Synthesis method of phosphate

A synthesis method and phosphoric acid ester technology, which are applied in the fields of phosphorus organic compounds, chemical instruments and methods, and compounds of Group 5/15 elements of the periodic table, etc. Problems such as poor reproducibility of color and luster products, to achieve the effects of product stability, mild conditions and high esterification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

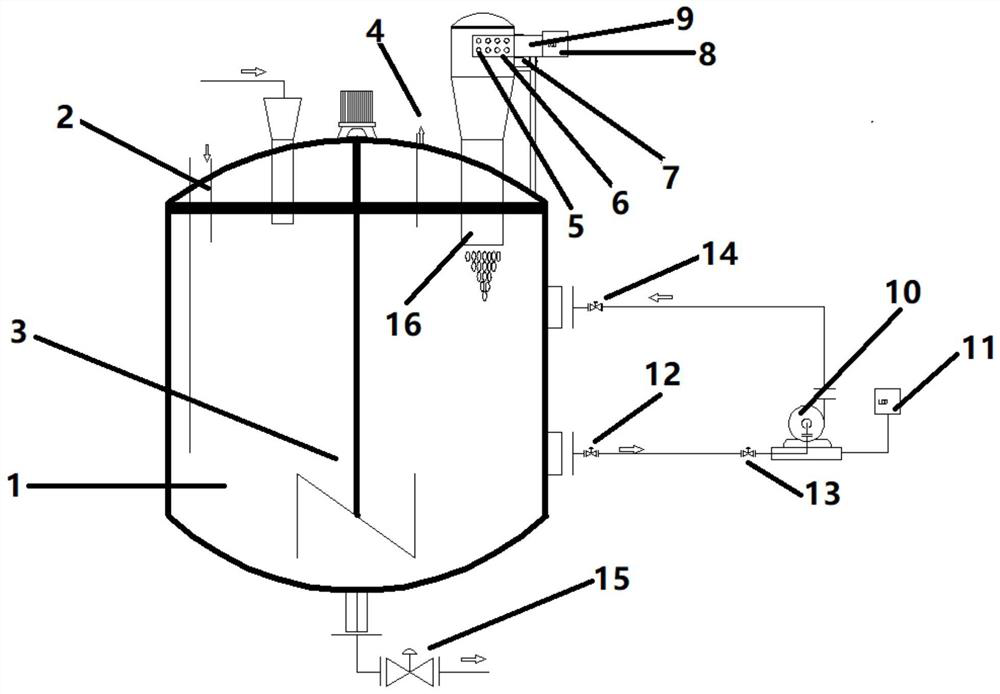

[0029] A kind of synthetic method of phosphoric acid ester, comprises the steps: with 15kg fatty alcohol polyoxyethylene ether (C 12 h 25 (OC 2 h 4 ) 2 OH) into the reactor, the 2.7kg P 2 o 5 Add the feeding box, set the temperature of the reaction kettle to 40°C, set the rotation speed of the feeding box to 25r / s through the smart display 7, and finish adding in 2 hours. 2 o 5 During the feeding process, the circulation pump is started at the same time, and the speed of the external circulation of the circulating liquid is controlled by the intelligent display screen 11 to 8ml / s, P 2 o 5 After the addition, the temperature of the reaction vessel was raised to 70° C., and the reaction was continued for 6 hours to end the reaction to obtain a colorless transparent phosphoric acid ester.

[0030] Use QB / T 2949-2008 phosphoric acid ester to measure the content of phosphoric acid ester active matter, use the potentiometric titration method in Song Minggui's "Synthesis of F...

Embodiment 2

[0032] A kind of synthetic method of phosphoric acid ester, comprises the steps: with 6.25kg fatty alcohol polyoxyethylene ether (C 12 h 25 (OC 2 h 4 ) 2 OH) into the reactor, the 1.25kg P 2 o 5 Add the feeding box, set the temperature of the reaction kettle to 50°C, set the rotation speed of the feeding box to 12r / s through the smart display 7, and finish adding in 2 hours. 2 o 5 During the feeding process, the circulation pump is started at the same time, and the speed of the external circulation of the circulating liquid is controlled by the intelligent display screen 11 to 4ml / s, P 2 o 5 After the addition, the temperature of the reaction vessel was raised to 80° C., and the reaction was continued for 5 hours to end the reaction to obtain a colorless phosphoric acid ester.

[0033]After testing, the content of the obtained phosphoric acid ester active substance is 98.2%, wherein the phosphoric acid monoester content is 33.4%, the phosphoric acid diester content is ...

Embodiment 3

[0035] A kind of synthetic method of phosphoric acid ester, comprises the steps: with 10kg tristyrene phenol polyoxyethylene ether (C 50 h 82 o 17 ) into the reactor, the 2kg P 2 o 5 Add the feeding box, set the temperature of the reaction kettle to 55°C, set the rotation speed of the feeding box to 18r / s through the smart display 7, and finish adding in 2 hours. 2 o 5 During the feeding process, the circulating pump is started at the same time, and the speed of the external circulation of the circulating liquid is controlled by the intelligent display screen 11 at 6ml / s, P 2 o 5 After the addition, the temperature of the reactor was raised to 85° C., the reaction was continued for 7 hours, and the reaction was terminated to obtain light yellow phosphoric acid ester.

[0036] After testing, the content of the obtained phosphoric acid ester active matter is 83.2%, wherein the phosphoric acid monoester content is 27.4%, the phosphoric acid diester content is 52.1%, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com