A kind of extraction method of xylan in hickory nut shell

A pecan shell and extraction method technology, which is applied in the production and technical application fields of plant polysaccharides, can solve the problems such as the destruction or degradation of xylan molecules, the high residual rate of pigments and impurities, and the complex decolorization and purification process, and achieves mild extraction conditions. , high product purity, reducing the effect of extraction process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

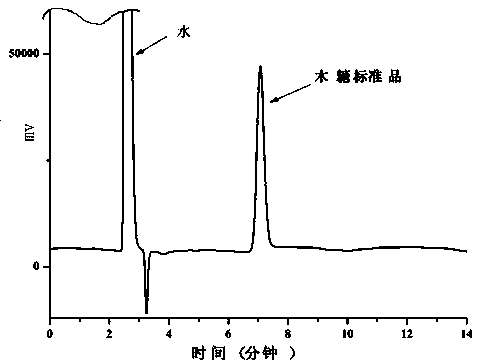

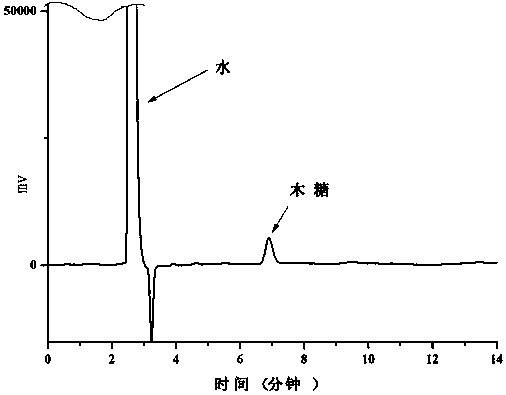

[0026] Put 4 g of pecan shell powder, 0.2 g of calcium carbonate and 0.2 g of talc into a ball mill, and mill at a speed of 400 rpm for 1 h; weigh 0.75 g of ball mill powder, add 30 mL of water to the obtained ball mill powder, and heat at 50 °C, Under the condition of 150 rpm, the shaking time was 1 h, centrifuged, the filtrate was collected, and freeze-dried to obtain xylan, its HPLC spectrum was as follows: figure 2 As shown, the peak time of its xylan is the same as figure 1 The peak elution time of the standard xylan shown is the same, according to the results of HPLC, combined with the yield of xylan and the calculation method of xylose content, the calculated yield is 9.7%, and the purity is 50.2%.

Embodiment 2

[0028] Put 4 g of hickory nut shells, 0.2 g of microcrystalline cellulose and 0.2 g of talc into a ball mill, and mill at a speed of 400 rpm for 2 h; weigh 0.75 g of ball-milled powder, add 30 mL of water to the obtained ball-milled powder, and heat at 50 °C 1. The shaking time was 1 h at a speed of 150 rpm, centrifuged, the filtrate was collected, and freeze-dried to obtain xylan with a yield of 11.9% and a purity of 48.2%.

Embodiment 3

[0030] Put 8 g of pecan shell powder, 0.4 g of calcium carbonate and 0.4 g of microcrystalline cellulose into a ball mill, and mill at a speed of 800 rpm for 2 h; weigh 0.5 g of ball mill powder, add 20 mL of water to the obtained ball mill powder, and Under the conditions of 150 rpm and 150 rpm, the shaking time was 1 h, centrifuged, the filtrate was collected, and freeze-dried to obtain xylan with a yield of 23.9% and a purity of 56.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com