Cleaning vehicle water saving and spraying mechanism and using method thereof

A technology for cleaning vehicles and cleaning mechanisms, which is applied in the direction of cleaning methods, road surface cleaning, spraying devices, etc., and can solve the problems of affecting the line of sight of vehicles in the opposite lane, potential safety hazards, and guardrails being easily eroded by dust, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

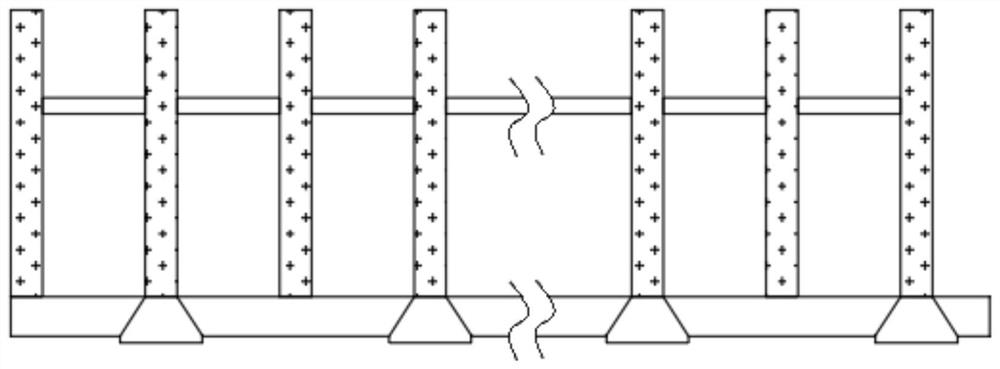

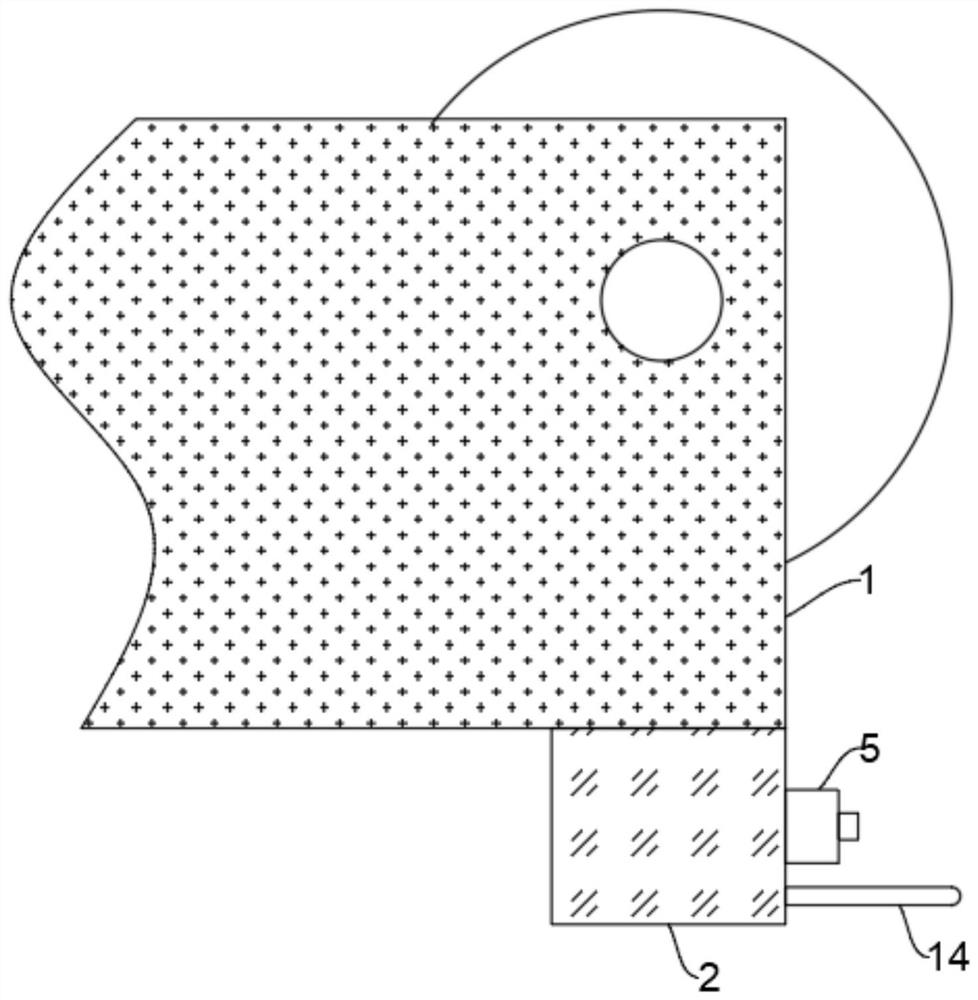

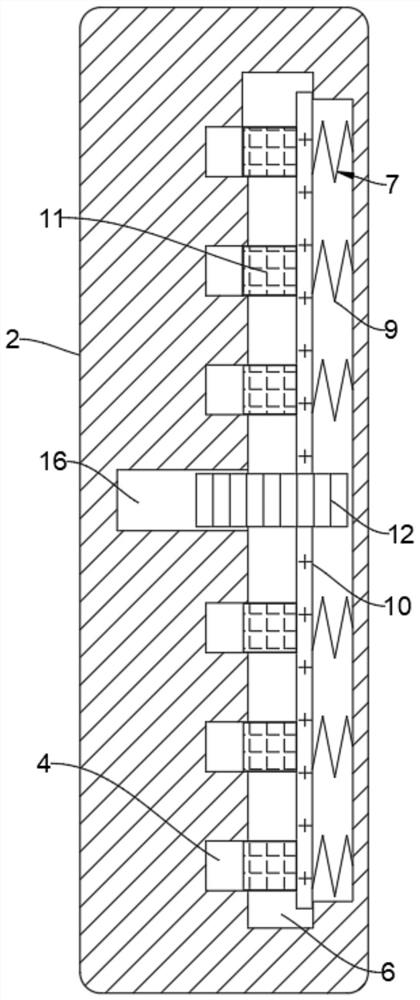

[0039] Such as Figure 1-6 As shown, a water-saving water spray mechanism for a cleaning vehicle and its use method include a cleaning mechanism 1, the cleaning mechanism 1 includes structures such as a cleaning vehicle body and a cleaning roller, the cleaning mechanism 1 is connected with a water spray housing 2, and the water spray housing 2 is provided with a water storage chamber 3, a side wall of the water storage chamber 3 is provided with a plurality of water outlets 4, and the other side of the water storage chamber 3 is provided with a water inlet pipe to ensure constant water pressure in the water storage chamber 3, The water outlet 4 is connected with a nozzle 5 , the side wall of the water outlet 4 is provided with a control chamber 6 , and a control mechanism 7 is provided in the control chamber 6 .

[0040]The control mechanism 7 is made up of a first spring 9, a control board 10 and a sealing strip 11. The first spring 9 is provided with a plurality and is locat...

Embodiment 2

[0053] Such as Figure 7-9 As shown, the difference between this embodiment and Embodiment 1 is that the upper and lower ends of the nozzle 5 are provided with fixed plates 19 fixedly connected to the water spray housing 2, and the nozzle 5 is rotatably connected between the two fixed plates 19. The spray head 5 communicates with the water outlet 4 through a hose.

[0054] The starting position of the shower head 5 is inclined towards the front.

[0055] Both ends of the spray head 5 are fixedly connected with a rotating shaft rotatably connected to the fixed plate 19 , wherein one side of the rotating shaft passes through the fixed plate 19 rotatably connected thereto and extends to the fixed plate 19 and the other side is fixedly connected with a rotating gear 20 .

[0056] The rotating gear 20 is meshed with the second rack 21 with the axis horizontally arranged, the side wall of the water spray housing 2 is provided with a through groove 22 communicating with the control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com