One-step color-development screening method for banned azo-dye in dyeing textiles

A technology for banning azo and textiles, applied in the field of analytical chemistry, can solve the problems of complex processing, long time, harsh detection conditions, etc., and achieve the effect of broad application prospects, simple technology, and easy to master.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

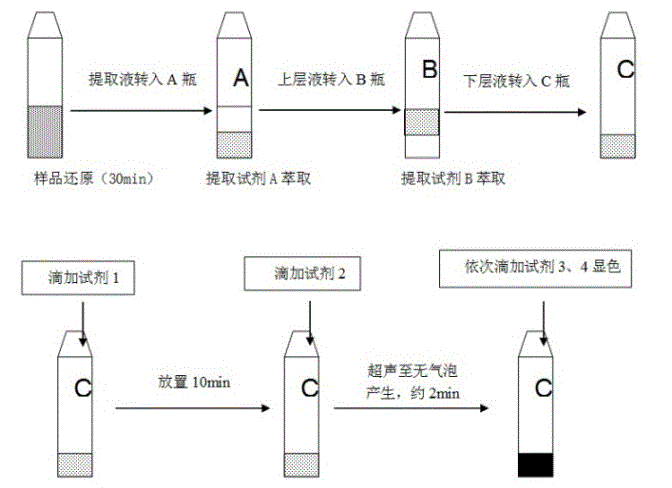

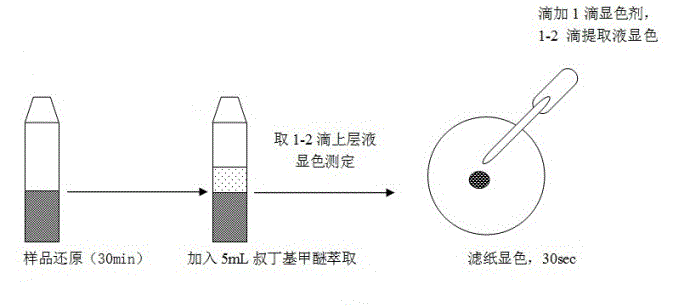

Method used

Image

Examples

Embodiment 1-29

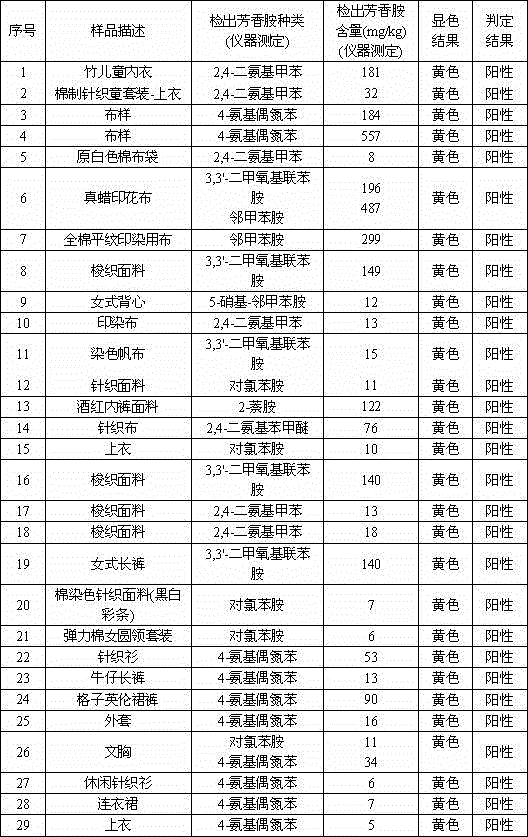

[0026] Embodiment 1-29: Test results of 29 actual fabric samples

[0027] First, the developer formula: dissolve 1g of N,N-dimethyl-4-aminobenzaldehyde in 75mL of ethanol, add 25mL of hydrochloric acid, mix well before use.

[0028] Secondly, the collected instruments were detected to contain 2-naphthylamine, p-chloroaniline, o-toluidine, 3,3'-dimethoxybenzidine, 5-nitro-o-toluidine, 2,4-diamino 8 kinds of banned aromatic amines such as toluene, 2,4-diaminoanisole and 4-aminoazobenzene, the content ranges from 29 cloth samples of 5 mg / kg-557 mg / kg, and is measured according to the steps of the present invention , are all colored, the detection rate of this method is 100%, and there is no false negative. Specific steps are as follows:

[0029] (1) Reduction of samples: Weigh 2.0 g of chopped representative samples into a reaction bottle, add 16 mL of citrate buffer solution (0.06 mol / L, pH=6) and 3.0 mL of sodium dithionite solution (200 mg / L mL, ready-to-use), seal the reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com