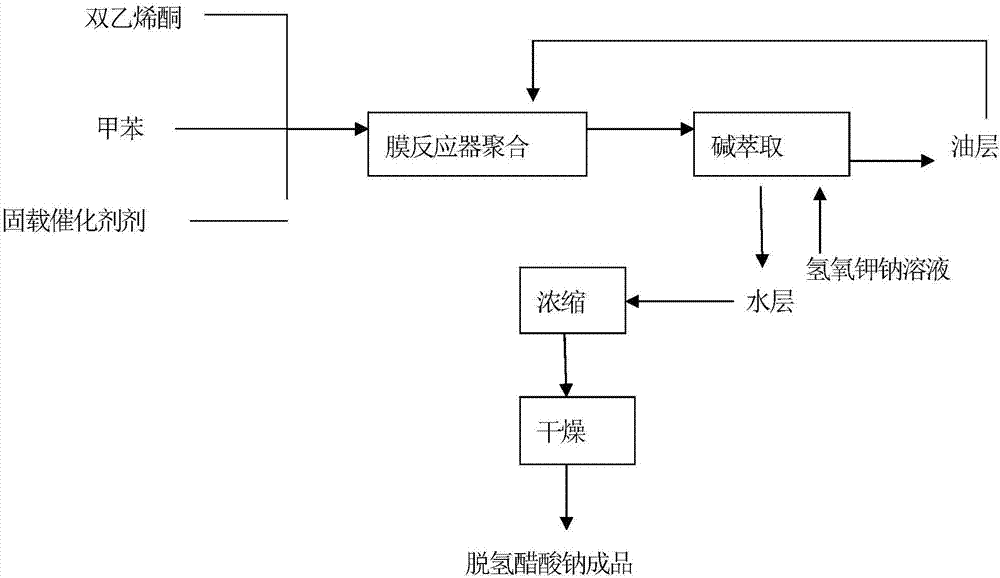

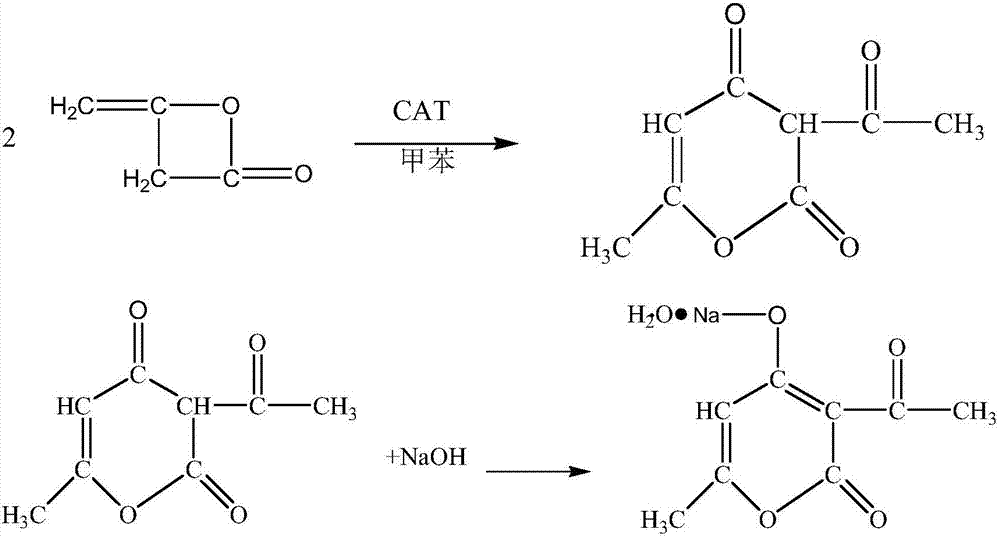

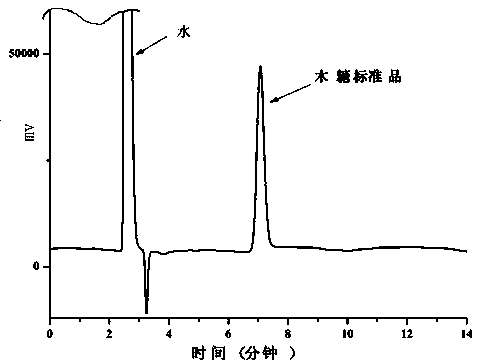

Technology for preparing sodium dehydroacetate in membrane reactor with immobilized catalyst

ActiveCN107987045AHigh catalytic activityHigh selectivityOrganic chemistryMolecular sieve catalystsAqueous sodium hydroxideReaction temperature

The invention discloses a technology for preparing sodium dehydroacetate in a membrane reactor with an immobilized catalyst. The technology comprises the following steps: firstly, pumping methylbenzene into the ceramic membrane reactor filled with the immobilized catalyst, adding ketene dimmer within 0.5 to 1 h, enabling the feeing mass ratio of ketene dimmer to methylbenzene to be 1:(5 to 15), controlling the reaction temperature to be 50 to 70 DEG C, and controlling the pressure of the reactor to be 0.8 to 2 MPa, wherein the addition quantity of the catalyst is 0.5wt% to 3wt% of total feeding quantity, the immobilized catalyst is prepared with an impregnation method; when the HPLC content of ketene dimmer in the reaction solution is greater than or equal to 0.5%, after a polymerization reaction ends, enabling a penetrating fluid to enter into a sodium hydroxide water solution used for an extraction tower for carrying out an extraction reaction according to the mole ratio of ketene dimmer to sodium hydroxide being 1:(1 to 1.5), concentrating a sodium dehydroacetate solution, and carrying out drying, smashing and product packaging at the temperature of 90 to 105 DEG C, wherein theyield of the prepared sodium dehydroacetate is greater than or equal to 99%, and the product content is greater than or equal to 99.8%. According to the technology, the production cost is effectivelyreduced, the quantity of three wastes during production is reduced, and the prepared sodium dehydroacetate is high in yield.

Owner:NANTONG ACETIC ACID CHEM

Method for refining dihydroquercetin from larch

The invention discloses a method for refining dihydroquercetin from larch by using micro-porous resin. The method comprises the following steps: (1) after crushing the raw material larch wood, adding ethanol water solution to extract, collecting extracting solution and concentrating to obtain extract; (2) performing liquid phase adsorption separation on the extract by using micro-porous resin MCI, performing gradient elution by taking the ethanol water solution with volume fraction of 0-30 percent as an eluant, collecting and combining elution components with volume fraction of 20-25 percent, concentrating and drying to obtain a dihydroquercetin rough product; and (3) recrystallizing the dihydroquercetin rough product to obtain refined dihydroquercetin. According to the method, environment-friendly solvents such as water and ethanol are adopted, are pollution-free and can be recycled; the used adsorbent micro-porous resin introduces less impurities and can be reused for times; the obtained product has purity of greater than 99 percent and has no toxic ingredient residues, and the pharmaceutical-grade raw material can be directly obtained. The method has the advantages of simple route, economy, environmental friendliness and high yield and is suitable for industrial production.

Owner:PEKING UNIV +1

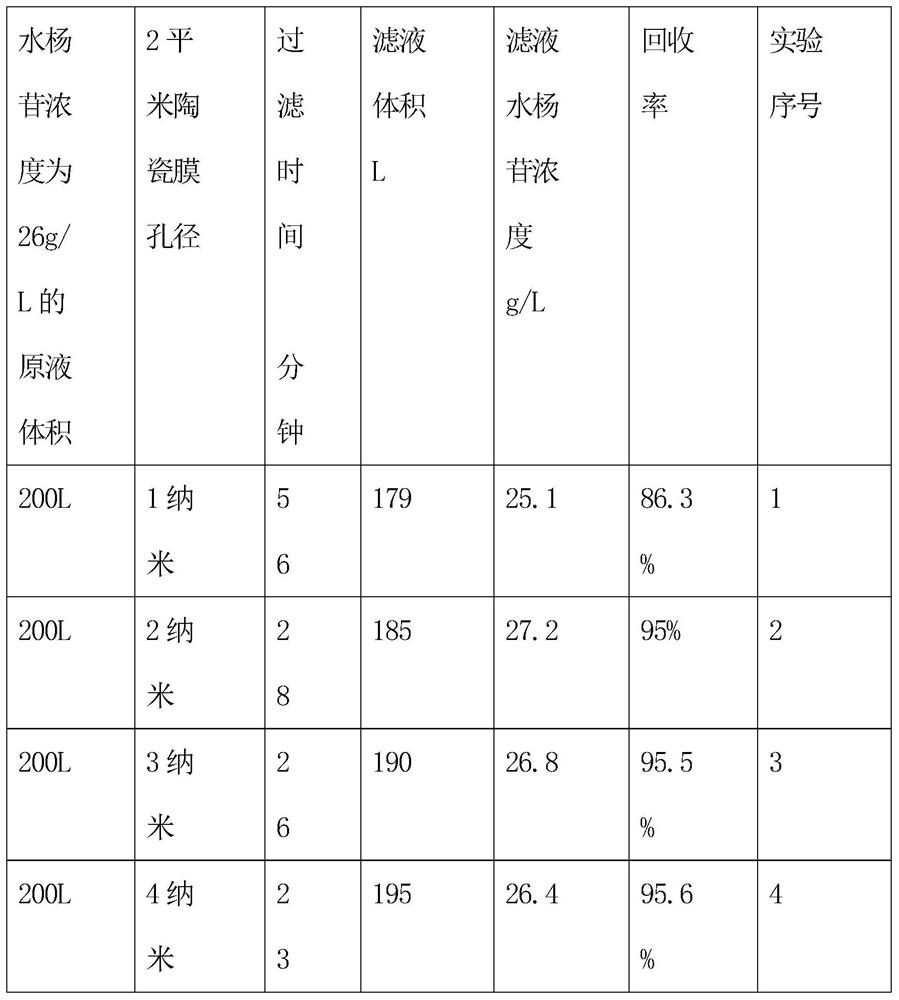

Method for extracting, separating and refining salicin from willow

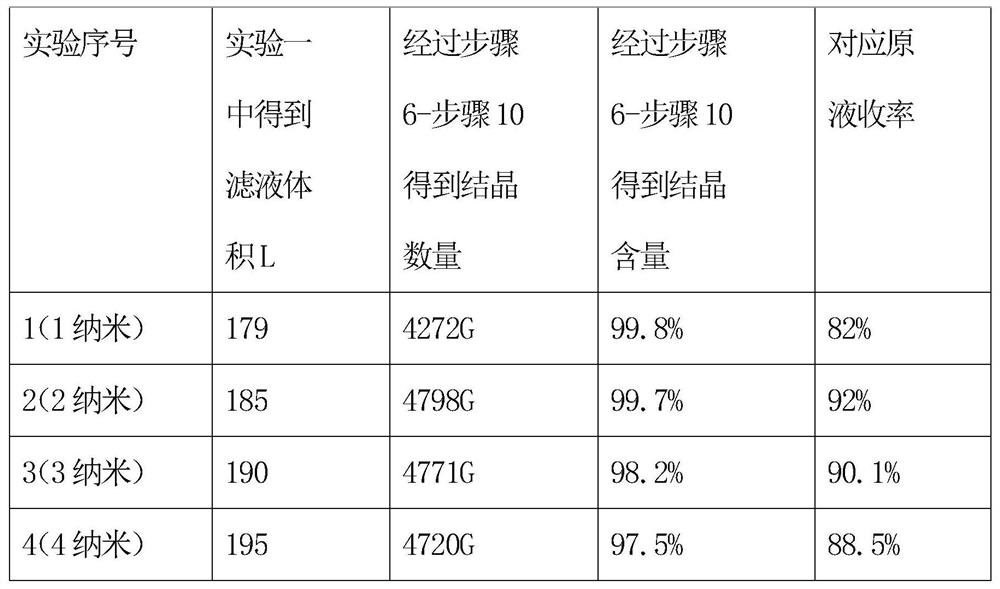

ActiveCN111647025AReduce cloggingReduce pollutionSugar derivativesSugar derivatives preparationAlcohol ethylCross-flow filtration

The invention discloses a method for extracting, separating and refining salicin from willow, and relates to the technical field of extraction and separation. The method comprises the following stepsof adding quick lime accounting for 8% of the weight of raw materials, sufficiently and uniformly stirring the quick lime, detecting the water content of the raw materials by using a rapid instrument,and spraying a proper amount of water; adding an ethanol solution with the concentration of 75% and the amount 7 times that of the raw materials, performing reflux extraction for 2 hours, and recovering an extracting solution; recovering ethanol from the extracting solution under reduced pressure until no alcohol exists, and performing standing to the room temperature to obtain a salicin aqueoussolution; carrying out dynamic cross-flow filtration on the aqueous solution by using a rotary ceramic membrane with the aperture of 2 nanometers, and collecting a filtrate; feeding the filtrate intoa refrigerating chamber for crystallization; and performing separation by using a centrifugal machine, collecting crystals, and performing drying to obtain salicin coarse crystals. According to the method, the alcohol consumption can be reduced, the time is saved, the production cost is reduced, and the salicin content of a prepared product can reach 99.5% or above.

Owner:甘肃天顺植物科技有限公司

A one-step chromogenic screening method for prohibited azo dyes in dyed textiles

ActiveCN104897665BQuick screeningSimple screening methodMaterial analysis by observing effect on chemical indicatorScreening methodChromogenic

The invention discloses a one-step color-development screening method for banned azo-dye in dyeing textiles. The one-step color-development screening method comprises the following steps: (1) reducing a sample; (2) color-development, to be specific, at the same position of filter paper, dripping a drop of a color-developing agent, and then dripping 1-2 drops of tert-butyl methyl ether extracting solution for color development, wherein the color-developing agent is an ethanol solution comprising paradimethylaminobenzaldehyde with the mass-volume ratio of 0.1-10% and hydrochloric acid with the volume ratio of 10-25%; (3) screening and determination, to be specific, judging results according to the fact that whether obvious color change occurs or not after dripping the sample solution on the color-developing agent, wherein if no obvious color change occurs after color development of the sample solution, the sample does not contain a substance to be detected or the concentration of the substance to be detected is lower than the detection limitation, and the result is negative; if obvious color change occurs after color development of the sample solution, the sample is likely to contain the banned azo-dye, the result is positive, and further confirmation is required to be carried out by a chromatographic apparatus. The one-step color-development screening method is simple and fast, the sample can be directly subjected to color-development to be determined after being reduced, and the whole color development process can be completed within 1 min.

Owner:INSPECTION & QUARANTINE TECH CENT SHANDONG ENTRY EXIT INSPECTION & QUARANTINE BUREAU

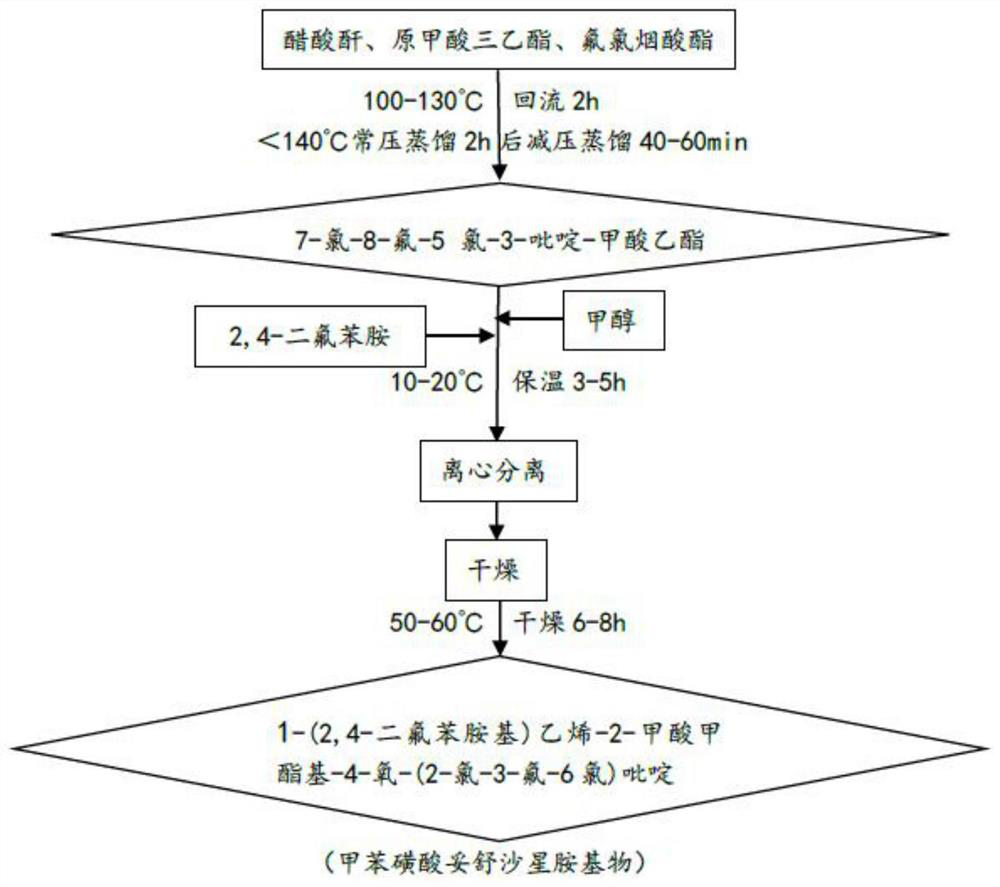

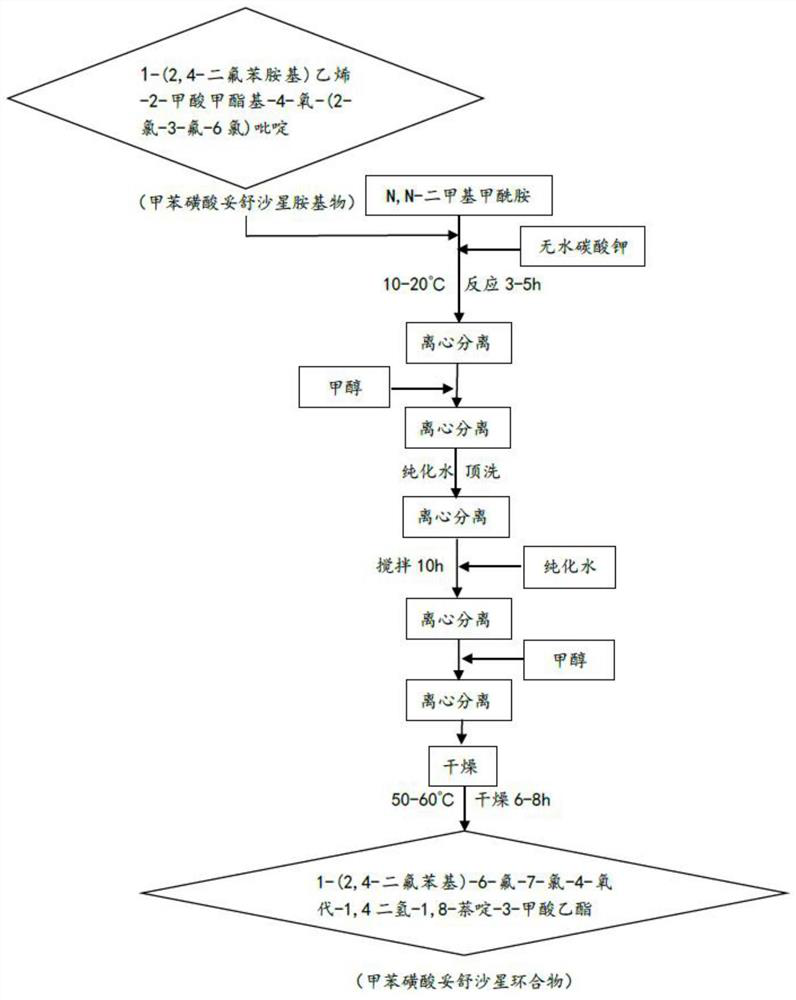

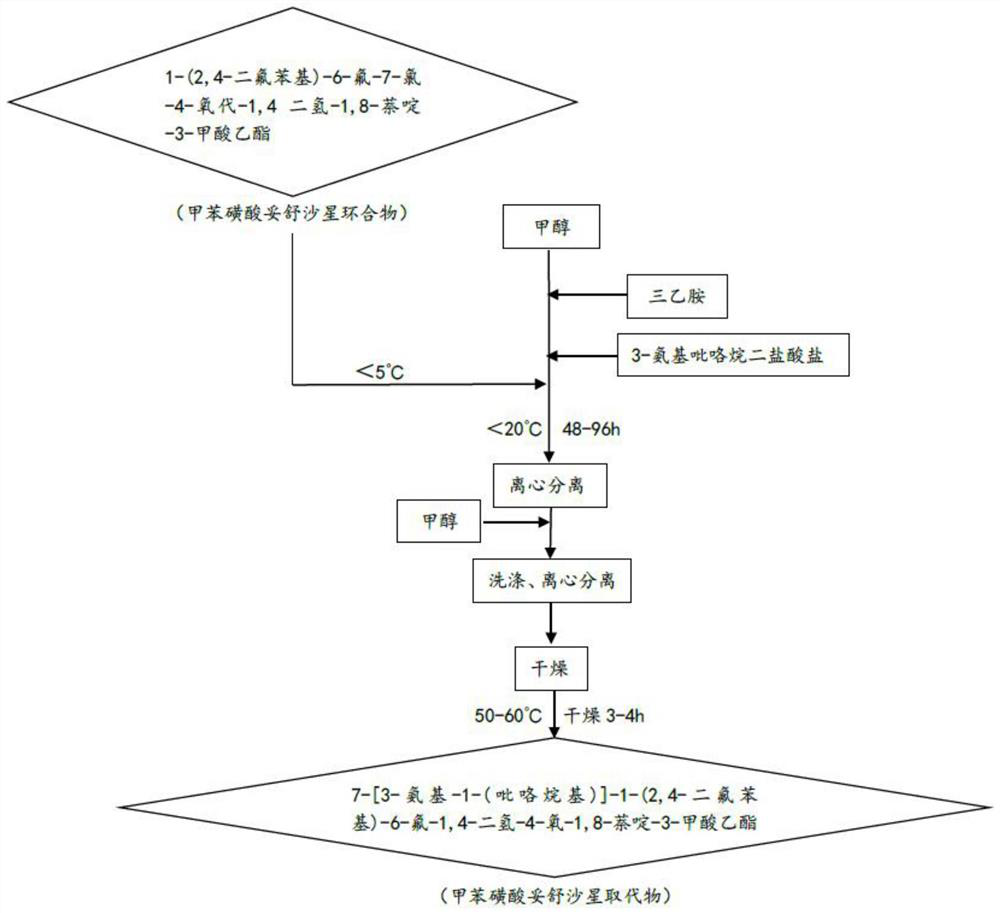

Tosufloxacin tosylate and preparation method thereof

PendingCN114369092AHigh purityHigh yieldOrganic compound preparationSulfonic acids salts preparationAcetic anhydrideNiacin

The invention provides tosufloxacin tosylate and a preparation method thereof, and the preparation method comprises the following steps: taking acetic anhydride, triethyl orthoformate, fluorine chloronicotinate, methanol and 2, 4-difluoroaniline as initial raw materials, and carrying out amination reaction to prepare tosufloxacin tosylate amido; based on the amino substance, preparing a tosufloxacin tosylate cyclization compound through cyclization reaction; preparing a tosufloxacin tosylate substitute through a substitution reaction on the basis of the cyclization compound; based on the substitutes, preparing a tosufloxacin tosylate crude product through a hydrolysis salt-forming reaction, and refining to obtain tosufloxacin tosylate. The preparation method covers all steps of a tosufloxacin tosylate synthesis route, a complete production chain is formed by designing all the steps of the synthesis route, and the prepared tosufloxacin tosylate is low in impurity content, high in purity and high in yield and meets the high-quality requirement of the medicine field for medicines.

Owner:赤峰万泽药业股份有限公司

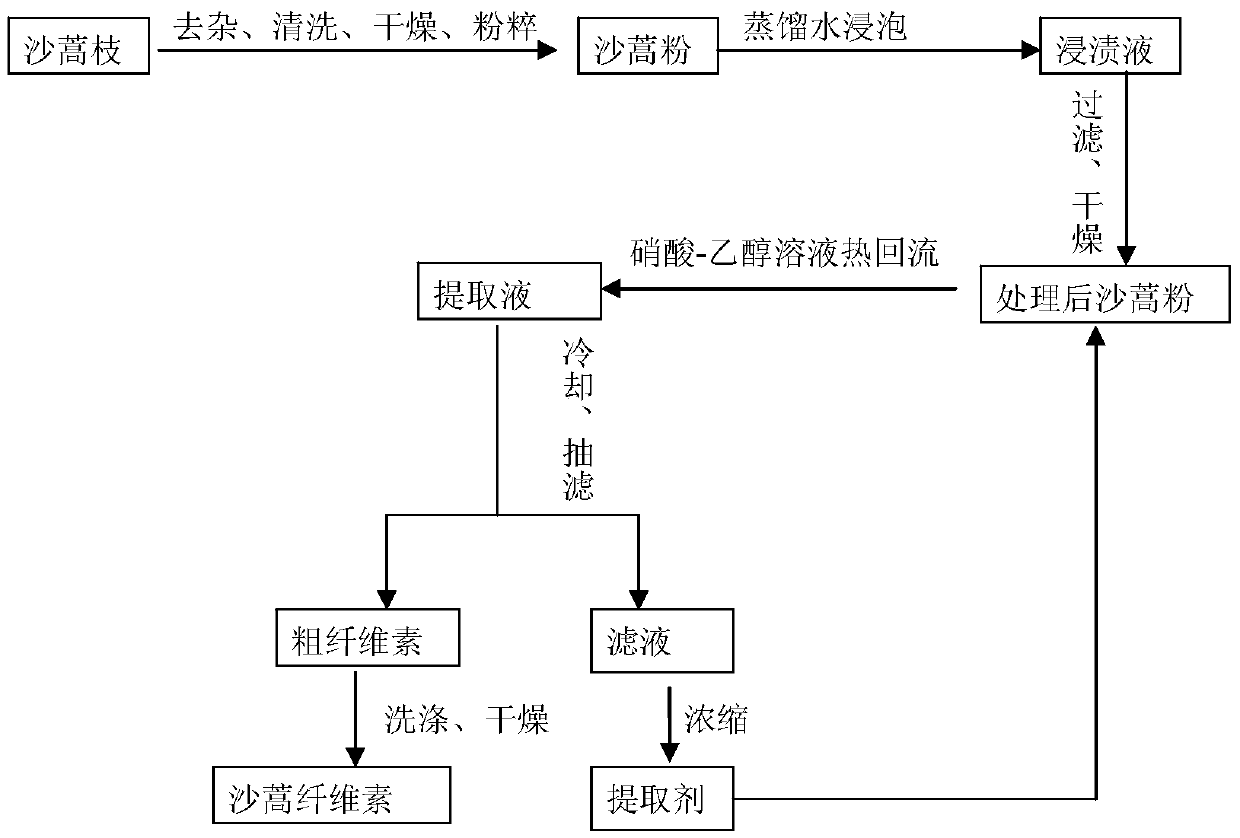

Method for extracting cellulose of Artemisia desertorum

InactiveCN105507050AHigh purityReduce hydrolysisPulping with organic solventsNon-woody plant/crop pulpCelluloseReflux extraction

A method for extracting cellulose of Artemisia desertorum comprises steps as follows: step 1, Artemisia desertorum is cleaned after impurities are removed; step 2, the cleaned Artemisia desertorum branches are dried, crushed and sieved, and Artemisia desertorum powder is obtained; step 3, the Artemisia desertorum powder is soaked in distilled water and decolored, and the ratio of a material to a liquid is 1:10; a product is dried for standby use; step 4, a nitric acid mixed solution with 95% ethanol as a solvent is added to the decolored Artemisia desertorum powder, the mass percentage of nitric acid is 10%-40%, and the mixture is subjected to reflux extraction at the temperature of 60-100 DEG C; step 5, an extract is cooled and subjected to suction filtration, a filter cake is washed to be neutral and dried, and the cellulose of the Artemisia desertorum is obtained. The extraction method is simple, a reagent is recyclable, pollution-free and environment-friendly, and the cellulose has high yield and good purity.

Owner:YULIN UNIV

A kind of environment-friendly food packaging paper

ActiveCN104032625BGood for healthNo decolorization requiredNon-fibrous pulp additionFlexible coversPullulanSterile water

The invention belongs to the technical field of papermaking, and particularly relates to an environment-friendly food packaging paper, which is made of the following raw materials in parts by weight: 100 parts of dry rice straw, 1-4 parts of pullulan, 1-4 parts of coagulated polysaccharide, glucomannan 0.12-0.18 parts of sugar and 40-50 parts of sterile water are prepared by crushing, refining, steaming, forming into film-shaped paper, and drying. It is environmentally friendly, natural, non-toxic, and hygienic.

Owner:ANQING TIANRUN PAPER PACKAGING

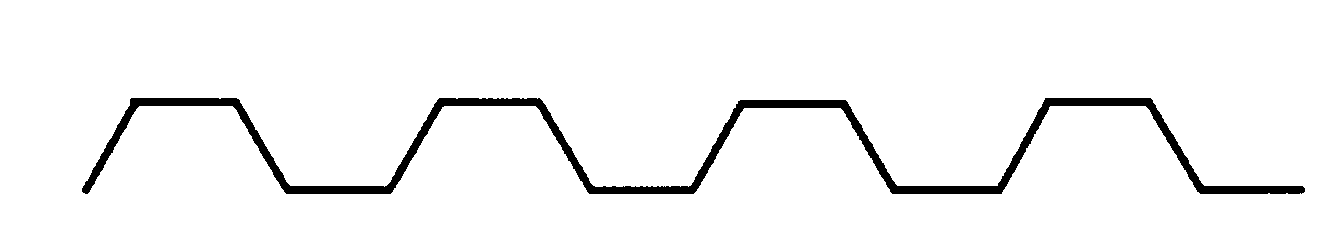

Method of manufacturing honeycomb core by spinning waste hot-press laminating

InactiveCN103158324APrecise structureReduce heat consumptionLamination ancillary operationsLaminationScrapHoneycomb structure

The invention discloses a method of manufacturing a honeycomb core by spinning waste hot-press laminating. The method is characterized in that the method comprises a first step of manufacturing a flattop wave fibreboard using the spinning waste; a step of reverting the spinning waste into reprocessing fiber by cutting and opening the spinning waste, and mixing the thermoplastic spinning waste and the normal spinning waste fully in proportion; a step of manufacturing fiber nets using the obtained reprocessing fiber; a step of dealing with the fleece with preheating, mould pressing and cooling in order to manufacture the flattop wave fibreboard with a honeycomb structure; a second step of laminating and cutting a waved plate; a step of coating adhesive tapes on a wave peak of the flattop wave plate which are obtained from the first step and laminating the wave plate, comprising a way of bonding the upper layer of the wave plate with the peak of the wave plate adjacent to the upper layer in order to gain lamination of the wave plate; a step of cutting section of the lamination of the wave plate to gain the honeycomb core according to height of the honeycomb core. The method has the advantages of using rigid spinning waste, and being accurate in honeycomb core structure, little in heat exhaustion because of heating once and short in craft by relatively laminating tensile method.

Owner:JIANGNAN UNIV

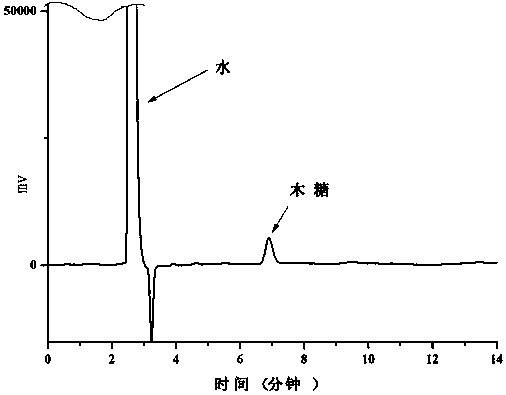

A kind of extraction method of xylan in hickory nut shell

The invention discloses a method for extracting xylan from hickory shells. The method comprises the following steps: adding hickory shell powder and a solid phase reagent into a ball mill, grinding the hickory shell powder and the solid phase reagent to obtain ball-milled mixed powder, adding a limited volume of water to the powder, vibrating and centrifuging the obtained solution, collecting theobtained supernatant, and freeze-drying the supernatant to obtain the xylan. The hickory shell powder and the solid phase reagent are commonly ground and crushed under the action of high-energy mechanical force, and water is as the solvent in the extraction process, so the emission of a waste liquid is reduced, the obtained xylan has the advantages of high purity, remarkably improved content of xylose in monosaccharide compositions, good color and no decolorizing, the process flow is simplified, and the production cost is reduced. The method has the advantages of simplicity in operation, shortextraction time, mild extraction conditions, high efficiency, low energy consumption, environmental protection, and easiness in large-scale industrial production, is a method for preparing xylan fromhickory shells, having a good promotion and application prospect, and lays a foundation for the further development and utilization of the xylan in the hickory shells.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com