Magnetic suspension support

A magnetic levitation and seat plate technology, applied in the field of magnetic levitation, can solve the problems that the integrity and smoothness of the magnetic levitation system cannot be guaranteed, and achieve the effect of ensuring train operation safety, assembly error assurance, integrity and smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

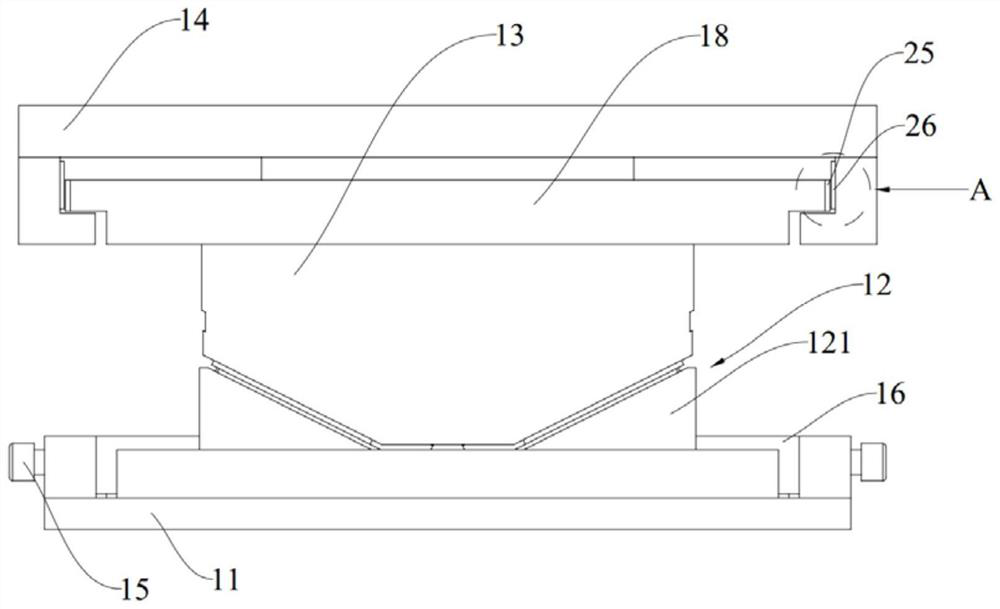

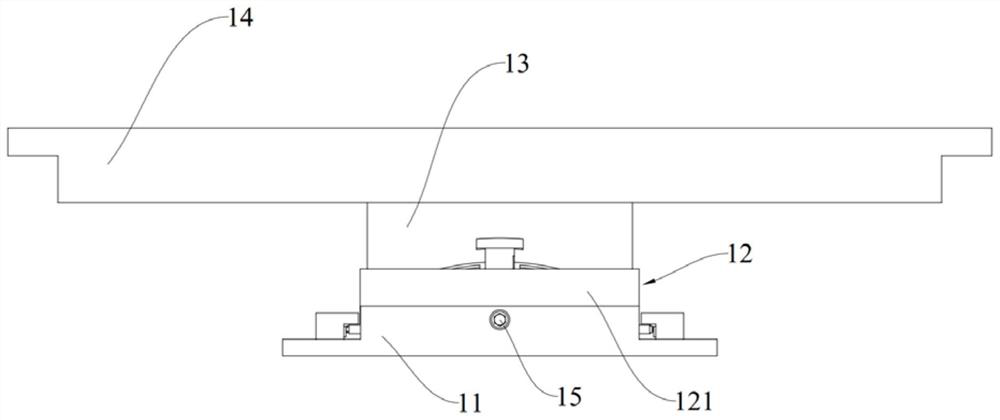

[0045] Such as Figure 1-5 As shown, this embodiment provides a magnetic levitation support, such as used in a vacuum pipeline of a magnetic levitation system. The magnetic levitation support includes a lower seat plate 11 and a position adjusting member 12 . The position adjusting member 12 is slidably arranged on the lower seat plate 11 and can slide relative to the lower seat plate 11 along the transverse direction.

[0046] Optionally, as in Figure 4-7 As shown, the position adjustment member 12 includes two position adjustment sliders 121, and the two position adjustment sliders 121 are arranged symmetrically. The position adjustment sliders 121 are provided with first protrusions 1212 on both sides along the transverse bridge direction. The lower seat plate 11 A second groove 111 cooperating with the first protrusion 1212 is provided on the top, and the first protrusion 1212 can slide relative to the second groove 111 along the transverse direction. The cooperation be...

no. 2 example

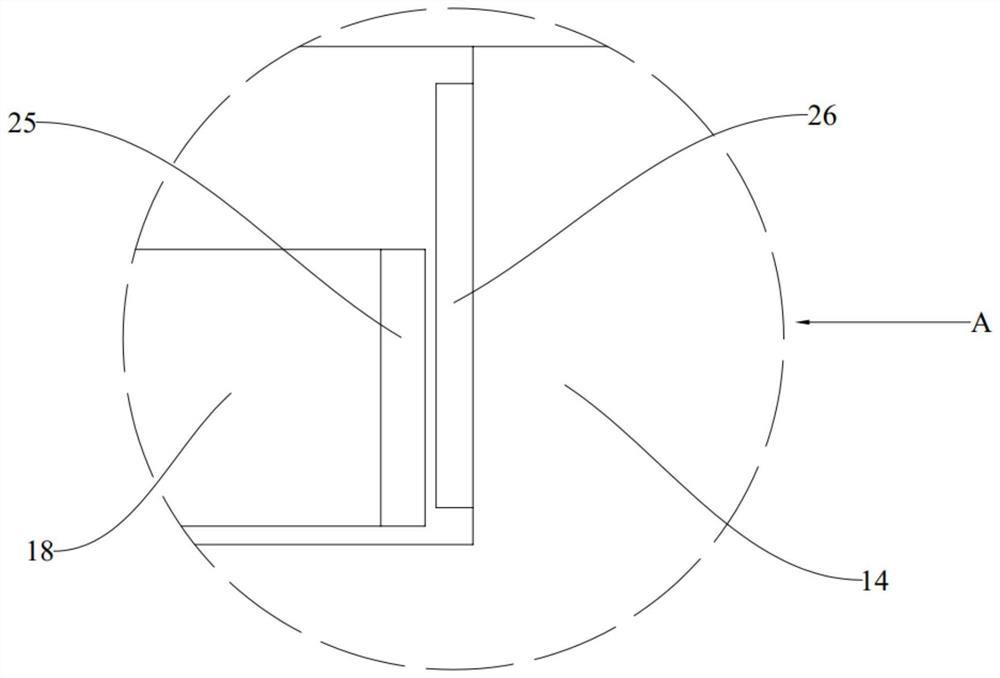

[0063] Such as Figure 14 As shown, this embodiment provides a magnetic levitation support. The structure of the magnetic levitation support of this embodiment is basically the same as that of Embodiment 1, the difference is that the magnetic levitation support of this embodiment also includes an upper seat plate retaining strip 27, two Two upper seat plate retaining strips 27 are respectively fixed on the two ends of the upper seat plate 14 along the bridge direction, and one side of the upper seat plate retaining strips 27 is close to the rotating sleeve 18, so that the rotating sleeve 18 and the upper seat plate 14 cannot be opposite in the bridge direction. Move, so that there is no relative movement between the lower seat plate 11 and the upper seat plate 14 in the direction along the bridge. This arrangement enables the load of the vacuum pipeline of the magnetic levitation system to the upper seat plate 14 along the bridge direction to be accurately transmitted to the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com