Composite magnetism gathering type permanent magnet guide rail mechanism applicable to high-speed superconductivity magnetic suspension system

A magnetic levitation and permanent magnet technology, which is applied in electric traction, electric vehicles, transportation and packaging, etc., can solve the problems of low utilization rate of magnetic energy, redundant structure of permanent magnet rails, increased cost, etc., to achieve variable structure, improved performance, The effect of ensuring the strength of the magnetic field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

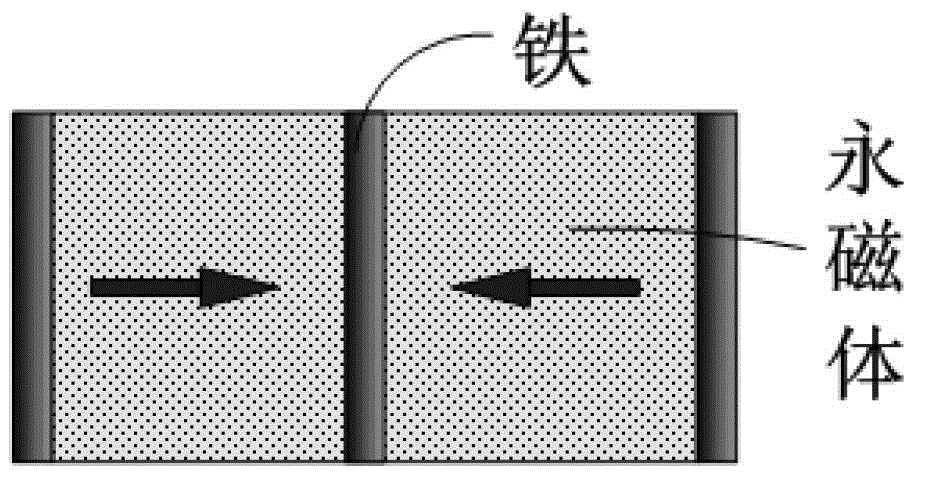

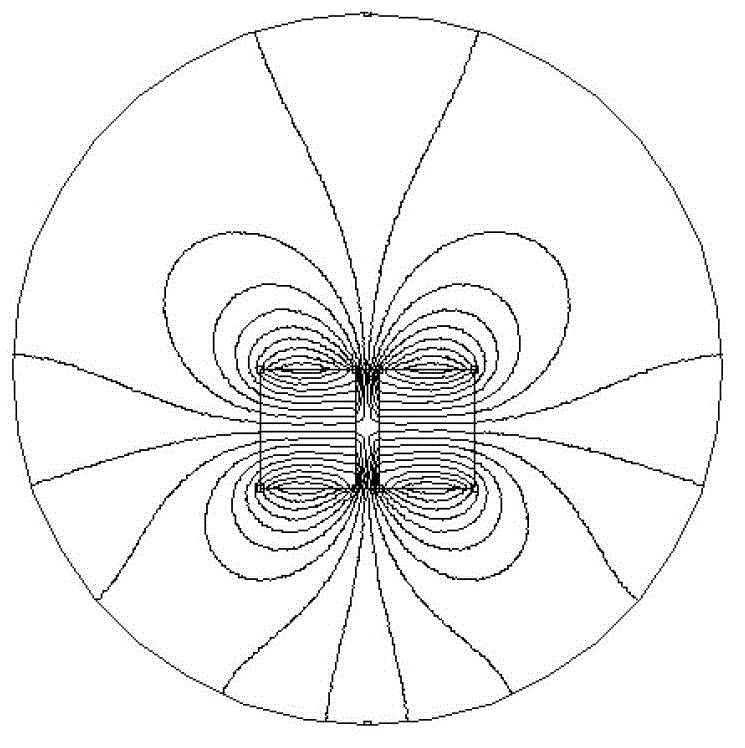

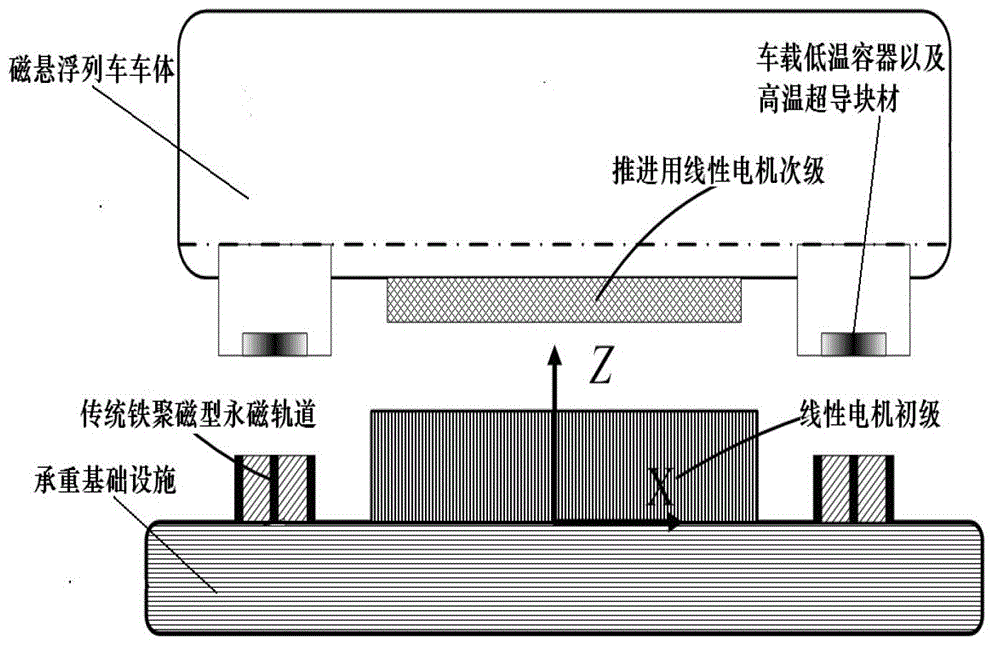

[0045] Embodiment 1 uses ferromagnetic materials as the main magnetic poles, and the high permeability of ferromagnetic materials can be used to suppress the damage caused by the processing and assembly of permanent magnetic materials and the installation of permanent magnetic mechanisms. image 3 The magnetic field inhomogeneity in the Y direction of the permanent magnet guide shown in . image 3 The inhomogeneity of the magnetic field in the Y direction of the medium permanent magnet guide rail may generate eddy currents inside the high-temperature superconducting block and cause magnetic flux movement in some applications, such as ultra-high-speed operation, resulting in loss and heat, reducing the suspension system. In severe cases, the accumulated heat may even cause partial failure inside the high-temperature superconducting bulk material, directly threatening the safety of the suspension system. Therefore, Embodiment 1 is a high-efficiency permanent magnet guide rail me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com