Material blank for clothes, especially for underwear

A technology for blanks and clothes, applied in the field of clothes material blanks and clothes according to claim 18, can solve the problems of high production cost, limited wearing comfort, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

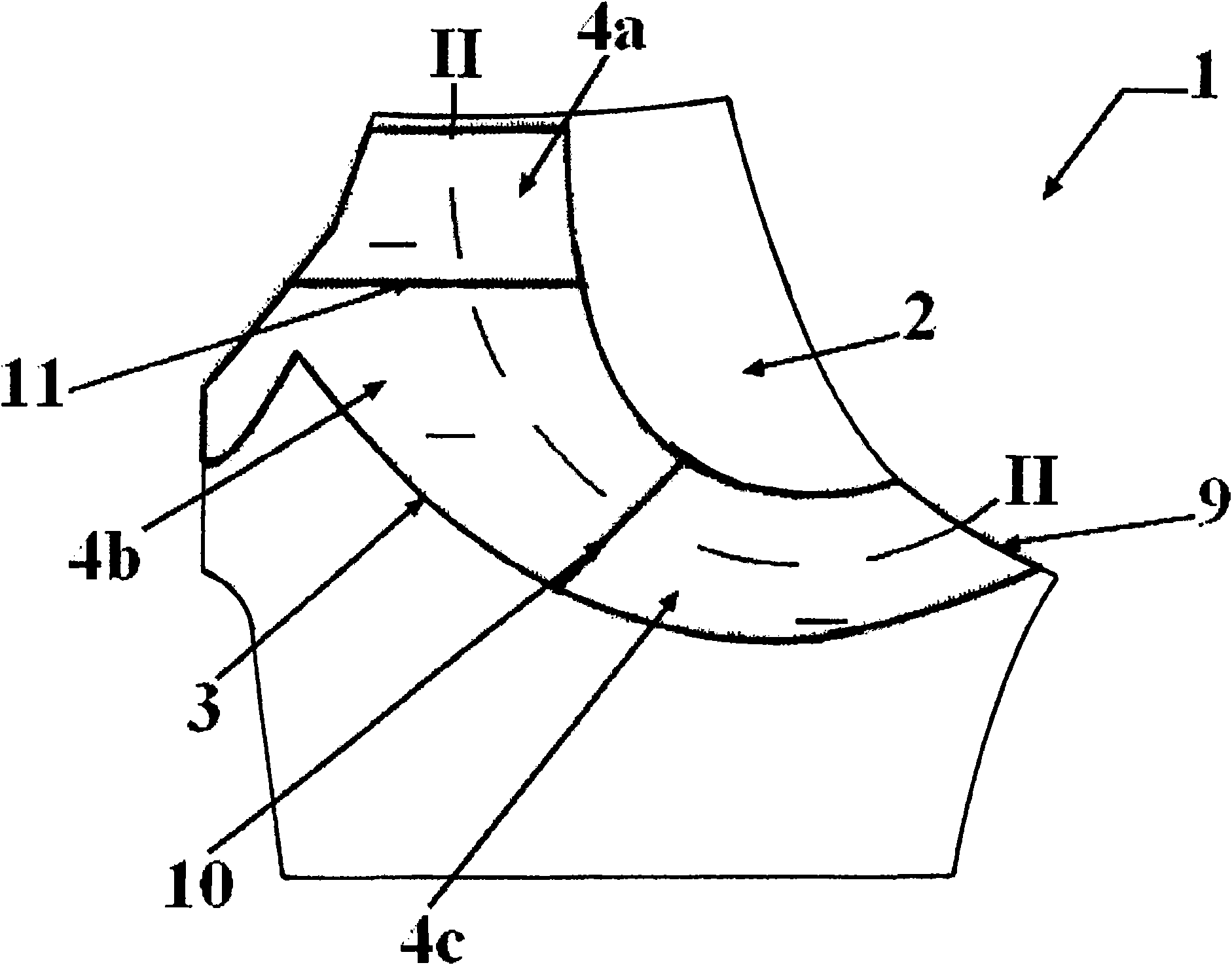

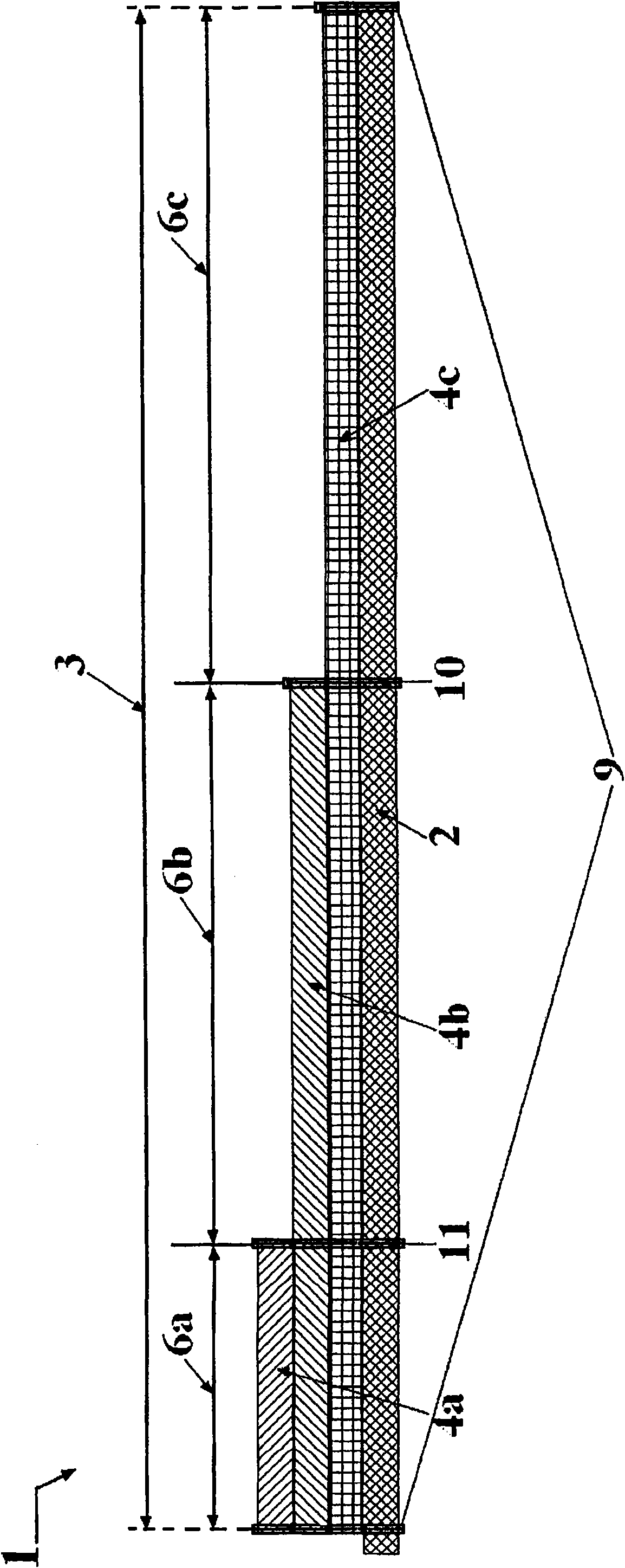

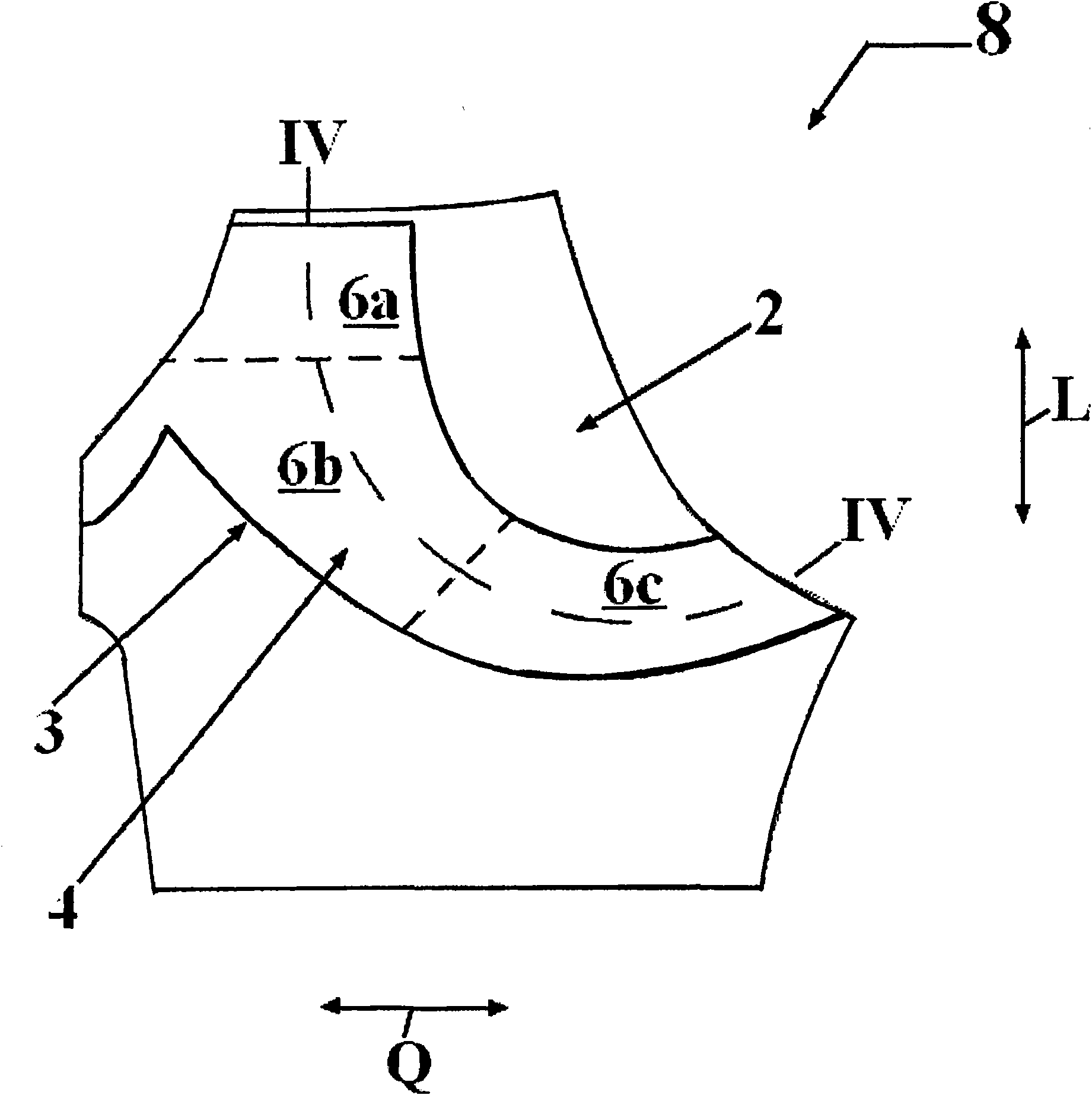

[0024] figure 1 A material blank 1 known from the prior art is shown consisting of an upper material 2 which is covered in one-sided, continuous reinforcement regions 3 with various lower material layers 4a, 4b, 4c. Material blank 1 based on figure 1 The embodiment shown in can be cut in reverse and reinforced material blanks and other decorative material parts in the middle connection area of the two material blanks can be sewn into tights, wherein the upper material 2 constitutes tights facing away from the wearing The outer side of the wearer, while the reinforced area 3 is attached to the wearer's skin from the inside and invisibly with the lower material layers 4a, 4b, 4c installed on it.

[0025] In addition, the upper material 2 and the lower material layers 4a, 4b, 4c are preferably each made of a stretch fabric with an elastic fiber component, so that the tights fit snugly on the wearer's body without the undergarment being exposed outwards through the outer garmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com