Optical fiber connector for field construction

A fiber optic connector and on-site construction technology, which is applied in light guides, optics, instruments, etc., can solve the problems of affecting pre-embedded optical fibers and connectors, lack of circumferential anti-rotation positioning, etc., and achieve the effect of convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

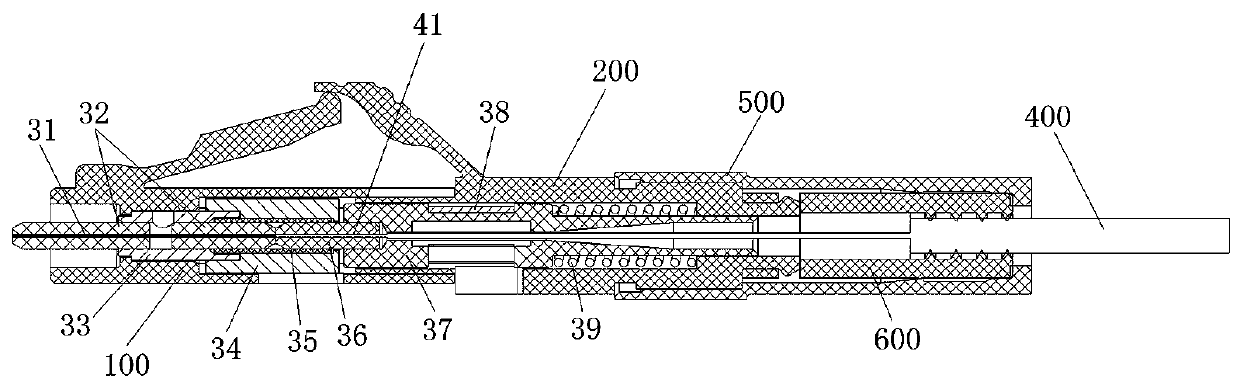

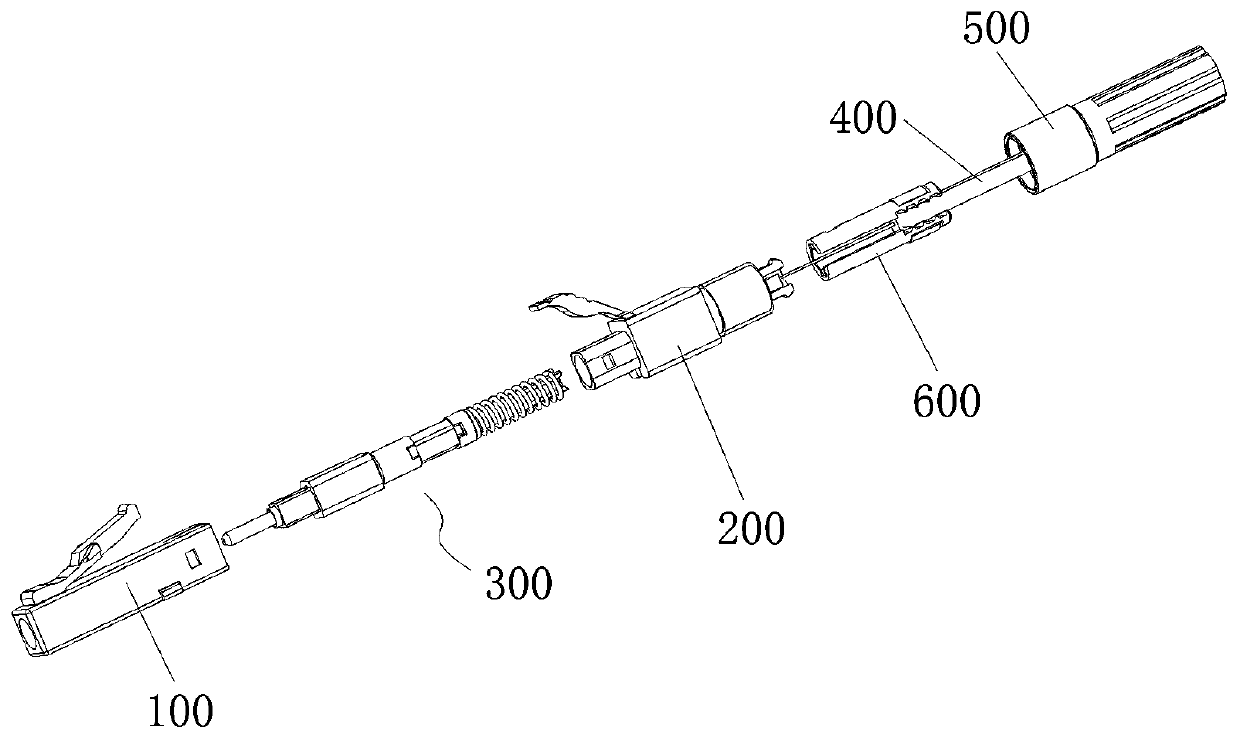

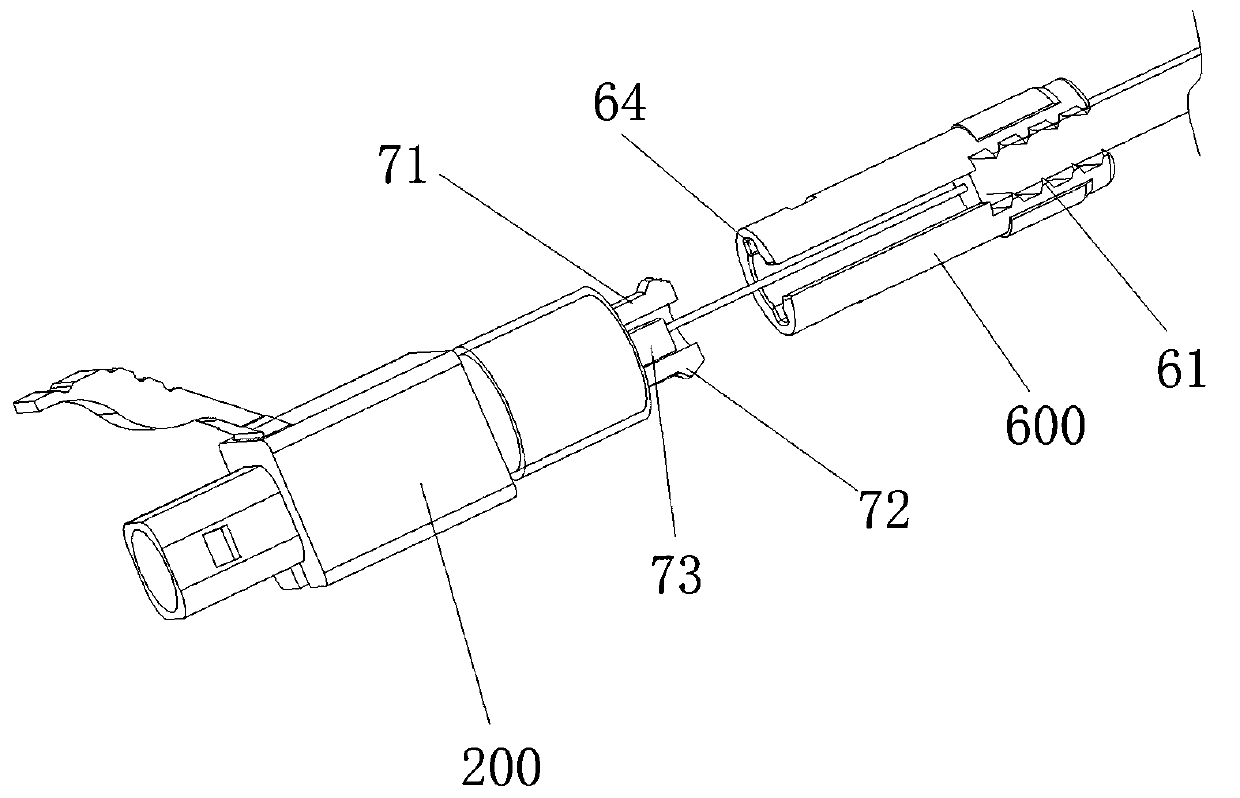

[0024] The specific embodiment of the optical fiber connector of on-site construction of the present invention, as Figure 1 to Figure 5 As shown, the optical fiber connector of the present invention can be assembled on site.

[0025] The optical fiber connector for on-site construction includes a connector housing and a quick-termination assembly 300 fixed in the connector housing. During on-site construction, the optical cable 400 is inserted into the connector housing, and the optical fiber connector also includes a connector for fixing the optical cable 400. End clip 600 and connection nut 500. In this embodiment, the front end of the connector housing is defined as the plug-in end for mating with the adapted fiber optic connector, and the rear end is the terminal.

[0026] like figure 1 and figure 2 As shown, the connector housing includes a fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com